Escolar Documentos

Profissional Documentos

Cultura Documentos

Re 07100

Enviado por

Efrain Ramos CruzDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Re 07100

Enviado por

Efrain Ramos CruzDireitos autorais:

Formatos disponíveis

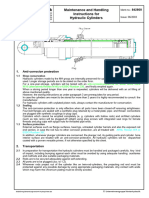

RE 07 100/12.

96

100/08.96

Assembly,

Commissioning and Maintenance

of Hydraulic Cylinders

1. General

Before commissioning hydraulic cylinders the guidelines

stated within the following catalogue sheets have to be

taken into account:

Relevant catalogue sheet

German standard DIN 24 346

ISO standard ISO 4413

2. Installation

2.1 Instalation guidelines

Before the hydraulic cylinder is fitted into the system, the

designation of the hydraulic cylinder should be compared

with the order data.

Cleanliness:

When installing the cylinder and the local area.

Piping and reservoir must, before installation, be

cleaned of dirt, scale, sand, swarf, etc.

Welded or hot formed pipes are to be pickeled, flushed

and finally oiled.

For cleaning only use lint free cloths or special paper.

Sealing materials such as hemp, putty or sealing tape

are not permissible.

2.2 Installation position

optional

2.3 Electrical connections

Position transducer

RE

07 100/12.96

Replaces: 08.96

3.2 Filtration

A reliable filtration increases the service life of the

hydraulic cylinder. Please take note of the maximum

recommended contamination grade to NAS 1638 as

stated within our catalogue sheet.

The maximum permissible filter element pressure

differential must not be exceeded.

We recommend that filters are fitted with clogging

indicators.

Great care with regard to cleanliness should be taken

when changing filter elements.

Contamination on the outlet side of the filter can be

flushed into the system and cause malfunctions.

Contamination of the inlet side reduces the service life of

the filter element.

3.3 Air bleeding

Under no load conditions loosen the bleed screws or pipe

fittings on the base or rod end.

Let the air escape.

Close the bleed screw or the fitting only when the

oil is free of bubbles.

Retighten the bleed screw or fitting.

4. Maintenance

4.1 Hydraulic cylinders are basically maintenance free;

However bearing lubrication e.g. swivel eyes or trunnions

has to be taken into account.

4.2 Check for leakage at frequent intervals.

Inductive limit switch

The pin allocation can be obtained from the relevant data

sheet.

3. Commissioning

3.1 Pressure fluid

The recommendations stated within the data sheets are

to be taken into account.

Pressure and temperature ranges are to be observed.

Check to ensure that the system pressure fluid is

compatable with the permissible (see part no.) pressure

fluid of the hydraulic cylinder.

Generally the following can be used:

Mineral oil (HL; HLP) to DIN 51 524

Phosphate ester (HFD-R)

Other fluids on request!

4.3 Changing seals

Moving seals are wear parts. Should internal or external

leakage reach an unacceptably high level, we recommend

that the hydraulic cylinders are returned to our works so that

when the seals are changed the guides etc. can also be

checked.

5. Storage

5.1 Storage room requirements:

Dry, dust free room, free of corrosive materials and

vapours.

5.2 When storing for longer than 6 months:

Fill the hydraulic cylinders with anti-corrosion oil and plug

the ports.

The guidelines stated in AB 01-02.11 are to be taken into

account.

The manufactures recommendations concerning maximum

temperatures should not be exceeded.

In order to obtain constant responce characteristics from the

system, it is recommended that the fluid temperature should

be held constant (5 C).

1/2

RE 07 100/08.96

Notes

Mannesmann Rexroth GmbH

D-97813 Lohr am Main

Jahnstrae 3-5 D-97816 Lohr am Main

Telefon 0 93 52 / 18-0 Telefax 0 93 52 / 18-10 40

Telex 6 89 418-0

2/2

Mannesmann Rexroth Limited

Cromwell Road, St. Neots,

Huntingdon, Cambs. PE19 2ES

Tel: (01480) 476041

Fax: (01480) 219052

The specified data is for product description purposes only and may not be deemed to be

guaranteed unless expressly confirmed in the contract. All rights reserved Subject to revision

Você também pode gostar

- Assembly, Commissioning and Maintenance of Hydraulic CylindersDocumento2 páginasAssembly, Commissioning and Maintenance of Hydraulic CylindersmuhammadAinda não há avaliações

