Escolar Documentos

Profissional Documentos

Cultura Documentos

RM0001 1

Enviado por

gmg210981Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

RM0001 1

Enviado por

gmg210981Direitos autorais:

Formatos disponíveis

Repair Manual

High Pressure Motor Valves

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

INDEX

Introduction ........................................................................................................................................ 1

Elastomers ........................................................................................................................................... 2

Materials ............................................................................................................................................... 3

Pressure Open to Pressure Close Conversion ........................................................................ 5

HPMV Disassembly ........................................................................................................................... 9

HMPV Inspection of Parts ............................................................................................................ 17

HPMV Assembly ............................................................................................................................... 19

HPMV Testing ................................................................................................................................... 25

Piston Balanced Disassembly ..................................................................................................... 27

Piston Balanced Inspection of Parts ......................................................................................... 35

Piston Balanced Assembly ........................................................................................................... 37

NOTE: We reserve the right to modify or change, without prior

notice, any statement or information contained herein. If exact

dimensions or specifications are required by the customer

certified prints will be furnished for a minimum charge upon

request to KIMRAY, Inc.

Copyright 2006, KIMRAY, Inc.

www.kimray.com

HIGH PRESSURE MOTOR VALVE REPAIR MANUAL

INTRODUCTION

SCOPE

This instruction manual contains repair information for the standard 1 and 2 Kimray High Pressure Motor

Valve and the 2 through 6 Piston Balanced High Pressure Motor Valve.

DESCRIPTION

The High Pressure Motor Valves are all actuated with a pneumatic actuator which features an open yoke

and travel indicator. The actuators are reversible between pressure opening and pressure closing configurations. The standard High Pressure Motor Valve employs a ball and cone seat configuration. The Piston

Balanced High Pressure Motor Valve shuts off with a resilient seat.

OPERATION

The Kimray High Pressure Motor Valves require no more than 30 psig to operate. The pneumatic pressure

drives a diaphragm against a return spring. When pneumatic pressure is relieved, the valve shuts.

MAINTENANCE

Maintenance should be performed on a regular basis. An initial inspection interval of 12 months is recommended. Depending on the service conditions and the condition of the valve, the inspection interval may be

decreased or increased. The valve can be repaired without being removed from the piping.

WARNING

Before performing any service be sure that the valve is fully isolated and that all pressure upstream and

down has been relieved.

Use bypass valves or fully shut off the process

Be sure that any operating or instrument gas lines have been disconnected.

Never assume that a check valve is fully blocking the downstream line.

Never tighten any fitting or the main connections to the regulator while there is pressure on the line.

To get the long service you have come to expect from Kimray products, always use GENUINE KIMRAY

PARTS when doing repairs. Remember, parts made to less than Kimray specifications dont save you

money!!!

ENG-002.3 REV. 4 Issued 1-11-2012

www.kimray.com

Page 1

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

ELASTOMERS

AFLAS

VITON

is a trade mark of Asahi Glass Co

is a trade mark of Dupont

TEMPERATURE:

-25 to +500 F

-30 to +260 C

TEMPERATURE:

-10 to +350 F

-23 to +177 C

APPLICATION:

Crude Oil & Gas Production (High heat), Steam

Flood Production Chemicals (corrosion inhibitors) Amine

Sweetener Systems, Gasoline, Diesel, Fuel Oil Systems

APPLICATION:

Crude Oil & Gas Production, Glycol Dehydrators,

Gasoline, Jet Fuel & Diesel Fuel Pumping, Water Disposal,

Methanol Injection Pumps. (Also Vacuum Service) (Gas

permeability is very low)

FLUID / GAS:

Crude Oil & Gas Production, H2S, Steam, Petroleum

fluids, Sea Water

HSN (Highly Saturated Nitrile)

FLUID / GAS:

Crude Oil & Gas, Sour Gas (C02), Propane, Gasoline,

Diesel, Fuel Oil Systems

DO NOT USE WITH:

Hot Water, Not preferred for wet H2S, Methyl Alcohol,

Amines, Sodium hydroxide solutions

TEMPERATURE:

-15 to +300 F

-26 to +149 C

APPLICATION:

Crude Oil & Gas Production w/ H2S C02

FLUID / GAS:

Crude Oil & Gas H2S, C02, Sea Water

NITRILE

TEMPERATURE:

Buna-N:

-40 to +220 F

-40 to +105 C

Low-Temp:

-85 to +120 F

-65 to +49 C

ETHYLENE PROPYLENE

TEMPERATURE:

-65 to +300 F

-54 to +148 C

APPLICATION:

Steam Flood

FLUID / GAS:

Steam, Water, Alcohol

DO NOT USE WITH:

Crude Oil & Gas, Diester Lubricants (Lube Oils)

POLYURETHANE

APPLICATION:

Crude Oil & Gas Production Glycol Dehydrators,

Gasoline, Jet Fuel & Diesel Fuel Pumping, Water Disposal,

Methanol Injection Pumps, Water pump seals, hydraulic

pump seals

FLUID / GAS:

Crude Oil & Gas, Good to Poor in Sour Production (See

HSN), Water, Glycols, Hydraulic Oils, Resistance to crude

oil in the presence of hydrogen sulfide and amines, Diesel

fuel, fuel oils

TEMPERATURE:

-40 to +220 F

-40 to +104 C

APPLICATION:

High abrasion resistance Seats, Diaphragms

FLUID / GAS:

Crude Oil gas and Water, Sour Gas (C02), propane,

butane, fuel, mineral oil and grease

POLYACRYLATE

DO NOT USE WITH:

Aromatic hydrocarbons, chlorinated hydrocarbons,

phosphate esters (hydraulic fluids)

GYLON

TEMPERATURE:

0 to +300 F

-17 to +149 C

TEMPERATURE:

-350 to +500 F

APPLICATION:

Production Heaters, Thermostats

APPLICATION:

High heat, high chemical resistance, highly resistance

to gas permeation

FLUID / GAS:

Crude Oil & Gas at High Temperature

DO NOT USE WITH:

