Escolar Documentos

Profissional Documentos

Cultura Documentos

United States Patent (191: Stiicker Et A) - Patent Number: Date of Patent: (1 1)

Enviado por

Balvinder SinghTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

United States Patent (191: Stiicker Et A) - Patent Number: Date of Patent: (1 1)

Enviado por

Balvinder SinghDireitos autorais:

Formatos disponíveis

United States Patent [191

[1 1]

[45]

Stiicker et a].

[54]

PRESSURE SWING ADSORPTION

CONTROL METHOD AND APPARATUS

[75] Inventors: Jiirg Stiicker, St. Stevens-Woluwe;

Michael Whysall, Wilrijk, both of

Belgium

[73] Assignee: Union Carbide Corporation,

Danbury, Conn.

55/163; 55/179

Field of Search ..................... .. 55/21, 26, 74, 163,

55/179

4/1965

3,703,068

11/1972

4,070,164

l/ 1978

Asztalos ......... ..

4,475,930

10/1984

Asztalos

4,693,730

9/1987

. .. . . . .

55/21

. . . . . ..

55/26

Miller et a1. ...................... .. 55/ 26 X

Primary Examiner-Kathleen J. Prunner

Attorney, Agent, or Firm-Morris N. Reinisch

ABSTRACT

for automatically controlling product repressurization

in a pressure swing adsorption (PSA) process. Accord

ing to the invention the same valve employed for with

drawing product from a bed during'adsorption is em

ployed to feed product gas to that bed during product

repressurization. This enables the elimination of several

improving system reliability. The same controllable

valve may also be used to control the pressure in the

Kiyonaga .............................. .. 55/26

Wagner . . . . . . . .

4,360,362 1 [/1982

valves, including a system-dependent valve, thereby

References Cited

U.S. PATENT DOCUMENTS

3,176,444

Aug. 2, 1988

The present invention provides a method and apparatus

Sep. 1, 1987

[22] Filed:

[51] Int. Cl.4 ............................................ .. B01D 53/04

[52] US. Cl. ......................................... .. 55/21; 55/26;

[56]

4,761,165

4,234,322 11/1980 De Meyer et a1. ............... .. 55/21 X

4,299,595 1 1/ 1981 Benkmann et al. ..

55/ 21

[57]

[21] Appl. No.: 91,889

[53]

Patent Number:

Date of Patent:

. . . . . ..

PSA system.

55/21

Miwa et al. ........................... .. 55/26

22 Claims, 4 Drawing Sheets

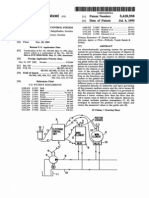

US. Patent

Aug. 2, 1988

Sheet 1 0f 4

A, "30

36

4,761,165

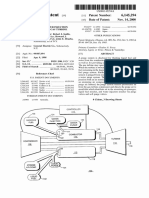

US. Patent

Aug. 2, 1988

Sheet 3 of4

4,761,165

4,761,165

must be removed due to valve failure. However, one

PRESSURE SWING ADSORPTION CONTROL

METHOD AND APPARATUS

BACKGROUND TO THE INVENTION

The present invention relates to control of a pressure

valve (namely, 101) is employed in product repressur

ization of all of the nine beds shown in FIG. 1. Thus,

should this valve fail, the whole unit would have to be

5 shut down.

There is a present need for a scheme which would

permit rearranging ?ow in a pressure swing adsorption

swing adsorption system; and, more particularly, to a

method and apparatus for controlling product repres

system to eliminate one or more valves, especially

where this is consistent with the need to maintain a

surization in a multi-bed system to improve system reli

ability.

10

Pressure swing adsorption (PSA) provides an ef?

substantially constant flow of product from the system.

Moreover, it would be especially desirable to have an

cient and economical means for separating a multicom

improved system which eliminated system-dependent

ponent gas stream containing at least two gases having

different adsorption characteristics. The more-strongly

valves, which, if they failed, could cause shutdown of

all beds of a multi-bed system.

adsorbable gas can be an impurity which is removed

from the less-strongly adsorbable gas which is taken off

as product; or, the more-strongly adsorbable gas can be .'

the desired product, which is separated from the less

strongly adsorbable gas. For example, it may be desired

to remove carbon monoxide and light hydrocarbons

from a hydrogen-containing feed stream to produce a

puri?ed (99+ %) hydrogen stream for a hydrocracking

or other catalytic process where these impurities could

adversely affect the catalyst or the reaction. On the

other hand, it may be desired to recover more-strongly

adsorbable gases, such as ethylene, from a feed to pro

duce an ethylene-rich product.

In pressure swing adsorption, a multicomponent gas

is typically fed to at least one of a plurality of adsorption

beds at an elevated pressure effective to adsorb at least

one component, while at least one other component

passes through. At a de?ned time, feed to the adsorber

is terminated and the bed is depressurized by one or

more cocurrent depressurization steps wherein pressure

is reduced to a de?ned level which permits the sepa

rated, less-strongly adsorbed component or components

remaining in the bed to be drawn off without signi?cant

concentration of the more-strongly adsorbed compo

SUMMARY OF THE INVENTION

The present invention provides such in a new method

and apparatus for controlling product repressurization

in a pressure swing adsorption system.

The process comprises: during product repressuriza

tion of a vessel, supplying product gas through a con

trollable valve at the outlet end of the vessel, the con

trollable valve being the same valve as employed to

release product gas from the vessel during the adsorp

tion step.

The apparatus comprises: a conduit connecting the

outlet end of a pressure swing adsorption vessel to a

product header for a multi-bed system; a positionable

valve in the conduit; and means for generating a control

signal to open the valve to permit ?ow from the prod

uct header during product repressurization and to per

mit ?ow of product from the vessel to the product

header during adsorption.

