Escolar Documentos

Profissional Documentos

Cultura Documentos

Chemical Feed Valves Guide

Enviado por

Phyu Mar Thein KyawDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Chemical Feed Valves Guide

Enviado por

Phyu Mar Thein KyawDireitos autorais:

Formatos disponíveis

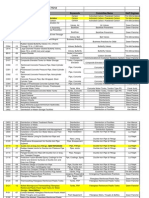

Chemical Feed Department

Stance

Valves for Special Chemicals

No.

161

Revision

:

P1

Page:

1 of 5

Application:

Type of Feed System: Liquid

Stance:

The typical valve for most liquid chemical feed systems is a Schedule 80 PVC or

CPVC ball valve, unless noted otherwise.

All valves must be constructed of material that is similar to the piping material.

Valves that are 3 inches and larger are not to be ball type.

Throttling valves are not to be ball valves.

Aqua ammonia metallic ball valve

Carbon dioxide metallic ball valve

Dry pressurized chlorine metallic ball valve

Vacuum chlorine plastic PVC ball valve

Hydrogen peroxide metallic drilled ball valve

Lime slurry pinch valve

Methanol metallic ball valve

Polymer solution (3 inches and larger) butterfly valve

Powder activated carbon slurry weirless diaphragm valve or pinch valve

Sodium hydroxide plug valve

Sodium hypochlorite (0.8%) drilled ball valve

Sodium hypochlorite (12.5%) diaphragm valve

Sulfuric acid metallic ball valve

Rationale:

Most liquid chemicals are compatible with thermoplastic materials; therefore, a

Schedule 80 PVC or CPVC ball valve is acceptable. The ball valves are in-line, true

union, and full port. Teflon and Viton are the preferred materials for the seat and

seals. The operator is a lever, and the end connections are to be socket. Flanges

are acceptable where equipment connections are flanged.

Valve material must match that of the piping in which they are installed. Mixing

metallic valves with plastic piping or vice versa is unacceptable due to poor

File name:

Stance 161- Valves for

Special Chemicals

Date of issue:

12/9/2009

Date printed:

7/24/2015

Water Proprietary and Confidential

Prepared by:

Reviewed/Approved by:

Edward D. Vogt

Page 1 of 5

CONTROLLED when read online

Printed copy is UNCONTROLLED

Chemical Feed Department

Stance

Valves for Special Chemicals

No.

161

Revision

:

P1

Page:

2 of 5

connection strength. In addition, the valve material must be similar to the piping

material. Finally, the size of the valve must be the same as the pipe size.

Valves that are 3 inches and larger should not be ball type due to difficulty of

operation, weight, height, and installation. For plastics, butterfly or diaphragm type

valves should be considered. For metals, butterfly or gate valves should be

considered.

Aqua Ammonia - Valves in aqua ammonia service are Class 600, ASTM A 105

forged steel ball valves. The valves are in-line, three piece, bolted body, fire-safe,

and full port. The seat, washer, and seal material is Teflon, and the ball and stem

are stainless steel. The operator is a lever and the ends are socket weld. Plastic

valves are not used in aqua ammonia service due to chemical incompatibilities.

Carbon Dioxide Valves in carbon dioxide (pressurized gas and solution) service

are Class 600, ANSI B16.34 stainless steel ball valves. The valves are in-line, three

piece, bolted body, and full port. The body, ball, and stem are constructed of

stainless steel. The seat and seal are Teflon. The operator is a lever and the end

connection is socket weld. Plastic valves are not designed for pressurized carbon

dioxide gas service.

Chlorine Valves in pressurized chlorine gas service are Class 600, ANSI B16.34,

carbon steel ball valves. The valves are in-line, three piece, bolted body, and full

port. The seat and seal are Teflon. The body is carbon steel, while the ball and

stem are Monel or Hastelloy C. These valves are identified by the manufacturer as

Chlorine Valves. The operator is a lever and the end connections are socket weld.

Plastic valves are not designed for pressurized chlorine gas service.

Hydrogen Peroxide - Valves in hydrogen peroxide service are drilled ball valves.