Alcohol, Glycols

Page 2

www.kimray.com

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

MATERIALS

Standard materials in the standard Kimray High Pressure Motor Valve include:

Exterior Parts:

Bonnet

Body

Ductile Iron ASTM - A395

Cast Steel ASTM - A216 WCB

Interior Parts:

Stem

Cage

Stuffing Box

Seat

Plug

303 Stainless Steel

Free Machining Steel AISI 12L14

Free Machining Steel AISI 12L14

Tool Steel AISI D2

Carbide/303 Stainless

Elastomers:

Packing

O-Rings

Diaphragm

Nitrile/Teflon

Nitrile

Nitrile

Standard materials in the Kimray Piston Balanced High Pressure Motor Valve include

Exterior Parts:

Bonnet:

Body

Ductile Iron ASTM - A395

Cast Steel ASTM - A216 WCB

Interior Parts:

Upper Housing

Stem

Cage

Stuffing Box

Seat

Piston

Steel AISI C1018

316 Stainless Steel

316 Stainless Steel

Free Machining Steel AISI 12L14

Tool Steel AISI D2

Tool Steel AISI D2

Elastomers:

Packing

O-Rings

Diaphragm

Nitrile/Teflon

Nitrile

Nitrile

To get the long service you have come to expect from Kimray products, always use GENUINE KIMRAY

PARTS when doing repairs. Remember, parts made to less than Kimray specifications dont save you

money!!!

www.kimray.com

Page 3

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

NOTES

Page 4

www.kimray.com

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

PRESSURE OPEN TO PRESSURE CLOSE CONVERSION

STEP 1

BLOCK DISASSEMBLY

Start from disassembling the Travel

Indicator Block (Fig. 1.1)

Figure 1.1

STEP 2

BREATHER PLUG

Remove the breather plug from the

Bonnet (Fig. 2.1)

Figure 2.1

STEP 3

ADJUSTING SCREW

Remove the Adjusting Screw from top of

Bonnet (Fig. 3.1)

Figure 3.1

STEP 4

PIVOT

Remove Pivot from Adjusting Screw

(Fig. 4.1)

Figure 4.1

STEP 5

BONNET

Remove the Bonnet by loosing the bolts

(Fig. 5.1 and 5.2)

Figure 5.1

www.kimray.com

Figure 5.2

Page 5

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

PRESSURE OPEN TO PRESSURE CLOSE CONVERSION

STEP 6

SPRING

Remove the Spring from the Diaphragm

Plate (Fig. 6.1)

Figure 6.1

STEP 7

DIAPHRAGM PLATE

Use an adjustable wrench to hold the

Upper Stem (Fig. 7.1) while loosening the

Diaphragm Plate (Fig. 7.2)

Remove the Diaphragm Plate from the

Yoke (Fig. 7.3)

Figure 7.1

Figure 7.2

Figure 7.3

STEP 8

RETRIEVING O-RING

NOTE: THIS STEP SHOULD BE

FOLLOWED IF YOU DO NOT HAVE AN

EXTRA O-RING.

Remove the bolts from the Yoke (Fig. 8.1)

Flip the Yoke upside down and loosen the

Lower Adjusting Screw (Fig. 8.2)

Figure 8.1

Figure 8.2

Use a pick remove the O-Ring from the

Adjusting Screw (Fig. 8.3)

After the O-Ring has been removed, tighten Adjusting Screw back in Yoke and then

attach Yoke back to Body.

Figure 8.3

Page 6

www.kimray.com

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

PRESSURE OPEN TO PRESSURE CLOSE CONVERSION

STEP 9

DIAPHRAGM ASSEMBLY

Insert the Pivot in the bottom of the Yoke

(Fig. 9.1)

Place the Spring Plate on top of the Pivot

(Fig. 9.2)

Insert the Spring on top of the Spring

Plate with the Spring plate on top (Fig.

9.3)

Figure 9.1

Figure 9.2

Figure 9.3

Figure 9.4

Figure 9.5

Figure 9.6

Figure 9.7

Figure 9.8

Figure 9.9

Figure 9.10

Insert the Diaphragm Plate on top of the

Spring (Fig. 9.4)

Use an adjustable wrench to hold the

Upper Stem (Fig. 9.5) while tightening the

Diaphragm Plate (Fig. 9.6)

Insert bolts in Bonnet (Fig. 9.7) and tighten them with an impact gun (Fig. 9.8)

Insert O-Ring on the Upper Adjusting

Screw (Fig. 9.9) and tighten it on top of

Bonnet (Fig. 9.10)

www.kimray.com

Page 7

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

PRESSURE OPEN TO PRESSURE CLOSE CONVERSION

STEP 10

BREATHER PLUG

Insert Breather plug on Yoke (Fig. 10.1)

Figure 10.1

STEP 11

COUPLING BLOCK

When you assemble the Coupling Block,

make sure the bevels are in the same side

of the block as show in (Fig.11.1)

Place the threaded half Block on back

side (Fig 11.2)

Figure 11.1

Figure 11.2

Figure 11.3

Figure 11.4

Tighten the bolts in the Coupling Block

with a socket (Fig. 11.3)

Make sure the Travel Indicator tag shows

the correct operation of the valve.

(Fig. 11.4) In this case we are converting

from Pressure Opening to Pressure Close

Page 8

www.kimray.com

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

HPMV DISASSEMBLY

KIMRAY TOOLS

Seat Pullers

Figure A shows the Kimrays Seat & Cage

Removal Tool. The handles flange the

disc to the body while pulling the seat or

cage.

Figure B shows a Kimrays Seat Removal

Tools able to remove the seat from body

when the cage has been removed.

