Escolar Documentos

Profissional Documentos

Cultura Documentos

Beispiel EMPB

Enviado por

chandra9000Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Beispiel EMPB

Enviado por

chandra9000Direitos autorais:

Formatos disponíveis

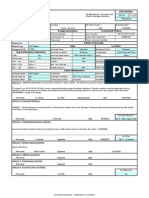

ThyssenKrupp Steel Europe

Sender

First Sample Test Report VDA

ThyssenKrupp Steel Europe AG

Kaiser-Wilhelm-Str. 100

47166 Duisburg

First sampling

Page 1 from 3

Re-sampling

New part

Product modifikation

Production transfer

Address

Change in the production procedures

Aaaaaaa Bbbbbbb

Ccccccc Ddddddd

Eeeeeee Feeeeee

Long production pause

New subcontractor

Product with DwSpA

Production / Inspection and Test Plan prepared

FMEA carried out

Test Report other samples

02 Dimensional Check

Appendices

07 Evidence for Inspection and Test

Equipment Capability

08 Inspection and Test Equipment List

03 Material Testing

09 EU Data Safety Sheet

15 Design Approval

04 Reliability Test

10 Haptics

16 Constituents of Purchased parts

05 Process Capability Evidence

11 Acoustics

17 Other

06 Process Flow Chart

12 Odors

01 Functional Test

Identification No., Supplier:

13 Appearance

14 Certificate

Identification No., Customer:

Test Report No.:

s. enclosure

Revision:

Subject Number:

1111111

Test Report No.:

Subject Number:

Drawing Number:

11006418

Drawing Number:

Status / Date:

Status / Date:

Revision Number:

Revision Number:

ID Number (MDB) / Revision:

Revision:

Designation:

DC03 / DIN EN 10130 02.2007

Designation:

Order Call-off No. / Date:

Delivery Note No. / Date:

Incoming Goods No. / Date:

Quantity delivered:

Delivery Destination:

Charge Number:

s. enclosure

Sample Weight:

s. enclosure

Supplier Confirmation:

It is hereby confirmed, that the sampling has been carried out according to VDA Volume 2 Chapter 4, edition 3 (1998)

Name:

Scheuer

Comment:

Department:

TIS-PT-A

0203 52 28731 / 0203 52 25594 /

Telephone/Fax/E-Mail:

frank.scheuer @thyssenkrupp.com

Inspection certificate 3.1 according to DIN EN 10204

Material data s. enclosure

06.01.2015

Date

Chemical composition s. enclosure

Mechanical / technological properties s. enclosure

Signature

Customer Decision:

According to Appendix:

Overall

10 11 12 13 14 15 16 17

Approved

Conditionally approved

Rejected, re-sampling necessary

Deviation Concession No.:

When returning, Delivery note No. / Date:

Name:

Comment:

Department:

Telephone/Fax/E-Mail:

Date

Distribution:

3903376.docx

Signature

1

10

11

12

13

14

Page 1 from 3

ThyssenKrupp Steel Europe

Report about dimension-, weight- and material test of first delivery

Supplier:

Customer:

TKSE Works-No.:

Reference:

Quality:

ThyssenKrupp Steel Europe AG

Aaaaaaaaaa Bbbbbbbbb

TKSE Position:

1111111

11006418

DC03 / DIN EN 10130 02.2007

Certificate-No.:

Remarks:

Nominal values

Thickness:

Thickness min.:

Thickness max.:

Results

HeatNo.

528214

6487590

Dimension [mm] and Weight [kg]

Width:

Width min.:

Width max.:

1,2

1,17

1,23

Length:

Length min.:

Length max.:

807

807

810

Weight min.:

Weight max.:

7.000

12.500

Dimension [mm] and Weight [kg]

Sample-ID

Bundle-ID

Thickness

Width

124307E

C262026

C262027

C262028

C262029

1,19

1,19

1,19

1,19

808

808

808

808

Nominal values

min.

max.

001

Length

Weight

(Net)

8.270

8.270

8.060

8.060

Remarks

Chemical Composition of the ladle sample [%]

Si

Mn

Al

0,10

Mo

0,40

Nb

0,035

Ni

0,025

Ti

Cr

Cu

Cr

Cu

min.

max.

