Escolar Documentos

Profissional Documentos

Cultura Documentos

1061

Enviado por

BAlaDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

1061

Enviado por

BAlaDireitos autorais:

Formatos disponíveis

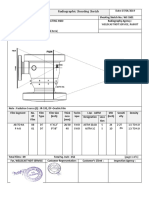

Laboratory

Industrial Radiographic Inspection Co., SP 111, Ambattur Industrial

Estate, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025:2005

Discipline

Non - Destructive Testing

Issue Date

09.05.2014

Certificate Number

Last Amended on

T-2211

-

Valid Until

Page

08.05.2016

1 of 3

S.No.

Product /

Material of

Test

Specific Test

Performed

Test Method Specification

against which tests are

performed

Range of Testing /

Limits of Detection

I. METALS AND ALLOYS

A. RADIOGRAPHY TEST

1.

Weld Joints

Radiography

ASME Sec-V Article 2,22:2013

ASTM E-94-04 (2013)

ASME Sec VIII:2013

ASME Sec IX:2013

BS EN 444:1994

ASME B 31.1:2012

ASME B 31.3:2012

AWS D1.1/D1.1 M:2010

ASTM E94-04 (2010)

ASTM E 1416-04

BS 2600:1983

BS EN 1435:1997

BS 2910:1994

BS EN 12517:2008

ASTM E 390-01(2006)

X ray:2mm to 50 mm

Gamma rayIridium 192:5mm to 70mm

Cobalt 60: 50mm to 200mm/

max 2% sensitivity

2.

Casting

Radiography

ASME Sec-V Article 2,22:2013

ASTM E-155:2010

ASME E 505:2011

ASME Sec VII:2011

ASME B 16.34:2013

ASME E 1030-05(2011)

BS EN 4080:2009

BS EN 12681:2003

ASTM E 186 Vol II:2010

ASTM E 280 Vol II:2010

ASTM E 446 Vol II:2010

X ray:2mm to 50 mm

Gamma rayIridium 192:5mm to 70mm

Cobalt 60: 50mm to 200mm/

max 2% sensitivity

B. ULTRASONIC TESTING

Laboratory

Industrial Radiographic Inspection Co., SP 111, Ambattur Industrial

Estate, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025:2005

Discipline

Non - Destructive Testing

Issue Date

09.05.2014

Certificate Number

Last Amended on

T-2211

-

Valid Until

Page

08.05.2016

2 of 3

S.No.

Product /

Material of

Test

Specific Test

Performed

Test Method Specification

against which tests are

performed

Range of Testing /

Limits of Detection

1.

Weld Joints

Detection of Internal Flaws /

Detection of Surface & SubSurface Flaws / Thickness

measurement

ASME Sec-V Article 4,5:20103

ASME B 31.1:2012

ASME B 31.3:2012

ASTM E 273:10

BS EN1714:1998

BS EN 1713:1998

BS EN 1712:1997

BS EN 583:2008

ASME Sec V III DIV 1:2013

3mm to 300mm/

/2 detection sensitivity

2.

Casting

Detection of Internal Flaws /

Detection of Surface & SubSurface Flaws / Thickness

measurement

ASME Sec-V Article 23:2013

ASTM A 609/A 609M 91

(R- 2012)

ASME B 16.34:2013

BS EN 12680:2011

15mm to 500mm/

/2 detection sensitivity

3.

Steel Plates

Detection of Internal Flaws /

Detection of Surface & SubSurface Flaws / Thickness

measurement

ASME Sec-V Article 23:2013

ASTM A 435/A 435M 90

(R- 2012)

ASTM A 578/A 578M-07

8mm to 100/

/2 detection sensitivity

4.

Forging

Detection of Internal Flaws /

Detection of Surface & SubSurface Flaws / Thickness

measurement

ASME Sec-V Article 23:2013

ASTM A 388/A 388M-11

ASTM A 745/A 745M-94

(R2012)

10mm to 800mm/

/2 detection sensitivity

C. MAGNETIC PARTICLE TESTING

1.

Weld Joints

Magnetic Particle (Prod &

Yoke) Surface Defect & Sub

Surface Defect

ASME Sec-V Article 7,25:2013

ASTM E-709-08

ASME Sec VIII Div 1:2013

BS EN 1290:1998

BS EN 1291:1998

AWS D1.1/D1.1M:2010

Surface Defect and SubSurface Defect

(Upto 5 mm Depth)

2.