Both the method and apparatus provide signi?cant

advantages by eliminating at least one system-depend

ent valve and thereby improving reliability of opera

tion. Moreover, other advantages ?ow from implement

ing the invention in speci?c multi-bed con?gurations.

nents. Then, the bed is depressurized by a countercur

rent depressurization step wherein the pressure on the 40 For example, it is possible to eliminate a set of valves

bed is further reduced by withdrawing desorbed gas

countercurrently to the direction of feed. Finally, the

bed is purged and repressurized. The ?nal stage of re

pressurization is with product gas and is often referred

typically provided for ?rst pressure equalization, and to

then perform the ?rst equalization through either: (i)

available, idle valves provided for another equalization,

or (ii) through available valves for another equalization

to as product repressurization.

45 which normally takes place simultaneously, by per

forming two equalizations sequentially but within the

In multi-bed systems there are typically additional

time period normally employed for only one.

steps, and those noted above may be done in stages. U.S.

Pat. Nos. 3,176,444 to Kiyonaga, 3,986,849 to Fuderer

et a1, and 3,430,418 and 3,703,068 to Wagner, among

BRIEF DESCRIPTION OF THE DRAWINGS

others, describe multi-bed, adiabatic pressure swing 50 The invention will be better understood and its ad

adsorption systems employing both cocurrent and

vantages will become more apparent when the follow

countercurrent depressurization, and the disclosures of

ing detailed description is read with reference to the

these patents are incorporated by reference in their

accompanying drawings wherein:

entireties.

FIG. 1 is a schematic of a single adsorption bed show

Every adsorber in a multi-bed system (PSA unit) is

equipped with a plurality of valves operated by a cycle

controller. In addition to feed, product, and waste gas

valves, other valves are typically employed to enable

pressure equalizations between adsorbers. Pressure

swing adsorption in multi-bed systems remains essen

tially a batch process, simply cycling a number of beds

through a coordinated series of steps, and a number of

valves are idle at any given time.

Typically, there are valves in a PSA unit which, if

they fail, can cause shutdown of the entire unit. In U.S. 65

Pat. No. 4,234,322, De Meyer et al describe a PSA unit

ing representative adsorbed gas loading at various

stages of a single cycle of operation;

FIG. 2 is a graph showing a pressure pro?le of a

single adsorption bed for a single cycle of operation;

FIG. 3 is a schematic showing a four-bed PSA sys

tem; and

FIG. 4 is a chart showing a representative sequencing

of a four-bed PSA system through a complete cycle of

operation.

DETAILED DESCRIPTION

The pressure swing adsorption process is an essen

having at least eight phase staggered operated beds

tially adiabatic process for separating a multicomponent

which permits continued operation even where one bed

fluid containing at least one selectively-adsorbable com

4,761,165

ponent. FIG. 1 shows feed ?uid stream 10 comprising

which is controlled by controller 50 to achieve the rate

of ?ow desired at any given time.

It is preferred in most PSA units to provide a constant

an admixture of impurity and product ?uids, entering

adsorption zone 12 containing a bed 14 of adsorbent

material capable of selectively adsorbing the impurity

?ow of product gas from the system. This requires that

the flow of product gas from header 38 through valve

48 (or other valve associated with another vessel under

going product repressurization) be maintained at a con

from the feed ?uid stream.

The term impurity denotes the component or com

ponents which are more-strongly adsorbed in the pro

cess. Thus, the material described as impurity is not

stant rate. This can be accomplished in a number of

limited to a common de?nition of the term which de

ways. For example, as shown in FIG. 1, controller 50

notes something unwanted and to be discarded. The

can receive a signal from a pressure sensor P and con

term product denotes the less-strongly adsorbed ?uid

in the feed ?uid stream and does not necessarily mean

that this component is the desired component to which

the process is directed.

The bed, because of the packing of the adsorbent

material, contains non-selective voids. The feed ?uid

trol valve 48 in response thereto. By sensing the pres

sure in the vessel 14 undergoing product repressuriza

tion, and determining the difference between the sensed

value and the end pressure of product repressurization,

the ?ow can be effectively controlled.

Alternatively, the ?ow of product from the system

can be measured and the ?ow of product gas through

stream is introduced and contacted with the bed at an

inlet end 16 of the adsorption zone at a ?rst elevated

valve 48 to vessel 14 controlled in response thereto to

maintain the ?ow of product gas from the system at a

substantially constant rate.

pressure, thereby adsorbing the impurity in the adsor

bent material and trapping part of the product ?uid in

the voids. An impurity-depleted product ?uid 18 is

discharged from the opposite end 20 of the adsorption

Representative stage times for a single bed and associ

ated pressures for each stage are shown in FIG. 2.

Both the method and apparatus provide signi?cant

advantages by eliminating at least one system-depend

ent valve and thereby improving reliability of opera

tion. Moreover, other advantages ?ow from implement

ing the invention in speci?c multi-bed con?gurations.

zone.

As feed to the bed progresses, an impurity adsorption

front is established at the inlet end of the adsorption

zone and progressively moves_longitudinally through

the adsorption zone toward the discharge end to a pre

determined level 22

the zone. The introduction

For example, it is possible to eliminate a set of valves

of the feed ?uid is then terminated.

30 typically provided for ?rst pressure equalization, and to

The product ?uid trapped in the voids is then re

then perform the ?rst equalization through either: (i)

available, idle valves provided for another equalization,

moved through the discharge end 20 of the adsorption

zone by cocurrently depressurizing the adsorption zone

vated pressure. This cocurrent depressurization causes

or (ii) through available valves for another equalization

which normally takes place simultaneously, by per

forming two equalizations sequentially but within the

the impurity adsorption front to advance toward the

time period normally employed for only one.

discharge end of the bed to a new level 26. Preferably,

A further advantage is that product pressure, e. g., the

pressure of the ?nal product stream from the system,

can be effectively controlled. For example, because the

system product pressure is dependent on the pressure of

from the ?rst elevated pressure to a lower but still ele

one or more intermediate steps of pressure equalization

are comprised in cocurrent depressurization to bring the

front to level 24, with the ?nal stage of cocurrent de

pressurization advancing the front to level 26. In multi

bed systems the cocurrent depressurization stage also

provides purge gas to a bed undergoing regeneration.

Thus, this step can be termed a provide purge step and

is so referred to in FIG. 4.