Results

Chemical Composition of the ladle sample [%]

Heat

No.

528214

Si

Mn

Al

0,023

0,018

0,170

0,010

0,0050

0,038

Heat

No.

Mo

Nb

Ni

Ti

Remarks:

3903376.docx

Page 2 from 3

ThyssenKrupp Steel Europe

Nominal values

Mechanical properties (Tensile test)

min.

max.

Results

SamplePosition

Temp.

[C]

20

R

[MPa]

140

240

Tensile test

Rm

Re/Rm

[MPa]

[%]

270

370

R

[MPa]

192

Tensile test

Rm

Re/Rm

[MPa]

[%]

317

A

[%]

34

r-value

n-value

BH2

[MPa]

A

[%]

38,7

r-value

n-value

BH2

[MPa]

Mechanical properties (Tensile test)

HeatNo.

528214

SampleID

124307E

Nominal values

SamplePosition

T

Temp.

[C]

20

Mechanical properties (Roughness and Coating)

SamplePosition

Ra US

[m]

Roughness

Ra LS

Pc US

[m]

[1/cm]

Coating

Lower side

[g/m]

Pc LS

[1/cm]

Upper side

[g/m]

Pc LS

[1/cm]

Coating

Upper side Lower side

[g/m]

[g/m]

Two sided

[g/m]

min.

max.

nom.

Results

Mechanical properties (Roughness and Coating)

HeatNo.

SampleID

Sample Position

SamplePosition

Ra US

[m]

Roughness

Ra LS

Pc US

[m]

[1/cm]

Mechanical properties

L = longitudinal / T = transverse

Remarks / Other:

Name:

Scheuer

Department:

TIS-PT-A

Phone / Fax:

0203 52 28731 / 0203 52 25594

3903376.docx

Date:

06.01.2015

Signature:

Page 3 from 3

Você também pode gostar

- Sample Autoclave Validation Report 1-04-2013Documento10 páginasSample Autoclave Validation Report 1-04-2013Abd Al-Rahmman Al-qatananiAinda não há avaliações

- ITP For Bench Calibration of Instruments Rev.ADocumento9 páginasITP For Bench Calibration of Instruments Rev.AGanga DaranAinda não há avaliações

- Quality Procedure For Dual FBE Coating Rev.01Documento39 páginasQuality Procedure For Dual FBE Coating Rev.01Nebu Mathew100% (1)

- ABAP For Functional ConsultantsDocumento69 páginasABAP For Functional ConsultantsRaviChowdary100% (1)

- ABAP For Functional ConsultantsDocumento69 páginasABAP For Functional ConsultantsRaviChowdary100% (1)

- Additional Valves CertificatesDocumento98 páginasAdditional Valves CertificatesDiana100% (1)

- PQR 014 (Qualified Sa 106 GR BDocumento5 páginasPQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- SO238051 Test Report CMT0036Documento10 páginasSO238051 Test Report CMT0036mpedraza-1Ainda não há avaliações

- Polo 85TSI Comfortline Shown With Optional R-Line and Driver Assistance PackagesDocumento24 páginasPolo 85TSI Comfortline Shown With Optional R-Line and Driver Assistance Packageschandra9000Ainda não há avaliações

- Kinematics Problem SetDocumento1 páginaKinematics Problem SetMohammad JubranAinda não há avaliações

- IsirDocumento4 páginasIsirIkhwandi BdrAinda não há avaliações

- 21Documento6 páginas21Dannis AnantoAinda não há avaliações

- Contractor QAP for HT Breaker PanelDocumento1 páginaContractor QAP for HT Breaker Panelmadhu_bedi12Ainda não há avaliações

- Astec Valves Inspection Certificate SummaryDocumento4 páginasAstec Valves Inspection Certificate SummaryShankar RajAinda não há avaliações

- Final Assessment Report E-2225BDocumento2 páginasFinal Assessment Report E-2225BvancongthanhAinda não há avaliações

