Escolar Documentos

Profissional Documentos

Cultura Documentos

Influence of Storage On Sunflower Seeds

Enviado por

Robert RomanTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Influence of Storage On Sunflower Seeds

Enviado por

Robert RomanDireitos autorais:

Formatos disponíveis

International Journal of Plant Production 3 (4), October 2007

ISSN: 1735-6814 (Print), 1735-8043 (Online)

This is a refereed journal and all articles are professionally screened and reviewed.

GUASNR

www.ijpp.info

Influence of storage conditions on quality and viability of

high and low oleic sunflower seeds

A. Ghasemnezhada, B. Honermeierb

a

Department of Horticulture, Faculty of Agriculture, Gorgan University of Agricultural Sciences and Natural

Resources, Gorgan, Iran.

b

Institute of plant production and plant breeding I, Faculty of Agriculture, Justus Leibig University of Giessen,

Giessen, Germany.

*corresponding author; Email: azim.ghasemnezhad@agarat.uni-giessen.de

Received 24 Dec 2008; Accepted after revision 7 August 2009; Published online 17 September 2009

Abstract

Storage conditions of oil seeds before industrial extraction might influence the quality of the

crude oil. The aim of present study was to clarify the storage able potency of high and low oleic

cultivars of sunflower based on oil and fatty acid changes of seeds and their viability. The seed

samples of four sunflower cultivars (two high oleic and two low oleic) were stored in three different

temperature conditions (4-5 C, 21-22 C, and 35 C) in a period of four months. Results show that

quality parameters of seeds such as oil content, fatty acid composition and protein content were

significantly influenced by storage conditions in most cases. In all experimental cultivars oil content

was significantly influenced by storage time. Indeed, the longer storage times the higher oil reduction

and vice versa. In most cases the oleic acid reduced as storage time progressed. Free fatty acid content

of crude oil increased in longer storage time and higher temperature. No clear effect of storage time

and storage temperature was observed on seed germination of used cultivars. Generally it can be

conclude that the storage life of sunflower seed can be decreased by longer storage time and higher

storage temperature.

Keywords: free fatty acid; high oleic sunflower; linoleic acid; seed viability; storage conditions;

storage temperature

Introduction

Storage conditions of oil seeds before industrial extraction might influence the quality

of the crude oil (Martini and Anon, 2005). Storage is done to maintain harvesting quality of

product not to improve it (Sisman and Delibas, 2004). During storage time product

specially stored oils compositions can be influenced by several storage conditions. A fatty

acid composition is the most important factor which determines oils susceptibility to

oxidation. The types of fatty acids present in an oil, and in particular their number of double

bounds, determine the type and extent of chemical reactions which occur during the storage

40

A. Ghasemnezhad & B. Honermeier / International Journal of Plant Production (2009) 3(4): 39-48

time (Morello et al., 2004). The unsaturated fatty acids are very important for the stability

of oils because of the chemical reactions occurring at the double bonds. Oilseed plant ever

industrial oilseed or oilseeds which used for dietetics, cosmetics or lipochemistry are very

important in human life. In contrast to animal fats which are predominantly saturated and

with low reaction potency with another chemicals especially oxygen, unsaturated vegetable

oils are more reactive and instable (Naz et al., 2004). According to Sisman and Delibas

(2004) and Sisman (2005) during storage period the oil content of sunflower (Heliantus

annus) decreased progressively. They reported that increase in temperature and humidity

caused to spoil of oil and increasing of free fatty acid. Neg and Anderson (2005) showed

that storage time and storage temperature had significant effect on free fatty acid content in

the Quinoa (Chenopedium quinoa) seed oil. Villiers et al., (1986) indicated that high

storage temperature and humidity had significant effect on sunflower seed oil quality as

well as quality. Martini and Anon (2005) reported that during storage of sunflower seed in

different temperature the oil content did not influence. It seems temperature; moisture and

the storage duration are the most important factors which influence on stored product

quality and quantity (Anderson and Lingnert, 1998; Chen and Ahn, 1998). The aim of this

investigation was to study the effect of storage conditions on quality and quantity of

sunflower seed oil.

Material and Methods

The newly harvested seeds of low oleic sunflower cultivars (Jazzy and PRO64A54) and

high oleic sunflower cultivars (Atomic and Olsavil) were obtained from the research station

of Justus Leibig university in Gross-Gerau (Germany). The temperature chosen for this

experiment were: 3-4 C, 21-22 C and 35 C for low, moderate and high temperature,

respectively.

At the beginning of the experiment the relative air humiditys of 40-45%, 60-65% and

30-35% were recorded in room conditions (21-22 C), growth chamber (35 C) and

refrigerator (4-5 C), respectively. The seed samples were stored under mentioned

temperature conditions for a period of four months. There were four replications for each

treatment. Regularly every month stored seed samples were examined their oil percentage,

fatty acid composition, free fatty acid content, acid value and seed viability.