Figure A

Figure B

KIMRAY SEAT & CAGE

REMOVAL TOOL

KIMRAY SEAT

REMOVAL TOOL

PART #

LINE SIZE

PART #

LINE SIZE

3032

1"

615

1"

3033

2"

614

2"

STEP 1

AJUSTING SCREW

Use a socket to remove the adjusting

screw on top of the Bonnet (Figure 1.1

and 1.2)

Figure 1.1

Figure 1.2

Figure 2.1

Figure 2.2

STEP 2

BONNET

Remove the bolts in the interface between

the Bonnet and the Yoke (Fig. 2.1)

Remove Breather Plug From Bonnet

(Fig. 2.2)

Remove Bonnet from Yoke (Fig. 2.3)

Figure 2.3

www.kimray.com

Page 9

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

HPMV DISASSEMBLY

STEP 3

SPRING

Remove Pivot from top of the spring plate

(Figure 3.1)

Remove Spring Plate from top of the

Spring (Figure 3.2)

Figure 3.1

Figure 3.2

Remove the spring from top Spring Plate

(Fig. 3.3)

Figure 3.3

STEP 4

DIAPHRAGM PLATE

BOLTED DIAPHRAGM NUT:

Spin the Diaphragm plate in a counter

clock wise direction loosing it from the

Upper Stem while holding the Upper Stem

with a small crescent wrench (Fig. 4.1).

If the HPMV has screws holding the

Diaphragm, use a screw driver to remove

them (Fig. 4.2)

Figure 4.1

Figure 4.2

Figure 4.3

Figure 4.4

Figure 4.5

Figure 4.6

Remove the Diaphragm Nut from the

Diaphragm Plate (Fig. 4.3)

Remove the Diaphragm from the

Diaphragm Plate (Fig. 4.4)

THREADED DIAPHRAGM NUT:

Use a pair of pliers to remove the

Diaphragm Nut (Fig. 4.5)

Remove the Diaphragm from the

Diaphragm Plate (Fig. 4.6)

Page 10

www.kimray.com

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

HPMV DISASSEMBLY

STEP 5

TRAVEL INDICATOR

Remove the bolts from the travel Indicator

Block (Fig. 5.1)

Remove the Block from stem (Fig. 5.2)

Figure 5.1

Figure 5.2

Figure 6.1

Figure 6.2

Figure 6.3

Figure 6.4

Figure 6.5

Figure 6.6

Figure 6.7

Figure 6.8

STEP 6

YOKE ASSEMBLY

Use a wrench to remove the bolts from

the Yoke base (Fig. 6.1)

Slide out the Yoke from the Body

(Fig. 6.2)

Flip the Yoke upside down, then take a

socket and remove the Lower Adjusting

Screw with an impact gun

(Fig. 6.3 and 6.4)

Slide out the Upper Stem from the Lower

Adjusting Screw (Fig. 6.5)

Remove the outside O-Ring from the

Lower Adjusting Screw (Fig. 6.6)

Remove O-Ring from the inside of the

Lower Adjusting Screw (Fig. 6.7)

Use a pair of snap ring pliers to remove

the Snap Ring (Fig. 6.8)

www.kimray.com

Page 11

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

HPMV DISASSEMBLY

Remove the Retainer washer (Fig. 6.9)

Remove the Wiper from the Lower

Adjusting Screw (Fig. 6.10)

Figure 6.9

Figure 6.10

Figure 7.1

Figure 7.2

Figure 7.3

Figure 7.4

Figure 7.5

Figure 7.6

Figure 7.7

Figure 7.8

STEP 7

STUFFING BOX ASSEMBLY

Use an adjustable wrench to remove the

stuffing Box from the Body (Fig. 7.1)

Remove the Stuffing Box from the Body

(Fig. 7.2)

Clamp the two flat sides of the Stuffing

Box in vise and loosen seat with an

adjustable wrench. (Fig. 7.3)

Leave the Seat attached to cage. Insert

a screw driver through cage and unscrew

(Figure 7.4).

Note: Leaving the seat attached prevents

the cage from egg shaping.

Pull Stem and Cage out of Stuffing Box

(Fig. 7.5), if it doesnt come out then flip

the Stuffing Box over and tap the Stem

with a hammer and a small punch (Fig.

7.6)

Remove Cage and Stem from the Stuffing

Box (Fig. 7.7)

Remove the Spring (Fig. 7.8)

Page 12

www.kimray.com

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

HPMV DISASSEMBLY

Remove the Cage from the Ball and Stem

(Fig. 7.9)

Remove O-Ring from the Seat (Fig 7.10)

Figure 7.9

Figure 7.10

Figure 7.11

Figure 7.12

Figure 7.13

Figure 7.14

Figure 7.15

Figure 7.16

Remove O-Ring from Stuffing Box (Fig.

7.11)

Remove Follower from the Stuffing Box

(Fig. 7.12)

Remove the Packing Rings from the

Stuffing Box (Fig. 7.13)

Remove the Packing Sleeve from the

Stuffing Box (Fig. 7.14)

Use a pair of snap ring pliers to remove

the Snap Ring (Fig. 7.15)

Remove the Retainer washer from the

Stuffing Box (Fig. 7.16)

Remove the Wiper from the Stuffing Box

(Fig. 7.17)

Figure 7.17

www.kimray.com

Page 13

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

HPMV DISASSEMBLY

SPECIAL CASES

SEAT PULLERS

Some times the Seat does not come out

with Stuffing Box and Cage. We have a

couple of options if this happens.

First Option:

If the Seat is the only part that stays stuck

in Body:

1. Use the wire seat pullers and insert

them in seat (Fig. 8.1).

2. Slide a wrench or small rod

between the wire Seat Pullers

3. Tap up pulling the seat out

(Fig. 8.2)

Figure 8.1

Figure 8.2

Second Option:

If the Stuffing Box comes out by it self

leaving seat, Ball & Stem and Cage stuck

in Body.

1.

2.

3.

Thread Seat & Cage Removal Tool

on to Cage (Fig. 8.3)

Tighten flange down against Body

Pull Case and Seat out of Body

(Figure 8.4)

Figure 8.3

Figure 8.4

The other end of the tool is used in case

just the Seat stays in Body.(Fig. 8.5)

1.

2.

3.