- CM, CME Certificates GuideDocumento3 páginasCM, CME Certificates GuideislamakthamAinda não há avaliações

- Liquid Thermal ExpansionDocumento2 páginasLiquid Thermal ExpansionSaeid Rahimi MofradAinda não há avaliações

- Rapid Chloride Permeability TestDocumento7 páginasRapid Chloride Permeability Testuocmogiandi_aAinda não há avaliações

- Essar Pump Data 208810Documento9 páginasEssar Pump Data 208810Rakhee SinhaAinda não há avaliações

- Penetration of Water in Concrete with Adhesive AnchorsDocumento9 páginasPenetration of Water in Concrete with Adhesive AnchorsAsmir SofticAinda não há avaliações

- Industrial Pressure Gauge DimensionsDocumento4 páginasIndustrial Pressure Gauge DimensionsSandi AslanAinda não há avaliações

- Declaratie de ConformitateDocumento2 páginasDeclaratie de ConformitateStirbu Marius100% (1)

- SAM PLE: Inspection Certificate 3.2 (Manufacturer's Certificate)Documento3 páginasSAM PLE: Inspection Certificate 3.2 (Manufacturer's Certificate)CaoQuocAinda não há avaliações

- Corrosion Damage Report (CDR)Documento4 páginasCorrosion Damage Report (CDR)diaccessltd_17172961Ainda não há avaliações

- Rev A. Magnetic Level Gauge With Level Transmitter Datasheet PDFDocumento15 páginasRev A. Magnetic Level Gauge With Level Transmitter Datasheet PDFNguyễnQuíTrọngAinda não há avaliações

- 21.02.15 Tuv Visit ReportDocumento5 páginas21.02.15 Tuv Visit ReportssmullaAinda não há avaliações

- F4281-GEDI-M-SS-ITP-1039-3 ITP For Equipment and Pipe Installation in - Compressed Air System PDFDocumento19 páginasF4281-GEDI-M-SS-ITP-1039-3 ITP For Equipment and Pipe Installation in - Compressed Air System PDFDang Hieu NguyenAinda não há avaliações

- Inspection & Test PlanDocumento4 páginasInspection & Test PlanShivarajJadhavAinda não há avaliações

- HD - Planta de PVCDocumento7 páginasHD - Planta de PVCDavid LapacaAinda não há avaliações

- Btanl0200rev2en 001Documento13 páginasBtanl0200rev2en 001TajmirMahmudAinda não há avaliações

- A05-004 - Inspection Test Plan - Shell & Tube Heat Exchangers - 5-210D-HA-01 A B C DDocumento14 páginasA05-004 - Inspection Test Plan - Shell & Tube Heat Exchangers - 5-210D-HA-01 A B C Dbingmin100% (4)

- Gas Pipeline SpecDocumento4 páginasGas Pipeline SpecA_bener100% (1)

- Corrosion Damage Report SummaryDocumento4 páginasCorrosion Damage Report Summarydiaccessltd_17172961Ainda não há avaliações

- PE-ADZ-7E05010104-PIT-712-R00 Powerhouse - Quality Assurance Plan - Excitation CubiclesDocumento8 páginasPE-ADZ-7E05010104-PIT-712-R00 Powerhouse - Quality Assurance Plan - Excitation CubiclesCoquin AntAinda não há avaliações

- Apqp FormsDocumento25 páginasApqp FormsgkspAinda não há avaliações

- P.E.D. Declaration of Conformity: RP/QC/142 Rev 3 (16/02/2005)Documento1 páginaP.E.D. Declaration of Conformity: RP/QC/142 Rev 3 (16/02/2005)wawaAinda não há avaliações

- Electrical Equipment QAPDocumento2 páginasElectrical Equipment QAPrajkumarrakhra0% (1)

- 049-Itp For Lighting and Small Power (Building) PDFDocumento15 páginas049-Itp For Lighting and Small Power (Building) PDFKöksal Patan100% (1)

- Catalogo Cps11dDocumento19 páginasCatalogo Cps11djesushuamantunagrandAinda não há avaliações

