Escolar Documentos

Profissional Documentos

Cultura Documentos

Ultrasonic Pulse Velocity

Enviado por

anpyaaDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Ultrasonic Pulse Velocity

Enviado por

anpyaaDireitos autorais:

Formatos disponíveis

Civil Engineering Dept, ISM Dhanbad

Structural Engg Laboratory (MTech)

Ultrasonic Pulse Velocity

Objective of the experiment: To determine the quality of the concrete using ultrasonic pulse

velocity.

Theory: This is one of the non-destructive testing methods for concrete. The ultrasonic pulse

velocity method could be used to establish the homogeneity of the concrete, the quality of the

concrete in relation to standard requirements, the quality of one element of concrete in

relation to another, and the values of dynamic elastic modulus of the concrete. The ultrasonic

pulse is generated by an electro-acoustical transducer. When the pulse is induced into the

concrete from a transducer, it undergoes multiple reflections at the boundaries of the material.

A complex system of stress waves is developed which includes longitudinal (compression),

shear (transverse) and surface (Rayleigh) waves. The receiving transducer detects the onset of

the longitudinal waves, which is the fastest. Because the velocity of the pulses is almost

independent of the geometry of the material through which they pass and depends only on its

elastic properties, hence pulse velocity method is a convenient technique for investigating

structural concrete. In case of poorer quality, lower velocities are obtained. If there is a crack,

void or flaw inside the concrete which comes in the way of transmission of the pulses, the

pulse strength is attenuated and it passes around the discontinuity, thereby making the path

length longer. Consequently, lower velocities are obtained. The actual pulse velocity obtained

depends primarily upon the materials and mix proportions of concrete. Density and modulus

of elasticity of aggregate also significantly affect the pulse velocity.

The pulse velocity is determined by

Path length (l )

Pulse velocity

Transit ti me (t )

Where path length is the distance of pulse velocity travelled from transmitter to receiver in

mm, transmit time in microsecond (s) gives the velocity in Km/s.

Methods of propagating ultrasonic pulse:

In the figure

a. Direct transmission.

b. Semi-direct transmission.

c. Indirect or surface transmission.

Procedure:

Connect the mains led to the socket at the back power supply.

Connect the crystal probes to TRANS and REC terminals.

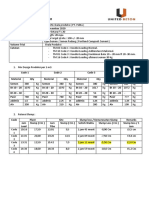

Put Sl.No

Path

Transmit

Pulse

Quality of

on

.

length (l)

Time (t)

Velocity (l/t)

Concrete

of

and

the grease

the faces

the probes

press the

faces

together

and if required use the SET ZERO control for initial correction, so that the display

reads 00.0+/-1.

Now the grease the opposite face of the specimen across which the measurement has

to be made. Put a probe on these greased spots and apply pressure on them.

Now read the display and note down the reading, which is a transmit time in

microseconds.

Measure the distance between the two faces of the specimen.

Velocity of the ultrasonic pulse can be calculated from the above equation.

The quality of the concrete is known by comparing the velocity from the Table 2 of Indian

Standard code IS 13311 (Part 1):1992.

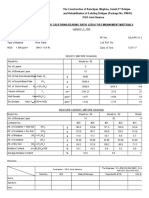

Velocity Criterion for Concrete Quality Grading [IS13311 (Part 1):1992]

Sl.No

Pulse velocity by cross probing (Km/s)

1

Above 4.5

2

3.5 to 4.5

3

3 to 3.5

4

Below 3

Note - In case of doubtful quality it may be necessary to carry out further tests.

Observation table:

Concrete quality grading

Excellent

Good

Medium

Doubtful

Result: The quality of the concrete mould (block/cylinder) is found _______.

