Escolar Documentos

Profissional Documentos

Cultura Documentos

Jpe 8-4-8

Enviado por

Hieu LETítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Jpe 8-4-8

Enviado por

Hieu LEDireitos autorais:

Formatos disponíveis

354

Journal of Power Electronics, Vol. 8, No. 4, October 2008

JPE 8-4-8

Precision Position Control of PMSM using Neural Observer and

Parameter Compensator

Jong-Sun Ko, Young-Ger Seo* and Hyun-Sik Kim*

Department of Electronic and Electric Eng., Dankook University, Yongin, Korea

ABSTRACT

This paper presents neural load torque compensation method which is composed of a deadbeat load torque observer and

gains compensation by a parameter estimator. As a result, the response of the PMSM (permanent magnet synchronous

motor) obtains better precision position control. To reduce the noise effect, the post-filter is implemented by a MA

(moving average) process. The parameter compensator with an RLSM (recursive least square method) parameter estimator

is adopted to increase the performance of the load torque observer and main controller. The parameter estimator is

combined with a high performance neural load torque observer to resolve problems. The neural network is trained in online phases and it is composed by a feed forward recall and error back-propagation training. During normal operation, the

input-output response is sampled and the weighting value is trained multi-times by the error back-propagation method at

each sample period to accommodate the possible variations in the parameters or load torque. As a result, the proposed

control system has a robust and precise system against load torque and parameter variation. Stability and usefulness are

verified by computer simulation and experiment.

Keywords : Permanent magnet synchronous motor, Neural deadbeat observer, Parameter compensator, Back-propagation

method

1. Introduction

Recently, precision position control has become more

and more important in LCD inspection of LM drives, chip

mounted machines, semiconductor production machines,

precision milling machines, high resolution CNC

machines, precision assembly robots, high speed hard disk

drivers, etc. It is merging with nanotechnology, as a part

of nano-fabrication, and is also spreading to the

Manuscript received July 8, 2008; revised Aug. 27, 2008

Corresponding Author: jsko@dku.edu

Tel: +82-31-8005-3602, Fax: +82-31-897-6104, Dankook Univ.

*

Dept. of Electronic and Electric Eng., Dankook Univ.

bio-engineering

field

and

optical

equipment.

Additionally, it is very important in direct drive systems.

A PMSM has replaced many DC motors since industry

applications require smaller and more powerful actuators.

The PMSM has low inertia, large power-to-volume ratio,

and low noise as compared to permanent magnet DC

servomotors having the same output rating [1,2] . However,

the disadvantages of this machine are high cost and the

need for a more complex controller because of its

nonlinear characteristic.

The proportional-integral (PI) controller usually used in

PMSM control is simple to realize but it is difficult to

obtain a sufficiently high performance in tracking

Precision Position Control of PMSM using Neural Observer and Parameter Compensator

applications. A new systematic approach was done in state

space using digital position information in a PMSM

system[3-6]. However, the machine flux linkage is not

exactly known for a load torque observer thus creating the

problem of uncertainty[7,8]. With the cogging effect, some

damage on the permanent magnet over the current can

affect the value of k t . This causes small position or speed

errors and increases the chattering effect, which should be

reduced as much as possible. It also makes miss-estimated

load torque in deadbeat observer systems. In this paper a

parameter compensator with an RLSM parameter

estimator is suggested to increase the performance of the

load torque observer and main controller. This

compensator makes the system work as if was in a

nominal system parameter. Therefore the deadbeat load

torque observer has a good performance as if there was no

parameter variation. Finally, this controller can be used in

robot or vestibular systems which are simulators. These

systems need exact sinusoidal speed control even when an

unbalanced load is injected. Other production equipment

can use this controller to increase production quality.

355

A new state is defined for the tracking controller as Eqn.

(3). Where r is the rotor speed reference [2]. The control

input becomes Eqn. (4).

z& = r

(3)

iqc1 = k1 k 2 k3 z .

(4)

The augmented system for the speed control of a PMSM

is expressed as follows:

p

p

0 0 kt

&

2J

0

2J

J

+ 0 i 0 T

=

1

0

0

qs L 0 r

z& 0 1 0 z 0

0

1

(5)

y = [0 1 0] .

z

(6)

If the load torque TL is known, an equivalent current

command i qc 2 can be expressed as

2. Modeling of PMSM

The system equations of a PMSM model can be

described as

commands the output controller and compensates for load

torque effect. However, disturbances are unknown or

inaccessible in a real system.

(2)

3.2 Load torque observer and MA process

It is well known that an observer is available when input

is unknown and inaccessible. For simplicity, a 0-observer is

selected [4]. The system equation can be expressed as

3 p

m i qs .

2 2

where

p : number of poles

m : flux linkage of permanent magnet

: angular velocity of rotor

J :inertia moment of rotor

B :viscous friction coefficient.

3. Control Algorithm

3.1 Position controller

(7)

(1)

= r

Te =

1

TL .

kt

Then, the feeding forward equivalent q axis current

p

3 1 p

B

=

TL

m i qs

2 J 2

J

2J

i qc 2 =

p

p

B

0 kt

&

2J

2J

& J

0 y + 0 iqs + L y [0 1 0] y .

y = 1 0

T& 0 0

TL

0 TL 0

(8)

To reduce the disadvantages of a deadbeat observer

356

Journal of Power Electronics, Vol. 8, No. 4, October 2008

which is too noise sensitive a moving average (MA) filter

is considered [9].