The valve should be constructed of 316 series stainless steel. The valves are in-line

and full port, with socket weld connections, and Teflon seats and seals. As

hydrogen peroxide degrades, oxygen is released. To prevent this released oxygen

from becoming trapped inside the ball and over-pressurizing, a hole is drilled in the

ball such that the cavity is vented to the upstream side of the valve. Plastic valves

are not used in hydrogen peroxide service due to chemical incompatibilities.

Lime Slurry Valves in lime slurry service are Class 125/150, ASTM A48, cast iron

pinch valves. The valves consist of the valve body, elastomer sleeve liner, pinch

File name:

Stance 161- Valves for

Special Chemicals

Date of issue:

12/9/2009

Date printed:

7/24/2015

Water Proprietary and Confidential

Prepared by:

Reviewed/Approved by:

Edward D. Vogt

Page 2 of 5

CONTROLLED when read online

Printed copy is UNCONTROLLED

Chemical Feed Department

Stance

Valves for Special Chemicals

No.

161

Revision

:

P1

Page:

3 of 5

bars, pull bars, actuator shaft, actuator base plate or yoke, and assembly

hardware. The elastomer sleeve liner is Buna-N with polyester reinforcing cord ply,

the pull and pinch bars are AISI Type 316 stainless steel, and the end connection

are ASME B16.1, Class 125/150, flat faced flanges. The operator is a handwheel.

Plastic valves are not used in lime slurry service due to slurry abrasiveness.

Methanol - Valves in methanol service are Class 600, ASTM A 105 forged steel ball

valves. The valves are in-line, three piece, bolted body, fire-safe, and full port. The

seat, washer, and seal material is Teflon, and the ball and stem are stainless steel.

The operator is a lever and the ends are threaded. Plastic valves are not used in

methanol service due to chemical incompatibilities and National Fire Protection

Association (NFPA) requirements).

Polymer Solution (larger than 3 inches) - It is very common for polymer solution

pipe sizes to be larger than 3 inches, and the optimum valve to use in these

instances is a PVC wafer style butterfly valve. The butterfly valve is Class 150, with

ASME B16.5 flanged connections. The shaft and stem are AISI 316 stainless steel,

the seat is Viton or EPDM, and the disc is PVC. Ball valves are not acceptable in this

size range due to operation difficulty.

Powder Activated Carbon Slurry Valves in powder activated carbon slurry service

are Class 150, stainless steel weirless diaphragm valve. The diaphragm is a twopiece, un-bonded EPDM, and the connections are ASME B16.1, Class 150, flat faced

flanges. The operator is a handwheel with travel-stop and a position indicator.

Valves in powder activated carbon slurry service can also be Class 125/150, ASTM

A48, cast iron pinch valves. The valves consist of the valve body, elastomer sleeve

liner, pinch bars, pull bars, actuator shaft, actuator base plate or yoke, and

assembly hardware. The elastomer sleeve liner is Buna-N with polyester reinforcing

cord ply, the pull and pinch bars are AISI Type 316 stainless steel, and the end

connection are ASME B16.1, Class 125/150, flat faced flanges. The operator is a

handwheel.

Sodium Hydroxide Valves in sodium hydroxide service are Class 150, carbon steel

plug valves. The plug valves are non-lubricated with a tapered plug constructed of

316 stainless steel. The plug seal and seal diaphragm are Teflon, and the end

connections may be socket weld or flanged. The operator is a lever. Ball valves are

not acceptable in sodium hydroxide service due to crystallization and the coating it

File name:

Stance 161- Valves for

Special Chemicals

Date of issue:

12/9/2009

Date printed:

7/24/2015

Water Proprietary and Confidential

Prepared by:

Reviewed/Approved by:

Edward D. Vogt

Page 3 of 5

CONTROLLED when read online

Printed copy is UNCONTROLLED

Chemical Feed Department

Stance

Valves for Special Chemicals

No.

161

Revision

:

P1

Page:

4 of 5

leaves on the ball surface. Eventually, these crystals will prevent the valve from

functioning properly.

Sodium Hypochlorite (0.8%) Valves in 0.8% sodium hypochlorite service are

Schedule 80 CPVC drilled ball valves. The drilled ball valves are in-line, true union,

and full port. Teflon and Viton are the preferred materials for the seat and seals.