At the beginning of the experiment the experimental samples were analyzed and the

results of the first measurements i.e., seed oil percentage, fatty acid composition, free fatty

acid percentage and peroxide value were used as a control for remaining storage times.

Seed samples were finely ground in a coffee grinder (Bran) and extracted using nhexane in a Soxhlet apparatus. The extraction lasted 8 hours at a constant temperature of 70

C. Fatty acid composition of seed samples was determined as methyl esters after

transesterification by GC according to a modified method of Court et al., (1993). Varian

3800 gas chromatograph with dual FID detector which was equipped with a Permabond (r)

FFAP column (25m 0.25 mm i.d., film thickness 0.25 m) with CP-SIL 88 foe FAME

stationary phase and a CS-FUSED-Silica precolumn was used in this experiment. For

analysis one microliter injection was made with a Varian CX auto sampler. The column

oven was temperature programmed from 200 to 240 at 10 C/m and held at 220 C for 1

min (120 C to 200 C at 3 C/min recommended by Court et al., (1993).

A. Ghasemnezhad & B. Honermeier / International Journal of Plant Production (2009) 3(4): 39-48

41

The injector and detector temperature in the method of Court et al., (1993) was 183 C

and 200 C, respectively. In our study both injector and detector the temperature was

increased to 280 C. The carrier gas (helium) flow rate was 2.0 ml/min. The free fatty acid

percentage and peroxide value (PV) were determined according to IUPAC method (1987).

The statistical analysis was performed using the SPSS software version 12.1 based on two

ways ANOVA. Least significant differences (LSD) at =5% were computed for

measurements with F-value <0.05.

Results and Discussion

Oil content of seed

From the results of the four months of storage in which the oil analyses of the seed

samples were carried out, it can be inferred that there is a significant effect of storage time

on seed oil content of both high and low oleic cultivars (Table 1). The oil content of high

oleic cultivars varied from maximum of 51.1% after one month of storage for Atomic and

55.5% for control samples in Olsavil to minimum (after 4 months of storage) of 49.3% and

53.9 % for Atomic and Olsavil cultivars, respectively. The changes in the oil content of low

oleic cultivars Jazzy and PRO64A54 (PR) were relatively the same. In both cultivars the

lowest oil percentage was recorded from the samples that stored longer. These results are in

conformity with Sisman (2004), Sisman and Delibas (2005) who showed that during a

period of three months of storage (independent from storage conditions) the percentage of

seed oil gradually decreased with increasing the storage time. Same result was reported by

Ghasemnezhad et al., (2007) in evening primrose. They showed that as the storage time

increased, a rapid decrease of the oil percentage compared to the control samples was

observed.

In vegetable oils, oxygen-dependent deterioration of lipids is known as rancidity. The

development of rancidity has been recognized as the predominant cause of oil deterioration

and reduction during storage (Ahmadkhan et al., 2000; Morello et al., 2004).

Due to the presence of double bonds in unsaturated fatty acids these fatty acids are

susceptible to oxidation, which is a reaction between unsaturated fatty acids (regardless of

whether they are in their free state or esterified in a triaglycerol molecule) and oxygen. It is

well known that the rate of oxidation increases with the increase in oxygen concentration

and the duration of exposure (the length of storage time). The oxidation of oil requires the

presence of atmospheric oxygen. The longer the storage time the higher the oxygen

availability and vice versa. This might be a reason why the percentage of oil of stored seeds

tended to reduce during storage.

On the other hand, the metabolism of seeds during storage to provide energy for its

physiological activities could be another reason of the seed oil reduction during storage.

Enzymes such as acyl-CoA oxidase, malate synthase, citrate synthase, catalase and lipases

are the main enzymes which are involved in oil and fatty acids metabolism of the seeds

(Kindle, 1987). The activities of most of these enzymes are partially or wholly requiring the

presence of oxygen. This can be another reason of observed reduction of oil content during

storage. The activities of most of enzymes are partially or wholly requiring the presence of

oxygen. Temperature as an important environmental factor of storage had significant

42

A. Ghasemnezhad & B. Honermeier / International Journal of Plant Production (2009) 3(4): 39-48

influence on the oil content of experimental cultivars except Atomic. The effect of

temperature was not the same for all cultivars wherein Olsavil recorded the lowest oil

percentage for seed samples which stored in low temperature conditions. Jazzy and PR

cultivars recorded the lowest oil percentage at room conditions and high temperature

conditions, respectively.

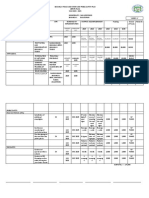

Table 1. Changes in seed composition of high oleic sunflower under different storage conditions.