1

~

T L (k ) = (TL (k ) + TL (k 1))

2

(9)

] , T (k ) = [ (k ) y (k ) iqs (k ) ] .

where T = [

An RLSM can estimate the real parameter. The resultant

equations are as follows [14-16]:

3.3 Parameter estimator and compensator

The discrete dynamic equation of the PMSM can be

written as

y (k + 1) = (k ) + y (k ) + iqs (k ) + TL (k )

where =

(10)

B

h

P J

J J Bh

J

(h + e J ) ,

(1 e J ) , = 1 , = kt

2J B

B B

B

~ ~

F (k ) (k ) (k ) T F (k )

~

~

1 + (k ) T F (k ) (k )

~

E (k + 1) = y (k + 1) (k ) T (k )

where T (k ) = [

~

[10]

. The control input,

to compensate for parameter variation and to make the

system an equivalent nominal system, is defined as

follows:

iqc (k ) = C1 (k ) (k ) + C2 (k ) y (k ) + C3 (k ) iqc (k )

(11)

Therefore the resultant compensated system is equal to

the nominal equivalent system.

y(k +1) = (k) + y(k) + (C1 (k)(k) + C2 (k) y(k) + C3 (k)iqc (k))

= n (k) + n y(k) + n iqs (k)

(12)

and n , n , n

F (0) =

TL

,

k t

(0 < << 1)

3.4 Proposed neural network observer

The approximation of the multi-variable neural network

can be done by the Hornick function method. This neural

network can compensate for the effects of system

parameter variations [17-19]. Fig. 1 shows a controller with a

back-propagation neural network (BPNN) used which is

based on an augmented state feedback [20-23].

This BPNN uses rotor speed, rotor speed reference,

speed error, and equivalent q-phase current commands of

the torque observer as input nodes to learn the optimal

current command. The error between the real controller

output and neural network propagate back to a hidden

layer under the following bipolar activation function.

parameters and nominal parameters, respectively. These

values can be obtained easily with Eqn. (12) as

( n )

( n )

C1 =

, C2 =

, C 3 = n respectively.

Parameter compensation requires real parameter

estimation [11-13]. Using a discrete system equation without

disturbance Eqn. (13) a parameter and a measured

parameter can be separated.

(13)

(15)

(16)

are actual

y (k + 1) = (k ) + y (k ) + iqs (k ) = T (k )

(14)

],

Based on the assumption that there is no effect, the load

torque, feed back gain and feed forward gain are defined

where , ,

F (k + 1) = F (k )

T (k ) = (k ) y (k ) iqs (k )

P J J

J Bh

=

( h e J )

2J B B

B

as C1 , C 2 and C3 respectively

(k + 1) = (k ) + F (k + 1) (k ) E (k + 1)

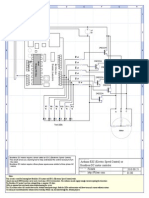

Fig. 1 Diagram of the neural network using the error

back-propagation

Precision Position Control of PMSM using Neural Observer and Parameter Compensator

f (netk ) =

2

1

1 + exp(netk )

357

(17)

netk = kj y j

(18)

ok = f (netk )

(19)

The slope of the activation function is considered as 1

for simplicity and weight is changed according to the delta

learning rule. Eqn. 19 represents the neural network output

of the each node.

E=

1 n

(d k ok ) 2

2 k =1

kj =

E

kj

Fig. 2 Block diagram of the proposed algorithm

(20)

4. Configurations of Overall Systems

(21)

The total block diagram of the proposed controller is

shown in Fig. 2. The C-Language program and a

TMS320C31 DSP implement the digital control.

where d k is iqc . A connection weight wkj is a weight

between j-th and k-th hidden layer is of NN. This delta

rule can guarantee weight movement to the negative line

of the error variation. The error signal is known as Eqn. 22

applying a chain rule. Therefore from Eqn. 17 and Eqn. 22

the error signal can be obtained as Eqn. 23.

ok =

ok =

E

E o k

=

net k

ok net k

1

2

( d k ok )(1 o k )

2

(22)

Fig. 3

From these results, the weighting functions are adapted

by the delta learning rule as follows [24]:

kj (k + 1) = kj (k ) + ok y j

Block diagram of the proposed control system

(23)

Experimental load systems directly coupled to the motor

axis are depicted in Fig. 3. This system creates time

varying load torque to show the effectiveness of the

proposed algorithm.

(24)

PMSM

Load

Hidden layer weights are also changed by the same

method.

yj =

n

1

2

(1 y j ) ok kj

2

k =1

ji ( k + 1) = ji ( k ) + yj x i

PMSM

r2

r1

(25)

Bar Load

t1

(26)

(a) Inertial load

The resultant block diagram of the proposed controller is

shown in Fig. 2.

(b) bar load

Fig. 4 The figure of load for parameter and load variation

358

Journal of Power Electronics, Vol. 8, No. 4, October 2008

[A]

3

2.5

2

1.5

1

0.5

0

-0.5 12

-1

-1.5

-2

-2.5

-3

13

14

15

16

17

18

[sec]

(a) Augmented state feedback

Fig. 5

The configuration of the experiment system

Position

1

0.8

0.6

5. Simulation and Experimental Results

0.4

The parameters of a PMSM motor used in this

simulation and this experiment are shown in Table 1.

[rad]

0.2

0

12

13

14

15

16

17

18

16

17

18

-0.2

-0.4

-0.6

-0.8

-1

Table 1

Power : 400 watt

PMSM parameters

0.363 104

Inertia :

Rated torque : 1.3 Nm

[sec]

kgm2

Iqc

3

2.5

Stator resistance : 1.07

2

1.5

Phase inductance : 4.2 mH

1

0.5

[A]

Rated current : 2.7 A

0

-0.5

12

13

14

15

-1

The hysteresis band gap is chosen as 0.01[ A ] and the

sampling time h is determined as 0.2 [ ms ]. The weighting

-1.5

-2

-2.5

matrix is selected as Q = diag [0.1 80 30000] , R = 1

and

the

optimal

gain

matrix

becomes

-3

[sec]

(b) Dead beat observer and parameter compensator algorithm

k = [0.0773 4.9807 62.5080]. The deadbeat observer

L = [9623.9 2.7000 275.20]

[25]

Position

1

0.8

0.6

0.4

0.2

[rad]

and the gain matrices are calculated from nominal values.