The operator is a lever, and the end connections are socket or flanged. As sodium

hypochlorite degrades, oxygen is released (but much less than 12.5%). To prevent

this released oxygen from becoming trapped inside the ball and over-pressurizing,

a hole is drilled in the ball such that the cavity is vented to the upstream side of

the valve.

Sodium Hypochlorite (12.5%) Valves in 12.5% sodium hypochlorite service are

Schedule 80 CPVC diaphragm valves. The diaphragm valves are Class 150 with

socket weld or ASME B16.1 Class 150 flat faced flanges. The diaphragm is twopieced and unbonded. The piece exposed to sodium hypochlorite is Teflon, and

EPDM is used for the backing, although sometimes a third barrier is used between

the Teflon and the EPDM The operator is a handwheel with travel stop and position

indicator. Ball valves are not used in sodium hypochlorite service for two reasons.

The first is that sodium hypochlorite releases oxygen as it degrades and builds

pressure if trapped, such as it would be in a closed ball valve. The second is that

sodium hydroxide, which is a component of 12.5% sodium hypochlorite, will

crystallize on the ball and eventually render it inoperable. While a drilled ball valve

would correct the first issue, it will not correct the second. Therefore, ball valves of

any type are unacceptable in 12.5% sodium hypochlorite service.

Sulfuric Acid Valves in sulfuric acid are ANSI Class 600 Carpenter 20 Cb-3 UNS

NO8020 ball valves. The ball valves are in-line, three piece, bolted body, and full

port. The seats and seals are constructed of Teflon. The body, ball, and stem are

Carpenter 20 Cb-3 UNS NO8020. The operator is a lever and the ends are socket

weld. If flanged connections are used, flange diapers are required. Plastic ball

valves are not used in sulfuric acid service due to chemical incompatibilities.

Options/Alternatives:

Aqua ammonia Another acceptable valve for aqua ammonia service is a Class

150, ASTM A276-316 stainless steel ball valve. The valves are in-line, two piece,

end entry, and full port. The seat, washer, and seal material is Teflon. The body,

File name:

Stance 161- Valves for

Special Chemicals

Date of issue:

12/9/2009

Date printed:

7/24/2015

Water Proprietary and Confidential

Prepared by:

Reviewed/Approved by:

Edward D. Vogt

Page 4 of 5

CONTROLLED when read online

Printed copy is UNCONTROLLED

Chemical Feed Department

Stance

Valves for Special Chemicals

No.

161

Revision

:

P1

Page:

5 of 5

ball, and stem material is 316 stainless steel. The operator is a lever and the end

connection is a Class 150 flange.

Carbon dioxide solution Another acceptable valve for carbon dioxide solution

(carbonic acid) is a PVC or CPVC ball valve.

Sodium hydroxide (low-use valves) Valves in sodium hydroxide service that are

not used frequently, such as tank drain and p-trap assembly valves, may be

diaphragm type valves as described for 12.5% sodium hypochlorite. If diaphragm

valves are installed, they must have CPVC bodies and the piping is Schedule 80

CPVC. Sodium hydroxide will build up scale, so ball valves are not acceptable.

Sodium hypochlorite When metallic piping (titanium or Hastelloy C) is used, an

acceptable valve for sodium hypochlorite service (0.8% or 12.5%) is a drilled plug

valve constructed of Hastelloy C. The plug valve shall be straight-way and the body

and plug constructed of Hastelloy C. The end connections shall be Class 150 ANSI

B16.5 flanges and the operator shall be a lever. A small hole shall be drilled into

the plug to prevent sodium hypochlorite from becoming trapped between the body

and the plug. Due to the cost of these valves and the associated Hastelloy C

piping, they should only be considered when the required sodium hypochlorite

pressure is above the limits of Schedule 80 CPVC piping and valves.