ST

OC

T

AT

PA

OL

AT

SA

OL

AT

OA

OL

AT

LA

OL

AT

FFA

OL

AT

PC

OL

AT

OL

Control

50.1

55.5

4.5

3.7

2.2

1.6

90.6

92.7

2.6

1.8

2.2

1.8

15.2

15.9

ST1

51.0

54.8

3.8

3.0

2.4

1.7

90.7

92.3

2.7

2.4

2.7

2.2

15.2

15.5

ST2

50.2

54.4

4.0

3.1

2.2

1.6

90.6

87.1

3.1

1.9

3.0

1.9

15.1

15.5

ST3

50.7

53.9

4.0

3.2

2.2

1.6

90.6

92.9

3.1

1.9

3.5

1.9

15.2

16.7

ST4

49.3

53.9

3.8

3.2

2.8

1.6

88.2

92.9

3.5

1.9

3.9

1.9

14.5

15.6

T1

50.4

53.4

3.9

3.2

2.4

1.6

89.6

92.8

3.1

2.0

2.9

1.8

15.1

16.2

T2

50.3

54.1

4.1

3.2

2.4

1.6

90.4

92.9

2.9

1.9

2.8

1.6

15.0

15.9

T3

50.1

54.8

4.1

3.3

2.3

1.6

90.4

89.1

2.9

2.0

3.4

2.3

15.0

15.5

ST p-value

0.00

0.01

0.00

0.00

0.00

0.01

0.00

ns

0.00

0.00

0.010

0.00

0.000

0.00

ns

0.04

ns

ns

ns

ns

0.01

ns

ns

ns

0.000

0.00

ns

0.00

STT

ns

ns

ns

ns

ns

ns

ns

ns

ns

0.00

0.010

ns

ns

ns

0.66

1.33

0.23

0.14

0.23

0.10

0.80

0.43

0.17

0.30

0.25

0.27

0.50

1.2

1.1

1.2

0.22

0.43

STT

0.44

1.2

ST LSD 5%

AT: Atomic, OL: Olsavil, ST: storage time (month), T: storage temperature; T1: 4-5 C, T2: 21-22 C, T3: 35 C,

SO: seed oil, PA: palmetic acid, SA: stearic acid, OA: oleic acid, LA: linoleic acid, FFA: free fatty acid.

The observed conflict in oil content of different cultivars stored under different

temperature conditions is not clear. Our results are in confirmation with Manti et al., (2005)

in sunflower and Ghasemnezhad et al., (2007) in evening primrose who reported that there

was no clear variation tendency in sunflower seed oil percentage with storage temperature.

The interaction of storage time and temperature on oil content of Olsavil (Figure 1)

indicates that during first and second months of storage the samples stored in room

temperature conditions had the lowest oil content. During third month of storage no

significant difference was observed among different temperature conditions. As storage

time increased the samples which were stored under high temperature conditions had the

lowest oil percentage. Based on the observed results it can be concluded that a total of

different parameters influence on seed oil content and its composition and the observed

changes in a measured parameter mostly are not related to a single factor.

A. Ghasemnezhad & B. Honermeier / International Journal of Plant Production (2009) 3(4): 39-48

43

Protein content

The protein content of all experimental seed samples was significantly influenced by

time of storage (Table 1 and 2). As presented in Table 1 and 2, although the protein content

of seeds was influenced by storage time, no clear effect was observed. For instance in both

Atomic and Olsavil cultivars (high oleic) the protein content of seed samples increased after

third months of storage. On the other hand, the protein content of seed samples of

PRO64A54 a low oleic cultivar gradually increased as storage progressed. The reason of

protein content fluctuation during storage is not clear. It may be due to the negative

correlation between seed oil and protein. The same result was observed by Ghasemnezhad

et al., (2007) in evening primrose seed. They concluded that based on the negative relation

between seed oil and protein content, the observed increased in protein percentage of stored

seed could be due to oil content reduction of seeds during storage. The observed irregular

changes of protein in sunflower seed samples can not be explain by direct relationship of

oil and protein content.

Table 2. Changes in seed composition of low oleic sunflower under different storage conditions.