The gain is obtained using the pole placement method at

origin

in

z

domain

and

becomes

0

12

. The simulation

-0.2

results are shown in Fig. 5 and Fig. 6. Fig. 5 shows the

speed response of the conventional controller. There is a

small speed ripple and small overshoot caused by a current

ripple of the hysteresis band gap and parameter variation.

-0.6

13

14

15

16

17

18

16

17

18

-0.4

-0.8

-1

[sec]

Iqc

3

2.5

2

1.5

1

Position

0.5

[A]

0.8

0.6

0.4

12

13

14

15

-1

-1.5

0.2

[rad]

0

-0.5

-2

0

12

13

14

15

-0.2

16

17

18

-2.5

-3

-0.4

[sec]

-0.6

-0.8

(c) Parameter compensation algorithm

-1

[sec]

359

Precision Position Control of PMSM using Neural Observer and Parameter Compensator

Position

Position

0.8

0.8

0.6

0.78

0.4

0.76

0

12

13

14

15

16

17

18

[rad]

[rad]

0.2

-0.2

0.74

-0.4

-0.6

0.72

-0.8

-1

0.7

[sec]

12

12.5

13

13.5

14

14.5

15

[sec]

Iqc

(c) Proposed algorithm

2.5

2

Fig. 7

1.5

1

[A]

0.5

0

-0.5

12

13

14

15

16

17

18

Performance comparison of three controllers for the

parameter variation, Zoom in the rotor position(0.7rad~

0.8rad)

-1

-1.5

-2

-2.5

-3

[s ec]

(d) Proposed algorithm

Fig. 6

Simulation results of the rotor position, q phase current

command for load

The inertial parameter has 100 times the permanent

magnet value and two times the R and L value. This

conventional algorithm makes a large current ripple due to

parameter variation. Fig. 6 shows the results of a proposed

algorithm that has the same position command and same

disturbance condition as Fig.4. The load effects are reduced

by the proposed algorithm of the parameter compensation.

In the proposed system with NN, the error is markedly

decreased, more than in the case of the parameter

compensation.

Fig. 7 presents 0.1[rad] scaled simulation results to

show a comparison between the two controllers. The

conventional controller in Fig. 7(a) has a large position

ripple compared with the proposed system Fig 7(c). The

parameter compensation is not as good as in the parameter

compensation plus NN case. This is the result of a

parameter compensator with a neural network.

(a) Augmented state feedback algorithm

Position

0.8

0.78

[rad]

0.76

0.74

0.72

0.7

12

12.5

13

13.5

14

14.5

15

[sec]

(b) Load torque observer algorithm

(a) Load torque observer algorithm

Position

0.8

0.78

[rad]

0.76

0.74

0.72

0.7

12

12.5

13

13.5

14

14.5

15

[sec]

(b) Parameter compensation algorithm

(c) Parameter compensation algorithm

360

Journal of Power Electronics, Vol. 8, No. 4, October 2008

(d) Proposed algorithm

Fig. 8

Experimental results of the rotor position and

q-phase current command with a inertia load

The experimental results are depicted in Fig. 8 and Fig.

9. In this experiment, real observable gains are reduced to

about 30% to obtain some effectiveness in parameter

compensation. The parameter compensator calculates the

real parameter and compensates for current miss turned

gains. Fig. 8 shows experimental results of the position

with current command at about 3 seconds in duration.

There is a current ripple in a steady state and large position

overshoot in transient state shown in Fig. 8(a) and 8(b).

However, after 20 minutes, there is no current ripple and

the position error in the proposed system as shown in Fig.

8(b). A more detailed figure is shown in Fig. 9 from 0 to

20 minutes. This figure has a scale between 0.1[rad]

(0.7[rad] ~ 0.8[rad]) with a zooming data and shows that

position error decreases gradually as time goes on.

(c) Disturbance observer and parameter compensator

(after twenty minutes)

Fig. 9 Experiment results of zoom in the rotor position for

inertia load

6. Conclusions

A new deadbeat load torque observer with a system

parameter compensator was proposed to obtain better

performance from the PMSM in a precision position

control system. This compensator makes a real system

work as in a nominal parameter system. Therefore the

deadbeat load torque observer demonstrated a good

performance and acted as if there were no parameter

variation. To reduce of the effect of noise a post-filter was

implemented by an MA process. The system response

comparison was conducted between the deadbeat gain

observer and the parameter compensated system with a

deadbeat observer. Since the parameter compensated

system acted as if there was no parameter variation, the

conventional deadbeat load torque is well adapted to real

systems. It can be used to cancel out steady state and

transient position errors due to external disturbances, such

as friction, load torque and the small chattering effect of

the deadbeat control.

Acknowledgment

(a) Disturbance observer algorithm

This

work

was

supported

by

grant

No.(R01-2006-000-10118-0) from the Basic Research

Program of the Korea Science & Engineering Foundation.

References

(b) Disturbance observer and parameter compensator

(after one minute)

[1] D. W. Novotny, R. D. Lorentz, Introduction to field

orientation and high performance AC drives, IEEE-IAS

Tutorial Course, 1986.

[2] P. C. Krause, Analysis of electric machinery, McGraw-Hill,

Precision Position Control of PMSM using Neural Observer and Parameter Compensator

1984.

[3] Nandam P. K., Sen P. C., A Comparative Study of a

Luenberger Observer and Adaptive Observer-Based Variable

Structure Speed Control System using a Self-Controlled

Synchronous Motor, IEEE Trans. Industrial Electronics,

Vol. 37, No. 2, pp. 127132, 1990.