Thread Seat & Cage Removal Tool

on seat

Tighten flange against Body

Pull the seat out by turning the

handle in a clock wise direction

Figure 8.5

Page 14

www.kimray.com

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

HPMV DISASSEMBLY

SHOP MADE SEAT REMOVAL TOOL

This seat removal tool can be made with the

following parts:

QTY

PART

DESCRIPTION

2889

Cage

2837

Cage

Stops

Disc 1 3/4" x 3/4"

Rod

1 3/8" x 22"

Handle

11 3/4" od. x 3/8" id. x 5 1/2" lg.

22"

3"

3/4"

PART 2889

3/8"

2 1/2"

5 1/2"

1 3/4"

PART 2837

Figure 9.1

If Seat is stuck in Body (Fig. 9.2), use the

appropriate cage size and thread on seat.

(Fig. 9.3).

Figure 9.2

Slide Handle forcefully upwards until you

hit the upper stop (Fig. 9.4). The Handle

impact will break loose the seat.

Figure 9.3

www.kimray.com

Figure 9.4

Page 15

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

NOTES

Page 16

www.kimray.com

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

HPMV INSPECTION of PARTS

MOST COMMONLY REPLACED PARTS

OCCASIONALLY CHANGED PARTS

Seat Body

Stem & Ball Spring

Diaphragm

O-Rings

Packing

BALL & STEM

Check for scratches

Replace:

If there are scratches present

(Fig. 1.1)

Figure 1.1

SEAT

Replace:

If the seat has indication of leakage

(Fig 2.1)

Figure 2.1

BODY

Replace:

If grooves are present on the seating

surface (Fig.3.1)

Figure 3.1

www.kimray.com

Page 17

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

NOTES

Page 18

www.kimray.com

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

HPMV ASSEMBLY

STEP 1

DIAPHRAGM ASSEMBLY

CASE 1

BOLTED DIAPHRAGM NUT:

Tighten Diaphragm Base Plate in Vice

(Fig. 1.1)

Insert Diaphragm on the Diaphragm Plate

aligning holes with both parts (Fig. 1.2)

Figure 1.1

Figure 1.2

Figure 1.3

Figure 1.4

Figure 1.5

Figure 1.6

Insert Diaphragm Plate in to Base Plate

making sure holes are aligned (Fig. 1.3)

Use gasket sealant material to dip each

screw in before putting in hole. Tighten

screws in a criss-cross pattern and then

retighten very tight (Fig. 1.4)

CASE 2

THREADED DIAPHRAGM NUT:

Tighten Diaphragm Plate in vice and

insert Diaphragm on the Diaphragm Plate

(Fig. 1.5)

Grease the Diaphragm inside edge (Fig.

1.6)

Insert the Diaphragm Nut and use a pair

of pliers to tighten (Fig. 1.7)

Note: Make sure the Diaphragm does not

wrinkle.

Figure 1.7

STEP 2

STUFFING BOX ASSEMBLY

Insert Wiper in the Stuffing Box (Fig. 2.1)

Insert the retainer with the sharp edge on

top (Fig. 2.2)

Figure 2.1

www.kimray.com

Figure 2.2

Page 19

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

HPMV ASSEMBLY

Use a pair of snap ring pliers to insert the

Snap Ring (Figure 2.3)

Insert the packing rings on the Packing

Sleeve (Fig. 2.4)

Figure 2.3

Figure 2.4

Figure 2.5

Figure 2.6

Figure 2.7

Figure 2.8

Figure 2.9

Figure 2.10

Figure 2.11

Figure 2.12

Grease the Packing before inserting it in

the stuffing Box, with the large blue end of

sleeve down (Fig. 2.5)

Grease the Stuffing Box (Fig. 2.6)

Insert the Packing in the Stuffing Box

(Fig. 2.7)

Use a socket to push the Packing down

(Fig. 2.8)

Insert Follower in the Stuffing Box (Fig.

2.9)

Fill the Stuffing Box with grease

(Fig. 2.10)

Insert O-Ring on Stuffing Box (Fig. 2.11)

Insert Spring in the Stuffing Box

(Fig. 2.12)

Page 20

www.kimray.com

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

HPMV ASSEMBLY

Insert O-Ring on Seat (Fig. 2.13)

Introduce the Stem in Cage (Fig. 2.14)

Figure 2.13

Figure 2.14

Figure 2.15

Figure 2.16

Figure 2.17

Figure 2.18

Figure 2.19

Figure 2.20

Figure 3.1

Figure 3.2

Thread the Seat in Cage (Fig. 2.15)

Place the flat edges of stuffing box in vice

(Fig. 2.16)

Insert Seat, Cage and Stem in the stuffing

Box and tighten with a wrench

(Fig. 2.17 and 2.18)

Tap the Stem until Ball seats (Fig. 2.19)

Use a brush to grease O-Rings (Fig. 2.20)

STEP 3

BODY

Flip the Body upside down and tighten

Body on Stuffing Box Assembly

(Fig. 3.1 and 3.2)

www.kimray.com

Page 21

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

HPMV ASSEMBLY

BODY TESTING:

Apply air pressure on the upstream side of

the valve (Fig. 3.3)

Test for leakage in the downstream side

Figure 3.3

STEP 4

LOWER ADJUSTING SCREW

Insert O-Ring in the Lower Adjusting

Screw (Fig. 4.1)

Flip the Lower Adjusting Screw over and

insert Wiper (Fig. 4.2)

Figure 4.1

Figure 4.2

Figure 4.3

Figure 4.4

Figure 4.5

Figure 4.6

Figure 4.7

Figure 4.8

Insert Retainer on top of Wiper making

sure the sharp edge side is located on top

(Fig. 4.3)

Use a pair of snap ring pliers to insert the

Snap Ring (Fig. 4.4)

Insert O-Ring on Lower Adjusting Screw

and grease it (Fig. 4.5 and 4.6)

Insert Upper Stem in Lower Adjusting

Screw, being careful not to share O-Ring

(Fig. 4.7)

Tighten Lower Adjusting Screw on the bottom part of Yoke (Fig. 4.8)

Page 22

www.kimray.com

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

HPMV ASSEMBLY

STEP 5

DIAPHRAGM ASSEMBLY

Place the Yoke on top of the Body (Fig.