File name:

Stance 161- Valves for

Special Chemicals

Date of issue:

12/9/2009

Date printed:

7/24/2015

Water Proprietary and Confidential

Prepared by:

Reviewed/Approved by:

Edward D. Vogt

Page 5 of 5

CONTROLLED when read online

Printed copy is UNCONTROLLED

Você também pode gostar

- ValvesDocumento42 páginasValvesSundara MoorthyAinda não há avaliações

- Typical Ball Valve Material SelectionDocumento12 páginasTypical Ball Valve Material SelectionabsherlockAinda não há avaliações

- Zhejiang Marco Valve Co., Ltd. IntroductionDocumento48 páginasZhejiang Marco Valve Co., Ltd. Introductionesmeralda diazAinda não há avaliações

- CEU 228 Oct15 PDFDocumento11 páginasCEU 228 Oct15 PDFMohamed AdelAinda não há avaliações

- Tech Pneumatic AccDocumento1 páginaTech Pneumatic AccAlexandru StănucAinda não há avaliações

- Ball Valve - Training Material (Compatibility Mode)Documento115 páginasBall Valve - Training Material (Compatibility Mode)kart_rl80% (10)

- Installation Notes For Check Valve: Products ListDocumento2 páginasInstallation Notes For Check Valve: Products ListMashudi FikriAinda não há avaliações

- Section 15100 - Valves, Pipe Fittings, and Piping: Part 1 - General 1.1 Related Sections: 1.2 Scope of SectionDocumento11 páginasSection 15100 - Valves, Pipe Fittings, and Piping: Part 1 - General 1.1 Related Sections: 1.2 Scope of SectionNoushad P HamsaAinda não há avaliações

- Flanged Standard Bore Ball Valves: ANSI CLASS 150 & 300Documento8 páginasFlanged Standard Bore Ball Valves: ANSI CLASS 150 & 300marpadanAinda não há avaliações

- American ValveDocumento12 páginasAmerican Valveviller_lpAinda não há avaliações

- Published Standards for Water SystemsDocumento7 páginasPublished Standards for Water Systemsdương_thành_28Ainda não há avaliações

- Valves: Continuing Education From The American Society of Plumbing EngineersDocumento19 páginasValves: Continuing Education From The American Society of Plumbing Engineers185412Ainda não há avaliações

- 2005 Valve Catalog Full ASAHIDocumento150 páginas2005 Valve Catalog Full ASAHIRicardo Rodriguez MartinezAinda não há avaliações

- SDV PPTDocumento58 páginasSDV PPTSai Kamala100% (2)

- Cryogenic Ball Valve: Lishui Oak Valve Parts Co,.LtdDocumento7 páginasCryogenic Ball Valve: Lishui Oak Valve Parts Co,.LtdShams TabrezAinda não há avaliações

- 07 ValvesDocumento33 páginas07 Valvesshiva_ssk17Ainda não há avaliações

- Piping PresentationDocumento144 páginasPiping PresentationSUNIL TVAinda não há avaliações

- Two BallDocumento5 páginasTwo Ballchartwithsam0041653Ainda não há avaliações

- C-15 ValvesDocumento49 páginasC-15 ValvesChuy LeeAinda não há avaliações

- Valves & Manifold BrochureDocumento33 páginasValves & Manifold BrochurearavindAinda não há avaliações

- VALVULASDocumento58 páginasVALVULASTai FloresAinda não há avaliações

- ValvesDocumento22 páginasValvesimsarvesh05Ainda não há avaliações

- Applications Guideline-Flashing (Water)Documento2 páginasApplications Guideline-Flashing (Water)strahor7492Ainda não há avaliações

- Inside Sales For Valves PART 2Documento8 páginasInside Sales For Valves PART 2niket honnalliAinda não há avaliações

- These Are Two Different Types of Ball ValvesDocumento18 páginasThese Are Two Different Types of Ball Valvesgabi_nanaAinda não há avaliações

- Piping I PDFDocumento73 páginasPiping I PDFSyawaldi Bin KamaharuddinAinda não há avaliações

- Apollo ValvesDocumento16 páginasApollo Valvesvijuindia1111Ainda não há avaliações

- Worcester Controls F819/829 Full Bore Ball ValvesDocumento8 páginasWorcester Controls F819/829 Full Bore Ball ValvesVăn Đình NhậtAinda não há avaliações