Following cocurrent depressurization, the adsorption

zone is desorbed countercurrently to the direction of

feed by further decreasing the pressure in the bed and

withdrawing desorbed gas at 16. This step brings the

product ?owing from any bed undergoing adsorption

45

and the pressure of any product being utilized for prod

uct repressurization, it is possible by controlling the rate

of ?ow to the vessel undergoing product repressuriza

tion, to control system product pressure.

EXAMPLE

This Example describes the operation of a four-bed

pressure adsorption system as shown in FIG. 3 for puri

front to level 28. The bed is purged with cocurrent 50 ?cation of a hydrogen-rich gas stream from a steam

reformer (typically, on a molar basis, 75% hydrogen,

depressurization effluent from another bed, or purged

with pure product, to bring the front to level 30.

Prior to employing the vessel for another adsorption

4% methane, 3% carbon monoxide, 0.5% nitrogen,

the second stage, product repressurization, product gas

cycle.

alone is supplied to the vessel. According to the inven

This process can be performed with any suitable

adsorbent, such as zeolitic molecular sieves, activated

carbon, silica gel, activated alumina, and the like, as set

with the balance being carbon dioxide, and being satu

step, it must be repressurized to avoid damage to the

rated with water) to produce 99+ mole percent hydro

bed. Repressurization is typically conducted in two 55 gen, with minimal, e.g., less than 10 parts per million,

principal stages. In the ?rst, void space gas from a vessel

concentration of carbon monoxide. The invention is,

undergoing cocurrent depressurization is supplied until

however, applicable to other multi-bed systems and can

the pressure in the two vessels is equalized. This is

be employed also where the more-strongly adsorbed

termed pressure equalization and can be accomplished

gas is the product gas.

in several steps with void space gas from several vessels

Each of the four beds will have a lower layer of

supplied at sequencially increasing pressures. In the

activated carbon and an upper layer of zeolite and un

?nal equalization, product gas may also be supplied. In

dergoes each of the noted stages through a complete

tion, product gas is supplied to the vessel 14 through the

same valve, namely controllable valve 48, employed to

withdraw product gas during the adsorption step.

Valve 48 is preferably a continuously positionable valve

forth in the above-referenced Kiyonaga patent, having

a selectivity for the impurity over the product ?uid.

4,761,165

FIG. 4 is a chart showing the direction of flow within

purges adsorber B and flows out, together with de

each of the beds shown in FIG. 3 during each of the

sorbed impurities, through valves 4B and 37. The purge

stages of the cycle and the sequencing of all of the beds

stops when the termination pressure for cocurrent de

through one complete cycle of adsorption and regener

pressurization is reached. See FIG. 2 for example. Dur

ation.

ing this stage the impurity front advances towards the

FIG. 4 is based on a 15-minute cycle time. Cycle time

top of the depressunizing adsorber (e. g., level 26 in FIG.

is de?ned as the time that is required for all four adsorb

1).

ers to go through a complete cycle of adsorption and

Time Period 4

regeneration. FIG. 4 describes in detail the twelve time

periods that each adsorber goes through during one 10 (a) Simultaneously, valves 1D and 2D open to begin

complete cycle. A single process step may cover several

adsorption in adsorber D while valves 1A and 2A close

time periods. The graph in FIG. 2 shows representative

to stop adsorption in adsorber A.

pressures versus time for each step in the cycle for a

(b) Valves 3A and 3B open to begin equalization from

single adsorber. In the following description, unless the

adsorber A to adsorber B.

valves are indicated as being open, they are closed.

(0) Part of the product ?ow is diverted from product

header 138 through valve 2B for product repressuriza

Time Period 1

(a) Simultaneously, valves 1A and 2A open to begin

adsorption in adsorber A while valves 1C and 2C close

tion of adsorber B.

(d) Valves 4C and 37 open to begin blowdown of

adsorber C.

to stop adsorption in adsorber C.

Time Period 5

(b) Valves 3C and 3D open to begin equalization

from adsorber C to adsorber D. During pressure equal

(a) Adsorber D continues adsorption.

ization, adsorber C is depressurized cocurrently

(b) Adsorber C continues blowdown.

through valve 3C to an intermediate pressure. The gas

released ?ows directly to adsorber D undergoing re

(c) Valve 3A closes ending equalization between

adsorbers A and B. Adsorber A remains in a hold condi

pressurization (see FIGS. 3 and 4) to provide gas for

partial repressurization of that adsorber. Valve 2D is

partially open to allow product gas produced from

tion through the rest of the step.

(d) Adsorber B continues product repressurization.

adsorber A to ?ow into adsorber D at a controlled rate.

This rate will be controlled by controller 150 as a func 3O

Time Period 6

tion of the pressure measured in vessel D by the pres

sure sensor P associated with it. The impurity front

(a) Adsorber D continues adsorption.

(b) Adsorber B continues product repressurization.

(c) Adsorber C is purged by the effluent from cocur

advances during this step, e.g., to a degree represented

as level 24 in FIG. 1. During this repressurization stage,

rent depressurization of adsorber A. Adsorber A pro

vides clean hydrogen gas through valves 3A and 3C.

, adsorber D is repressurized from two sources of hydro 35 The clean hydrogen gas purges adsorber C and flows

gen:

out through valves 4C and 37.

(1) Pressure equalization with gas from vessel C as

(d) Adsorber A provides purge gas until the pressure

described in (b) above; and

drops to the cocurrent termination pressure.

(2) Also with-product gas according to the invention

Time Period 7

through a continuously positionable valve 2D.

(0) Valves 4B and 37 open to begin the countercur

(a) Simultaneously, valves 1B and 2B open to begin

rent depressurization (blowdown) step of adsorber B.

adsorption in adsorber B while valves 1D and 2D close

During blowdown, the adsorber is depressurized out of

to stop adsorption in adsorber D.

the bottom of the vessel (countercurrently) through

(b) Valves 3C and 3D open to begin equalization

valves 4B and 37 to waste stream pressure. Impurities 45 from adsorber D to adsorber C.

are desorbed and vented, and the impurity front drops,

say proportional to level 28 in FIG. 1.

(0) Part of the product flow is diverted from product

header 138 through valve 2C for product repressuriza

tion of adsorber C.