Casting

Magnetic Particle (Prod &

Yoke)

ASME Sec-V Article 7,25:2013

ASTM Sec V III Div 1:2013

Surface Defect and SubSurface Defect

Laboratory

Industrial Radiographic Inspection Co., SP 111, Ambattur Industrial

Estate, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025:2005

Discipline

Non - Destructive Testing

Issue Date

09.05.2014

Certificate Number

Last Amended on

T-2211

-

Valid Until

Page

08.05.2016

3 of 3

S.No.

3.

Product /

Material of

Test

Forging

Specific Test

Performed

Test Method Specification

against which tests are

performed

Range of Testing /

Limits of Detection

Surface Defect &

Sub-Surface Defect

ASME B 16.34:2009

ASTM E 709-08

(Upto 5 mm Depth)

Magnetic Particle (Prod &

Yoke)

Surface Defect & Sub-Surface

Defect

ASME Sec-V Article 7,25:2013

ASTM Sec V III Div 1:2013

ASTM E 709-08

Surface Defect and SubSurface Defect

(Upto 5 mm Depth)

ASME Sec-V Article 6,24:2013

ASTM E 165-12

ASME Sec VIII Div 1:2013

AWS D1.1/D1.1M:2010

BS EN 1289:1998

ASME Sec-V Article 6,24:2013

ASME B 16.34:2013

BS EN ISO 3452:2013

ASME Sec VIII Div 1:2013

Defects open to Surface

D. PENETRANT TESTING

1.

Forging

Liquid Penetrant

(Solvent Removable)

Surface Defect

2.

Casting

Liquid Penetrant

(Solvent Removable)

Surface Defect

-X-X-X-X-X-X-X-X-X-X-X-X-X-X-X-

Defects open to Surface

Você também pode gostar

- Industrial radiography A Complete Guide - 2019 EditionNo EverandIndustrial radiography A Complete Guide - 2019 EditionAinda não há avaliações

- E125-97 MT Ref PhotosDocumento2 páginasE125-97 MT Ref PhotosveluAinda não há avaliações

- 4#600 Body RSSDocumento1 página4#600 Body RSSRavi patelAinda não há avaliações

- Ut ReportDocumento6 páginasUt ReportVijay PandeyAinda não há avaliações

- High-Strength Copper-Base and Nickel-Copper Alloy Castings: Standard Reference Radiographs ForDocumento5 páginasHigh-Strength Copper-Base and Nickel-Copper Alloy Castings: Standard Reference Radiographs ForSarita SharmaAinda não há avaliações

- E9018 G Welding ElectrodeDocumento1 páginaE9018 G Welding ElectrodeSai PrasathAinda não há avaliações

- IACS Rec-69-Rev2-Oct-2020-Ul (NDT)Documento21 páginasIACS Rec-69-Rev2-Oct-2020-Ul (NDT)Al aminAinda não há avaliações

- E 543 - 04 - Rtu0mw - PDFDocumento11 páginasE 543 - 04 - Rtu0mw - PDFUpul Eranda AbeyrathnaAinda não há avaliações

- 38DLPlus Training Power PointDocumento236 páginas38DLPlus Training Power PointVegaGonzalezAinda não há avaliações

- Phasec2d Data SheetDocumento2 páginasPhasec2d Data SheetMaria DazaAinda não há avaliações

- Thickness Gauging Level 2 (Questions & Answers)Documento3 páginasThickness Gauging Level 2 (Questions & Answers)kingston100% (2)

- L4-UAE-046E (Rev 4) Densitometer Calibration ProcedureDocumento4 páginasL4-UAE-046E (Rev 4) Densitometer Calibration ProcedureRahul DubeyAinda não há avaliações

- 005 - Calculating Snells LawDocumento9 páginas005 - Calculating Snells LawdaddadAinda não há avaliações

- Zzze) I (ZFRP: QW-163 Acceptance Criteria - Bend Tests QW-163 Acceptance Criteria - Bend TestsDocumento1 páginaZzze) I (ZFRP: QW-163 Acceptance Criteria - Bend Tests QW-163 Acceptance Criteria - Bend TestsSARSAN NDTAinda não há avaliações