- Qcf305 Ut ReportDocumento1 páginaQcf305 Ut ReportminhnnAinda não há avaliações

- Inspection Certificate 3.1 Certificat de Reception 3.1 Abnahmepruefzeugnis 3.1 - EN 10204 / 3.1Documento2 páginasInspection Certificate 3.1 Certificat de Reception 3.1 Abnahmepruefzeugnis 3.1 - EN 10204 / 3.1Sezgin BayrakAinda não há avaliações

- Approval of Chinese Pressure Vessel ManufacturersDocumento34 páginasApproval of Chinese Pressure Vessel Manufacturerslimcsiang99Ainda não há avaliações

- Installation Lightning - Level 1Documento1 páginaInstallation Lightning - Level 1vominhthaimeAinda não há avaliações

- ARIES Marine Sample Testing of Different QualitiesDocumento1 páginaARIES Marine Sample Testing of Different QualitiesMurugan RajaAinda não há avaliações

- Hardware Inspection ReportDocumento20 páginasHardware Inspection Reportრაქსშ საჰაAinda não há avaliações

- RfiDocumento8 páginasRfiShem BarroAinda não há avaliações

- Vật Tư Thiếu Do Kho Hết HàngDocumento5 páginasVật Tư Thiếu Do Kho Hết HàngMai Thế ToanAinda não há avaliações

- LGDD ZZ ITTDSXS 00 45671233 0 Instrument DatasheetDocumento37 páginasLGDD ZZ ITTDSXS 00 45671233 0 Instrument DatasheetuyaiekanemAinda não há avaliações

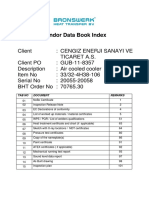

- Vendor Data Book IndexDocumento110 páginasVendor Data Book Indexhasan arif100% (1)

- Or TrelleborgDocumento3 páginasOr Trelleborgalexre1973Ainda não há avaliações

- Connectors - Safety Requirements and Tests: Test Report IEC 61984Documento23 páginasConnectors - Safety Requirements and Tests: Test Report IEC 61984Brajan's B.Ainda não há avaliações

- Tag No., Batch No., Serial No., Cast, Heat No: SummaryDocumento4 páginasTag No., Batch No., Serial No., Cast, Heat No: SummarySyed JafarAinda não há avaliações

- Quality PlanDocumento11 páginasQuality PlanArief Bahtiar BahryAinda não há avaliações

- PI-13022-005 - Mounded Bullets PDFDocumento5 páginasPI-13022-005 - Mounded Bullets PDFsélem AzAinda não há avaliações

- CDR 07-055Documento4 páginasCDR 07-055diaccessltd_17172961Ainda não há avaliações

- Corrosion Damage Report (CDR)Documento4 páginasCorrosion Damage Report (CDR)diaccessltd_17172961Ainda não há avaliações

- Section III Bareiß-BaumannDocumento32 páginasSection III Bareiß-BaumannAndreij MichalskiAinda não há avaliações

- Corrosion Damage Report (CDR)Documento4 páginasCorrosion Damage Report (CDR)diaccessltd_17172961100% (1)

- VENDOR DOCUMENT REVIEW OF PRESSURE RELIEF VALVE DATA SHEETSDocumento8 páginasVENDOR DOCUMENT REVIEW OF PRESSURE RELIEF VALVE DATA SHEETSMichael HaiseAinda não há avaliações

- IMIR Report No5Documento1 páginaIMIR Report No5Chava Teja100% (1)

- Corrosion Damage Report (CDR)Documento4 páginasCorrosion Damage Report (CDR)diaccessltd_17172961Ainda não há avaliações

- Product Drawing: Customer Project Tag No. Unit Description of Service Location PID No./Line NumberDocumento6 páginasProduct Drawing: Customer Project Tag No. Unit Description of Service Location PID No./Line NumberMWBABARAinda não há avaliações

- 2009 02 M HD 319 0Documento5 páginas2009 02 M HD 319 0ZoebairAinda não há avaliações

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1No EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Nota: 3.5 de 5 estrelas3.5/5 (3)