[4] K. J. Astrm, B. Wittenmark, Computer controlled system,

Prentice Hall, International, 1997.

[5] J. S. Ko, T. H. Lee, B. L. Park, C. W. Jeon, Precision Speed

Control of PMSM for Stimulation of the Vestibular System

Using Rotatory Chair, Transaction on KIPE, Vol. 5, No. 5,

pp. 459466, Oct. 2000.

[6] J. S. Ko, T. H. Lee, C. W. Jeon, S. S. Lee, Precision Speed

Control of PMSM Using Disturbance Observer and

Parameter Compensator, Transaction on KIPE, Vol. 6, No. 1,

pp. 98106, 2001.

[7] D. Alazard, P. Apkarian, Exact Observer-Based Structure

for Arbitrary Compensators, Int. J. Control, Vol. 41, No. 6,

pp. 15651575, 1999.

[8] J. S. Ko, S. K. Youn, A Study of Adaptive Load Torque

Observer and Robust Precision Position Control of BLDD

Motor, Transaction on KIPE, Vol. 4, No. 2, pp. 138143,

April 1999.

[9] C. T. Chen, Linear System Theory and Design, Holt,

Rinehart and Winston, Inc., 1984.

[10] C. Y. Huang, T. C. Chen, C. L. Huang, Robust Control of

Induction Motor with A Neural-Network Load Torque

Estimator and A Neural-Network Identification, IEEE

Transaction on Industrial Electronics, Vol. 46, No. 5, pp.

990998, 1999.

[11] K. S. Narendra, K. Parthasarathy, Identification and

Control of Dynamical Systems using Neural Network,

IEEE Trans. on Neural Networks, Vol. 1, No. 1, pp. 427,

1990.

[12] S. Chen, S. A. Billings, Neural Networks for Nonlinear

Dynamic System Modeling and Identification, Int. J.

Control, Vol. 56, No. 2, pp. 319346, 1992.

[13] Tanaka K, Yuzawa T, Moriyama R, Miki I., Initial Rotor

Position Estimation for Surface Permanent Magnet

Synchronous Motor, Record of Thirty-Sixth Industry

Applications Conference, Vol. 4, No. 30, pp. 25922597,

2001.

[14] J. D. Landau, System Identification and Control Design.

Englewood Cliffs, NJ, Prentice-Hall, 1990.

[15] G. C. Goodwin, K. S. Sin, Adaptive Filtering Prediction

and Control. Englewood Cliffs, NJ, Prentice-Hall, 1984.

[16] Faa-Jeng Lin, Po-Hung Shen, Ying-Shieh Kung, Adaptive

Wavelet Neural Network Control for Linear Synchronous

361

Motor Servo Drive, IEEE Transaction on Magnetics, Vol.

41, No. 12, pp. 44014412, 2005.

[17] Fukuda, T., Shibata, T., Theory and Application of Neural

Networks for Industrial Control Systems, IEEE Trans. on

Industrial Electronics, Vol. 39, No. 6, 1992.

[18] J. O. P. Pinto, B. K. Bose, L. E. B. da Silva, A Stator Flux

Oriented Vector-Controlled Induction Motor Drive with

Space Vector PWM and Flux Vector Synthesis by Neural

Networks, IEEE Trans. Ind. Applicat., Vol. 37, pp.

13081318, 2001.

[19] Yang Yi, D. Mahinda Vilathgamuwa, Azizur Rahman,

Implementation of an Artificial-Neural-Network-Based

Real-Time Adaptive Controller for an Interior

Permanent-Magnet Motor Drive, IEEE Trans., Ind.

Applic., LA-39, No. 1, pp. 96104, 2003.

[20] Naomitsu Urasaki, Tomonobu Senjyu, Toshihisa Funabashi,

Hideomi Sekine, An Adaptive Dead-time Compensation

Strategy for a Permanent Magnet Synchronous Motor Drive

Using Neural Network, Journal of Power Electronics, Vol.

6, No. 4, pp. 279289, Oct. 2006.

[21] Naomitsu Urasaki, Tomonobu Senjyu, High Efficiency

Drive Technique for Synchronous Reluctance Motors

Using a Motors Using a Neural Network, Journal of

Power Electronics, Vol. 6, No. 4, pp. 340346, Oct. 2006.

[22] Mona N. Eskander, Neural Network Controller for a

Permanent Magnet Generator Applied in Wind Energy

Conversion System, Journal of Power Electronics, Vol. 2,

No. 1, pp. 4654, January 2002.

[23] Mona N. Eskander, Minimization of Losses in Permanent

Magnet Synchronous Motors Using Neural Network,

Journal of Power Electronics, Vol. 2, No. 3, pp. 220229,

July 2002.

[24] Fayez Fahim El-Sousy, A Vector-Controlled PMSM Drive

with a Continually

On-Line Learning Hybrid

Neural-Network Model-Following Speed Controller,

Journal of Power Electronics, Vol. 5, No. 2, pp. 129141,

April 2005.

[25] J. S. Ko, J. H. Lee, S. k. Chung, M. J. Youn, A Robust

Position Control of Brushless DC motor with Dead Beat

Load Torque Observer, IEEE Transaction on Industrial

Electronics, Vol. 40, No. 5, pp. 512520, 1993.