- Saferad ProcedureDocumento19 páginasSaferad ProcedureExsan OthmanAinda não há avaliações

- Table 6.7Documento2 páginasTable 6.7AngelTinocoAinda não há avaliações

- LPT As Per Asme & IsoDocumento2 páginasLPT As Per Asme & IsosbmmlaAinda não há avaliações

- MTC Er70s 2Documento1 páginaMTC Er70s 2Mirza BaigAinda não há avaliações

- 38 MM DAC Block - Master SUDHANDocumento5 páginas38 MM DAC Block - Master SUDHANmaxpan maxAinda não há avaliações

- Lamtiation Ut ProcdureDocumento12 páginasLamtiation Ut ProcduremnmsingamAinda não há avaliações

- RT Standards NotesDocumento4 páginasRT Standards NotesprabhuAinda não há avaliações

- Astm E1065 E1065m 20Documento10 páginasAstm E1065 E1065m 20Mohamed AboelkhierAinda não há avaliações

- Certification Statement For NDT Level IIIDocumento1 páginaCertification Statement For NDT Level IIISantanu SahaAinda não há avaliações

- Visual and Ultrasonic Inspection of CraneDocumento7 páginasVisual and Ultrasonic Inspection of CranePDDELUCA100% (2)

- DS 324 ManualDocumento44 páginasDS 324 ManualAshish Srivastava100% (1)

- E428Documento6 páginasE428valentinAinda não há avaliações

- Procedure For UtDocumento12 páginasProcedure For UtMohammad SyeduzzamanAinda não há avaliações

- Ut Report-1 PDFDocumento1 páginaUt Report-1 PDFsureshrathod2Ainda não há avaliações

- 5.1 UT Procedure - ASME VIII Rev. 0 - KESB Tangguh Expansion ProjectDocumento33 páginas5.1 UT Procedure - ASME VIII Rev. 0 - KESB Tangguh Expansion ProjectSiriepathi SeetharamanAinda não há avaliações

- Visual Testing of Asme Codes & Iso Standars Differences and SimilaritiesDocumento2 páginasVisual Testing of Asme Codes & Iso Standars Differences and SimilaritiesNaik Kiran GopiAinda não há avaliações

- N F: NFT S C: EAR Ield Tandard Alibration TubeDocumento1 páginaN F: NFT S C: EAR Ield Tandard Alibration TubeMahmood KhanAinda não há avaliações

- UT Shear Wave Skip Distances and Search For Indications LabDocumento4 páginasUT Shear Wave Skip Distances and Search For Indications Lab1248a9a9a1q3we71Ainda não há avaliações

- PCN Training and Certification of PCN Level 2 and 3 Course Brochure - BIT - BINDT, 2020Documento13 páginasPCN Training and Certification of PCN Level 2 and 3 Course Brochure - BIT - BINDT, 2020AMITAinda não há avaliações

- APIRP586 Sec 1 Heat Exch Tubing InspsecondballottrackDocumento48 páginasAPIRP586 Sec 1 Heat Exch Tubing InspsecondballottrackUsman NaseemAinda não há avaliações

- Holiday Detector SK22436Documento1 páginaHoliday Detector SK22436Mohammad ShamimAinda não há avaliações

- ET DOUBTS SolvedDocumento4 páginasET DOUBTS SolvedRameez FaroukAinda não há avaliações

- Astm e 2446Documento9 páginasAstm e 2446김경은Ainda não há avaliações

- Astm E1962 19Documento4 páginasAstm E1962 19Mohamed AboelkhierAinda não há avaliações

- En 13927 - 2003Documento12 páginasEn 13927 - 2003gorkembaytenAinda não há avaliações

- RT ProcedureDocumento44 páginasRT Procedureefmartin21100% (1)

- Work Instruction FOR: Charpy Impact TestDocumento4 páginasWork Instruction FOR: Charpy Impact TestmahendraAinda não há avaliações

- 2-Asme BPVC Section Ix-2013Documento2 páginas2-Asme BPVC Section Ix-2013Reda ElsawyAinda não há avaliações

- Measurement of Prep Ene Trant EtchDocumento6 páginasMeasurement of Prep Ene Trant EtchPDDELUCAAinda não há avaliações