ST

0

1

2

3

4

ST Pvalue

T

ST

LSD

1

2

3

OC

JA

PR

51.8 50.4

50.6 50.2

51.9 49.3

52.3 49.2

52.1

49

52.7 49.8

50.2 49.7

52.3 49.4

JA

6.1

6.4

6.6

6.9

5.8

6.4

6.4

6.2

PA

PR

6.6

6.1

6.5

6.5

6.1

6.4

6.4

6.2

JA

3.3

3.2

2.8

2.8

3.4

3.1

3.1

3

SA

PR

4.1

4.37

4.26

4.29

4.49

4.24

4.32

4.34

OA

JA

PR

39.9 21.9

41.1 22.7

40.5 22.3

39.8 23.5

39.7 21.9

40.4 22.6

40

22.5

40.2 22.3

JA

49.8

50.2

50.2

50.2

49.5

49.9

50.2

49.8

LA

PR

66.3

65.8

66.5

66

65.5

66

66.3

65.7

JA

0.3

1.8

1.9

2.2

2.3

1.7

1.3

2.1

FFA

PR

1.7

2.1

2.6

4.4

4.5

2.5

2.7

4

JA

14.4

15.4

15.4

15

15

15.3

15.4

14.4

PC

PR

15.9

14.7

14.2

15.5

15.5

15.2

15.3

15

0.00

0.00

0.37

0.05

0.48

0.00

0.00

0.07

0.00

0.42

0.00

0.00

0.11

0.00

0.28

0.03

0.00

0.45

0.00

0.01

0.31

0.77

0.04

0.31

0.00

0.00

0.00

0.55

1.63

0.44

ns

0.40

ns

0.10

0.61

ns

0.42

ns

0.22

0.1

ns

0.69

5%

T

ns

0.34 0.37

ns

0.14

0.1

ns

ns

0.33

ns

0.19

0.1

0.71

JA: Jazzy, PR: PRO64A54, ST: storage time (month), T: storage temperature; T1: 4-5 C, T2: 21-22 C, T3: 35

C, SO: seed oil, PA: palmetic acid, SA: stearic acid, OA: oleic acid, LA: linoleic acid, FFA: free fatty acid.

LA, P-valu= 0.00, LSD 5%= 0.44

5.0

FFA, P-valu= 0.01, LSD 5%= 1.2

4.5

4.0

3.5

(%) 3.0

2.5

2.0

1.5

1.0

0.5

0.0

T1

T2

control

T3

T1

T2

ST1

T3

T1

T2

ST2

T3

T1

T2

ST3

T3

T1

T2

T3

ST4

Figure 1. The interaction effect of storage time and temperature on linolenic acid percentage of Atomic and free

fatty acid percentage of Olsavil (High oleic cultivars).

ns

44

A. Ghasemnezhad & B. Honermeier / International Journal of Plant Production (2009) 3(4): 39-48

Fatty acid composition

Fatty acid composition and the proportions of different fatty acids of the seed oil during

storage are dependent on the degradation rate of different fatty acids, which convert to each

other (Ahmadkhan and Shahidi, 2000; Muangkaeo et al., 2005). In the present study the

profile of fatty acids in both high and low oleic acid was significantly influenced by storage

time (Table 1 and 2). As presented in Table 1, the content of palmetic acid and stearic acid

of high oleic cultivars were significantly changed during storage but no clear direction was

observed for this changes. Oleic acid as a predominant fatty acid in high oleic cultivar

Atomic clearly decreased as storage time increased. Table 1 shows that after third month of

storage of Atomic seeds a high reduction was observed (from 90.6% at the beginning of

storage to 88.2% after four months of storage). This strong reduction in oleic acid could be

related to the production of free fatty acid and the conversion to other fatty acid. Results

indicate that contrary to oleic acid the content of free fatty acid gradually increased during

storage. Fatty acids in free forms are more susceptible to oxidation. It can be concluded that

increase of the free form of oleic acid and its oxidation during storage could be the reason

why the content of this fatty acids decreased. Contrary to oleic acid a relative increase in

the content of other measured fatty acids was observed during storage. It could be

concluded that the conversion of oleic acid to other fatty acids like palmetic and linoleic

acids is another possible reason of observed reduction in oleic acid. In low oleic cultivars

although the content of linoleic acid as a predominant fatty acids significantly increased at

the fourth month of storage, the reduction level was not high. Our finding about variation in

the content of seed oil fatty acids was confirmed by Morello et al. (2004) in olive oil. In an

investigation with olive oil they showed that after a certain period of storage a reduction in

the content of linoleic and linolenic acid was observed. Contrary to that the content of oleic

acid tended to increase. Figure 1 shows that in Olsavil cultivar after three months of storage

a significant increase in the content of free fatty acids was observed in samples which were

stored at high temperature conditions. Based on this finding it can be concluded that a

combination of high temperature a long storage time can increase the oxidation of oil even

in seed. The same result was observed by Ghasemnezhad et al. (2007) in evening primrose.

It can be suggested that high FFA accumulation in experimental samples in a long storage

period and high temperature could be related to higher activity of hydrolysis by lipases and

other enzymes which are involved in fatty acid degradation. The results indicate that

storage time and storage temperature had significant effect on lipid peroxide value (PV) of

sunflower seed (since the PV of oil samples was measured only at the beginning and the

end of experiment the results were not presented). Similar trends in the peroxide value of

vegetables oil have been observed by Ghasemnezhad et al. (2007) in evening primrose,

Abramovic and Abram (2005) in Camelina and Ullah et al. (2003) in sunflower and

soybean. Ullah et al. (2003) demonstrated that the peroxide value of sunflower and soybean

oil at room temperature and under different light conditions (fluorescent light, ambient light

and dark conditions) sharply increased during a five-week period of storage.

