Escolar Documentos

Profissional Documentos

Cultura Documentos

System Description: S5X New Forestry Control System

Enviado por

coulibalyoumarDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

System Description: S5X New Forestry Control System

Enviado por

coulibalyoumarDireitos autorais:

Formatos disponíveis

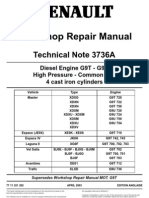

S5X

New Forestry

Control System

System

Description

247

223,5

POWER

82,25

SYSTEM

77,75

MODE

8,5

8,5

10

STATUS

9

10

164,5

10,3

AMP Stecker

AMP Connector

14

15

29

28

42

16

52,5

S5X New Forestry Control System

System Description

Overview

DESCRIPTION

The Sauer-Danfoss New Forestry System combines the capabilities of modern digital

electronics with the worldwide proven Sauer-Danfoss hydrostatic components, to

enhance the machine performance and operation.

The microprocessor-based S5X provides the necessary performance for a flexible and

future oriented drive control concept.

With easy-to-change parameters (in software) it is possible to make an individual setup

for different machine types.

It is possible to select between several kinds of input like buttons or levers or to get

inputs via CAN on machines which sophisticated Man Machine Interfaces.

FEATURES

Environmentally proofed for mobile applications.

Supply voltage 12 VDC or 24 VDC.

Software changes without hardware operations.

Individual setup per software possible.

SYSTEM COMPONENTS

S5X-XX G2 AMP K167C S5X Electronic with CAN

Manual Graphic Interface, english

(512208)

Manual SUSMIC-DIA 1/3, english

(512209)

2001, Sauer-Danfoss

Sauer-Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Sauer -Danfoss reserves the

right to alter its products without prior notice. This also applies to products already ordered provided that such alterations can be made without

subsequent changes being necessary in specifications already agreed. All trademarks in this material are properties of the respective companies.

Sauer-Danfoss and the Sauer-Danfoss logotype are trademarks of the Sauer-Danfoss Group. All rights reserved.

BLN 96-9908-E Rev. D 10/2001

S5X New Forestry Control System

System Description

Dimensions

LED OVERVIEW

247

7

6

223,5

5

POWER

4

82,25

SYSTEM

77,75

MODE

8,5

8,5

10

STATUS

9

10

164,5

10,3

14

15

28

29

16

52,5

42

S5X

Mounting slots

AMP connectors

Diagnostic LED red

Error check

(STATUS)

Lights up if an error is detected.

Diagnostic LED yellow

Software check

(MODE)

Flashes with approx. 0.5Hz (slow), if the program is running fine.

Flashes with approx. 5Hz (fast), if no program is loaded.

Shining if in setup mode.

Diagnostic LED green

5VDC internal

(SYSTEM)

Lights up if 5VDC internal is O.K.

Diagnostic LED green

Battery after ignition switch

(POWER)

Lights up if the battery voltage is connected after ignition.

S01752a

BLN 96-9908-E Rev. D 10/2001

S5X New Forestry Control System

System Description

System Block Diagram

SYSTEM BLOCK DIAGRAM

PPU gearbox RPM

EGAS

M

PPU engine RPM

Engine

Shown position: Neutral

Shown position: gearbox feedback inactive

Shown position: Transport

Shown position: 1st gear

Shown position: Stabilizer inactive

Shown position: Work brake inactive

Shown position: Chair forward

PPU motor RPM

Forward

Reverse

Pump

valve

Motor

valve

Prop

Out

Timer

Prop

Out

Automotive

control

Timer

Prop

Out

Timer

Front pedal

Dig

Out

1st gear valve

Dig

Out

2nd gear valve

Dig

Out

Brake valve

Dig

Out

Stabilizer valve

Rear pedal

RV

Inch

potentiometer

Prop

Out

D

RV

Forward

Neutral

Reverse

FNR-Switch

Gearbox

feedback

Toggle switch

Transport/work

Gear select

1st/2nd gear

DI

Stabilizer

active

DI

Work brake

active

DI

Chair

forward/reverse

DI

DI

1st gear

DI

2nd gear

Status (red)

DI

Mode (yellow)

RS232 Interface for

SUSMIC-DIA or GPI

Voltage regulator

F

V

A

+

Batt.