- Inspection Report Bifab Ut On Duplex Stainless Steel Piping PDFDocumento11 páginasInspection Report Bifab Ut On Duplex Stainless Steel Piping PDFquiron2014Ainda não há avaliações

- Radiography Test Procedure Part - 1Documento21 páginasRadiography Test Procedure Part - 1Ahmed Lepda100% (1)

- Ultrasonic Inspection Angles On Curved Surfaces - Holloway NDT & Engineering PDFDocumento11 páginasUltrasonic Inspection Angles On Curved Surfaces - Holloway NDT & Engineering PDFSASIAinda não há avaliações

- 2001 ASME V Article 6Documento8 páginas2001 ASME V Article 6Patrick DominguezAinda não há avaliações

- Welding of Pipelines and Related Facilities: Api Standard 1104 Nineteenth Edition, September 1999Documento62 páginasWelding of Pipelines and Related Facilities: Api Standard 1104 Nineteenth Edition, September 1999Riki AkbarAinda não há avaliações

- Ultrasonic Examination Based Acceptance CriteriaDocumento2 páginasUltrasonic Examination Based Acceptance CriteriaAngelTinocoAinda não há avaliações

- PAUT Procedure EEISDocumento13 páginasPAUT Procedure EEISZakirUllahAinda não há avaliações

- GE Hardness-testing-FAQ MIC 10Documento19 páginasGE Hardness-testing-FAQ MIC 10Harshit MehtaAinda não há avaliações

- UT Formula SheetDocumento2 páginasUT Formula SheetOktayKulAinda não há avaliações

- AMS2643 Structural Examination of Titanium Alloys Chemical Etch Inspection Procedure Rev. EDocumento5 páginasAMS2643 Structural Examination of Titanium Alloys Chemical Etch Inspection Procedure Rev. ERubén Eduardo Galindo CarmonaAinda não há avaliações

- Introduction To UT Flaw DetectorDocumento26 páginasIntroduction To UT Flaw DetectorNail Widya Satya100% (1)

- Mechanical Metigurical DimensionalDocumento4 páginasMechanical Metigurical DimensionalPaviter SinghAinda não há avaliações

- Usa Mechanical1046-01Documento5 páginasUsa Mechanical1046-01Rick HenbidAinda não há avaliações

- Hellenic Accreditation System: Annex F1/12 To The Certificate No. 124-5Documento4 páginasHellenic Accreditation System: Annex F1/12 To The Certificate No. 124-5santu_23Ainda não há avaliações

- Parker Test BarDocumento1 páginaParker Test BarTechnical A-Star Testing & Inspection MalaysiaAinda não há avaliações

- Ultrasonic Inspection-Test BlocksDocumento0 páginaUltrasonic Inspection-Test BlocksSreeji ChittamveeduAinda não há avaliações

- WPS 01 WQT PDFDocumento1 páginaWPS 01 WQT PDFkiki270977Ainda não há avaliações

- WPS 01 WQTp2 PDFDocumento1 páginaWPS 01 WQTp2 PDFkiki270977Ainda não há avaliações

- Welding Procedure Specificaton (WPS)Documento2 páginasWelding Procedure Specificaton (WPS)kiki270977100% (1)

- APS6 Automated Pipe ScannerDocumento2 páginasAPS6 Automated Pipe Scannerkiki270977Ainda não há avaliações

- APS3 Automated Pipe ScannersDocumento2 páginasAPS3 Automated Pipe Scannerskiki270977Ainda não há avaliações

- Method Statement WeldingDocumento9 páginasMethod Statement Weldingkiki270977Ainda não há avaliações

- Elearning Course Title - Project - Budgeting and Capital Budgeting Management 479387Documento1 páginaElearning Course Title - Project - Budgeting and Capital Budgeting Management 479387kiki270977Ainda não há avaliações

- Pipe Support Sleeve PEDocumento2 páginasPipe Support Sleeve PEkiki270977Ainda não há avaliações

- AGS 2 Automated General Purpose ScannerDocumento2 páginasAGS 2 Automated General Purpose Scannerkiki270977Ainda não há avaliações

- Submersible Pumpset For 200Mm Borewell (V6 - V8 Combination - 183Mm Od) Radial FlowDocumento2 páginasSubmersible Pumpset For 200Mm Borewell (V6 - V8 Combination - 183Mm Od) Radial Flowkiki270977Ainda não há avaliações