- Installation, Commissioning and Servicing of Hydraulic Pumps and MotorsDocumento2 páginasInstallation, Commissioning and Servicing of Hydraulic Pumps and Motorsbhaswath2000Ainda não há avaliações

- Installation, Commissioning and Maintenance of Proportional ValvesDocumento4 páginasInstallation, Commissioning and Maintenance of Proportional ValvesEmrah BinayAinda não há avaliações

- Re 07700Documento2 páginasRe 07700Ahmed Abd ElhakeemAinda não há avaliações

- Propping CylDocumento2 páginasPropping CyljulioferoAinda não há avaliações

- Installation, Commissioning and Maintenance Guidelines: For Electrohydraulic SystemsDocumento0 páginaInstallation, Commissioning and Maintenance Guidelines: For Electrohydraulic Systemsanta77100% (1)

- 5 Safety Requirements Pneumatic Control SystemDocumento5 páginas5 Safety Requirements Pneumatic Control Systemwarehousekiyanly.giAinda não há avaliações

- Overhauling of TransformersDocumento9 páginasOverhauling of TransformersVibhor Gaur100% (5)

- Installation, Commissioning and Maintenance of Industrial ValvesDocumento2 páginasInstallation, Commissioning and Maintenance of Industrial ValvesEmrah BinayAinda não há avaliações

- 04 Transformer Maintenance#Documento17 páginas04 Transformer Maintenance#aimiza100% (1)

- Catalogo de Industria Minera PoberajDocumento48 páginasCatalogo de Industria Minera PoberajWillintonPoloAinda não há avaliações

- Manual - Burner L1-L3 - GB98Documento40 páginasManual - Burner L1-L3 - GB98Игорь88% (16)

- General Maintenance Procedures: Caution!Documento14 páginasGeneral Maintenance Procedures: Caution!Henry HuayhuaAinda não há avaliações

- C Part4 Hydraulics and PneumaticsDocumento12 páginasC Part4 Hydraulics and PneumaticszsmithAinda não há avaliações

- Re 07900Documento2 páginasRe 07900lizbethdiosesAinda não há avaliações

- C-14 Selection and Limitation of Piping ComponentsDocumento14 páginasC-14 Selection and Limitation of Piping ComponentscristhianAinda não há avaliações

- HL2-90 Compressor Instr ManualDocumento12 páginasHL2-90 Compressor Instr ManualCosmin Iulian100% (3)

- Es2184d - Cleaning and Flushing of Hydraulic Systems & ComponentsDocumento9 páginasEs2184d - Cleaning and Flushing of Hydraulic Systems & Componentsferfilho100% (2)

- 0242 0001 4@1Documento4 páginas0242 0001 4@1Polaris BridgemanAinda não há avaliações

- Winezone Air Handler System: Wzah #4 1Documento29 páginasWinezone Air Handler System: Wzah #4 1constantin.iacomi3837Ainda não há avaliações

- TEC - TA05NALDEA #125869 v1 MT 2721 0 312 02 7507 - ConstruccionDocumento110 páginasTEC - TA05NALDEA #125869 v1 MT 2721 0 312 02 7507 - ConstruccionandinoAinda não há avaliações

- Almig Pistons 'A' Range Operating ManualDocumento22 páginasAlmig Pistons 'A' Range Operating ManualAndy MitchellAinda não há avaliações

- Installation and ServiceDocumento19 páginasInstallation and ServiceJosé Emilio D' LeónAinda não há avaliações

- Ecodan Splits PUHZ-SW40 Service Manual - OCH525, October 2012Documento60 páginasEcodan Splits PUHZ-SW40 Service Manual - OCH525, October 2012Serban Tiberiu100% (1)

- Grúa Tadano Faun ATF 130 G5Documento67 páginasGrúa Tadano Faun ATF 130 G5Reinaldo ZorrillaAinda não há avaliações

- I PM380-125 07 05 enDocumento8 páginasI PM380-125 07 05 enOmprakash_janaAinda não há avaliações

- Manual de Multiplicadora Jason en Buques MercantesDocumento35 páginasManual de Multiplicadora Jason en Buques MercantesAbelardo Aguilar100% (1)

- Ref Compressor HASEEGAVA PDFDocumento65 páginasRef Compressor HASEEGAVA PDFigorAinda não há avaliações

- PUHY P200 250YREM A Service HandbookDocumento124 páginasPUHY P200 250YREM A Service HandbookGingubaAinda não há avaliações