The relation of pulse velocity and the properties of materials can be given as

E

V=

---- (1)

Where E is Elasticity modulus in N/mm2;

is density of material in KN/mm3

Você também pode gostar

- Bhaktivedanta Vidyapitha SB Canto 1 OverviewDocumento44 páginasBhaktivedanta Vidyapitha SB Canto 1 Overviewanpyaa88% (8)

- Flexural RigidityDocumento2 páginasFlexural Rigidityanpyaa88% (8)

- NES 729 Part 5 Requirements For Non-Destructive Examination MethodsDocumento70 páginasNES 729 Part 5 Requirements For Non-Destructive Examination MethodsJEORJEAinda não há avaliações

- Dispersive Characteristics of Clay Soil by Double HydrometerDocumento3 páginasDispersive Characteristics of Clay Soil by Double Hydrometerโก อู๋Ainda não há avaliações

- Department of Civil Engineering, ISM Dhanbad Structural Analysis-I Practical ManualDocumento6 páginasDepartment of Civil Engineering, ISM Dhanbad Structural Analysis-I Practical ManualanpyaaAinda não há avaliações

- Unsymmetrical BendingDocumento5 páginasUnsymmetrical BendinganpyaaAinda não há avaliações

- Lighten Up Infinite Possibilities: ZONE Sonography® Technology Plus (ZST+)Documento2 páginasLighten Up Infinite Possibilities: ZONE Sonography® Technology Plus (ZST+)N SyarifAinda não há avaliações

- VMC Class 8 Physics AssignmentDocumento22 páginasVMC Class 8 Physics AssignmentAbhideep JainAinda não há avaliações

- Bender Element Test: ObjectiveDocumento6 páginasBender Element Test: ObjectiveNaman KantesariaAinda não há avaliações

- Profometer PM-6 Sales Flyer EnglishDocumento11 páginasProfometer PM-6 Sales Flyer EnglishProceq SAAinda não há avaliações

- Ultrasonic Pulse Velocity Test: (NDT On Hardened Concrete)Documento12 páginasUltrasonic Pulse Velocity Test: (NDT On Hardened Concrete)Fahmy AzizAinda não há avaliações

- Compressive Strength of Concrete CubesDocumento3 páginasCompressive Strength of Concrete CubesoneakshayAinda não há avaliações

- Evaluasi Mutu BetonDocumento9 páginasEvaluasi Mutu BetonDIANAinda não há avaliações

- Brazilian TestDocumento55 páginasBrazilian TestGoh Ching SoonAinda não há avaliações

- ResumeDocumento3 páginasResumeS MUTHYALAIAHAinda não há avaliações

- Development of Material Test and Survey Laboratory Application SystemsDocumento4 páginasDevelopment of Material Test and Survey Laboratory Application SystemsInternational Journal of Innovative Science and Research Technology100% (1)

- PWD UPDATdEDocumento41 páginasPWD UPDATdEmukeshAinda não há avaliações

- Beton PorousDocumento67 páginasBeton PorousAnonymous uDt8PYAinda não há avaliações

- Asia Pile Testing Company Profile PDFDocumento73 páginasAsia Pile Testing Company Profile PDFWray TanAinda não há avaliações

- Mat Boundary Spring Generator With KX Ky KZ KMX KMy KMZDocumento3 páginasMat Boundary Spring Generator With KX Ky KZ KMX KMy KMZcesar rodriguezAinda não há avaliações

- Astm D422 Sieve Analysis: Client: ProjectDocumento1 páginaAstm D422 Sieve Analysis: Client: ProjectHassan RazaAinda não há avaliações

- Sta.32+250 BK 13Documento2 páginasSta.32+250 BK 13Kris SiregarAinda não há avaliações

- Concrete Test-Hammer TestDocumento1 páginaConcrete Test-Hammer Testemut_mAinda não há avaliações

- Transportation Engineering: Approaches To Pavement DesignDocumento15 páginasTransportation Engineering: Approaches To Pavement DesignSaddaqatAinda não há avaliações

- LAB 1 - Colour Contrast Penetrant TestDocumento9 páginasLAB 1 - Colour Contrast Penetrant TestRaiham EffendyAinda não há avaliações

- Ringkasan Trial Mix BetonDocumento10 páginasRingkasan Trial Mix BetonyohanesfernandoAinda não há avaliações

- Permeabilidad 1 Lugeon LeonDocumento2 páginasPermeabilidad 1 Lugeon LeonFernando BarreraAinda não há avaliações

- Record of Water Pressure Test Pltu Bantaeng, Sulawesi SelatanDocumento7 páginasRecord of Water Pressure Test Pltu Bantaeng, Sulawesi SelatandoddyAinda não há avaliações