- Section 15100 - Valves, Pipe Fittings, and Piping: Part 1 - General 1.1 Related Sections: 1.2 Scope of SectionDocumento5 páginasSection 15100 - Valves, Pipe Fittings, and Piping: Part 1 - General 1.1 Related Sections: 1.2 Scope of SectionAamir Abdul RahmanAinda não há avaliações

- Broady 3500 BrochureDocumento12 páginasBroady 3500 Brochureahmedm2020Ainda não há avaliações

- Piping 5.0 - Introduction to Piping EngineeringDocumento32 páginasPiping 5.0 - Introduction to Piping EngineeringSteve WanAinda não há avaliações

- Valves Election EssentialsDocumento8 páginasValves Election EssentialsmailmaverickAinda não há avaliações

- Ansi-Valve Body Material SelectionDocumento3 páginasAnsi-Valve Body Material SelectionsatthukotienAinda não há avaliações

- 08 - SpeckDocumento5 páginas08 - SpeckSezer CetinAinda não há avaliações

- BS 5351 Ball Valves CatalogDocumento10 páginasBS 5351 Ball Valves CatalogcatalineulaAinda não há avaliações

- G209 IDocumento8 páginasG209 IJaider CamachoAinda não há avaliações

- AV-C Butterfly ValveDocumento20 páginasAV-C Butterfly ValveSopon SrirattanapiboonAinda não há avaliações

- Butterfly ValveDocumento8 páginasButterfly Valveswapnil PATILAinda não há avaliações

- Chapter 12 Vacuum ValvesDocumento46 páginasChapter 12 Vacuum ValvesYashwant RajeshirkeAinda não há avaliações

- As 0201 en Gauge Valves and Pressure Gauge AccessoriesDocumento36 páginasAs 0201 en Gauge Valves and Pressure Gauge AccessoriesTache MihaiAinda não há avaliações

- SABRE FLITE - CertiifcateDocumento5 páginasSABRE FLITE - CertiifcaterentalqatarAinda não há avaliações

- Powell Valves - Handbook of Valve InformationDocumento28 páginasPowell Valves - Handbook of Valve InformationdokundotAinda não há avaliações

- Valve StandardsDocumento5 páginasValve StandardsSingaravel GanesanAinda não há avaliações

- As 2601 en E Series Valves and ManifoldsDocumento52 páginasAs 2601 en E Series Valves and ManifoldsTache MihaiAinda não há avaliações

- Rising Stem Gate Valve OS&YDocumento13 páginasRising Stem Gate Valve OS&YSalman AkramAinda não há avaliações

- Velan Ball Valve 1 PDFDocumento9 páginasVelan Ball Valve 1 PDFMilena Lemus FonsecaAinda não há avaliações

- Forged Steel Ball ValvesDocumento5 páginasForged Steel Ball ValvesMichael Valves100% (1)

- ValvesDocumento11 páginasValvesAdamAinda não há avaliações

- USPVH-0012 M94 4Pg BrochureDocumento4 páginasUSPVH-0012 M94 4Pg Brochurebkup2007Ainda não há avaliações

- Ratio Pressure Reducing ValvesDocumento4 páginasRatio Pressure Reducing Valveskanem1Ainda não há avaliações

- SECTION 15100 ValvesDocumento10 páginasSECTION 15100 ValvesintequabAinda não há avaliações

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryAinda não há avaliações

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryNo EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryNota: 5 de 5 estrelas5/5 (3)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesNo EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesAinda não há avaliações

- Pocket Guide to Flanges, Fittings, and Piping DataNo EverandPocket Guide to Flanges, Fittings, and Piping DataNota: 3.5 de 5 estrelas3.5/5 (22)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerNo EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerNota: 5 de 5 estrelas5/5 (1)

- Centrifugal Pumps PDFDocumento54 páginasCentrifugal Pumps PDFthomastheinkyaw100% (1)

- Air Compressor Specifiction (Atlas Copco)Documento3 páginasAir Compressor Specifiction (Atlas Copco)Phyu Mar Thein KyawAinda não há avaliações

- Branch Discharge Line CalculationsDocumento2 páginasBranch Discharge Line CalculationsPhyu Mar Thein KyawAinda não há avaliações