A. Ghasemnezhad & B. Honermeier / International Journal of Plant Production (2009) 3(4): 39-48

45

100

97

97

97

99

99

98

99

98

97

96

96

96

96

95

95

94

94

92

S eed germ ination (% )

S eed germ ination (% )

99

98

98 97

97

97

97

97

95

95

96

95

95

93

94

91

90

90

88

86

90

T1

T2

T3

control

T1

T2

T3

ST1

T1

T2

T3

T1

ST2

T2

T3

ST3

T1

T2

T1

T3

T2

T3

T1

control

ST4

T2

ST1

T3

T1

T2

T3

T1

ST2

T2

T3

T1

T2

ST3

T3

ST4

Storage time (ST) and temperature (T)

Storage time (ST) and temperature (T)

Figure 2. Seed germination percentage of Jazzy (left) and PR (Right) two high oleic cultivars under different

storage temperatures and times.

Table 3. The interaction effect of storage time and temperature on oil content, fatty acid composition and protein

content of Jazzy and PRO64A54 (Low oleic cultivars).

ST

OC

PA

JA

51.8

50.2

51.9

50.8

51.8

50.5

53.5

54.1

50.7

52.2

51.7

51.4

51.2

PR

50.4

51

49.7

49.7

49.4

49.5

49.1

49.5

49.6

48.7

48.7

49.4

48.9

STT

0.02

0.04

STT

2.36

0.76

C

ST1

ST2

ST3

ST4

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

JA

6.1

6.7

6.9

5.6

6.5

6.7

6.6

6.8

7.1

6.8

6.1

5.4

6

0.0

9

-

SA

OA

LA

FFA

PC

PR

6.6

6.6

6.6

5

6.4

6.5

6.6

6.2

6.3

7

6.2

6.2

6

JA

3.3

3.2

3.2

3.2

2.7

2.9

2.7

2.8

2.8

2.6

3.6

3.2

3.4

PR

4.1

4.3

4.5

4.4

4.2

4.2

4.3

4.1

4.3

4.4

4.5

4.5

4.5

JA

39.9

40.9

41.1

41.3

41.3

40.4

39.8

40

39.4

40

39.8

39.2

40

PR

21.9

22.4

22.6

23.2

22.7

21.9

22.2

23.8

24

22.6

22

22.3

21.4

JA

49.8

50.4

50.7

49.6

49.6

50.7

50.3

49.9

50.7

49.9

49.8

49.2

49.6

PR

66.3

65.1

67.1

65.2

66.1

66.8

66.4

65.8

65.6

66.6

66.7

65.9

63.9

JA

0.3

1.6

1.6

2.2

1.8

1.4

2.5

2.3

1.5

2.9

2.5

1.8

2.6

PR

1.5

1.73

1.63

1.87

1.9

1.73

1.97

2.27

1.87

2.23

2.5

2.07

2.5

JA

14.4

14.4

16.3

15.5

16.1

16.3

13.7

15.7

15.1

14.1

15.7

15.1

14.1

PR

15.9

15.4

14.2

14.5

14.3

14.2

14

15.1

16.1

15.2

15.2

16.1

15.2

0.3

0.03

0.25

0.87

0.02

0.13

0.01

0.02

0.36

0.34

0.17

0.72

0.37

0.11

1.42

JA: Jazzy, PR: PRO64A54, ST: storage time (month), T: storage temperature; T1: 4-5C, T2: 21-22 C, T3: 35 C,

SO: seed oil, PA: palmetic acid, SA: stearic acid, OA: oleic acid, LA: linoleic acid, FFA: free fatty acid.

Seed viability

Figure 2 shows that after first month of storage, the lowest seed germination both in

Jazzy and PR cultivars was recorded in seed samples stored under 35 C. Two months after

storage the germination behavior was quite different. In Jazzy the seeds which were stored

in room temperature conditions had the lowest germination percentage. Contrary to that

seeds of PR which were stored in low temperature conditions had the lowest germination

percentage. Three months after storage a strong reduction in seed germination was observed

in both cultivars specially when stored in high temperature conditions. On the other hand,

in next month an increase in seed germination was observed again. No clear effect of

storage conditions on seed germination percentage of Olsavil and Atomic (low oleic

cultivars) was observed in present study. For example the highest reduction in seed

46

A. Ghasemnezhad & B. Honermeier / International Journal of Plant Production (2009) 3(4): 39-48

germination of Atomic cultivar was observed in the seed samples which were stored under

room temperature conditions in a period of one month. In contrary, in Olsavil cultivar the

highest reduction in seed germination was observed four months after storage at room

temperature. Generally based on obtained results it is not easy to describe the effect of

single parameters. But the results show that independent from temperature conditions of

storage, progressive in storage time negatively influence on seed viability.