- London Pavilion - Soil Investigation - FINAL REPORTDocumento149 páginasLondon Pavilion - Soil Investigation - FINAL REPORTkho kai feiAinda não há avaliações

- Hasil Hydrometer Dan Sieve AnalysisDocumento6 páginasHasil Hydrometer Dan Sieve AnalysisEko NugrohoAinda não há avaliações

- Example 4: Design of A Circular Raft For A Cylindrical CoreDocumento18 páginasExample 4: Design of A Circular Raft For A Cylindrical Corevaranasirk1Ainda não há avaliações

- Universal Testing MachineDocumento4 páginasUniversal Testing MachineTomy GeorgeAinda não há avaliações

- Soil CompactionDocumento24 páginasSoil Compactionsyah123Ainda não há avaliações

- Rebar DetectorDocumento6 páginasRebar DetectorChalakAhmedAinda não há avaliações

- Grafik DCPDocumento10 páginasGrafik DCPYoviDwiyanaAinda não há avaliações

- Field and Laboratory Evaluation of A Soft Clay Southern IraqDocumento14 páginasField and Laboratory Evaluation of A Soft Clay Southern Iraqvidyaranya_bAinda não há avaliações

- Perhitungan Dynamic Cone PenetrationDocumento15 páginasPerhitungan Dynamic Cone Penetrationmp3okebangetAinda não há avaliações

- Slump Test: Sourse /location:: CC Pavement Grade of Concrete:: M30 Water Cement Ratio:: 0.45Documento37 páginasSlump Test: Sourse /location:: CC Pavement Grade of Concrete:: M30 Water Cement Ratio:: 0.45ChManikumarAinda não há avaliações

- Constant Head Permeability Test Lab ManualDocumento3 páginasConstant Head Permeability Test Lab ManualmmAinda não há avaliações

- Geotech Vane Shear TestDocumento78 páginasGeotech Vane Shear Test'Sayed AsadullahAinda não há avaliações

- Rekayasa Fondasi Dalam: Tiang Pancang Dan Tiang BorDocumento38 páginasRekayasa Fondasi Dalam: Tiang Pancang Dan Tiang BorAriq AhmadAinda não há avaliações

- Pavetest-Matest BrochureDEF PDFDocumento47 páginasPavetest-Matest BrochureDEF PDFMax Cedeño De LeónAinda não há avaliações

- AASHTO Rigid Design IDocumento11 páginasAASHTO Rigid Design Ietikaf100% (1)

- CBR OsjiDocumento6 páginasCBR OsjiSA023Ainda não há avaliações

- Indirect Tensile Strength of Modified Bitumen MixtureDocumento6 páginasIndirect Tensile Strength of Modified Bitumen Mixturedbpublications100% (1)

- Terzaghi and PeckDocumento7 páginasTerzaghi and PeckRaja Hendra Solihin RambeAinda não há avaliações

- Direct Shear Test - Lab ManualDocumento4 páginasDirect Shear Test - Lab ManualmmAinda não há avaliações

- Geotechnical Laboratory Measurements For Engineers: Unconsolidated Undrained Triaxial Compression TestDocumento5 páginasGeotechnical Laboratory Measurements For Engineers: Unconsolidated Undrained Triaxial Compression TestYusi SulastriAinda não há avaliações

- Bitumen ExtractorDocumento7 páginasBitumen ExtractorNirmal NayakAinda não há avaliações

- Is.13311.2.1992 Rebound HammerDocumento12 páginasIs.13311.2.1992 Rebound HammerChockalingamAinda não há avaliações

- Data Triaxial TestDocumento9 páginasData Triaxial TestVania Novianti SAinda não há avaliações

- Ayni-Panjakent-Uzbekistan Border Road: List of Test FormsDocumento58 páginasAyni-Panjakent-Uzbekistan Border Road: List of Test FormsGolam Masud100% (1)

- Assignment 1Documento1 páginaAssignment 1Suman RoyAinda não há avaliações

- Packer Test Form Lumina Copper SAC: ClientDocumento7 páginasPacker Test Form Lumina Copper SAC: ClientWilmerCamposBarbozaAinda não há avaliações