- 1 Advertisement PDFDocumento1 página1 Advertisement PDFkiki270977Ainda não há avaliações

- AGS 1 Automated General Purpose ScannerDocumento2 páginasAGS 1 Automated General Purpose Scannerkiki270977Ainda não há avaliações

- Cable Size Calculations SpreadsheetDocumento4 páginasCable Size Calculations Spreadsheetkiki270977Ainda não há avaliações

- Bohler Fox S Ev 50: Stick Electrode, Unalloyed BasicDocumento1 páginaBohler Fox S Ev 50: Stick Electrode, Unalloyed Basickiki270977Ainda não há avaliações

- Welder ProfileDocumento1 páginaWelder Profilekiki270977Ainda não há avaliações

- Fitter ProfileDocumento1 páginaFitter Profilekiki270977Ainda não há avaliações

- Miter Bend CalculationDocumento1 páginaMiter Bend Calculationkiki270977Ainda não há avaliações

- Alloy Conversion ChartsDocumento4 páginasAlloy Conversion Chartskiki270977Ainda não há avaliações

- Ko 2015Documento22 páginasKo 2015Mudavath Babu RamAinda não há avaliações

- Inversion of Time-Lapse Surface Gravity Data For DDocumento25 páginasInversion of Time-Lapse Surface Gravity Data For DFatimah Az ZahraAinda não há avaliações

- Micheslon'S Interferometer: ConstructionDocumento5 páginasMicheslon'S Interferometer: Construction21MS0073KritarthaAinda não há avaliações

- Siemens Sivacon s8 - Part1Documento8 páginasSiemens Sivacon s8 - Part1Mohamed NasrAinda não há avaliações

- Modelling of Graphene Nano-Ribbon Transistors (Gnr-Fets) With Enhanced Drive CurrentsDocumento9 páginasModelling of Graphene Nano-Ribbon Transistors (Gnr-Fets) With Enhanced Drive CurrentsShailendra YadavAinda não há avaliações

- Dissertation CGDocumento147 páginasDissertation CGChiheb BaAinda não há avaliações

- Locking Ring Calculator OD2700Documento10 páginasLocking Ring Calculator OD2700muscleglassesAinda não há avaliações

- Computational and Data Sciences: FacultyDocumento2 páginasComputational and Data Sciences: FacultyAmarjeet KrishhnanAinda não há avaliações

- Controversial Electro ProblemDocumento16 páginasControversial Electro ProblemJorge AlcarazAinda não há avaliações

- VC.03 The Gradient Literacy: NameDocumento8 páginasVC.03 The Gradient Literacy: NameSri RaghavanAinda não há avaliações

- Modern Chemistry Chapter 3Documento39 páginasModern Chemistry Chapter 3Ruby GallowayAinda não há avaliações

- Government Boys Degree College Usta Muhammad: Prospectus 2021-22Documento22 páginasGovernment Boys Degree College Usta Muhammad: Prospectus 2021-22Vision AcademyAinda não há avaliações

- Extra Practice Week 01Documento6 páginasExtra Practice Week 01devikaAinda não há avaliações

- IEC Guide 115-2007Documento54 páginasIEC Guide 115-2007Gastón MelgrattiAinda não há avaliações

- Fluid Statics - AdvanceDocumento20 páginasFluid Statics - AdvanceRenzel BaulaAinda não há avaliações

- Poly Phase IM Windings: - The Winding of A Machine Is The Arrangement ofDocumento78 páginasPoly Phase IM Windings: - The Winding of A Machine Is The Arrangement ofashebir berhanuAinda não há avaliações

- Ficha Tecnica Unid Evaporadora TC SMSVDocumento12 páginasFicha Tecnica Unid Evaporadora TC SMSVAsistente MantenimientoAinda não há avaliações

- Indux R4, Indux R5 and Indux R7: Industrial X-Ray FilmsDocumento2 páginasIndux R4, Indux R5 and Indux R7: Industrial X-Ray FilmsMian Ahmer AliAinda não há avaliações

- Analisis Kekuatan Tarik, Kekerasan, Dan Struktur PengelasanDocumento10 páginasAnalisis Kekuatan Tarik, Kekerasan, Dan Struktur PengelasanNurkholis NurkholisAinda não há avaliações