Conclusion

It was expected that sunflower oil is more stable during storage. The reason of observed

low stability in seed oil is not clear. In this experiment the experimental design did not

cover the record of some factors like moisture content of the seeds at the beginning and

during storage, the relative humidity of the air of storage, the level of seed damage after

threshing. This could be the reason why oil in the seeds did not seem so stable. On the other

hand, the used cultivars could be another reason of why the observation is contrary to the

expectations that the experimental cultivars, Olsavil, a high oleic cultivar, showed a strong

increase in free fatty acid accumulation, when it was stored at high temperature conditions

and a relative long storage time. Generally it can be conclude that the storage life of

sunflower seed can be decreased by longer storage time and higher storage temperature.

100

97

97

99

97

100

97

99

99

97

97

95

96

98

100

100

S eed germ ination (% )

Seed germination (%)

100

95

90

85

80

80

75

70

97

97

97

99

97

95

97

97

95

95

95

95

91

90

90

86

85

80

75

70

65

65

T1

T2

control

T3

T1

T2

ST1

T3

T1

T2

ST2

T3

T1

T2

T3

ST3

Storage time (ST) and temperature (T)

T1

T2

ST4

T3

T1

T2

control

T3

T1

T2

ST1

T3

T1

T2

ST2

T3

T1

T2

T3

ST3

T1

T2

T3

ST4

Storage time (ST) and temperature (T)

Figure 3. Seed germination percentage of Atomic (left) and Olsavil (Right) two low oleic cultivars under different

storage temperatures and times.

References

Ahmadkhan, M., Shahidi, F., 2000. Oxidative stability of stripped and no stripped Borage and Evening primrose

oils and their emulsions in water. Journal of the American Oil Chemistry Society. 77: 9. 963-968.

Anderson, K., Lingnert, H., 1998. Influence of oxygen and copper concentration on lipid oxidation in rapeseed oil.

Journal of the American Oil Chemists Society. 75: 8. 1041-1046.

Chen, X.C., Ahn, D.U., 1998. Antioxidant activities of six natural phenolic against lipid oxidation induced by Fe+2

or ultraviolet light. Journal of the American Oil Chemists Society. 75: 12. 1717-1721.

Court, A.W., Hendel, J.G., Pocs, R., 1993. Determination of the fatty acids and oil content of evening prime rose

(O.biennis L). Food Research. 26: 181-186.

Kindle, H., 1987. -Oxidation of Fatty Acids by specific Organelles. In: Stumpf PK and Conn EE (Editors): The

Biochemistry of Plants. 9, Lipids: Structure and Function, chapter 2. San Diego, California: Harcourt Brace

Jovanovich publishing company. Pp: 31-53.

A. Ghasemnezhad & B. Honermeier / International Journal of Plant Production (2009) 3(4): 39-48

47

Ghasemnezhad, A., Cergel, S., Honermeier, B., 2007. The impact of storage time and storage temperature on the

quality of the oil of evening primrose (Oenothera biennis L.). Journal of Medicinal and Spice Plants. 12: 4.

175-180.

IUPAC, 1987. International union for pure and applied chemistry, standard methods of analysis for the analysis of

oil. Fats and Derivatives, 7th.End. Blacwell, Jevent Publishers, Oxford.

Martini, S., Anon, M.S., 2005. Storage of sunflower seed: variation on the wax content of the oil. European

Journal of Lipid Science and Technology. 107: 74-79.

Morello, J.R., Motilva, M.J., Tovar, M.J., Romero, M.P., 2004. Changes in commercial virgin olive oil (CV

Arbequina) during storage with special emphasis on the phenolic fraction. Journal of Food Chemistry. 85:

357-364.

Muangkaeo, R., Srichuwong, S., Pawelzik, E., Verasilp, S., 2005. Influence of packaging material and storage

time on seed viability and chemical component of rice seed, the global food and product chain dynamics,

innovations, conflicts, strategies,: Deucher Tropentag, October. 11-13, Hohenheim.

Naz, S., Seddiqi, R., Sheikh, H., Sayeed, S.A., 2005. Deterioration of olive, corn and soybean oils due to air, light,

heat and deep frying, Food Research International. 38: 127-134.

Neg, S.C., Anderson, A., 2005. Lipid oxidation in Quinoa (Chenopodium quinoa) as determinated through

accelerated aging, Journal of Environmental, Agriculture and Food Chemistry. 4: 4. 1010-1020.

Sisman, C., Delibas, L., 2004. storing sunflower seed and quality losses during storage, Journal of Central

European Agriculture. 4: 239-250.

Sisman, C., 2005. Quality losses in temporary sunflower stores and influences of storage conditions on quality

losses during storage, Journal of Central European Agriculture. 6: 143-150.