- FR3 Change From Mineral Oil in Transformer Na3072835Documento4 páginasFR3 Change From Mineral Oil in Transformer Na3072835classicalgasAinda não há avaliações

- GFP23 Non-LubeServiceDocumento1 páginaGFP23 Non-LubeServiceJeff LangleyAinda não há avaliações

- Manual Bomba Versa MaticDocumento18 páginasManual Bomba Versa Maticregue_g_801719926100% (1)

- Grúa Tadano Faun ATF 130 G5Documento93 páginasGrúa Tadano Faun ATF 130 G5Reinaldo ZorrillaAinda não há avaliações

- Plan Api 23Documento20 páginasPlan Api 23JAIMEAinda não há avaliações

- Fallas ScrollDocumento8 páginasFallas ScrollLucas MaturanoAinda não há avaliações

- 390 InstructionsDocumento48 páginas390 InstructionsemaanazeemAinda não há avaliações

- S1 AM019 C DenisonDocumento25 páginasS1 AM019 C DenisonEmerson MazzaroloAinda não há avaliações

- Central Gas Equipment For Industrial Gases (2011 Edition in English) UK586 - 103230Documento64 páginasCentral Gas Equipment For Industrial Gases (2011 Edition in English) UK586 - 103230maspanuciAinda não há avaliações

- Testing 1Documento28 páginasTesting 1jiguparmar20094903Ainda não há avaliações

- P9 Guidelines For The Flushing of Hydraulic Systems I2Documento18 páginasP9 Guidelines For The Flushing of Hydraulic Systems I2Nano VillanuevaAinda não há avaliações

- Testing Procedure Part-IIDocumento36 páginasTesting Procedure Part-IIAshok PatelAinda não há avaliações

- s05nmdl2sm PDFDocumento22 páginass05nmdl2sm PDFmn_aminAinda não há avaliações

- Compressed Gas Cylinders Safety ChecklistDocumento4 páginasCompressed Gas Cylinders Safety ChecklistKhairul AmilinAinda não há avaliações

- ARIEL Maint intervalSEK PDFDocumento7 páginasARIEL Maint intervalSEK PDFMargaret Daugherty100% (1)

- Servicing of HFC Based Air-ConditionersDocumento20 páginasServicing of HFC Based Air-ConditionersPablo TovarAinda não há avaliações

- Pefy P VMH e F T S (Mee04k286)Documento30 páginasPefy P VMH e F T S (Mee04k286)Costi CosticaAinda não há avaliações

- H Im 67GDocumento52 páginasH Im 67GMaria DazaAinda não há avaliações

- Refrigerant Changeover Guidelines CFC R-502 To HFC R-404A/R-507Documento8 páginasRefrigerant Changeover Guidelines CFC R-502 To HFC R-404A/R-507phankhoa83Ainda não há avaliações

- Maintenance and Repair InstructionsDocumento12 páginasMaintenance and Repair InstructionsDhananjay NilkuteAinda não há avaliações

- Turbashed EmersonDocumento2 páginasTurbashed EmersonGERARDO JARDON ZAMBRNOAinda não há avaliações

- XB 13 InstallDocumento8 páginasXB 13 InstalljbozakAinda não há avaliações

- AAEDR-F-005 Rev 1 (Extended Storage PA)Documento6 páginasAAEDR-F-005 Rev 1 (Extended Storage PA)Jose G LopezAinda não há avaliações

- Re90223 HF Fluids Axial PistonDocumento8 páginasRe90223 HF Fluids Axial PistonlamehesAinda não há avaliações

- Guide-to-Compressed-or-Liquefied-Gases-in-Laboratories ACETYLENEDocumento10 páginasGuide-to-Compressed-or-Liquefied-Gases-in-Laboratories ACETYLENEvermaravi11449922Ainda não há avaliações

- Preventive Maintenance - Keeping Refrigeration Equipment in ShapeDocumento5 páginasPreventive Maintenance - Keeping Refrigeration Equipment in ShapeSanjay RanaAinda não há avaliações

- Defender 90 110 Workshop Manual 5 WiringDocumento112 páginasDefender 90 110 Workshop Manual 5 WiringChris Woodhouse50% (2)

- Gardner Denver MH5 HydrapakDocumento8 páginasGardner Denver MH5 HydrapakManualstoHelp0% (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitAinda não há avaliações