Jong-Sun Ko was born in South Korea in

1960. He received his B.S. degree from Seoul

National University, Seoul, South Korea, in

1984, and his M.S. degree from Korea

Advanced Institute of Science and

Technology (KAIST), Taejon, South-Korea,

362

Journal of Power Electronics, Vol. 8, No. 4, October 2008

in 1989. He received his Ph.D. in Electrical Engineering at

KAIST in 1994. He has been with the Production Engineering

R&D Center of Samsung Electronics Co. from 1983 to 1996. He

was a visiting scholar at the University of Tennessee in 1999. He

was a Prof. of Electric & Electronic Engineering in Wonkwang

University, Iksan, South Korea from 1996 to 2003. He has been a

professor of Electronic and Electric Engineering in Dankook

University, Seoul, South Korea since 2003. His research interests

are in drive systems, digital control, robust control, and factory

automation. He is a member of IEEE, KIEE and KIPE. He has

done projects with the Samsung Company and other universities

in the field of automatic production, automatic controllers,

PMSM controllers, and Torque Observers for PMSM.

Young-Ger Seo was born in South Korea in

1982. He received his B.S. degree from

Dankook University, Seoul, South Korea, in

2007. He is currently a M.S. student at

Dankook University. His research interests

are in motor drive controls, development of

simulators and wind power systems.

Hyun-Sik Kim was born in South Korea in

1978. He received his B.S. degree in

Electrical Engineering from Wonkwang

University, South Korea, in 2004.

He

received his M.S. degree from Dankook

University. He is currently working towards

his Ph.D. at Dankook University. His research interests are in

drive systems, digital control, and control of AC motors.

Você também pode gostar

- Self-Tuning Controller For Servo Motor With An Adaptive Disturbance ObserverDocumento5 páginasSelf-Tuning Controller For Servo Motor With An Adaptive Disturbance ObserverrezadigitAinda não há avaliações

- A New Control Strategy of A Wind Power Generation andDocumento8 páginasA New Control Strategy of A Wind Power Generation andjnyagatoAinda não há avaliações

- A PI Controller Based On Gain-Scheduling For Synchronous GeneratorDocumento11 páginasA PI Controller Based On Gain-Scheduling For Synchronous GeneratoratirinaAinda não há avaliações

- Automatic Voltage Regulator and Fuzzy Logic Power System StabilizerDocumento6 páginasAutomatic Voltage Regulator and Fuzzy Logic Power System Stabilizerayou_smartAinda não há avaliações

- Constrained Predictive Control of a Servo-Driven Tracking TurretDocumento6 páginasConstrained Predictive Control of a Servo-Driven Tracking TurretVu Duc TruongAinda não há avaliações

- Synthesis of The Adaptive Excitation Control System of High Power Synchronous GeneratorsDocumento14 páginasSynthesis of The Adaptive Excitation Control System of High Power Synchronous Generators3KaiserEAinda não há avaliações

- Research and Apply PID Hybrid Fuzzy Control TechnologyDocumento6 páginasResearch and Apply PID Hybrid Fuzzy Control TechnologyhoangepuAinda não há avaliações

- Fault Detection of PM Synchronous Motor Via Modulating FunctionsDocumento6 páginasFault Detection of PM Synchronous Motor Via Modulating Functionsjithesh87Ainda não há avaliações

- Control System NotesDocumento199 páginasControl System NotesCarson R. Dick100% (2)

- PMSM Decoupling Control Study Based On The Inverse SystemDocumento4 páginasPMSM Decoupling Control Study Based On The Inverse Systemrigo84Ainda não há avaliações

- Controller of Dynamic Reactive Power Compensation Based On FPGADocumento7 páginasController of Dynamic Reactive Power Compensation Based On FPGANicholas KnappAinda não há avaliações

- Multiple Controllers For Boost Converters Under Large Load Range: A GA and Fuzzy Logic Based ApproachDocumento6 páginasMultiple Controllers For Boost Converters Under Large Load Range: A GA and Fuzzy Logic Based ApproachDaltonVidorAinda não há avaliações

- Predictive Control AlgorithmDocumento7 páginasPredictive Control AlgorithmIngole DeepakAinda não há avaliações

- Hard Disk Drive Servo ControlDocumento20 páginasHard Disk Drive Servo ControlMohammad IkhsanAinda não há avaliações

- Implementation of Digital Signal Controller TMS320C28027 Based PWM For A Single Phase Bidirectional High Frequency Link Photovoltaic InverterDocumento8 páginasImplementation of Digital Signal Controller TMS320C28027 Based PWM For A Single Phase Bidirectional High Frequency Link Photovoltaic InverterIfan Seven SeasAinda não há avaliações

- Reduction of Torque Ripple in DTC For Induction Motor Using Input-Output Feedback LinearizationDocumento14 páginasReduction of Torque Ripple in DTC For Induction Motor Using Input-Output Feedback LinearizationChengyu NiuAinda não há avaliações

- Discrete Time Synergetic Control For DC-DC Converter: N M N×N N×MDocumento6 páginasDiscrete Time Synergetic Control For DC-DC Converter: N M N×N N×MAnonymous KhhapQJVYtAinda não há avaliações

- Online Control of SVC Using ANN Based Pole Placement ApproachDocumento5 páginasOnline Control of SVC Using ANN Based Pole Placement ApproachAbdo AliAinda não há avaliações

- Speed Anti-Windup PI Strategies Review For Field Oriented Control of Permanent Magnet Synchronous MachinesDocumento6 páginasSpeed Anti-Windup PI Strategies Review For Field Oriented Control of Permanent Magnet Synchronous MachinesOmegalpha5Ainda não há avaliações

- PMSMDocumento8 páginasPMSMBan KaiAinda não há avaliações

- Internal ModelDocumento15 páginasInternal ModelDiego RamirezAinda não há avaliações

- Djagarov EEEIC 2012Documento6 páginasDjagarov EEEIC 2012jagarov4954Ainda não há avaliações

- Ovation Advanced Control Algorithms: PredictorDocumento10 páginasOvation Advanced Control Algorithms: PredictorMuhammad UsmanAinda não há avaliações