12/24V DC

CAN

CAN BUS

S01514a

BLN 96-9908-E Rev. D 10/2001

S5X New Forestry Control System

System Description

Theory of Operation

THEORY OF OPERATION

PPU gearbox RPM

EGAS

PPU engine RPM

5

4

3

PPU motor RPM

M

Engine

2

1

Drive setpoint

Inch setpoint

FNR switch

Setpoint

generation

Ramps

Automotive

curves

Speed

limitation

Current

setpoints

Antistall

control

Work/transport switch

Engine

control

Prop

Out

Dig

Out

1st gear valve

Dig

Out

2nd gear valve

Brake

control

Dig

Out

Brake valve

Stabilizer

control

Dig

Out

Stabilizer valve

Gear select

1st/2nd gear

Gear

control

Brake switch

Stabilizer switch

S01824a

BLN 96-9908-E Rev. D 10/2001

S5X New Forestry Control System

System Description

Theory of Operation

THEORY OF OPERATION

(CONTINUED)

General

The Sauer-Danfoss S5X Mobile Computer controls a hydraulic drive system with hydraulic

pump and motor. The system controls the combustion engine with an E-Gas actuator.

Adjustable Automotive Curves

There are adjustable automotive curves for the engine, the pump and the motor. For

different drive conditions there are adjustable acceleration and deceleration times. These

automotive curves can be different for the three drive modes (see below).

Inch Function

With the inch function, the automotive curves can be changed by the driver for the

whole speed range down to zero speed.

Antistall Controller

The full range antistall controller guarantees, that the drive system uses only the available

power of the engine.

Overspeed Protection

An overspeed protection for the combustion engine is always active.

Speed Limit Function

The vehicle speed can be limited by the speed limit function.

Drive Modes

The system has 3 different drive modes. There are 2 modes for transport (1st gear and

2nd gear). In the work mode, the system can drive with a constant engine RPM value. It

is possible to learn and store these RPM value in the computer, so that the system can

use this stored value later.

Digital Outputs

The system controls 2 digital outputs, to select the gear and outputs for the work brake

valve and the stabilizer valve.

Auto Vehicle Configuration

With the auto vehicle configuration, it is possible to select the vehicle type without any

tool. A lot of default parameter sets are available.

Setup

The pedals and the potentiometer do not need any setup. The setup for the pump

deadband and the E-Gas actuator can be done without any external tool.

Parameters

The default parameter sets are stored in separate files. The up- and download functions

for parameter files are implemented. It is also possible, to upload a parameter description

file with the actual parameters.

Error History

All errors occurred in the system will be stored in an error history and can uploaded later

for service and diagnostic.

CAN-Bus

Over the CAN-Bus, other systems have the possibility, to get information about the actual

status of the system. For example diesel speed, vehicle speed, distance meter, errors etc...

BLN 96-9908-E Rev. D 10/2001

S5X New Forestry Control System

System Description

System Connection Diagram

SYSTEM CONNECTION DIAGRAM

1

2

3

4

Shown position: Neutral

Shown position: Gearbox feedback inactive

Shown position: Transport

Shown position: 1st gear

Shown position: Stabilizer inactive

Shown position: Work brake inactive

Shown position: Chair forward

5

6

7

Ignition

switch

AMP connector, 42-pin

Battery (+)

Sensor (+)

PPU Input 0

PPU Input 3

Digital Input 2

Digital Input 5

Digital Input 8

Analog Input 0

Analog Input 4

Terminals (+)

RV

Battery

12/24V DC

Inch potentiometer

Terminals (+)