- German Nouns Have Genders: The German Cases Explained: A 5-Part Guide To Finally Understand The Cases in GermanDocumento18 páginasGerman Nouns Have Genders: The German Cases Explained: A 5-Part Guide To Finally Understand The Cases in Germanchandra9000Ainda não há avaliações

- Transaction Variant - A Step by Step Guide For CreationDocumento8 páginasTransaction Variant - A Step by Step Guide For Creationchandra9000Ainda não há avaliações

- Creating A Pair of SSH KeysDocumento4 páginasCreating A Pair of SSH Keyschandra9000Ainda não há avaliações

- Sap Abap Course ContentDocumento6 páginasSap Abap Course Contentchandra9000Ainda não há avaliações

- Transaction Variant - A Step by Step Guide For CreationDocumento8 páginasTransaction Variant - A Step by Step Guide For Creationchandra9000Ainda não há avaliações

- Sap Idoc Interface (Development)Documento50 páginasSap Idoc Interface (Development)chandra9000Ainda não há avaliações

- Panch Tantra Stories Complete Five BooksDocumento197 páginasPanch Tantra Stories Complete Five Booksmomin100% (1)

- Full Text of Supreme Court Judgement in Ayodhya Land Dispute CaseDocumento1.045 páginasFull Text of Supreme Court Judgement in Ayodhya Land Dispute CaseNDTV96% (26)

- QMPTIPDocumento113 páginasQMPTIPsankargeliviAinda não há avaliações

- ABAP TutorialsDocumento512 páginasABAP Tutorialsskumar4787Ainda não há avaliações

- SAP QM Interview QuestionsDocumento9 páginasSAP QM Interview Questionschandra9000100% (1)

- Sap Idoc Interface (Technology)Documento173 páginasSap Idoc Interface (Technology)chandra9000Ainda não há avaliações

- Smartform For Production Order Opk8Documento2 páginasSmartform For Production Order Opk8chandra9000Ainda não há avaliações

- Smartform For Production Order Opk8Documento2 páginasSmartform For Production Order Opk8chandra9000Ainda não há avaliações

- How To Create Sales Order Using BAPIDocumento5 páginasHow To Create Sales Order Using BAPIchandra9000Ainda não há avaliações

- Borrar MaterialDocumento13 páginasBorrar MaterialmoralestorresAinda não há avaliações

- SP Rao Abap MaterialDocumento464 páginasSP Rao Abap Materialpavan79% (29)

- PO Creation Using BAPIDocumento3 páginasPO Creation Using BAPIchandra9000Ainda não há avaliações

- SAP PP Common Tables for MRP, Demand, Planned Orders & Repetitive ManufacturingDocumento2 páginasSAP PP Common Tables for MRP, Demand, Planned Orders & Repetitive Manufacturingchandra9000Ainda não há avaliações

- User Exit QMDocumento3 páginasUser Exit QMchandra9000Ainda não há avaliações

- LSMW - Pavan Golesar - Direct Input Approach v1.5 PDFDocumento25 páginasLSMW - Pavan Golesar - Direct Input Approach v1.5 PDFMarouane DaliAinda não há avaliações

- How To Use BAPIDocumento71 páginasHow To Use BAPIDora Babu100% (2)

- ALE-IDoc GOOD For TrainingDocumento142 páginasALE-IDoc GOOD For Trainingamanblr12Ainda não há avaliações

- Workflowtroubleshootingguide PDFDocumento68 páginasWorkflowtroubleshootingguide PDFrajeshkothamasuAinda não há avaliações

- Sap Idoc Interface (Technology)Documento173 páginasSap Idoc Interface (Technology)chandra9000Ainda não há avaliações

- No UD Before RR PDFDocumento11 páginasNo UD Before RR PDFvjeevan5Ainda não há avaliações

- Quality Notification TypesDocumento4 páginasQuality Notification Typeschandra9000Ainda não há avaliações

- JKF8 Intelligent Reactive Power Compensation ControllerDocumento4 páginasJKF8 Intelligent Reactive Power Compensation ControllerGuillermo Morales HerreraAinda não há avaliações

- Adobe Scan 12 Aug 2022Documento3 páginasAdobe Scan 12 Aug 2022surabhi kalitaAinda não há avaliações