- Simulation work on Fractional Order PIλ Control Strategy for speed control of DC motor based on stability boundary locus methodDocumento7 páginasSimulation work on Fractional Order PIλ Control Strategy for speed control of DC motor based on stability boundary locus methodseventhsensegroupAinda não há avaliações

- Modeling and cascade control of a clutch actuator system for dual clutch transmissionsDocumento5 páginasModeling and cascade control of a clutch actuator system for dual clutch transmissionsSiva ReddyAinda não há avaliações

- A Torque Control Method of Three-Inertia Torsional System With Backlash856Documento6 páginasA Torque Control Method of Three-Inertia Torsional System With Backlash856Mohamed BerririAinda não há avaliações

- A Sliding Mode-Multimodel Control For A Sensorless Pumping SystemDocumento6 páginasA Sliding Mode-Multimodel Control For A Sensorless Pumping SystemKatherine DukeAinda não há avaliações

- Model Predictive Control of A Permanent Magnet Synchronous Motor With Experimental ValidationDocumento19 páginasModel Predictive Control of A Permanent Magnet Synchronous Motor With Experimental ValidationAlimamy KoromaAinda não há avaliações

- Extended Kalman Filter Tuning in Sensorless PMSM DrivesDocumento6 páginasExtended Kalman Filter Tuning in Sensorless PMSM Drivesbadro1980Ainda não há avaliações

- An Algorithm For Robust Noninteracting Control of Ship Propulsion SystemDocumento8 páginasAn Algorithm For Robust Noninteracting Control of Ship Propulsion SystemmohammadfarsiAinda não há avaliações

- Design, Simulation and Experiment of a PID Controller for a Buck ConverterDocumento8 páginasDesign, Simulation and Experiment of a PID Controller for a Buck ConverterOdair TrujilloAinda não há avaliações

- Antenna Azimuth and Its Simulation by Lab View Program: School of Electrical and Electronoic EngineeringDocumento25 páginasAntenna Azimuth and Its Simulation by Lab View Program: School of Electrical and Electronoic EngineeringKenneth CastroAinda não há avaliações

- Network ReconfigurationDocumento7 páginasNetwork ReconfigurationtungqnaAinda não há avaliações

- Mca 01 00066Documento7 páginasMca 01 00066djkeags24Ainda não há avaliações

- Modeling and simulation of TCSC for optimal power flow solution using NR methodDocumento4 páginasModeling and simulation of TCSC for optimal power flow solution using NR methodumubyeyidevothaAinda não há avaliações

- Non-Linear Predictive Control of A DC-to-DC ConverterDocumento5 páginasNon-Linear Predictive Control of A DC-to-DC ConvertermenguemengueAinda não há avaliações

- Comparative Study Between The Conventional Regulators and Fuzzy Logic Controller: Application On The Induction MachineDocumento17 páginasComparative Study Between The Conventional Regulators and Fuzzy Logic Controller: Application On The Induction Machinemechernene_aek9037Ainda não há avaliações

- 16th Int'l Conf on EE detection using PMU dataDocumento6 páginas16th Int'l Conf on EE detection using PMU datadennypolariszAinda não há avaliações

- Control of Axial Flux Permanent Magnet Motor Using A Hybrid PI/ Fuzzy Logic ControllerDocumento8 páginasControl of Axial Flux Permanent Magnet Motor Using A Hybrid PI/ Fuzzy Logic ControllerKein Huat ChuaAinda não há avaliações

- Novel Modeling and Damping Technique For Hybrid Stepper MotorDocumento6 páginasNovel Modeling and Damping Technique For Hybrid Stepper MotorVashik BedasieAinda não há avaliações

- 5 Controlled Rectifier DC Drives-Closed Loop - PpsDocumento41 páginas5 Controlled Rectifier DC Drives-Closed Loop - PpsRanjan KumarAinda não há avaliações

- Researches Regarding Functional Stabilization of Electro-Hydraulic Servo-SystemsDocumento4 páginasResearches Regarding Functional Stabilization of Electro-Hydraulic Servo-SystemsMaria Gabriela BusteloAinda não há avaliações

- A Digital-Based Optimal AVR Design of Synchronous Generator Exciter Using LQR TechniqueDocumento13 páginasA Digital-Based Optimal AVR Design of Synchronous Generator Exciter Using LQR Technique3KaiserEAinda não há avaliações

- MEC522: Control Engineering PBL AssignmentDocumento3 páginasMEC522: Control Engineering PBL Assignmentanisalyaa100% (1)

- A Novel Technique For The Design of Controller of A Vector-Controlled Permanent Magnet Synchronous Motor DriveDocumento6 páginasA Novel Technique For The Design of Controller of A Vector-Controlled Permanent Magnet Synchronous Motor Driveshoebhussain01Ainda não há avaliações

- Self-Tuning Adaptive Algorithms in The Power Control of Wcdma SystemsDocumento6 páginasSelf-Tuning Adaptive Algorithms in The Power Control of Wcdma SystemsSaifizi SaidonAinda não há avaliações

- Review PPT Modified KLJLKDocumento30 páginasReview PPT Modified KLJLKPranith KumarAinda não há avaliações

- Jeas 0408 94Documento7 páginasJeas 0408 94Jun Chee LimAinda não há avaliações

- Buck BoostDocumento6 páginasBuck BoostAngel MarianoAinda não há avaliações

- Paper Title: Ajay Kumar Gudla and Saikat ChakrabartiDocumento5 páginasPaper Title: Ajay Kumar Gudla and Saikat ChakrabartiAshutosh KumarAinda não há avaliações

- Design and Implementation of Model Predictive Control For Electrical Motor DrivesDocumento12 páginasDesign and Implementation of Model Predictive Control For Electrical Motor Drivestariq76Ainda não há avaliações