RV

F

8A

Front pedal

Rear pedal

10

11

PWM Out 5

12

PWM Out 0

PWM Out 3

13

Chassis

15

PPU engine RPM

14

PPU gearbox RPM

HST Motor Return 16

PPU motor RPM

PPU Input 1

Digital Input 0

17

Forward

18

Neutral

Digital Input 3

19

Digital Input 6

20

Digital Input 9

21

Analog Input 2

22

Toggle switch transport/work

Analog Input 5

23

Gear select 1st/2nd gear

FNR-Switch

Reverse

24

Digital Out 3

25

Digital Out 1

PWM Out 1

26

Gearbox feedback

1st gear

2nd gear

Stabilizer active

Terminals (-)

Pump forward valve

27

Pump reverse valve

28

Terminals (-)

Battery (-)

Sensor (-)

29

EDC Return

31

PPU Input 2

Digital Input 1

32

33

Work brake active

Digital Input 4

Digital Input 7

34

35

Chair forward/reverse

Analog Input 1

36

Analog Input 3

37

38

Digital Out 0

41

PWM Out 2

42

TxD

CAN GND

CAN High

6

7

Auto vehicle type

Motor valve

1st gear valve

2nd gear valve

Brake valve

AMP connector, 16-pin

RxD

EGAS

3

2

39

40

M

4

30

Digital Out 2

Stabilizer valve

1

2

3

4

5

6

7

8

9

5

6

9-pin

SUB-DSUB-DStecker,

connector

9-polig

(socket

(Buchse)

version)

fr

Service

for

service

und

and

Diagnose

diagnosis

7

CAN-Bus

8

9

Bootstrap loader low 10

11

CAN Low

12

RS232CAN GND

5V tool supply

13

Bootstrap

connector

14

15

Bootstrap loader high 16

512211a

BLN 96-9908-E Rev. D 10/2001

OUR PRODUCTS

Sauer-Danfoss Hydraulic Power Systems

Market Leaders Worldwide

Hydrostatic transmissions

Hydraulic power steering

Electric power steering

Closed and open circuit axial piston

pumps and motors

Gear pumps and motors

Bent axis motors

Radial piston motors

Orbital motors

Transit mixer drives

Planetary compact gears

Proportional valves

Sauer-Danfoss is a comprehensive supplier providing complete

systems to the global mobile market.

Sauer-Danfoss serves markets such as agriculture, construction, road

building, material handling, municipal, forestry, turf care, and many

others.

We offer our customers optimum solutions for their needs and

develop new products and systems in close cooperation and

partnership with them.

Sauer-Danfoss specializes in integrating a full range of system

components to provide vehicle designers with the most advanced

total system design.

Sauer-Danfoss provides comprehensive worldwide service for its

products through an extensive network of Authorized Service

Centers strategically located in all parts of the world.

Directional spool valves

Cartridge valves

Hydraulic integrated circuits

Hydrostatic transaxles

Integrated systems

Fan drive systems

Electrohydraulic controls

Digital electronics and software

Battery powered inverter

Sensors

Sauer-Danfoss (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239-6000, Fax: +1 515 239-6618

Sauer-Danfoss (Neumnster) GmbH & Co. OHG

Postfach 2460, D-24531 Neumnster

Krokamp 35, D-24539 Neumnster, Germany

Phone: +49 4321 871-0, Fax: +49 4321 871-284

Sauer-Danfoss (Nordborg) A/S

DK-6430 Nordborg, Denmark

Phone: +45 7488-4444, Fax: +45 7488-4400

Sauer-Danfoss (US) Company

3500 Annapolis Lane North

Minneapolis, MN 55447, USA

Phone: +1 763 509-2084, Fax: +1 763 559-0108

BLN-96-9908-E Rev. D 10/2001

www.sauer-danfoss.com

Você também pode gostar

- Modulo Sauer Danfoss S5XDocumento6 páginasModulo Sauer Danfoss S5Xrmartins_23947450% (2)

- New Holland TM 175 Service ManualDocumento6 páginasNew Holland TM 175 Service ManualH50% (2)