(d) Valves 4A and 37 open to begin the blowdown

step of adsorber A.

Time Period 2

(a) Adsorber A continues adsorption.

(b) Adsorber B continues blowdown.

Time Period 8

(c) Valve 3C closes, ending equalization between

adsorbers C and D. Adsorber C remains in a hold condi

(a) Adsorber B continues adsorption.

tion through the rest of the step.

(d) Adsorber D continues product repressurization

through valve 2D, the rate being controlled by adjust

ment of valve 2D in response to the pressure measured

in vessel D. Preset conditions and sensed pressure in line

138 can also be employed to control valve 2D.

(b) Adsorber A continues blowdown.

55

(c) Valve 3D closes ending equalization between

adsorbers D and C. Adsorber D remains in a hold con

dition through the rest of the step.

(d) Adsorber C continues product repressurization.

Time Period 9

Time Period 3

(a) Adsorber B continues adsorption.

(b) Adsorber C continues product depressurization.

(c) Adsorber A is purged by adsorber D. Adsorber D

provides clean hydrogen gas through valves 3D and

(a) Adsorber A continues adsorption.

(b) Adsorber D continues product repressurization

through valve 2D.

(c) Adsorber B is purged by the effluent from the last 65 3A. The clean hydrogen gas purges adsorber A and

stage of cocurrent depressurization of adsorber C. Ad

sorber C provides essentially clean hydrogen gas

through valves 3C and 3B. The clean hydrogen gas

?ows out through valves 4A and 37.

(d) Adsorber D provides purge gas until the pressure

drops to the cocurrent termination pressure.

4,761,165

5. A pressure swing adsorption process employing a

Time Period 10

plurality of pressure swing adsorption vessels, each

(a) Simultaneously, valves 1C and 2C open to begin

containing an adsorbent and void space, comprising:

adsorption in adsorber C while valves 1B and 2B close

to stop adsorption in adsorber B.

(b) Valves 3A and 3B open to begin equalization from

swing adsorption vessel at a ?rst elevated pressure

supplying feed ?uid to a feed end of a ?rst pressure

while withdrawing product gas through a continuously

adsorber B to adsorber A.

tion of adsorber A.

positionable valve from a discharge end of said ?rst

vessel; terminating supply of feed to said ?rst vessel;

withdrawing void space product from said ?rst vessel

and (i) for a ?rst period, supplying said void space prod

(d) Valves 4D and 37 open to begin the blowdown

step of adsorber D.

uct to a second pressure swing adsorption vessel at an

elevated pressure lower than that of said ?rst vessel to

(0) Part of the product ?ow is diverted from product

header 138 through valve 2A for product repressuriza

Time Period 11

(a) Adsorber C continues adsorption.

(b) Adsorber D continues blowdown.

(c) Valve 3B closes ending equalization between ad

equalize its pressure with said ?rst vessel, and (ii) for a

later period, supplying said void space product to a

15 further pressure swing adsorption vessel at a still lower

but elevated pressure to purge said later vessel of impu

rities; purging said ?rst vessel of impurities; partially

sorbers B and A. Adsorber B remains in a hold condi

repressurizing said ?rst vessel to a second elevated pres

sure; and product repressurizing said ?rst vessel to said

tion through the rest of the step.

(d) Adsorber A continues product repressurization.

Time Period 12

20

first elevated pressure by supplying product gas

through said valve previously employed to withdraw

product gas therefrom.

(a) Adsorber C continues adsorption.

6. A process according to claim 5 wherein at least

(b) Adsorber A continues product pressurization.

three adsorption vessels are operated as a system to

(c) Adsorber D is purged by adsorber B. Adsorber B 25 obtain a constant ?ow of product gas from a common

provides clean hydrogen gas through valves 3B and 3D.

product gas header which receives product gas from

The clean hydrogen gas purges adsorbes D and ?ows each of the vessels.

Oll

song V V68

an

(d) Adsorber B provides purge gas until the pressure

drops to the cocurrent termination pressure. At the end

of time period 12, the system returns to time period 1

and the cycle is repeated.

The above description is for the purpose of teaching

the person of ordinary skill in the art how to practice

the present invention, and it is not intended to detail all

those obvious modi?cations and variations of it which

will become apparent to the skilled worker upon read

ing the description. It is intended, however, that all such

. A process accorcimg to ciaim 4 w erein said con

stant flow of product gas is controlled, during product

repressurization of said ?rst vessel, by: sensing the pres

sure within said ?rst vessel undergoing product repres

surization, and controlling the feed of product gas to

said ?rst vessel through said continuously positionable

valve at a substantially constant rate in response to

sensed pressure.

8. A process according to claim 6 wherein said con

stant ?ow of product gas is controlled, during product

repressurization of said ?rst vessel, by: sensing the ?ow

obvious modi?cations and variations be included within

of product gas from said system; and varying ?ow to

the scope of the present invention which is de?ned by 40 said ?rst vessel during product repressurization through

the following claims.

said continuously positionable valve in response to the

We claim:

1. A process for controlling product repressurization

sensed value.

9. A process according to claim 5 which further in

in a pressure swing adsorption vessel of a multi-bed

cludes at least one subsequent pressure equalization step

pressure adsorption system, comprising:

following said ?rst period.

supplying product gas to said vessel for product re

10. In an adiabatic pressure swing adsorption process

pressurization through a controllable valve at the

for separating a gas mixture by adsorbing at least one

outlet end of said vessel, said valve being the same

gas component in each of a plurality of adsorbent beds,

as also employed to release product gas from said

wherein each of the adsorbent beds is cyclically oper

vessel during an adsorption step; and

50 ated in subsequent operation steps including adsorption;

controlling the rate of supply by adjusting said valve.

at least two depressurization steps; countercurrent

2. A process according to claim 1 wherein product

purging; and at least two repressurization steps, at least

?ow from the system is maintained substantially con

the ?nal one being product repressurization; the im

stant by maintaining a constant How of product to said

provement comprising: during product repressurization

vessel undergoing product repressurization.