5.1)

Insert Bolts and tighten them with a

wrench (Fig. 5.2)

Figure 5.1

Figure 5.2

Figure 5.3

Figure 5.4

Figure 5.5

Figure 5.6

Figure 5.7

Figure 5.8

Figure 5.9

Figure 5.10

Use a brush to grease the Upper Stem

(Fig. 5.3)

Use an adjustable wrench to hold the

stem while tightening the Diaphragm Plate

(Fig. 5.4 and 5.5)

Grease the Pivot surface of the

Diaphragm Plate (Fig. 5.6)

Insert Spring Plate in the Pivot Sleeve

(Fig. 5.7)

Insert Spring on Diaphragm Plate

(Fig. 5.8)

Insert Spring Plate on top of Spring

(Fig. 5.9)

Place the Bonnet on top of Yoke making

sure the sure the Breather and the Supply

holes are aligned (Fig. 5.10)

www.kimray.com

Page 23

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

HPMV ASSEMBLY

Insert bolts on top of the Bonnet and tighten them with the impact gun (Fig. 5.11)

Grease the Adjusting Screw (Fig. 5.12)

Figure 5.11

Figure 5.12

Figure 5.13

Figure 5.14

Figure 5.15

Figure 5.16

Figure 6.1

Figure 6.2

Figure 6.3

Figure 6.4

Place the Pivot on top of the Adjusting

Screw and grease the top part of the Pivot

(Fig. 5.13 and 5.14)

Screw the Adjusting Screw on top of

Bonnet and tighten it with an adjustable

wrench (Fig. 5.15 and 5.16)

STEP 6

BLOCK

When you assemble the Block, make sure

the bevels are in the same side of the

block as show in (Fig. 6.1)

Place the threaded Half Block on the back

side (Fig. 6.2)

Tighten the bolts in the Block with a

socket (Fig. 6.3)

Make sure the Travel Indicator tag shows

the correct operation of the valve either

PO or PC (Fig. 6.4)

Page 24

www.kimray.com

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

HPMV TESTING

EQUIPMENT & REQUIREMENTS

SUPPLY PRESSURE: 100 psi

SUPPLY CONNECTION: Device that will reduce your regulator end to any

air supply connection.

Fig. A shows an example of this device. It is important to have a valve in

this device for testing purposes.

Figure A

STEP 7

HPMV PO TESTING

Apply air supply pressure (do not exceed

45 psi) on Yoke (Fig. 7.1) This will open

the valve and will pressurize the bottom

part of the Diaphragm.

Spray soaped solution on the Lower

Adjusting Screw to check for any leakage

(Fig. 7.2)

Figure 7.1

Figure 7.2

Spray soaped solution on the Interface

between the Bonnet and the Yoke. Check

for leakage (Fig. 7.3)

Figure 7.3

www.kimray.com

Page 25

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

NOTES

Page 26

www.kimray.com

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

PISTON BALANCED DISASSEMBLY

KIMRAY SEAT WRENCH W SERIES

PART NUMBER

LINE SIZE

386SW

3" & 4" HPMVPB

Note: Seat Wrench W Series are mainly used for Treater

Valves, but they can be used to assemble the Diaphragm

Nut for 3 and 4 High Pressure Motor Valves.

Figure A

KIMRAY SEAT WRENCH W SERIES

PART NUMBER

LINE SIZE

5296

2" HPMVPB

5297

3" HPMVPB

5298

4" HPMVPB

Figure B

6 Piston Assembly Puller

Use this tool to lift the Piston Assembly out of the Body by

pulling it with a hoist.

Note: This is a shop made tool using a Coupling Block,

Upper Stem and a ring.

Figure C

www.kimray.com

Page 27

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

PISTON BALANCED DISASSEMBLY

STEP 1

ADJUSTING SCREW

Use a wrench to remove the Adjusting

Screw on top of the Bonnet (Fig. 1.1)

Figure 1.1

STEP 2

BONNET

Remove the bolts in the interface between

the Bonnet and the Yoke (Fig. 2.1)

Remove Breather Plug from Bonnet

(Fig. 2.2)

Figure 2.1

Figure 2.2

Remove Bonnet from Yoke (Fig. 2.3)

Figure 2.3

STEP 3

SPRING

Remove Pivot and the Spring Plate from

top of the Spring (Fig. 3.1)

Remove the Spring from top Spring Plate

(Fig. 3.2)

Figure 3.1

Figure 3.2

Figure 4.1

Figure 4.2

STEP 4

DIAPHRAGM PLATE

Spin the Diaphragm plate in a counter

clock wise direction loosening it from the

Upper Stem while holding the Upper Stem

with a small crescent wrench (Fig. 4.1).

Remove the Diaphragm Nut from the

Diaphragm Plate (Fig. 4.2)

Page 28

www.kimray.com

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

PISTON BALANCED DISASSEMBLY

Remove the Diaphragm from the

Diaphragm Plate (Fig. 4.3)

Figure 4.3

STEP 5

TRAVEL INDICATOR

Remove the bolts from the Travel

Indicator Block (Fig. 5.1)

Remove the Coupling Block (Fig. 5.2)

Figure 5.1

Figure 5.2

Figure 6.1

Figure 6.2

Figure 6.3

Figure 6.4

Figure 6.5

Figure 6.6

STEP 6

YOKE ASSEMBLY

Use a wrench to remove the bolts from

Yoke (Fig. 6.1)

Slide out the Yoke from Body (Fig. 6.2)

Flip Yoke upside down and remove the

Upper Stem from the Lower Adjusting

Screw (Fig. 6.3)

Take a socket and remove the Lower

Adjusting Screw with an impact gun

(Fig. 6.4)

Remove the outside O-Ring from the

Lower Adjusting Screw (Fig. 6.5)

Remove O-Ring from the inside of the

Lower Adjusting Screw (Fig. 6.6)

www.kimray.com

Page 29

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

PISTON BALANCED DISASSEMBLY

Use a pair of snap ring pliers to remove

the Snap Ring (Fig. 6.7)