- Part 09 - Classification of Rock MassDocumento21 páginasPart 09 - Classification of Rock MassAfendi AriffAinda não há avaliações

- Some Useful NumbersDocumento6 páginasSome Useful NumbersKemal HadzicAinda não há avaliações

- In Situ Test SPTDocumento6 páginasIn Situ Test SPTAnonymous fE2l3DzlAinda não há avaliações

- Tabel SondirDocumento5 páginasTabel SondirLuthfi ElBarcaAinda não há avaliações

- Geotech2 LS10 Site InvestigationDocumento11 páginasGeotech2 LS10 Site InvestigationChairul Syam HafilAinda não há avaliações

- Quality Control Pekerjaan Rigid Pavement Dengan Metode Qpass Dan QlassicDocumento17 páginasQuality Control Pekerjaan Rigid Pavement Dengan Metode Qpass Dan Qlassicavitra nur hasanAinda não há avaliações

- Final Resume Hammer TestDocumento7 páginasFinal Resume Hammer Testheni luthfiAinda não há avaliações

- Result of Atterberg Limit: (Kadar Air Asli)Documento3 páginasResult of Atterberg Limit: (Kadar Air Asli)DudiAinda não há avaliações

- Perhitungan Penurunan Menggunakan AllpileDocumento1 páginaPerhitungan Penurunan Menggunakan AllpileSu NarkoAinda não há avaliações

- Geotechnical / Sub - Soil Investigation: Shreeji Imports and Exports, JamnagarDocumento28 páginasGeotechnical / Sub - Soil Investigation: Shreeji Imports and Exports, JamnagarMaheshAinda não há avaliações

- 4-Method Statement UPV ASTM C597 - VER - 001Documento4 páginas4-Method Statement UPV ASTM C597 - VER - 001Kamal PakdamanAinda não há avaliações

- Ultrasonic Pulse VelocityDocumento16 páginasUltrasonic Pulse VelocityShivamBose100% (1)

- Ultrasonic Pulse Velocity TestDocumento4 páginasUltrasonic Pulse Velocity TestDeepak SahAinda não há avaliações

- Specification of Indian Standard Sand - TAMINDocumento1 páginaSpecification of Indian Standard Sand - TAMINanpyaaAinda não há avaliações

- Approximate Settlement of Inundation Test On Opencast Backfill at CorbyDocumento3 páginasApproximate Settlement of Inundation Test On Opencast Backfill at CorbyanpyaaAinda não há avaliações

- PermeameterDocumento1 páginaPermeameteranpyaaAinda não há avaliações

- Galerkin MethodDocumento24 páginasGalerkin MethodanpyaaAinda não há avaliações

- Hypothesis TestingDocumento44 páginasHypothesis Testinganpyaa100% (1)

- Non-Destructive Evaluation of Concrete Using Ultrasonic Pulse VelocityDocumento6 páginasNon-Destructive Evaluation of Concrete Using Ultrasonic Pulse VelocityanpyaaAinda não há avaliações

- Chi Square TestDocumento5 páginasChi Square TestanpyaaAinda não há avaliações

- Research Methodology For ISMDocumento97 páginasResearch Methodology For ISManpyaaAinda não há avaliações

- Civil Engineering Dept, ISM Dhanbad Structural Engg Laboratory (M.Tech) Rebar DetectorDocumento2 páginasCivil Engineering Dept, ISM Dhanbad Structural Engg Laboratory (M.Tech) Rebar DetectoranpyaaAinda não há avaliações

- Department of Civil Engineering, ISM Dhanbad Structural Analysis-I Practical ManualDocumento3 páginasDepartment of Civil Engineering, ISM Dhanbad Structural Analysis-I Practical ManualanpyaaAinda não há avaliações

- Footing - Tut 1.0Documento1 páginaFooting - Tut 1.0anpyaaAinda não há avaliações

- GT Assignment - IIDocumento1 páginaGT Assignment - IIanpyaaAinda não há avaliações

- GT Assignment - IDocumento2 páginasGT Assignment - IanpyaaAinda não há avaliações