Ullah, J., Hamayoun, M., Ahmad, T., Ayub, M., Zafarullah, M., 2003. Effect of light and natural synthetic

antioxidants on stability of edible oil and fats. Asian Journal of Plant Science. 2: 1192-1194.

Villiers, J.B.M., Toit, L.J., Pretorius, H.E., 1986. The behaviour of decorticated sunflower seeds stored under

favourable and unfavourable conditions, Lebensrn- Wiss U- Technol. 19: 472-476.

48

A. Ghasemnezhad & B. Honermeier / International Journal of Plant Production (2009) 3(4): 39-48

Você também pode gostar

- Phytic Acid Reduction in Whole Wheat Flour DoughDocumento57 páginasPhytic Acid Reduction in Whole Wheat Flour DoughRobert RomanAinda não há avaliações

- ZT Prod Notes FinalDocumento47 páginasZT Prod Notes FinalMahkom BeAmrellahAinda não há avaliações

- Chicago Food Machinery Blender Manual PDFDocumento6 páginasChicago Food Machinery Blender Manual PDFRobert RomanAinda não há avaliações

- Vitamin C-Lipid MetabolitesDocumento5 páginasVitamin C-Lipid MetabolitesRobert RomanAinda não há avaliações

- Sharp Dust SensorDocumento3 páginasSharp Dust SensorRobert RomanAinda não há avaliações

- Sharp Dust SensorDocumento3 páginasSharp Dust SensorRobert RomanAinda não há avaliações

- Regnier 1968 CHDocumento9 páginasRegnier 1968 CHRobert RomanAinda não há avaliações

- Phy TaseDocumento6 páginasPhy TaseRobert RomanAinda não há avaliações

- Comparison of Chemical Compositions and Bioactive Compounds of Germinated Rough Rice and Brown Rice-2010-MoongngarmDocumento7 páginasComparison of Chemical Compositions and Bioactive Compounds of Germinated Rough Rice and Brown Rice-2010-Moongngarmavr999Ainda não há avaliações

- Electrolux z7040 PDFDocumento8 páginasElectrolux z7040 PDFRobert RomanAinda não há avaliações

- ZT Prod Notes FinalDocumento47 páginasZT Prod Notes FinalMahkom BeAmrellahAinda não há avaliações

- Electrolux z7040 PDFDocumento8 páginasElectrolux z7040 PDFRobert RomanAinda não há avaliações

- How To Replace Torn Off Buttons: If There Is A Hole, Mend ItDocumento2 páginasHow To Replace Torn Off Buttons: If There Is A Hole, Mend ItRobert RomanAinda não há avaliações

- How to Fix and Mount RADIK and KORALUX RadiatorsDocumento20 páginasHow to Fix and Mount RADIK and KORALUX RadiatorsRobert RomanAinda não há avaliações

- How To Replace Torn Off Buttons: If There Is A Hole, Mend ItDocumento2 páginasHow To Replace Torn Off Buttons: If There Is A Hole, Mend ItRobert RomanAinda não há avaliações

- How To Replace Torn Off Buttons: If There Is A Hole, Mend ItDocumento2 páginasHow To Replace Torn Off Buttons: If There Is A Hole, Mend ItRobert RomanAinda não há avaliações

- PL1.2-12 (12V1.2AH) : Valve Regulated Lead Acid BatteryDocumento2 páginasPL1.2-12 (12V1.2AH) : Valve Regulated Lead Acid BatteryRobert RomanAinda não há avaliações

- Conductivitate Electrica Apa PDFDocumento11 páginasConductivitate Electrica Apa PDFRobert RomanAinda não há avaliações

- Comparison of Juice Extractors: Enzymes: Michael Donaldson, PH.DDocumento0 páginaComparison of Juice Extractors: Enzymes: Michael Donaldson, PH.DRobert RomanAinda não há avaliações

- 2005 Brusse Tin Whiskers AF114 TransistorsDocumento24 páginas2005 Brusse Tin Whiskers AF114 TransistorsRobert RomanAinda não há avaliações

- Chicago Food Machinery Blender Manual PDFDocumento6 páginasChicago Food Machinery Blender Manual PDFRobert RomanAinda não há avaliações

- BL-020B Control PanelDocumento1 páginaBL-020B Control PanelRobert RomanAinda não há avaliações

- Better SolderingDocumento8 páginasBetter SolderingPYFAinda não há avaliações

- Guide To Electronics SolderingDocumento12 páginasGuide To Electronics Solderingnagendra sharadaAinda não há avaliações

- BL-020B Control PanelDocumento1 páginaBL-020B Control PanelRobert RomanAinda não há avaliações

- Centre de Premiere Doze Coca-ColaDocumento27 páginasCentre de Premiere Doze Coca-ColaRobert RomanAinda não há avaliações