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryAinda não há avaliações

- Prophet Muhammads Last Sermon 523 enDocumento3 páginasProphet Muhammads Last Sermon 523 enAnonymous 1qAH6CKCAinda não há avaliações

- Delivery Order: Dear Sir/Madam, Herewith Is Our Delivery Order Generated For Your PerusalDocumento1 páginaDelivery Order: Dear Sir/Madam, Herewith Is Our Delivery Order Generated For Your PerusalAnonymous 1qAH6CKCAinda não há avaliações

- CalibrationDocumento2 páginasCalibrationAnonymous 1qAH6CKCAinda não há avaliações

- Service ReportsDocumento1 páginaService ReportsAnonymous 1qAH6CKCAinda não há avaliações

- Prophet Muhammads Last Sermon 523 enDocumento3 páginasProphet Muhammads Last Sermon 523 enAnonymous 1qAH6CKCAinda não há avaliações

- Letter For CE ClientsDocumento1 páginaLetter For CE ClientsAnonymous 1qAH6CKCAinda não há avaliações

- Program Winch Teardown - 21-9-15Documento11 páginasProgram Winch Teardown - 21-9-15Anonymous 1qAH6CKCAinda não há avaliações

- TUKAUDocumento1 páginaTUKAUAnonymous 1qAH6CKCAinda não há avaliações

- Cpe Post MeetingDocumento2 páginasCpe Post MeetingAnonymous 1qAH6CKCAinda não há avaliações

- Hydraulic Brochure PowerDocumento5 páginasHydraulic Brochure PowerAnonymous 1qAH6CKCAinda não há avaliações

- Timken Bearing Cyc RollerDocumento5 páginasTimken Bearing Cyc RollerAnonymous 1qAH6CKCAinda não há avaliações

- Bolt Bolt Torque ChartDocumento5 páginasBolt Bolt Torque ChartjirrsamaAinda não há avaliações

- Pfce QT 5931 SkobDocumento1 páginaPfce QT 5931 SkobAnonymous 1qAH6CKCAinda não há avaliações

- DIN933Documento1 páginaDIN933Cheann LayaAinda não há avaliações

- Kuriyama Hydraulic Hose Fittings CatalogDocumento202 páginasKuriyama Hydraulic Hose Fittings CatalogAnonymous 1qAH6CKC100% (1)

- Program - Winch Tear DownDocumento11 páginasProgram - Winch Tear DownAnonymous 1qAH6CKCAinda não há avaliações

- Roda Gigi BerporosDocumento2 páginasRoda Gigi BerporosFebri NuansaAinda não há avaliações

- Course Application UpdateDocumento2 páginasCourse Application UpdateMohd HakimieAinda não há avaliações

- TimesheetDocumento1 páginaTimesheetAnonymous 1qAH6CKCAinda não há avaliações

- Schneider ContactorDocumento3 páginasSchneider ContactorAnonymous 1qAH6CKCAinda não há avaliações

- Thread GuideDocumento24 páginasThread GuideNeshaDavisAinda não há avaliações

- Yearly PM Checklist - Hercules CraneDocumento11 páginasYearly PM Checklist - Hercules CraneAnonymous 1qAH6CKCAinda não há avaliações

- Corning Gorilla Glass: Technical MaterialsDocumento2 páginasCorning Gorilla Glass: Technical MaterialsAnonymous 1qAH6CKCAinda não há avaliações

- Adapter Plate - InchDocumento1 páginaAdapter Plate - InchAnonymous 1qAH6CKCAinda não há avaliações

- Wire Rope To OrderDocumento1 páginaWire Rope To OrderAnonymous 1qAH6CKCAinda não há avaliações

- Python RopeDocumento36 páginasPython Ropemanuelperezz25Ainda não há avaliações

- Version - 2.0 Page - 1 - of - 14 Weights - and - Capacities - in - Metric - Tonnes, - Dimensions - in - Meters. - For - Reference - Only.Documento14 páginasVersion - 2.0 Page - 1 - of - 14 Weights - and - Capacities - in - Metric - Tonnes, - Dimensions - in - Meters. - For - Reference - Only.Anonymous 1qAH6CKCAinda não há avaliações

- SKF Composite Plain Bearings - 11004 EN - TCM - 12-107917 PDFDocumento60 páginasSKF Composite Plain Bearings - 11004 EN - TCM - 12-107917 PDFAnonymous 1qAH6CKCAinda não há avaliações

- HoistDocumento4 páginasHoistAnonymous 1qAH6CKCAinda não há avaliações