- Active Disturbance Rejection Control of A MEMS GyroscopeDocumento5 páginasActive Disturbance Rejection Control of A MEMS GyroscopekazimAinda não há avaliações

- A Modified Method For Tuning PID Controller For Buck-Boost ConverterDocumento7 páginasA Modified Method For Tuning PID Controller For Buck-Boost ConverterIJAERS JOURNALAinda não há avaliações

- 03 2008 JA PS A 1 008 CleanDocumento6 páginas03 2008 JA PS A 1 008 CleanBentarfa IslamAinda não há avaliações

- Erciyes University Mechatronics Engineering Control Systems-II PID Control ProjectDocumento12 páginasErciyes University Mechatronics Engineering Control Systems-II PID Control Projectsedo1991Ainda não há avaliações

- IEEE Power System Paper-Analysis of Power System Linearized Model With STATCOM Based Damping StabilizerDocumento7 páginasIEEE Power System Paper-Analysis of Power System Linearized Model With STATCOM Based Damping StabilizerAnoop MathewAinda não há avaliações

- Electrical Correcting Elements in Automatic Control and Regulation CircuitsNo EverandElectrical Correcting Elements in Automatic Control and Regulation CircuitsAinda não há avaliações

- Simulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorNo EverandSimulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorAinda não há avaliações

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetAinda não há avaliações

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNota: 2 de 5 estrelas2/5 (1)

- Florida State University Libraries: Development and Implementation of A 25 kVA Phasor-Based Virtual MachineDocumento114 páginasFlorida State University Libraries: Development and Implementation of A 25 kVA Phasor-Based Virtual MachineHieu LEAinda não há avaliações

- A Fuzzy Adaptive Comfort Temperature Mod PDFDocumento8 páginasA Fuzzy Adaptive Comfort Temperature Mod PDFHieu LEAinda não há avaliações

- A Fuzzy Adaptive Comfort Temperature Mod PDFDocumento8 páginasA Fuzzy Adaptive Comfort Temperature Mod PDFHieu LEAinda não há avaliações

- 6ES73231BH010AA0 Datasheet enDocumento4 páginas6ES73231BH010AA0 Datasheet enHieu LEAinda não há avaliações

- 2015 - Hindawe - Unknown Disturbance Estimation For A PMSM With A HybridDocumento8 páginas2015 - Hindawe - Unknown Disturbance Estimation For A PMSM With A HybridHieu LEAinda não há avaliações

- The Secret Book of FRC LabVIEW v0.2Documento135 páginasThe Secret Book of FRC LabVIEW v0.2Hieu LE100% (2)

- CompactRIO CRIO-FRC 8 SlotDocumento25 páginasCompactRIO CRIO-FRC 8 SlotHieu LEAinda não há avaliações

- 6ES73317KF020AB0 Datasheet enDocumento5 páginas6ES73317KF020AB0 Datasheet enHieu LEAinda não há avaliações

- CompactRIO CRIO-FRC 8 SlotDocumento25 páginasCompactRIO CRIO-FRC 8 SlotHieu LEAinda não há avaliações

- Getting Started With The C RIO and LabviewDocumento31 páginasGetting Started With The C RIO and LabviewTom KigeziAinda não há avaliações

- Bendaas 2014Documento7 páginasBendaas 2014Hieu LEAinda não há avaliações

- Research Article: Application of Quadratic Linearization For The Control of Permanent Magnet Synchronous MotorDocumento12 páginasResearch Article: Application of Quadratic Linearization For The Control of Permanent Magnet Synchronous MotorHieu LEAinda não há avaliações

- Extended Kalman Filter Based SpeedDocumento17 páginasExtended Kalman Filter Based SpeedHieu LEAinda não há avaliações

- Key Words Key Words ArduinoDocumento1 páginaKey Words Key Words ArduinoHieu LEAinda não há avaliações

- Mau Giay Thi Viet Chu DepDocumento3 páginasMau Giay Thi Viet Chu DepDal LeeAinda não há avaliações

- Ket Noi Real Time - MIDEM - 41 (2011) 2p122Documento10 páginasKet Noi Real Time - MIDEM - 41 (2011) 2p122Hieu LEAinda não há avaliações

- Prediction of The Inductance in A Synchronous Linear Permanent Magnet Generator 2011Documento5 páginasPrediction of The Inductance in A Synchronous Linear Permanent Magnet Generator 2011Hieu LEAinda não há avaliações

- Sensorless PMSM Control Using Luenberger ObserverDocumento5 páginasSensorless PMSM Control Using Luenberger ObserverSandeep RaiAinda não há avaliações

- 2014 Comparative Review of PMSM and BLDCM Based On Direct Torque Control MethodDocumento5 páginas2014 Comparative Review of PMSM and BLDCM Based On Direct Torque Control MethodHieu LEAinda não há avaliações

- Arduino ESC2.0Documento1 páginaArduino ESC2.0gunterbragaAinda não há avaliações

- 2014 - Comparative Study of PMSM and SRM Capabilities-IEEE - POWERENG - 2013 - LEBSIRDocumento5 páginas2014 - Comparative Study of PMSM and SRM Capabilities-IEEE - POWERENG - 2013 - LEBSIRHieu LEAinda não há avaliações

- H-Adaptive Sliding Mode Observer For A Class of Systems - V5!6!57Documento7 páginasH-Adaptive Sliding Mode Observer For A Class of Systems - V5!6!57Hieu LEAinda não há avaliações

- Ket Noi Ti Ltu Ex 08196 SeDocumento70 páginasKet Noi Ti Ltu Ex 08196 SeHieu LEAinda não há avaliações

- 2010-Improved Integral Sliding Mode Control Methods PMSMDocumento12 páginas2010-Improved Integral Sliding Mode Control Methods PMSMHieu LEAinda não há avaliações