- Volvo g900 Modelos PDFDocumento952 páginasVolvo g900 Modelos PDFAdrianDumescu100% (3)

- Schneider Power Supply PhaseoDocumento26 páginasSchneider Power Supply PhaseoScott EnnisAinda não há avaliações

- Chefs at HomeDocumento4 páginasChefs at Homezbdv2kyzv7Ainda não há avaliações

- Unit 5 Project ManagementDocumento19 páginasUnit 5 Project ManagementYashu RajAinda não há avaliações

- MC BreakdownDocumento5 páginasMC BreakdownThane SnymanAinda não há avaliações

- DOCUMENT guides the way with VLB-44 LED Marine BeaconDocumento4 páginasDOCUMENT guides the way with VLB-44 LED Marine BeaconbenAinda não há avaliações

- Perreaux E220 200W Stereo Power Amplifier from 1994Documento2 páginasPerreaux E220 200W Stereo Power Amplifier from 1994joaoraffa raffaAinda não há avaliações

- Resultados de La Web: GDDS - Traducción Al Español - Ejemplos Inglés - Reverso ..Documento3 páginasResultados de La Web: GDDS - Traducción Al Español - Ejemplos Inglés - Reverso ..Jo PaterninaAinda não há avaliações

- 800-40 Suspencion ChalmersDocumento7 páginas800-40 Suspencion ChalmersJhonatan Velasquez CastellanosAinda não há avaliações

- RC Design IIDocumento58 páginasRC Design IIvenkatesh19701Ainda não há avaliações

- A Kitchen in The Corner of The HouseDocumento2 páginasA Kitchen in The Corner of The HousedanielrubarajAinda não há avaliações

- Aac Block Adhesive: Product DescriptionDocumento2 páginasAac Block Adhesive: Product DescriptionmaznahAinda não há avaliações

- Tenofovir Disoproxil Fumarate: Riefing - Nfrared BsorptionDocumento4 páginasTenofovir Disoproxil Fumarate: Riefing - Nfrared BsorptionMostofa RubalAinda não há avaliações

- ArtsDocumento5 páginasArtsRhovi Christine AbandoAinda não há avaliações

- 3-Ph Induction MotorDocumento246 páginas3-Ph Induction MotorAn00pgadzillaAinda não há avaliações

- داينمك الملزمة كاملةDocumento79 páginasداينمك الملزمة كاملةarno assassin33% (3)

- Telemark PulloverDocumento2 páginasTelemark Pulloverkidknits100% (1)

- User Manual HDL 30 ADocumento36 páginasUser Manual HDL 30 AAgung KurniandraAinda não há avaliações

- Fossil Fuel and The Environment PPT Project FinalDocumento14 páginasFossil Fuel and The Environment PPT Project Finalapi-298052133Ainda não há avaliações

- Alberta Highway and Flood Projects 2016-2019Documento37 páginasAlberta Highway and Flood Projects 2016-2019Anonymous QRCBjQd5I7Ainda não há avaliações

- Making Soap From WoodDocumento6 páginasMaking Soap From WoodmastabloidAinda não há avaliações

- Evolis User ManualDocumento28 páginasEvolis User ManualIonmadalin1000Ainda não há avaliações

- Filtros MaquinasDocumento34 páginasFiltros MaquinasAndres AlfonzoAinda não há avaliações

- Study Plan NCEPU PDFDocumento2 páginasStudy Plan NCEPU PDFAhsan100% (1)

- Dr. Carlos S. Lanting College: College of Maritime EducationDocumento14 páginasDr. Carlos S. Lanting College: College of Maritime EducationJeynard Moler J. TanAinda não há avaliações

- Analytical Chemistry Lecture Exercise 2 Mole-Mole Mass-Mass: Sorsogon State CollegeDocumento2 páginasAnalytical Chemistry Lecture Exercise 2 Mole-Mole Mass-Mass: Sorsogon State CollegeJhon dave SurbanoAinda não há avaliações

- Etabloc Technical DataDocumento108 páginasEtabloc Technical Dataedward ksbAinda não há avaliações