- Bedok WRP velocity and pumping calculationsDocumento3 páginasBedok WRP velocity and pumping calculationsPhyu Mar Thein Kyaw100% (1)

- Calculation of Pipe Bend Trust ForceDocumento4 páginasCalculation of Pipe Bend Trust ForcePhyu Mar Thein Kyaw100% (1)

- Calculation of Air Pipe SizeDocumento6 páginasCalculation of Air Pipe SizePhyu Mar Thein Kyaw100% (1)

- Calculation of Orifice Plate DiameterDocumento2 páginasCalculation of Orifice Plate DiameterPhyu Mar Thein Kyaw100% (1)

- Basic Calculations Piping System Design PDFDocumento14 páginasBasic Calculations Piping System Design PDFjeff_shawAinda não há avaliações

- Calculation of Pipe SupportDocumento8 páginasCalculation of Pipe SupportPhyu Mar Thein Kyaw67% (6)

- Calculation of Jet ProjectileDocumento32 páginasCalculation of Jet ProjectilePhyu Mar Thein KyawAinda não há avaliações

- Calculation of Hydraulic Profile Single BranchDocumento14 páginasCalculation of Hydraulic Profile Single BranchPhyu Mar Thein KyawAinda não há avaliações

- Pipeline profile and reservoir water levelsDocumento7 páginasPipeline profile and reservoir water levelsPhyu Mar Thein KyawAinda não há avaliações

- Calculation of Height of The Siphon SystemDocumento2 páginasCalculation of Height of The Siphon SystemPhyu Mar Thein Kyaw100% (1)

- Calculation of Blower Air Pipe Pressure Loss (Ave)Documento30 páginasCalculation of Blower Air Pipe Pressure Loss (Ave)Phyu Mar Thein Kyaw100% (2)

- Calculation For Rention TimeDocumento2 páginasCalculation For Rention TimePhyu Mar Thein KyawAinda não há avaliações

- Calculation For Water CapacityDocumento2 páginasCalculation For Water CapacityPhyu Mar Thein KyawAinda não há avaliações

- ALL Purpose Worksheet (Conversions)Documento28 páginasALL Purpose Worksheet (Conversions)Phyu Mar Thein KyawAinda não há avaliações

- Calculation of Flow VelocityDocumento3 páginasCalculation of Flow VelocityPhyu Mar Thein KyawAinda não há avaliações

- Optimal Penstock Sizing for Increased FlowDocumento1 páginaOptimal Penstock Sizing for Increased FlowPhyu Mar Thein KyawAinda não há avaliações

- IncinerationDocumento11 páginasIncinerationPhyu Mar Thein KyawAinda não há avaliações

- Chapter 2: Heat Exchangers Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallDocumento85 páginasChapter 2: Heat Exchangers Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallNadirah RahmanAinda não há avaliações

- IncinerationDocumento11 páginasIncinerationPhyu Mar Thein KyawAinda não há avaliações

- Infomation of Compressed Air LineDocumento8 páginasInfomation of Compressed Air LinePhyu Mar Thein KyawAinda não há avaliações

- Basic Calculations Piping System Design PDFDocumento14 páginasBasic Calculations Piping System Design PDFjeff_shawAinda não há avaliações

- Hot Water System Sizing CalculationDocumento1 páginaHot Water System Sizing CalculationPhyu Mar Thein KyawAinda não há avaliações

- Air Tools and Air ConsumptionsDocumento2 páginasAir Tools and Air ConsumptionsPhyu Mar Thein KyawAinda não há avaliações

- IncinerationDocumento11 páginasIncinerationPhyu Mar Thein KyawAinda não há avaliações

- Infomation of GasDocumento31 páginasInfomation of GasPhyu Mar Thein KyawAinda não há avaliações

- Compressed Air Pressure Drop DiagramsDocumento6 páginasCompressed Air Pressure Drop DiagramsPhyu Mar Thein KyawAinda não há avaliações

- Calculation of Relief CapacityDocumento6 páginasCalculation of Relief CapacityPhyu Mar Thein Kyaw100% (1)