- Teaching IELTS Writing Module Through THAILAN2011Documento61 páginasTeaching IELTS Writing Module Through THAILAN2011Hieu LEAinda não há avaliações

- 2010 Adaptive Luenberger ObserverDocumento7 páginas2010 Adaptive Luenberger ObserverHieu LEAinda não há avaliações

- Matrix ReviewDocumento27 páginasMatrix ReviewPrtvi ImeanAinda não há avaliações

- Switched Inductor Quasi-Z-Source Inverter For PMSG Based Wind Energy Conversion SystemDocumento6 páginasSwitched Inductor Quasi-Z-Source Inverter For PMSG Based Wind Energy Conversion SystemHieu LEAinda não há avaliações

- I.E. Bss ParametersDocumento168 páginasI.E. Bss ParametersSalma CasasolaAinda não há avaliações

- WK3 - Multi Layer PerceptronDocumento59 páginasWK3 - Multi Layer Perceptronpaku deyAinda não há avaliações

- Automated Decision Making in Highway Pavement Preventive Maintenance Based on Deep Learning-维护-226145Documento19 páginasAutomated Decision Making in Highway Pavement Preventive Maintenance Based on Deep Learning-维护-226145Yuan ChowAinda não há avaliações

- Machine LearningDocumento885 páginasMachine LearningAnand Krishnan100% (1)

- Python Stats ML FE DL NLP DML MLOPS DSIQ Live Sessions Hindi StatsDocumento60 páginasPython Stats ML FE DL NLP DML MLOPS DSIQ Live Sessions Hindi StatsNex AwaAinda não há avaliações

- Backpropagation Neural Network MATLAB CodeDocumento13 páginasBackpropagation Neural Network MATLAB CodePiyush AgnihotriAinda não há avaliações

- Speed Control of DC Motor Using Neural Network ConfigurationDocumento4 páginasSpeed Control of DC Motor Using Neural Network Configurationtariq76Ainda não há avaliações

- Neural NetworksDocumento27 páginasNeural NetworksDania DallahAinda não há avaliações

- Machine Learning Lab Record: Dr. Sarika HegdeDocumento23 páginasMachine Learning Lab Record: Dr. Sarika Hegde4NM18CS142 SACHIN SINGHAinda não há avaliações

- Counterpropagation NetworksDocumento6 páginasCounterpropagation NetworksshardapatelAinda não há avaliações

- Convolutional Neural NetworksDocumento31 páginasConvolutional Neural NetworksAamir ayub100% (1)

- 1 s2.0 S1568494621001976 MainDocumento10 páginas1 s2.0 S1568494621001976 MainNagaraj R HalimaniAinda não há avaliações

- Application of Artificial Neural Network To Predict Squall Thunderstorms Using RAWIND DataDocumento6 páginasApplication of Artificial Neural Network To Predict Squall Thunderstorms Using RAWIND DatabrigitaAinda não há avaliações

- Training With Noise Is Equivalent To Tikhonov RegularizationDocumento8 páginasTraining With Noise Is Equivalent To Tikhonov RegularizationJavad RahmannezhadAinda não há avaliações

- Estimating Monthly Sunshine Duration Using Satellite Data and ANNDocumento26 páginasEstimating Monthly Sunshine Duration Using Satellite Data and ANNNimit HirparaAinda não há avaliações

- Ans PDFDocumento4 páginasAns PDFSureshAinda não há avaliações

- Viva1 VoceDocumento205 páginasViva1 VoceArockia Bazil RajAinda não há avaliações

- Back Propagation AlgorithmDocumento19 páginasBack Propagation Algorithmujwa princeAinda não há avaliações

- An Optical Communication's Perspective On Machine Learning and Its ApplicationsDocumento24 páginasAn Optical Communication's Perspective On Machine Learning and Its ApplicationsHassan RizwanAinda não há avaliações

- Multi Layer Feed-Forward NNDocumento15 páginasMulti Layer Feed-Forward NNsm-malikAinda não há avaliações

- Artificial Neural Network Based Load ForecastingDocumento8 páginasArtificial Neural Network Based Load ForecastingIJRASETPublicationsAinda não há avaliações

- Convolutional Neural Networks in PythonDocumento141 páginasConvolutional Neural Networks in PythonAnonymous rsGzBBiqk100% (2)

- Artificial Neural Networks - 12: Dr. Aditya AbhyankarDocumento42 páginasArtificial Neural Networks - 12: Dr. Aditya AbhyankaranuragAinda não há avaliações

- Neural Networks in Civil Engineering: 1989 2000: Hojjat AdeliDocumento17 páginasNeural Networks in Civil Engineering: 1989 2000: Hojjat Adelihemanta beheraAinda não há avaliações

- A Neural Network Based SRM Drive Control Strategy For Regenerative Braking in EV and HEVDocumento5 páginasA Neural Network Based SRM Drive Control Strategy For Regenerative Braking in EV and HEVRodrigoMaseroAinda não há avaliações

- Alex Minnaar Word2Vec Tutorial Part I The Skip-Gram ModelDocumento6 páginasAlex Minnaar Word2Vec Tutorial Part I The Skip-Gram ModelMohd. Zamri MurahAinda não há avaliações

- Development of An Intelligent System For Tool Wear Monitoring Applying Neural NetworksDocumento6 páginasDevelopment of An Intelligent System For Tool Wear Monitoring Applying Neural Networkshari0118Ainda não há avaliações

- 2009 International Conference On Computer Technology and DevelopmentDocumento5 páginas2009 International Conference On Computer Technology and DevelopmentkrongdakAinda não há avaliações

- Prediction of Stroke Using Deep Learning Model: October 2017Documento10 páginasPrediction of Stroke Using Deep Learning Model: October 2017darAinda não há avaliações