Remove the Retainer Washer (Fig. 6.8)

Figure 6.7

Figure 6.8

Remove the Wiper from the Lower

Adjusting Screw (Fig. 6.9)

Figure 6.9

STEP 7

STUFFING BOX ASSEMBLY

Use an adjustable wrench to remove the

Stuffing Box from the Body (Fig. 7.1 and

7.2)

Figure 7.1

Figure 7.2

Figure 7.3

Figure 7.4

Figure 7.5

Figure 7.6

Remove Spring and Follower from Stuffing

Box (Fig. 7.3)

Remove the Packing Sleeve and the

Packing Ring from the Stuffing Box

(Fig. 7.4)

Use a pair of snap ring pliers to remove

the Snap Ring (Fig. 7.5)

Remove the Retainer Washer from the

Stuffing Box (Fig. 7.6)

Page 30

www.kimray.com

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

PISTON BALANCED DISASSEMBLY

Remove the Wiper from the Stuffing Box

(Fig. 7.7)

Figure 7.7

STEP 8

UPPER HOUSING

Use an impact gun to remove the bolts

from the Upper Housing (Fig. 8.1)

Break the Upper Housing loose by prying

up with screw drivers (Fig. 8.2)

Remove the Upper Housing from the Body

(Fig. 8.3).

Figure 8.1

Figure 8.2

Figure 8.3

STEP 9

PISTON ASSEMBLY

Some times the Upper Cage will not break

loose easy. If this is the case use an

Upper Cage Puller.

Start by removing the O-Ring from the

Cage (Fig. 9.1)

Slide Upper Cage Pullers in O-Ring

groove on Cage and clamp with a water

hose clamp (Fig. 9.2)

Figure 9.1

Figure 9.2

Alternately tighten screw until cage breaks

loose from Body (Fig. 9.3)

Figure 9.3

www.kimray.com

Page 31

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

PISTON BALANCED DISASSEMBLY

Remove the Piston Assembly from Body

(Fig. 9.4)

Slide up Upper Cage from the Piston

Assembly (Fig. 9.5)

Figure 9.4

Figure 9.5

Figure 9.6

Figure 9.7

Figure 9.8

Figure 9.9

Figure 9.10

Figure 9.11

Remove the O-Ring and two Backups

(Fig. 9.6)

Remove the Lower Cage from Piston

Assembly (Fig. 9.7)

Use a socket to remove the screw that

holds the Ratio Plug (Fig. 9.8)

Remove the Ratio Plug (Fig. 9.9)

Remove O-Rings from Piston Assembly

(Fig. 9.10, 9.11 and 9.12)

Figure 9.12

Page 32

www.kimray.com

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

PISTON BALANCED DISASSEMBLY

STEP 10

SEAT

Remove seat from Body (Fig. 10.1 & 10.2)

Figure 10.1

Figure 10.2

Remove O-Ring from Seat (Fig. 10.3)

Figure 10.3

www.kimray.com

Page 33

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

NOTES

Page 34

www.kimray.com

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

PISTON BALANCED INSPECTION of PARTS

PISTON ROD

Replace:

If piston rod is bent (Fig. 1.1)

Figure 1.1

PISTON

Replace:

If the parts present corrosion in the

outside surface (Fig. 2.1)

Figure 2.1

SEAT

Replace:

In the presence of dings, nicks or co rrosion (Fig. 3.1)

Figure 3.1

RATIO PLUG

Replace:

In the presence of scratches, corro sion and wear (Fig. 4.1)

Note: This is one of the most affected

parts due to the severe impact of the particles that flow trough the valve.

Figure 4.1

CAGE

Replace:

If the Cage has lost its shape

(Fig. 5.1)

Note: If the valve was improperly disassembled, there is a high possibility to have

a Cage out-of-round.

Figure 5.1

www.kimray.com

Page 35

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

PISTON BALANCED INSPECTION of PARTS

STUFFING BOX

Replace:

In the presence of excessive corro sion and wear. (Fig. 6.1, 6.2 and 6.3)

Note: Most of the times this part can be

repair by cleaning and wire brushing the

inside and outside threads.

Figure 6.2

Figure 6.1

Page 36

www.kimray.com

Figure 6.3

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

PISTON BALANCED ASSEMBLY

KIMRAY SEAT WRENCH W SERIES

PART NUMBER

LINE SIZE

386SW

3" & 4" HPMVPB

Note: Seat Wrench W Series are mainly used for Treater Valves, but they

can be used to assemble the Diaphragm Nut for 3" and 4" High Pressure

Motor Valves.

Figure A

STEP 1

SEAT

Grease the seat surface inside the Body

(Figure 1.1)

Insert O-Ring on Seat and place it in Body

(Fig. 1.2)

Figure 1.1

Figure 1.2

Figure 2.1

Figure 2.2

Figure 2.3

Figure 2.4

Figure 2.5

Figure 2.6

STEP 2

PISTON ASSEMBLY

Insert O-Ring inside Piston Assembly

(Fig. 2.1)

Insert O-Ring in Ratio Plug (Fig. 2.2)

Insert O-Ring with the angled side on top

(Fig. 2.3 and 2.4)

Insert Ratio Plug in the Piston Assembly

(Fig. 2.5)

Finger tighten the screw holding the Ratio

Plug on Piston Assembly (Fig. 2.6)

www.kimray.com

Page 37

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

PISTON BALANCED ASSEMBLY

Use brass jaws to hold the Piston

Assembly in vice (Fig. 2.7)

Use a socket to tighten the Ratio Plug

Screw (Fig. 2.8)

Figure 2.7

Figure 2.8

Figure 2.9

Figure 2.10

Figure 2.11

Figure 2.12

Figure 2.13

Figure 2.14

Figure 2.15

Figure 2.16

Insert Lower Cage on Piston Assembly

(Fig. 2.9)

Grease the Piston Assembly (Fig. 2.10)

Insert Backup on Piston Assembly

(Fig. 2.11)

Insert O-Ring on Piston Assembly

(Fig. 2.12)

Insert Backup on Piston Assembly

(Fig. 2.13)

Grease O-Ring and Backups (Fig. 2.14)

Insert two O-Rings in the Upper Cage

grooves (Fig. 2.15 and 2.16)

Page 38

www.kimray.com

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

PISTON BALANCED ASSEMBLY

Insert Piston Assembly Stem in to Upper

Cage (Fig. 2.17). Press Upper Cage on to

Piston Assembly.