- F4HFE413KDocumento358 páginasF4HFE413Kjvega_53412067% (3)

- Service Manual: Transmission Electronic Controls APC100Documento38 páginasService Manual: Transmission Electronic Controls APC100Eduardo Gutierrez Mendez100% (1)

- Service Manual: ForewordDocumento24 páginasService Manual: ForewordRoman Chuba100% (2)

- JCB 407 Wheel Loading Shovel Service Repair Manual SN632700 Onwards PDFDocumento17 páginasJCB 407 Wheel Loading Shovel Service Repair Manual SN632700 Onwards PDFfjkskkdhsjmdn100% (1)

- Valtra T 140 T140 Tractor Service Repair Workshop Manual DOWNLOADDocumento2 páginasValtra T 140 T140 Tractor Service Repair Workshop Manual DOWNLOADzlkuofhrxfkkq33% (3)

- Meritor Service Manual DUCO - MM1127Documento83 páginasMeritor Service Manual DUCO - MM1127LUKASAinda não há avaliações

- Installation Manual ElectronicDocumento47 páginasInstallation Manual ElectronicLuis Josue100% (1)

- Kalmar DCE90-180, Diesel Forklift - Technical Information PDFDocumento10 páginasKalmar DCE90-180, Diesel Forklift - Technical Information PDFAhmad SaliminAinda não há avaliações

- Acom18 01GBDocumento54 páginasAcom18 01GBGeorge Jhonson50% (2)

- Valtra Fault CodesDocumento4 páginasValtra Fault Codeshelio100% (1)

- Cart Sauer DanfossDocumento8 páginasCart Sauer DanfossLhsan RajawiAinda não há avaliações

- Manitou 625 BT 3Documento14 páginasManitou 625 BT 3javierAinda não há avaliações

- EEM3 Faultcodes SW 1 5 0 0 - 2 5 0 0 STDDocumento5 páginasEEM3 Faultcodes SW 1 5 0 0 - 2 5 0 0 STDGaston SosaAinda não há avaliações

- A - Power Split Hydro-Mechanical Variable Transmission (HVT) For Off-Highway ApplicationDocumento12 páginasA - Power Split Hydro-Mechanical Variable Transmission (HVT) For Off-Highway ApplicationchuhuynhAinda não há avaliações

- motor-EEM3Troubleshoot v2 5Documento180 páginasmotor-EEM3Troubleshoot v2 5Nicoleta Costea100% (1)

- Hyster: ElectricalDocumento31 páginasHyster: ElectricalMelwyn Fernandes100% (1)

- DW03195104 PDFDocumento146 páginasDW03195104 PDFUmar Shamsudin100% (1)

- A808 AdBlue Supply Module - Flushing Process - EngDocumento5 páginasA808 AdBlue Supply Module - Flushing Process - EngGonçalo PereiraAinda não há avaliações

- RSD4531-5TL Electrical PDFDocumento77 páginasRSD4531-5TL Electrical PDFGeorge Jhonson100% (3)

- LMS Plus 7.5 Fault CodeDocumento10 páginasLMS Plus 7.5 Fault CodeNguyễn Văn Hùng100% (2)

- TCD / TTCD 6.1 L6 TCD 4.1 L4: Operation ManualDocumento96 páginasTCD / TTCD 6.1 L6 TCD 4.1 L4: Operation ManualDmitry100% (3)

- Motor GM H70 FTDocumento76 páginasMotor GM H70 FTRenato portelaAinda não há avaliações

- 18.45 enDocumento164 páginas18.45 endan PaulAinda não há avaliações

- Cat 214BDocumento20 páginasCat 214BNacer Mezghiche67% (3)

- ECU List 7 5 0 New Features ListDocumento54 páginasECU List 7 5 0 New Features Listkhaled kamel100% (1)

- TJ 810D 1110D EngDocumento14 páginasTJ 810D 1110D EngDavid StepićAinda não há avaliações