- Successful Organizational Change FactorsDocumento13 páginasSuccessful Organizational Change FactorsKenneth WhitfieldAinda não há avaliações

- Hillingdon Health Visiting ServiceDocumento12 páginasHillingdon Health Visiting ServiceAnnikaAinda não há avaliações

- Air Cycle Refrigeration:-Bell - Coleman CycleDocumento21 páginasAir Cycle Refrigeration:-Bell - Coleman CycleSuraj Kumar100% (1)

- Ielts Band 9 Sample Essay NoDocumento5 páginasIelts Band 9 Sample Essay NoNhã NguyễnAinda não há avaliações

- Jenga Cash Flow Solution: InstructionsDocumento1 páginaJenga Cash Flow Solution: InstructionsPirvuAinda não há avaliações

- Discount & Percentage Word Problems SolutionsDocumento4 páginasDiscount & Percentage Word Problems SolutionsrheAinda não há avaliações

- Intermediate Accounting Testbank 2Documento419 páginasIntermediate Accounting Testbank 2SOPHIA97% (30)

- 3000W InverterDocumento2 páginas3000W InverterSeda Armand AllaAinda não há avaliações

- EE3331C Feedback Control Systems L1: Overview: Arthur TAYDocumento28 páginasEE3331C Feedback Control Systems L1: Overview: Arthur TAYpremsanjith subramani0% (1)

- Acknowledgment: George & Also To Our Group Guide Asst. Prof. Simy M Baby, For Their Valuable Guidance and HelpDocumento50 páginasAcknowledgment: George & Also To Our Group Guide Asst. Prof. Simy M Baby, For Their Valuable Guidance and HelpKhurram ShahzadAinda não há avaliações

- Sample Contract Rates MerchantDocumento2 páginasSample Contract Rates MerchantAlan BimantaraAinda não há avaliações

- AnswersDocumento3 páginasAnswersrajuraikar100% (1)

- Telangana Budget 2014-2015 Full TextDocumento28 páginasTelangana Budget 2014-2015 Full TextRavi Krishna MettaAinda não há avaliações

- CCTV8 PDFDocumento2 páginasCCTV8 PDFFelix John NuevaAinda não há avaliações

- LeasingDocumento2 páginasLeasingfollow_da_great100% (2)

- Pass Issuance Receipt: Now You Can Also Buy This Pass On Paytm AppDocumento1 páginaPass Issuance Receipt: Now You Can Also Buy This Pass On Paytm AppAnoop SharmaAinda não há avaliações

- Central BankDocumento65 páginasCentral BankFarazNaseer100% (1)

- Business PlanDocumento9 páginasBusiness PlanRico DejesusAinda não há avaliações

- Assignment 2 - p1 p2 p3Documento16 páginasAssignment 2 - p1 p2 p3api-31192579150% (2)

- 2010 Yoshimura Book of SpeedDocumento83 páginas2010 Yoshimura Book of Speedacornwoods_brentAinda não há avaliações

- SABIC Ethanolamines RDS Global enDocumento10 páginasSABIC Ethanolamines RDS Global enmohamedmaher4ever2Ainda não há avaliações

- Password CrackingDocumento13 páginasPassword CrackingBlue MagicAinda não há avaliações

- Syllabus - Mech 3rd YearDocumento130 páginasSyllabus - Mech 3rd YearAbhishek AmarAinda não há avaliações

- Uniform Bonding Code (Part 2)Documento18 páginasUniform Bonding Code (Part 2)Paschal James BloiseAinda não há avaliações

- Forecasting AssignmentDocumento1 páginaForecasting AssignmentVarun Singh100% (1)

- FilesDocumento12 páginasFilesRajesh TuticorinAinda não há avaliações

- Final Biomechanics of Edentulous StateDocumento114 páginasFinal Biomechanics of Edentulous StateSnigdha SahaAinda não há avaliações

- WPB Pitch DeckDocumento20 páginasWPB Pitch Deckapi-102659575Ainda não há avaliações

- 3 0 Visual Weld InspectorDocumento74 páginas3 0 Visual Weld InspectorVincent Sofia RaphaelAinda não há avaliações

- AutocadDocumento8 páginasAutocadbrodyAinda não há avaliações