55 of a vessel, supplying product gas through a controlla

3. A process according to claim 2 wherein constant

ble valve at the outlet end of the vessel, the controllable

flow to said vessel undergoing product repressurization

valve being the same valve as employed to release prod

is maintained by: sensing the pressure within said vessel

uct gas from the vessel during the adsorption step.

11. An apparatus for controlling product repressur

the rate of product gas supplied to said vessel undergo 60 ization of a designated pressure swing adsorption vessel

undergoing product repressurization; and controlling

ing product repressurization through said controllable

valve in response to said pressure.

4. A process according to claim 2 wherein constant

of a multi-bed pressure adsorption system of the type

wherein each vessel encloses a bed comprising adsor

bent and void space and has a feed end in communica

flow to said vessel undergoing product repressurization

tion with a feed header and an outlet end in communica

is maintained by: sensing the flow of product gas from 65 tion with a system product header, and wherein each

said system; and varying ?ow to said vessel undergoing

bed is cycled through the steps of adsorption; cocurrent

product repressurization through said controllable

depressurization, during which void space product gas

valve in rPqnnncP m ?u: Q??c?f] value:

is FAA

4m Ana nam- LAA

PA.- ................ A-..-l:_-:__.

__

4,761,165

10

vide purge, wherein void space product gas is fed to

during product repressurization and to permit ?ow

another bed undergoing purge; countercurrent depres

surization; purge; and repressurization, which includes

pressure equalization with void space product received

of product from said vessel to said product header

?nal product pressurization; said apparatus comprising:

vessel undergoing product repressurization; and means

for controlling said continuously positionable valve in

during adsorption.

19. An apparatus according to claim 18 which further

from a bed undergoing cocurrent depressurization and 5 includes: means for sensing the pressure within said

a conduit connecting said outlet end of said desig

nated vessel to said product header;

response to said means for sensing said pressure.

20. An apparatus according to claim 18 which further

a controllable valve in said conduit; and

means for controlling said valve to permit flow to

includes: means for sensing the ?ow of product gas

from said system; and means for controlling said contin

uously positionable valve in response to said means for

sensing said ?ow.

21. An apparatus for controlling product repressur

ization in a pressure swing adsorption vessel of a multi

bed pressure adsorption system, said vessel having an

inlet end and an outlet end, said apparatus comprising:

said designated vessel during product repressuriza

tion and to permit ?ow therefrom during adsorp

tion.

12. An apparatus according to claim 11, further com

prising means for maintaining substantially constant

product ?ow from said system.

13. An apparatus according to claim 12 including

means for maintaining constant flow of product to a

vessel undergoing product repressurization.

14. An apparatus according to claim 13 wherein said 20

means for maintaining constant ?ow of product to a

a conduit connecting said outlet end of said vessel to

a product header for said system;

a continuously positionable valve in said conduit;

means for generating a control signal to open said

vessel undergoing product repressurization comprise:

valve to permit flow from said product header

means for sensing the pressure within said vessel under

during product repressurization and to permit ?ow

going product repressurization; and means for control

ling said controllable valve in response to said means for 25

sensing said pressure.

of product from said vessel to said product header

during adsorption;

'

means for sensing the pressure within said vessel

15. An apparatus according to claim 13 wherein said

undergoing product repressurization; and

means for maintaining constant ?ow of product to a

means for controlling said continuously positionable

vessel undergoing product repressurization comprise:

valve in response to said means for sensing said

means for sensing the ?ow of product gas from said 30

pressure.

system; and means for controlling said controllable

22. An apparatus for controlling product repressur

valve in response to said means for sensing said ?ow.

ization in a pressure swing adsorption vessel of a multi

16. An apparatus according to claim 13 wherein said

bed pressure adsorption system, said vessel having an

controllable valve is a continuously positionable valve.

17. An apparatus according to claim 11 which further 35 inlet end and an outlet end, said apparatus comprising:

a conduit connecting said outlet end of said vessel to

includes means for controlling the cocurrent depressuri

a product header for said system;

zation of each vessel to provide a first pressure equaliza

tion directly followed by a second pressure equaliza

a continuously positionable valve in said conduit;

means for generating a control signal to open said

tion, both preceding providing purge for a bed undergo

ing purge.

18. An apparatus for controlling product repressur

valve to permit ?ow from said product header

during product repressurization and to permit ?ow

ization in a pressure swing adsorption vessel of a multi

bed pressure adsorption system, said vessel having an

inlet end and an outlet end, said apparatus comprising:

a conduit connecting said outlet end of said vessel to 45

a product header for said system;

a continuously positionable valve in said conduit; and

means for generating a control signal to open said

valve to permit ?ow from said product header

50

55

65

of product from said vessel to said product header

during adsorption;

means for sensing the ?ow of product gas from said

system; and

means for controlling said continuously positionable

valve in response to said means for sensing said

?ow.

*

It

1k

Você também pode gostar

- Prevention of Actuator Emissions in the Oil and Gas IndustryNo EverandPrevention of Actuator Emissions in the Oil and Gas IndustryAinda não há avaliações

- Advances in PSADocumento14 páginasAdvances in PSAmichaelpardoAinda não há avaliações

- Sucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingNo EverandSucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingNota: 5 de 5 estrelas5/5 (9)

- Valves & Flare StackDocumento9 páginasValves & Flare Stackrezad100% (1)

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsAinda não há avaliações

- Method 27Documento6 páginasMethod 27sheeva SHAinda não há avaliações

- Flowmeter DEMONSTRATIONDocumento20 páginasFlowmeter DEMONSTRATIONAfiq IkhwanAinda não há avaliações

- TP201.3A Determination of 5 Inch WC Static Pressure Performance of Vapor Recovery Systems of Dispensing FacilitiesDocumento10 páginasTP201.3A Determination of 5 Inch WC Static Pressure Performance of Vapor Recovery Systems of Dispensing FacilitiesCésar Oswaldo Aguilera OjedaAinda não há avaliações

- Unlted States Piltgilt (19) (11) Patent Number: 5,428,958: Stenlund (45) Date of Patent: Jul. 4, 1995Documento6 páginasUnlted States Piltgilt (19) (11) Patent Number: 5,428,958: Stenlund (45) Date of Patent: Jul. 4, 1995ZEUJAinda não há avaliações