- Sauer Danfoss 520L0603 - Series 90 HST - TI - REV F PDFDocumento68 páginasSauer Danfoss 520L0603 - Series 90 HST - TI - REV F PDFluis sarmientoAinda não há avaliações

- New Holland Series TM Tractors Models TM120, TM130, TM140, TM155, TM175 and TM190Documento24 páginasNew Holland Series TM Tractors Models TM120, TM130, TM140, TM155, TM175 and TM190احمد الشبراوى100% (2)

- LMS Plus 7.5 Service ManualDocumento36 páginasLMS Plus 7.5 Service ManualNguyễn Văn Hùng100% (1)

- MID 130 TECU (ZF ECOMAT 2 PLUS) Caja de Cambio en InglesDocumento8 páginasMID 130 TECU (ZF ECOMAT 2 PLUS) Caja de Cambio en InglesRobAinda não há avaliações

- RH6.5 Prospekt PDFDocumento14 páginasRH6.5 Prospekt PDFДрагиша Небитни Трифуновић100% (1)

- Instalacion de WingpiDocumento12 páginasInstalacion de WingpijucapaAinda não há avaliações

- Volvo L120eDocumento16 páginasVolvo L120eJusto Ernesto Gutierrez SchweitzerAinda não há avaliações

- TD1474-07E DIM User ManualDocumento33 páginasTD1474-07E DIM User ManualDJAGBAAinda não há avaliações

- 78156eng Voith D863Documento19 páginas78156eng Voith D863Mohammed Yassine Garreb100% (1)

- MID 144 Vehicle Electronic Control Unit (VECU), Signal DescriptionDocumento4 páginasMID 144 Vehicle Electronic Control Unit (VECU), Signal DescriptionИгорь БасмановAinda não há avaliações

- 0298 199 0 SV en 300Documento56 páginas0298 199 0 SV en 300andis_a100% (1)

- Champion 120-135-150Documento812 páginasChampion 120-135-150Николай Петков100% (1)

- SM Mla 628 - 547860enDocumento749 páginasSM Mla 628 - 547860enaritmeticsAinda não há avaliações

- TL2 Operator's ManualDocumento110 páginasTL2 Operator's ManualNguyễn Văn HùngAinda não há avaliações

- Articulating Boom Work PlatformDocumento4 páginasArticulating Boom Work PlatformJuan Carlos Torres Martinez100% (1)

- Linked PDFDocumento110 páginasLinked PDFroparts cluj0% (1)

- BLN 96 0401 eDocumento12 páginasBLN 96 0401 eFadFad100% (1)

- 3736a g9t Common Rail SystemDocumento180 páginas3736a g9t Common Rail SystemKornelija Balandė50% (2)

- Workshop Manual Deutz VolvoDocumento28 páginasWorkshop Manual Deutz VolvoMarcelo Daniel Gonzalez LLanosAinda não há avaliações

- SingleLine General Manual GRASERADocumento40 páginasSingleLine General Manual GRASERAYoseth Jose Vasquez Parra67% (3)

- MF 6495Documento571 páginasMF 6495Federico Zingarini0% (1)

- Massey Ferguson Combine Service Manual MH S mf750 760Documento12 páginasMassey Ferguson Combine Service Manual MH S mf750 760Devi RahmadaniAinda não há avaliações

- MAMCING-01 CingoDocumento130 páginasMAMCING-01 CingoNicoleta CosteaAinda não há avaliações

- Service Manual: 1 2 3 A B C D E F G KDocumento3 páginasService Manual: 1 2 3 A B C D E F G KMariusz Pietrzak67% (3)

- Apc100 PDFDocumento38 páginasApc100 PDFDuvan100% (2)

- Terberg - RT223 4x4: DetailsDocumento4 páginasTerberg - RT223 4x4: DetailsAbdelhadi HoussinAinda não há avaliações

- APC200 ECM-ECI Error Codes Ver3.0Documento20 páginasAPC200 ECM-ECI Error Codes Ver3.0Man ManAinda não há avaliações