- ECCO Fit Guide v1 0Documento2 páginasECCO Fit Guide v1 0bsp123456Ainda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Knorr FinalDocumento25 páginasKnorr Finalimbree100% (3)

- Soni Clinic & Pathology Center Chanda: Address:-Front of TVS AgencyDocumento1 páginaSoni Clinic & Pathology Center Chanda: Address:-Front of TVS AgencyVishalAinda não há avaliações

- ISO 9001 2008-List of Sample Audit QuestionsDocumento5 páginasISO 9001 2008-List of Sample Audit QuestionsSaut Maruli Tua SamosirAinda não há avaliações

- Common Safety Method GuidanceDocumento66 páginasCommon Safety Method GuidanceDiego UngerAinda não há avaliações

- Certificate of Employment Document TitleDocumento1 páginaCertificate of Employment Document TitleAyni ReyesAinda não há avaliações

- PE1 q1 Mod6 ProperEtiquetteand-Safetyinthe-UseofFacilitiesEquip v1-ADMDocumento12 páginasPE1 q1 Mod6 ProperEtiquetteand-Safetyinthe-UseofFacilitiesEquip v1-ADMelvira.raagas2Ainda não há avaliações

- Role of Perioperative NurseDocumento30 páginasRole of Perioperative Nursealiyemany23Ainda não há avaliações

- Bioreactor For Air Pollution ControlDocumento6 páginasBioreactor For Air Pollution Controlscarmathor90Ainda não há avaliações

- Exudate Detection For Diabetic Retinopathy With Circular HoughDocumento7 páginasExudate Detection For Diabetic Retinopathy With Circular HoughAshif MahbubAinda não há avaliações

- Oxyprobe PDFDocumento16 páginasOxyprobe PDFSrinivasa RAinda não há avaliações

- Work, Energy Power RevDocumento31 páginasWork, Energy Power RevRency Micaella CristobalAinda não há avaliações

- Self-Adhesive Resin Cements Ph-Neutralization, HydrophilicityDocumento7 páginasSelf-Adhesive Resin Cements Ph-Neutralization, HydrophilicityCarolina Rodríguez RamírezAinda não há avaliações

- Reducing Malaria Infections in Sub-Saharan AfricaDocumento2 páginasReducing Malaria Infections in Sub-Saharan AfricaStansa SeniaAinda não há avaliações

- Load Summary for Premise Under 100kVADocumento2 páginasLoad Summary for Premise Under 100kVAMuhammad Zulhelmi ZawawiAinda não há avaliações

- Fall ProtectionDocumento5 páginasFall ProtectionAamir AliAinda não há avaliações

- Chapter 3 NotesDocumento10 páginasChapter 3 Notesmjamie12345Ainda não há avaliações

- Galapagos Penguins: Shelter, Niche and NeedsDocumento8 páginasGalapagos Penguins: Shelter, Niche and Needsjim munkAinda não há avaliações

- Barangay Peace and Order and Public Safety Plan Bpops Annex ADocumento3 páginasBarangay Peace and Order and Public Safety Plan Bpops Annex AImee CorreaAinda não há avaliações

- TLC Analysis of Siling Labuyo Extract ComponentsDocumento3 páginasTLC Analysis of Siling Labuyo Extract ComponentsJan Eric Balete0% (1)

- Chemistry Code No. 1/2 Set: 3 Time Allowed: 3 Hours Maximum Marks: 100 General InstructionsDocumento5 páginasChemistry Code No. 1/2 Set: 3 Time Allowed: 3 Hours Maximum Marks: 100 General InstructionsShalini KumariAinda não há avaliações

- JDP Rainbox Attenuation CratesDocumento6 páginasJDP Rainbox Attenuation CratesBerat DalyabrakAinda não há avaliações

- 4front Projects: BbbeeDocumento12 páginas4front Projects: BbbeeBrand Media OfficeAinda não há avaliações

- SureFlo RDocumento2 páginasSureFlo RKen NgAinda não há avaliações

- Food Regulations MalaysiaDocumento4 páginasFood Regulations MalaysiaSyafi'ie Syukri100% (1)

- Personal and Group Trainer Juan Carlos GonzalezDocumento2 páginasPersonal and Group Trainer Juan Carlos GonzalezDidier G PeñuelaAinda não há avaliações

- Smartphone Technician Cum App Tester: Trade PracticalDocumento218 páginasSmartphone Technician Cum App Tester: Trade PracticalF ZaidiAinda não há avaliações

- Deltair BrochureDocumento4 páginasDeltair BrochureForum PompieriiAinda não há avaliações

- 310 Ta PDFDocumento8 páginas310 Ta PDFVincent GomuliaAinda não há avaliações

- Makalah ThoughtDocumento5 páginasMakalah Thoughtifa safiraAinda não há avaliações

- Louise L HAY AffirmationsDocumento10 páginasLouise L HAY AffirmationsEvi Kutasi100% (2)