Grease O-Rings in Upper Cage (Fig. 2.18)

Figure 2.17

Figure 2.18

Figure 2.19

Figure 2.20

Figure 2.21

Figure 2.22

Figure 3.1

Figure 3.2

Figure 4.1

Figure 4.2

Spray Never Seez in the Piston Assembly

(Fig. 2.19)

Insert Piston Assembly in Body (Fig. 2.20)

Use a rubber hammer to press Piston

Assembly in Body (Fig. 2.21)

Use a rubber hammer to tap the Piston

Assembly Rod pressing the Seat in place

(Fig. 2.22)

STEP 3

UPPER HOUSING

Insert Upper Housing on Body (Fig. 3.1).

Make sure the Safety Relief Hole is facing

tapped holes on Body.

Insert bolts and tighten them in a crisscross pattern (Fig. 3.2)

STEP 4

STUFFING BOX

Insert two wipers in Stuffing Box (Fig. 4.1)

Insert Retainer Washer on top with the

sharp edge side facing up (Fig. 4.2)

www.kimray.com

Page 39

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

PISTON BALANCED ASSEMBLY

Use a pair or snap ring pliers to insert the

Snap Ring on top of the Retainer Washer

(Fig. 4.3)

Insert O-Ring on Stuffing Box (Fig. 4.4)

Figure 4.3

Figure 4.4

Figure 4.5

Figure 4.6

Figure 4.7

Figure 4.8

Figure 4.9

Figure 4.10

Figure 4.11

Figure 4.12

Grease the Stuffing Box Hole (Fig. 4.5)

Insert Packing Rings and Packing Sleeve

in Stuffing Box, with the large blue end of

sleeve down (Fig. 4.6).

Insert Follower in Stuffing Box (Fig. 4.7)

Insert Spring in Stuffing Box (Fig. 4.8)

Fill the Stuffing Box with grease (Fig. 4.9)

Spray Never Seez on the Stuffing Box

(Fig. 4.10)

Insert Stuffing Box in Upper Housing

(Fig. 4.11)

Tighten Stuffing Box with an adjustable

wrench (Fig. 4.12)

Page 40

www.kimray.com

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

PISTON BALANCED ASSEMBLY

STEP 5

LOWER ADJUSTING SCREW

Insert two Wipers in the Lower Adjusting

Screw (Fig. 5.1)

Insert Retainer Washer with the sharp

edge side facing up (Fig. 5.2)

Figure 5.1

Figure 5.2

Figure 5.3

Figure 5.4

Figure 5.5

Figure 5.6

Figure 5.7

Figure 5.8

Figure 6.1

Figure 6.2

Use a pair of snap ring pliers to insert the

Snap Ring on top of the Retainer Washer

(Fig. 5.3)

Insert O-Ring inside the Lower Adjusting

Screw (Fig. 5.4)

Insert O-Ring around the Lower Adjusting

Screw (Fig. 5.5)

Grease O-Rings in Lower Adjusting Screw

(Fig. 5.6)

Insert Upper Stem in Lower Adjusting

Screw (Fig. 5.7)

Note: Make sure you do not shear the

O-Ring.

Tighten Lower Adjusting Screw in Yoke

(Fig. 5.8)

STEP 6

YOKE

Insert Yoke on top of the Upper Housing

(Fig. 6.1)

Insert Bolts and tighten in a criss-cross

pattern (Fig. 6.2)

www.kimray.com

Page 41

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

PISTON BALANCED ASSEMBLY

STEP 7

DIAPHRAGM ASSEMBLY

Use a pair of brass jaws to hold the

Diaphragm Plate in a vice (Fig. 7.1)

Grease the Diaphragm Plate inside perimeter (Fig. 7.2)

Figure 7.1

Figure 7.2

Figure 7.3

Figure 7.4

Figure 7.5

Figure 7.6

Figure 7.7

Figure 7.8

Figure 7.9

Figure 7.10

Place Diaphragm on Diaphragm Plate

(Fig. 7.3)

Thread Diaphragm Nut on Diaphragm

Plate (Fig. 7.4)

Use a 386SW Seat Wrench W Series to

tighten the Diaphragm Nut (Fig. 7.5)

Note: Make sure the Diaphragm does not

wrinkle.

Grease the top hole of the Diaphragm

Plate (Fig. 7.6)

Insert Diaphragm Plate Assembly on top

of Yoke (Fig. 7.7)

Use an adjustable wrench to hold

the Upper Stem while tightening the

Diaphragm Plate (Fig. 7.8)

Grease the Sleeve on the Diaphragm

Plate (Fig. 7.9)

Insert the Spring Plate in Diaphragm Plate

(Fig. 7.10)

Page 42

www.kimray.com

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

PISTON BALANCED ASSEMBLY

Insert Spring on Diaphragm Plate

(Fig. 7.11)

Insert the second Spring plate on top of

Spring (Fig. 7.12)

Figure 7.11

Figure 7.12

Figure 7.13

Figure 7.14

Figure 7.15

Figure 7.16

Figure 7.17

Figure 7.18

Grease the top side of the Spring Plate

(Fig.7.13)

Insert Pivot on top of the Spring Plate

(Fig. 7.14)

Place the Bonnet on top of Yoke

(Fig. 7.15)

Tighten the Breather Plug on top of the

Bonnet (Fig. 7.16)

Insert bolts on the Bonnet and tighten in a

criss-cross pattern (Fig. 7.17 and 7.18)