- The Basic Anaesthetic MachineDocumento6 páginasThe Basic Anaesthetic Machineluis7lobato-2100% (1)

- Method 27 - Determination of Vapour TightnessDocumento11 páginasMethod 27 - Determination of Vapour TightnessGeorge NicolaidesAinda não há avaliações

- Feeding Devices: Fee FilterDocumento36 páginasFeeding Devices: Fee FilterPintasssAinda não há avaliações

- KingiiDocumento14 páginasKingiiSteven CollinsAinda não há avaliações

- Effectively Control Column PressureDocumento12 páginasEffectively Control Column Pressureromdhan88Ainda não há avaliações

- DryPipeSystems RevDocumento24 páginasDryPipeSystems RevCostel BalasoiuAinda não há avaliações

- Liquid Level Control PDFDocumento8 páginasLiquid Level Control PDFEfosaUwaifoAinda não há avaliações

- Surface Sampling of Reservoir FluidsDocumento6 páginasSurface Sampling of Reservoir FluidsMuhammad MufarridAinda não há avaliações

- Basics of VacuumDocumento7 páginasBasics of Vacuumsanthosh_yash1Ainda não há avaliações

- Procedure PSVDocumento24 páginasProcedure PSVAbakar MahamatAinda não há avaliações

- Techniques For Natural Gas SamplingDocumento5 páginasTechniques For Natural Gas Samplingmicroco4Ainda não há avaliações

- United States Patent (19) (111 4,230,151: Jonsson (45) Oct. 28, 1980Documento8 páginasUnited States Patent (19) (111 4,230,151: Jonsson (45) Oct. 28, 1980Stanislas AchardAinda não há avaliações

- Industrial Plant For Distillation of Sulphate TurpentineDocumento5 páginasIndustrial Plant For Distillation of Sulphate TurpentineDaniel YoworldAinda não há avaliações

- Industrial Plant For Distillation of Sulphate TurpentineDocumento5 páginasIndustrial Plant For Distillation of Sulphate TurpentineDaniel YoworldAinda não há avaliações

- Book04 - Supp ProcessDocumento6 páginasBook04 - Supp ProcessShau WilliamAinda não há avaliações

- Vacuum TheoryDocumento79 páginasVacuum TheoryrusyadAinda não há avaliações

- Membrane Filter Tester Instruction Manual: Part No. 396460 Rev. BDocumento23 páginasMembrane Filter Tester Instruction Manual: Part No. 396460 Rev. BWajid NizamiAinda não há avaliações

- Psa Operating ManualDocumento68 páginasPsa Operating Manualgautam_9694806975% (4)

- 7.3 Single-Column Rapid PSA SystemDocumento2 páginas7.3 Single-Column Rapid PSA Systemnobita18tAinda não há avaliações

- Troubleshooting FCC Circulation ProblemsDocumento6 páginasTroubleshooting FCC Circulation ProblemsLefter RinaldoAinda não há avaliações

- Dynamic Testing of CheckvalveDocumento10 páginasDynamic Testing of Checkvalveamirthraj74Ainda não há avaliações

- Relief Valve: Flare Header or Relief Header To A Central, Elevated Gas Flare Where It Is UsuallyDocumento3 páginasRelief Valve: Flare Header or Relief Header To A Central, Elevated Gas Flare Where It Is UsuallyKhaled RabeaAinda não há avaliações

- AerosolsDocumento29 páginasAerosolsKulbhushan SharmaAinda não há avaliações

- Bypass Control Valve: Special Features and ControlsDocumento13 páginasBypass Control Valve: Special Features and ControlsBrain J PérezAinda não há avaliações

- AerosolsDocumento31 páginasAerosolsArun PrasadAinda não há avaliações

- Tank Blanketing BasicsDocumento4 páginasTank Blanketing BasicsOmkar VazeAinda não há avaliações

- Relief Valves and Relief SystemsDocumento10 páginasRelief Valves and Relief Systemsmatteo2009Ainda não há avaliações

- Turbine Gland Seal Steam SystemDocumento15 páginasTurbine Gland Seal Steam SystemFahad Khalil75% (8)

- United States Patent (19) : (75) Inventor: Donald J. Hirz, Willowick, OhioDocumento9 páginasUnited States Patent (19) : (75) Inventor: Donald J. Hirz, Willowick, OhioMustafa ŞENAinda não há avaliações

- Pneumatic Test Checklist in Plants and Refinery ProjectsDocumento4 páginasPneumatic Test Checklist in Plants and Refinery Projectsmanoj thakkarAinda não há avaliações

- Pressure Safety ValvesDocumento15 páginasPressure Safety Valvesh_abdullah100% (2)

- Ep1005656b1 Fluid Sample Testing SystemDocumento27 páginasEp1005656b1 Fluid Sample Testing Systemzweisteine777Ainda não há avaliações

- Control Valve Actuators and PositionersDocumento23 páginasControl Valve Actuators and PositionersPg LisenAinda não há avaliações

- Manual Cm-760 - 780 InglesDocumento121 páginasManual Cm-760 - 780 InglesULISCHAP100% (1)

- Determination of 2 Inch WC Static Pressure Performance of Vapor Recovery Systems of Dispensing FacilitiesDocumento18 páginasDetermination of 2 Inch WC Static Pressure Performance of Vapor Recovery Systems of Dispensing FacilitiesEduardo N GanizaAinda não há avaliações

- Midterm - Unit OpsDocumento19 páginasMidterm - Unit OpsKrizzia Anne ShengAinda não há avaliações

- SJV Selection EjectorsDocumento9 páginasSJV Selection Ejectorskumarvns111Ainda não há avaliações

- Us8512443 PDFDocumento12 páginasUs8512443 PDFdollarrbillAinda não há avaliações

- 413 Impurities Testing in MedicalDocumento2 páginas413 Impurities Testing in MedicalIsmail MathakiyaAinda não há avaliações

- Level TransmitterDocumento16 páginasLevel Transmitterstolen mechieduc100% (2)