- November 3, 2009 Not For Submission: Indian Institute of Technology Kanpur Department of Mechanical EngineeringDocumento1 páginaNovember 3, 2009 Not For Submission: Indian Institute of Technology Kanpur Department of Mechanical EngineeringanpyaaAinda não há avaliações

- CementingTools NS 1 A4 WatermarkedDocumento7 páginasCementingTools NS 1 A4 Watermarkedislam atifAinda não há avaliações

- Keyence FS2 60Documento10 páginasKeyence FS2 60ntdien923Ainda não há avaliações

- Infrared-Ultrasonic Sensor Fusion For Support Vect PDFDocumento14 páginasInfrared-Ultrasonic Sensor Fusion For Support Vect PDFziafat shehzadAinda não há avaliações

- Tecnicas Monitoreo CorrosionDocumento8 páginasTecnicas Monitoreo CorrosionJavier GonzalezAinda não há avaliações

- Investigations of The Head Check Defects in RailsDocumento5 páginasInvestigations of The Head Check Defects in RailsmmAinda não há avaliações

- The Role of Electrotherapy in Contemporary Physio PracticeDocumento10 páginasThe Role of Electrotherapy in Contemporary Physio PracticeFaBeAnAinda não há avaliações

- Industrial Scanners Catalog en LTR 201602Documento32 páginasIndustrial Scanners Catalog en LTR 201602Satwant SinghAinda não há avaliações

- Section 1 Inspection and NDTDocumento84 páginasSection 1 Inspection and NDTariyamanjula2914100% (1)

- UltrasonicsDocumento40 páginasUltrasonics20. Ashish Mahajan 12th 'B'Ainda não há avaliações

- ToFD PDFDocumento7 páginasToFD PDFParanthaman Jayaraman100% (1)

- HC SR04Users ManualDocumento10 páginasHC SR04Users ManualAbner Franco HermsdorfAinda não há avaliações

- 3.1 General Properties of WavesDocumento6 páginas3.1 General Properties of WavesDhanBahadurAinda não há avaliações

- 15.cat c2 0809 Int ScreenDocumento618 páginas15.cat c2 0809 Int ScreenOzren Djuric100% (1)

- Application of A FMC/TFM Ultrasonic System To Inspection of Austenitic WeldsDocumento9 páginasApplication of A FMC/TFM Ultrasonic System To Inspection of Austenitic WeldsLuis Eduardo Perez RangelAinda não há avaliações

- E976-10 Standard Guide For Determining The Reproducibility of Acoustic ...Documento7 páginasE976-10 Standard Guide For Determining The Reproducibility of Acoustic ...MULTISERVICE CHSAinda não há avaliações

- Beijing Quanxin Ultrasonic CO.,LTD: More Information of Ultrasonic TransducerDocumento4 páginasBeijing Quanxin Ultrasonic CO.,LTD: More Information of Ultrasonic TransducerbG gAinda não há avaliações

- Homogenization and Lysis (2021!06!12)Documento22 páginasHomogenization and Lysis (2021!06!12)Wreck of HeartsAinda não há avaliações

- Ficha Tecnica UT AzulDocumento4 páginasFicha Tecnica UT Azulلوبيز إديسونAinda não há avaliações

- Maintenance StandardsDocumento39 páginasMaintenance StandardsTAHER AMMARAinda não há avaliações

- Service Manual: For Seca 777Documento28 páginasService Manual: For Seca 777Natalia VelasquezAinda não há avaliações

- IRIS Tube ID InspectionDocumento2 páginasIRIS Tube ID InspectionwholenumberAinda não há avaliações

- NDT Xl-Ut-05.1 Babbit QualityDocumento7 páginasNDT Xl-Ut-05.1 Babbit QualityRon KentAinda não há avaliações

- UT L3 FormulaDocumento11 páginasUT L3 FormulaJiten KarmakarAinda não há avaliações

- BS en 12680-3 2003Documento20 páginasBS en 12680-3 2003Renier Koen100% (1)

- UT - Questions and AnswersDocumento238 páginasUT - Questions and AnswersDeepak_Gurjar100% (7)

- Ultrasound TherapyDocumento8 páginasUltrasound Therapyrussel786Ainda não há avaliações