- A Note On Rakotch ContractionsDocumento7 páginasA Note On Rakotch ContractionsTalha WaheedAinda não há avaliações

- A) B) C) D) E) : Thermodynamics Technical AptitudeDocumento11 páginasA) B) C) D) E) : Thermodynamics Technical AptitudeAvinash GateAinda não há avaliações

- Spring 2020 Gems Gemology v2 PDFDocumento195 páginasSpring 2020 Gems Gemology v2 PDFJORGE LUIS HERNANDEZ DUARTE100% (1)

- Iocl 1030rDocumento1 páginaIocl 1030rLaxman AhirAinda não há avaliações

- H. P. Lovecraft - The Dunwich HorrorDocumento4 páginasH. P. Lovecraft - The Dunwich Horrorwot spgAinda não há avaliações

- (Chapter) Neonatal Infrared Thermography MonitoringDocumento43 páginas(Chapter) Neonatal Infrared Thermography MonitoringErwin SmithAinda não há avaliações

- Aditya College of Engineering & Technology (A), Surampalem Course End Survey Form-CSE-DSDocumento4 páginasAditya College of Engineering & Technology (A), Surampalem Course End Survey Form-CSE-DSahmedali51367Ainda não há avaliações

- Born's Conditions On The Wave FunctionDocumento4 páginasBorn's Conditions On The Wave FunctionSaswati BanerjeeAinda não há avaliações

- ArchaeogeophysicsDocumento280 páginasArchaeogeophysicskiko18400Ainda não há avaliações

- Applied OpticsDocumento9 páginasApplied OpticsMohammad Yahya AzabAinda não há avaliações

- Correlation of Objective and Subjective Evaluation of Vehicle Handling by Neural NetworksDocumento2 páginasCorrelation of Objective and Subjective Evaluation of Vehicle Handling by Neural NetworksPavel SteinbauerAinda não há avaliações

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontNo EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontNota: 4.5 de 5 estrelas4.5/5 (18)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionNo EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionNota: 3 de 5 estrelas3/5 (1)

- Waste: One Woman’s Fight Against America’s Dirty SecretNo EverandWaste: One Woman’s Fight Against America’s Dirty SecretNota: 5 de 5 estrelas5/5 (1)

- Introduction to Ecology and Environmental Laws in IndiaNo EverandIntroduction to Ecology and Environmental Laws in IndiaAinda não há avaliações

- Busted!: Drug War Survival Skills and True Dope DNo EverandBusted!: Drug War Survival Skills and True Dope DNota: 3.5 de 5 estrelas3.5/5 (7)

- The Rights of Nature: A Legal Revolution That Could Save the WorldNo EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldNota: 5 de 5 estrelas5/5 (1)

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionNo Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionAinda não há avaliações

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaNo EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaNota: 4 de 5 estrelas4/5 (1)

- Reduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksNo EverandReduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksAinda não há avaliações

- Environmental Education in Practice: Concepts and ApplicationsNo EverandEnvironmental Education in Practice: Concepts and ApplicationsAinda não há avaliações

- Introduction to Ecology and Environmental Laws in IndiaNo EverandIntroduction to Ecology and Environmental Laws in IndiaAinda não há avaliações

- Dawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawNo EverandDawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawNota: 4 de 5 estrelas4/5 (334)

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontNo EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontNota: 4.5 de 5 estrelas4.5/5 (9)

- Down to the Wire: Confronting Climate CollapseNo EverandDown to the Wire: Confronting Climate CollapseNota: 4.5 de 5 estrelas4.5/5 (8)

- Principles of direct and superior responsibility in international humanitarian lawNo EverandPrinciples of direct and superior responsibility in international humanitarian lawAinda não há avaliações

- Climate Action Challenge: A Proven Plan for Launching Your Eco-Initiative in 90 DaysNo EverandClimate Action Challenge: A Proven Plan for Launching Your Eco-Initiative in 90 DaysAinda não há avaliações

- Obstacles to Environmental Progress: A U.S. perspectiveNo EverandObstacles to Environmental Progress: A U.S. perspectiveAinda não há avaliações

- Land Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933No EverandLand Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933Ainda não há avaliações