- United States PatentDocumento5 páginasUnited States PatentPraveen SinghAinda não há avaliações

- Vacuum Regulation and Its Application in Dairy FARMING ..: Mr. Amal SibiDocumento21 páginasVacuum Regulation and Its Application in Dairy FARMING ..: Mr. Amal SibiArjun CAAinda não há avaliações

- Test de Impuerzas en Gases MedicinalesDocumento2 páginasTest de Impuerzas en Gases MedicinalesCristina Piñeres GonzalezAinda não há avaliações

- Spe-104202-Pa-P (1) - 2 MarzoDocumento6 páginasSpe-104202-Pa-P (1) - 2 MarzodanonninoAinda não há avaliações

- Pneumatic Conveying - GJ74, HauckDocumento6 páginasPneumatic Conveying - GJ74, Hauckjfejfe100% (1)

- 1.00 Manual Filter Press APIDocumento14 páginas1.00 Manual Filter Press APIMarcos IdemsmoisAinda não há avaliações

- Ce422l E5 4eg2Documento5 páginasCe422l E5 4eg2Christine Joyce A. CortezAinda não há avaliações

- United States Patent (19) (11) Patent Number: 6,145,294: Traver Et Al. (45) Date of Patent: Nov. 14, 2000Documento9 páginasUnited States Patent (19) (11) Patent Number: 6,145,294: Traver Et Al. (45) Date of Patent: Nov. 14, 2000Siva SubramaniyanAinda não há avaliações

- Design and Calculation of The Pressure Relief ValvesDocumento53 páginasDesign and Calculation of The Pressure Relief Valvesghassan hamadAinda não há avaliações

- BSEE Test ProcedureDocumento35 páginasBSEE Test ProcedureNatraji100% (2)

- Bio RefiningDocumento119 páginasBio RefiningBalvinder SinghAinda não há avaliações

- Succinic AcidKarya IlmiahDocumento10 páginasSuccinic AcidKarya IlmiahAnbibie FanggreaAinda não há avaliações

- E Coli Metabolica PDFDocumento98 páginasE Coli Metabolica PDFCarmen HaleAinda não há avaliações

- Separation & Purification of Crude GlycerolDocumento19 páginasSeparation & Purification of Crude GlycerolBalvinder SinghAinda não há avaliações

- Succinic AcidKarya IlmiahDocumento10 páginasSuccinic AcidKarya IlmiahAnbibie FanggreaAinda não há avaliações

- 18 Funny Facts About EngineersDocumento3 páginas18 Funny Facts About EngineersBalvinder SinghAinda não há avaliações

- A Comparative Evaluation of Physical and Chemical Properties of Biodiesel Synthesized From Edible and Non-Edible Oils and Study On The Effect of Biodiesel Blendinge EvaluationDocumento9 páginasA Comparative Evaluation of Physical and Chemical Properties of Biodiesel Synthesized From Edible and Non-Edible Oils and Study On The Effect of Biodiesel Blendinge EvaluationDr. Abdelaziz AtabaniAinda não há avaliações

- Feed Forward ControlDocumento19 páginasFeed Forward Controlsujithadharani9813Ainda não há avaliações

- Chapter 3Documento20 páginasChapter 3Balvinder SinghAinda não há avaliações

- Energies: Microbial Conversion of Waste Glycerol From Biodiesel Production Into Value-Added ProductsDocumento30 páginasEnergies: Microbial Conversion of Waste Glycerol From Biodiesel Production Into Value-Added ProductsAdrian StanAinda não há avaliações

- Diffusion: D. Crowley, 2007Documento10 páginasDiffusion: D. Crowley, 2007Balvinder SinghAinda não há avaliações

- LipaseDocumento10 páginasLipaseKoshal JadonAinda não há avaliações

- 2010 - Garrido-Ramirez Et Al - Clays and Oxide Minerals As Catalysts and Nanocatalysts in FentonDocumento11 páginas2010 - Garrido-Ramirez Et Al - Clays and Oxide Minerals As Catalysts and Nanocatalysts in FentonSoumyabrata TewaryAinda não há avaliações

- Book of Abstracts: 14 Symposium Novel Technologies and Economic Development"Documento5 páginasBook of Abstracts: 14 Symposium Novel Technologies and Economic Development"Olivera StamenkovicAinda não há avaliações

- Stearic Acid 1Documento4 páginasStearic Acid 1Mira FazziraAinda não há avaliações

- 1 s2.0 S0920586105008722 MainDocumento5 páginas1 s2.0 S0920586105008722 MainMohammad Siddiq JalilAinda não há avaliações

- Dynamic Operation of Chemical Reactors Friend or FoeDocumento9 páginasDynamic Operation of Chemical Reactors Friend or FoeSteve Wan100% (1)

- Dehkordi Et Al, 2008Documento11 páginasDehkordi Et Al, 2008jair salcedoAinda não há avaliações

- Factors Affecting Reaction RatesDocumento9 páginasFactors Affecting Reaction Ratesscsa31619Ainda não há avaliações

- Activated Carbon: For Catalyst SupportDocumento4 páginasActivated Carbon: For Catalyst SupportScott McLeanAinda não há avaliações

- Contents of Volume: Number 1Documento1.055 páginasContents of Volume: Number 1Sveti JeronimAinda não há avaliações

- DSGHRTHDDocumento12 páginasDSGHRTHDMary Grace VelitarioAinda não há avaliações

- Enzymes IntroDocumento33 páginasEnzymes IntropragyasimsAinda não há avaliações

- E. Dickson Ozokwelu.2014.TOLUENE - Kirk-Othmer Encyclopedia of Chemical Technology.Documento24 páginasE. Dickson Ozokwelu.2014.TOLUENE - Kirk-Othmer Encyclopedia of Chemical Technology.Tissa Novida Aulia ZahraAinda não há avaliações

- Asigación 1 - Equipo 2 - Sustancia 8Documento42 páginasAsigación 1 - Equipo 2 - Sustancia 8Andrea López BedoyaAinda não há avaliações

- Acryllonitrile UllmannDocumento10 páginasAcryllonitrile UllmannZek ZhangAinda não há avaliações