Tighten the Upper Adjusting Screw on top

of Bonnet (Fig. 7.19)

Figure 7.19

www.kimray.com

Page 43

HIGH PRESSURE MOTOR VALVES REPAIR MANUAL

PISTON BALANCED ASSEMBLY

STEP 8

COUPLING BLOCK

Make sure the bevels are aligned in the

Coupling Block (Fig. 8.1)

Use an impact gun to tighten the screws

in the Coupling Block (Fig. 8.2)

Figure 8.1

Figure 8.2

Make sure the Travel Indicator tag shows

the correct operation of the valve

(Fig. 8.3)

Figure 8.3

Page 44

www.kimray.com

HIGH PRESSURE MOTOR VALVE REPAIR MANUAL

NOTES

www.kimray.com

Você também pode gostar

- Iso Dis 45001Documento46 páginasIso Dis 45001gmg210981Ainda não há avaliações

- Iso Dis 45001Documento46 páginasIso Dis 45001gmg210981Ainda não há avaliações

- Makita Brusilica Sklop PDFDocumento2 páginasMakita Brusilica Sklop PDFvesna59Ainda não há avaliações

- DW 400Documento45 páginasDW 400gmg210981Ainda não há avaliações

- Valve Academy Focus on Flow ControlDocumento6 páginasValve Academy Focus on Flow Controlgmg210981Ainda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Term paper on shock absorbersDocumento23 páginasTerm paper on shock absorbersGopal GuptaAinda não há avaliações

- Vdocuments - MX - Naza Ria MPV PDFDocumento93 páginasVdocuments - MX - Naza Ria MPV PDFalangku09100% (2)

- 1 Jaguar XK XJ6 12 XJS E Type 1Documento49 páginas1 Jaguar XK XJ6 12 XJS E Type 1shylen sadienAinda não há avaliações

- Voith CompressorsDocumento8 páginasVoith CompressorsjakovpekovicAinda não há avaliações

- F500 ManualDocumento128 páginasF500 ManualBruno Pilieci100% (1)

- 5D22 (1H5D2450E1) T135HC SniperHCDocumento62 páginas5D22 (1H5D2450E1) T135HC SniperHCRenAinda não há avaliações

- Kastas NewProductsCatalogue enDocumento86 páginasKastas NewProductsCatalogue enjohnysonycum0% (2)

- Hallite Inch Fluid Power CatalogDocumento315 páginasHallite Inch Fluid Power CatalogjeanvirusAinda não há avaliações

- DT530 Manual EGES2101Documento364 páginasDT530 Manual EGES2101CODY WIMBERLY91% (23)

- Petroamazonas EP spare parts installation checklistDocumento33 páginasPetroamazonas EP spare parts installation checklistGiss YHAinda não há avaliações

- CQ2 Z PDFDocumento214 páginasCQ2 Z PDFLiêm HiếuAinda não há avaliações

- Assembly and Testing GuidelinesDocumento2 páginasAssembly and Testing GuidelinesCamilo Andres Cardozo FajardoAinda não há avaliações

- Automotive Mechanics Instructional Program Block 2: Engine FundamentalsDocumento116 páginasAutomotive Mechanics Instructional Program Block 2: Engine FundamentalsFreeman MudonhiAinda não há avaliações

- 2016 Grand Cherokee - 3.6L ENGINE PDFDocumento649 páginas2016 Grand Cherokee - 3.6L ENGINE PDFprueba2100% (1)

- I C EngineDocumento154 páginasI C EngineoperationmanagerAinda não há avaliações

- Yamaha F40B'03 (67C2) PDFDocumento66 páginasYamaha F40B'03 (67C2) PDFcurromioAinda não há avaliações

- Power Plant: I. Piston Engine II. Turbine Engine Iii. Engine Construction: IV. Engine Systems: V. Auxiliary Power UnitDocumento78 páginasPower Plant: I. Piston Engine II. Turbine Engine Iii. Engine Construction: IV. Engine Systems: V. Auxiliary Power UnitNirja ozaAinda não há avaliações

- KTCDocumento510 páginasKTCilham nugrohoAinda não há avaliações

- Free-Piston Engine: Terry Johnson Sandia National Laboratories Tuesday, May 15, 2012Documento27 páginasFree-Piston Engine: Terry Johnson Sandia National Laboratories Tuesday, May 15, 2012Kailash C BhosaleAinda não há avaliações

- Parker Piston T-Seal for Improved StabilityDocumento4 páginasParker Piston T-Seal for Improved StabilityGriphold PlantAinda não há avaliações

- Instruction Book L2738ed080120 PDFDocumento252 páginasInstruction Book L2738ed080120 PDFGiovanniJaraAinda não há avaliações

- PC500LC 10M0Documento28 páginasPC500LC 10M0kahrimanovicjasmin2Ainda não há avaliações

- 998206Documento72 páginas998206sandia_docsAinda não há avaliações

- Aba Aeg 2 0Documento25 páginasAba Aeg 2 0Diego NunesAinda não há avaliações

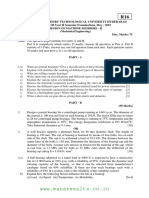

- WWW - Manaresults.co - In: (Mechanical Engineering)Documento2 páginasWWW - Manaresults.co - In: (Mechanical Engineering)Mohammed SohailAinda não há avaliações

- Pneumatic QuizDocumento8 páginasPneumatic QuizKrishna Geed100% (1)

- ENGINE 6.7L Diesel - Service Information - Ram Pickup PDFDocumento317 páginasENGINE 6.7L Diesel - Service Information - Ram Pickup PDFcharles100% (2)

- Connecting Rod Design and AnalysisDocumento29 páginasConnecting Rod Design and Analysisumair talashAinda não há avaliações

- Parts Tad1240ge Tad1241ge Tad1242gepdfDocumento203 páginasParts Tad1240ge Tad1241ge Tad1242gepdfstefan corjuc100% (2)

- 1 Xinhuafa BrochureDocumento14 páginas1 Xinhuafa BrochureAlice chenAinda não há avaliações