- Pvek DKMHPN500B102Documento4 páginasPvek DKMHPN500B102seaqu3stAinda não há avaliações

- SIMOCODE Pro Presentation For SIMODODE - DP CustomersDocumento24 páginasSIMOCODE Pro Presentation For SIMODODE - DP CustomersLeo SergioAinda não há avaliações

- Base Drive Operation: Stan Ar Ontrol Mo EsDocumento52 páginasBase Drive Operation: Stan Ar Ontrol Mo EsDuvel AragoAinda não há avaliações

- Common Rail Next Generation Engines EDC 7 Electronic Engine Control UnitDocumento41 páginasCommon Rail Next Generation Engines EDC 7 Electronic Engine Control UnitLuis Antonio Vega Parangueo100% (3)

- ADEC™ - Advancet Diesel Engine Controller For BR 4000 and BR 2000 - Generator Application - MTU® PDFDocumento49 páginasADEC™ - Advancet Diesel Engine Controller For BR 4000 and BR 2000 - Generator Application - MTU® PDFpevare100% (12)

- Jyhy Diesel Catalog 2018Documento9 páginasJyhy Diesel Catalog 2018coulibalyoumarAinda não há avaliações

- td1403 03 PDFDocumento42 páginastd1403 03 PDFcoulibalyoumarAinda não há avaliações

- td1403 03 PDFDocumento42 páginastd1403 03 PDFcoulibalyoumarAinda não há avaliações

- Hy17 8357 Uk - PCL4 PDFDocumento20 páginasHy17 8357 Uk - PCL4 PDFcoulibalyoumarAinda não há avaliações

- ZF Operating Manual Part Number 5872 194 002Documento5 páginasZF Operating Manual Part Number 5872 194 002coulibalyoumarAinda não há avaliações

- Kleenoil BrochureDocumento4 páginasKleenoil BrochurecoulibalyoumarAinda não há avaliações

- Kubota V3600 85HP Engine ManualDocumento75 páginasKubota V3600 85HP Engine Manualcoulibalyoumar100% (2)

- SK160 Manual - 1 PDFDocumento80 páginasSK160 Manual - 1 PDFcoulibalyoumar100% (1)

- S 300 PDFDocumento400 páginasS 300 PDFcoulibalyoumar100% (2)

- I.View Manual For Wheel Loader: Installation and Calibration ManualDocumento44 páginasI.View Manual For Wheel Loader: Installation and Calibration ManualcoulibalyoumarAinda não há avaliações

- BL 52 PDFDocumento57 páginasBL 52 PDFcoulibalyoumarAinda não há avaliações

- BL 52 PDFDocumento57 páginasBL 52 PDFcoulibalyoumarAinda não há avaliações

- 108 PDFDocumento28 páginas108 PDFcoulibalyoumarAinda não há avaliações

- Donax TD 10W30 PDFDocumento2 páginasDonax TD 10W30 PDFdarmawanpnAinda não há avaliações

- 1600 SERIES: Gear Pumps and MotorsDocumento16 páginas1600 SERIES: Gear Pumps and Motorscoulibalyoumar100% (1)

- Joystick DB Arlistak - File - 11 PDFDocumento69 páginasJoystick DB Arlistak - File - 11 PDFcoulibalyoumarAinda não há avaliações

- A Clutch Is A Mechanical DeviceDocumento7 páginasA Clutch Is A Mechanical DeviceParesh JoshiAinda não há avaliações

- General Transmission TroubleshootingDocumento2 páginasGeneral Transmission TroubleshootingWael Sherif100% (1)

- Vickers: Constant Pressure Reversible Power Transfer UnitDocumento4 páginasVickers: Constant Pressure Reversible Power Transfer UnitJivendra KumarAinda não há avaliações

- SEC Deck Machinery - EMW 160Documento146 páginasSEC Deck Machinery - EMW 160john smith100% (2)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Documento9 páginasInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768wilson claveriaAinda não há avaliações