- SRMJEEE 2023 Sample PapersDocumento115 páginasSRMJEEE 2023 Sample PapersShreshtha JaiswalAinda não há avaliações

- 20.1999.kinetic and Catalytic Aspects in The Hydrogen Peroxide Production Via AnthraquinoneDocumento8 páginas20.1999.kinetic and Catalytic Aspects in The Hydrogen Peroxide Production Via AnthraquinonesophixAinda não há avaliações

- 5 Enzymes: 0610 BiologyDocumento9 páginas5 Enzymes: 0610 BiologyAbdul HadiAinda não há avaliações

- (NagpurStudents - Org) Chemical Reactor DesignDocumento4 páginas(NagpurStudents - Org) Chemical Reactor Designsiddharth sharmaAinda não há avaliações

- Lec29 NonanimatedgfdsaDocumento54 páginasLec29 NonanimatedgfdsaTysir SarhanAinda não há avaliações

- Tetrabutylammonium IodideDocumento5 páginasTetrabutylammonium IodideVân Tú NguyễnAinda não há avaliações

- CH-08 - Introduction To Chemical KineticsDocumento5 páginasCH-08 - Introduction To Chemical KineticsAwais AliAinda não há avaliações

- A Literature Survey On Chan-Evans-Lam Protocol For Cross-Coupling Reaction and Its Modifications and Extensions With Applications.Documento41 páginasA Literature Survey On Chan-Evans-Lam Protocol For Cross-Coupling Reaction and Its Modifications and Extensions With Applications.Debashish DasAinda não há avaliações

- Jet Force Manual GBDocumento46 páginasJet Force Manual GBAntal LeventeAinda não há avaliações

- The Chemistry of Process Development in Pharmaceutical Industry 1Documento60 páginasThe Chemistry of Process Development in Pharmaceutical Industry 1Venugopal Rao Veeramaneni100% (1)

- Dioxygen Activation by Nonheme Iron Enzymes With The 2 His 1 Carboxylate Facial Triad That Generate High Valent Oxoiron OxidantsDocumento27 páginasDioxygen Activation by Nonheme Iron Enzymes With The 2 His 1 Carboxylate Facial Triad That Generate High Valent Oxoiron OxidantsCarlotaAinda não há avaliações

- Solution Infiltration of Palladium Into MOF-5: Synthesis, Physisorption and Catalytic Properties (Documento6 páginasSolution Infiltration of Palladium Into MOF-5: Synthesis, Physisorption and Catalytic Properties (BreenteeAinda não há avaliações

- Chapter 1 Feasibility StudyDocumento102 páginasChapter 1 Feasibility Studyolescoot67% (3)

- Kinetics of Alkaline Hydrolysis of Ethyl Acetate by Conductometric Measurement Approach Over Temperature Ranges (298.15-343.15K)Documento11 páginasKinetics of Alkaline Hydrolysis of Ethyl Acetate by Conductometric Measurement Approach Over Temperature Ranges (298.15-343.15K)Mohammad Kh100% (1)

- Catalytic ConvertersDocumento3 páginasCatalytic Convertersstardustmoonlight18Ainda não há avaliações

- Practical Reservoir Engineering and CharacterizationNo EverandPractical Reservoir Engineering and CharacterizationNota: 4.5 de 5 estrelas4.5/5 (3)

- Pocket Guide to Flanges, Fittings, and Piping DataNo EverandPocket Guide to Flanges, Fittings, and Piping DataNota: 3.5 de 5 estrelas3.5/5 (22)

- Flow Analysis for Hydrocarbon Pipeline EngineeringNo EverandFlow Analysis for Hydrocarbon Pipeline EngineeringAinda não há avaliações

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesNo EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesNota: 4 de 5 estrelas4/5 (2)

- Fundamentals and Applications of Bionic Drilling FluidsNo EverandFundamentals and Applications of Bionic Drilling FluidsAinda não há avaliações

- Well Control for Completions and InterventionsNo EverandWell Control for Completions and InterventionsNota: 4 de 5 estrelas4/5 (10)

- Abrasive Water Jet Perforation and Multi-Stage FracturingNo EverandAbrasive Water Jet Perforation and Multi-Stage FracturingAinda não há avaliações

- Machine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsNo EverandMachine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsNota: 4 de 5 estrelas4/5 (4)

- Casing and Liners for Drilling and Completion: Design and ApplicationNo EverandCasing and Liners for Drilling and Completion: Design and ApplicationNota: 5 de 5 estrelas5/5 (3)

- Well Testing Project Management: Onshore and Offshore OperationsNo EverandWell Testing Project Management: Onshore and Offshore OperationsAinda não há avaliações

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesNo EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesAinda não há avaliações

- Guide to the Practical Use of Chemicals in Refineries and PipelinesNo EverandGuide to the Practical Use of Chemicals in Refineries and PipelinesNota: 5 de 5 estrelas5/5 (1)

- The Petroleum Engineering Handbook: Sustainable Operations: Sustainable OperationsNo EverandThe Petroleum Engineering Handbook: Sustainable Operations: Sustainable OperationsNota: 3.5 de 5 estrelas3.5/5 (5)

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsNo EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsNota: 4 de 5 estrelas4/5 (6)

- Petroleum Production Engineering, A Computer-Assisted ApproachNo EverandPetroleum Production Engineering, A Computer-Assisted ApproachNota: 4.5 de 5 estrelas4.5/5 (11)

- Advanced Production Decline Analysis and ApplicationNo EverandAdvanced Production Decline Analysis and ApplicationNota: 3.5 de 5 estrelas3.5/5 (4)

- Advanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityNo EverandAdvanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityNota: 3 de 5 estrelas3/5 (2)

- Gas and Oil Reliability Engineering: Modeling and AnalysisNo EverandGas and Oil Reliability Engineering: Modeling and AnalysisNota: 4.5 de 5 estrelas4.5/5 (6)

- Heavy and Extra-heavy Oil Upgrading TechnologiesNo EverandHeavy and Extra-heavy Oil Upgrading TechnologiesNota: 4 de 5 estrelas4/5 (2)