- Mainternal Interval 3406Documento3 páginasMainternal Interval 3406Sandy Sanjaya100% (1)

- 2014 Infiniti Service Maintenance GuideDocumento48 páginas2014 Infiniti Service Maintenance Guidej01scottAinda não há avaliações

- Installation Manual MT-502: I. Accessory PartsDocumento5 páginasInstallation Manual MT-502: I. Accessory PartshashemAinda não há avaliações

- Ge08ti 950106-01166 PBDocumento384 páginasGe08ti 950106-01166 PBKeron TrotzAinda não há avaliações

- Mitsubishi Electric Heat Pump Parts Outdoor MUZ-GE25-50VA-A1 Outdoor PDFDocumento8 páginasMitsubishi Electric Heat Pump Parts Outdoor MUZ-GE25-50VA-A1 Outdoor PDFTony SavageAinda não há avaliações

- Eps Manual NissanDocumento8 páginasEps Manual Nissanjoiler pajueloAinda não há avaliações

- "CNC Machines": Sunil Kumar K 1Nt18Me152Documento30 páginas"CNC Machines": Sunil Kumar K 1Nt18Me152Mohan KumarAinda não há avaliações

- NSK RHPDocumento6 páginasNSK RHPGaudencio Rodriguez RomeroAinda não há avaliações

- Engine: Fuel SystemDocumento16 páginasEngine: Fuel SystemHallex OliveiraAinda não há avaliações

- Tomos4 Operating Manual PDFDocumento15 páginasTomos4 Operating Manual PDFEmir Jordamović100% (1)

- Canon Image Runner Copier MachineDocumento79 páginasCanon Image Runner Copier MachineRamAinda não há avaliações

- Manual Montesa 4RT 05Documento146 páginasManual Montesa 4RT 05jorgeAinda não há avaliações

- 330ERV SpecDocumento2 páginas330ERV SpecNaqqash SajidAinda não há avaliações

- 389 2017Documento188 páginas389 2017Paulo SouzaAinda não há avaliações

- 12x30 Mixing Mill QuotationDocumento2 páginas12x30 Mixing Mill QuotationsriAinda não há avaliações

- Singer Sewing Machine Manual For 518 - 538 - 514 - 513 - 533Documento40 páginasSinger Sewing Machine Manual For 518 - 538 - 514 - 513 - 533tarookmaktu67% (3)

- WA500 7 KomatsuDocumento20 páginasWA500 7 Komatsuwidyo saptotoAinda não há avaliações

- Modelmh-5: STANDARD SPECIFICATIONS: MH-S Electric Chain HoistDocumento7 páginasModelmh-5: STANDARD SPECIFICATIONS: MH-S Electric Chain HoistMiguel RuizAinda não há avaliações

- MachineryFaultsDiagnosis Poster Redesign enDocumento1 páginaMachineryFaultsDiagnosis Poster Redesign enlucascpizzettiAinda não há avaliações

- Cursor 10-13 RMDocumento338 páginasCursor 10-13 RMAminadavAinda não há avaliações

- Wato Gear Parts Catalogue - (2016-05)Documento28 páginasWato Gear Parts Catalogue - (2016-05)Екатерина Калашникова100% (1)

- 2009-2010 Dodge Journey PartsDocumento141 páginas2009-2010 Dodge Journey PartsFernando Gustavo Castro100% (1)

- 555 Off-Circuit Tap-Changer An Instruction ManualDocumento23 páginas555 Off-Circuit Tap-Changer An Instruction Manualhendrias_budiAinda não há avaliações

- Sanyo Sdh-A200 DehumidifierDocumento8 páginasSanyo Sdh-A200 DehumidifierzaxmavAinda não há avaliações

- CL#2 Maintenance Schedule 7 - 18 REDDocumento5 páginasCL#2 Maintenance Schedule 7 - 18 REDRicky WrightAinda não há avaliações