Escolar Documentos

Profissional Documentos

Cultura Documentos

Ts of 33 KV in Door Switch Board-I

Enviado por

Sunil SinghTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Ts of 33 KV in Door Switch Board-I

Enviado por

Sunil SinghDireitos autorais:

Formatos disponíveis

RASHMI METALIKS LTD

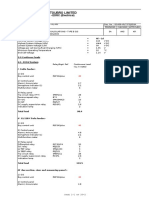

TECHNICAL SPECIFICATION OF 33KV IN DOOR SWITCH BOARD

FOR 350 CUM MBF AT KHARAGPUR

BID DOCUMENT

FOR

33 kV SWITCHBOARD PACKAGE

VOLUME I OF I

ENQUIRY NO.: RML/SPEC-33-SB/TS-05

RASHMI METALIKS LTD

TECHNICAL SPECIFICATION OF 33KV IN DOOR SWITCH BOARD

FOR 350 CUM MBF AT KHARAGPUR

VOLUME-I OF I

TECHNICAL SPECIFICATION OF 33 kV SWITCHBOARD

CONTENTS

S.NO.

1.

2.

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

2.9

2.10

2.11

2.12

2.13

2.14

2.15

2.16

2.17

2.18

2.19

2.20

2.21

2.22

3.0

4.0

5.0

DESCRIPTION

INTENT OF SPECIFICATION

TECHNICAL SPECIFICATION FOR 33 kV SWITCHBOARD

Introduction

Specific Requirements:

Standards

General Requirements

Busbars

Circuit Breakers

Earthing Trolleys

Current Transformers

Potential Transformer

Integrating Meters

Indicating Lamps

Relays

Control Switches and Push Buttons

Internal Wiring

Terminal Blocks

Cable Termination

Labels

Painting

Tests

List of Documents / Drawings to be Submitted

List of Operational Spares

Make of Components

CLEANING AND PACKING,SPARES:

DATA SHEETS AND SCHEDULES

TENDER DRAWING

PAGE NO.

2

3

3

3

4

5

7

8

10

10

11

11

12

13

13

14

14

14

15

15

15

16

18

19

20

29

RASHMI METALIKS LTD

TECHNICAL SPECIFICATION OF 33KV IN DOOR SWITCH BOARD

FOR 350 CUM MBF AT KHARAGPUR

1. INTENT OF SPECIFICATION

1.1

1.2

This specification is intended to cover the design, engineering,

manufacture, shop fabrication, assembly, pre-assembly, tests and

inspection at manufacturers work, packing, shipment, supervision of

erection at site of Rashmi Metaliks Ltd. at khadagpur.

The equipment and services furnished shall meet all the requirement of

this specification, data sheets etc., In case of any conflict / contradiction

among various part of the specification, data sheets the same shall be

referred to the engineer for clarification whose decision shall be final and

binding.

1.3

It is not the Intent to specify completely herein all aspects of design and

construction of equipment. Nevertheless, the equipment shall conform in

all respects to high standards of engineering, design and workmanship and

shall be capable of performing in continuous commercial operation in a

manner acceptable to the PURCHASER who will interpret the meaning

of the specification, drawings and shall have right to reject or accept any

work or material which in his assessment is not complete to meet the

requirements of this specification and / or applicable national and / or

international standards mentioned elsewhere in the specification.

1.4

Whenever material or item is specified or described by the name of a

particular brand, manufacturer or trade mark, the specific item shall be

understood as establishing type, function and quality desired. Other

manufacturer's products may also be considered provided sufficient

information is furnished so as to enable the PURCHASER to determine

that the products are equivalent to those named.

1.5

GENERAL INFORMATION ON ELECTRICAL & CONTROL VOLTAGES:

1.5.1 Auxiliary electrical equipment shall be suitable for operation on the following supply

system:

Spring charging motor, Closing & Tripping : 110 volts D.C. supply

Auxiliary supply

: 240 volts, 1 phase 50 HZ A.C supply.

RASHMI METALIKS LTD

TECHNICAL SPECIFICATION OF 33KV IN DOOR SWITCH BOARD

FOR 350 CUM MBF AT KHARAGPUR

1.5.2

The above voltage may vary as follows. All devices shall be suitable for continuous

operation over the entire range of voltages.

A.C. Supply variation:

i)

Voltage variation

10%

ii)

Frequency variation

5%

iii)

iv)

Combined voltage and

Frequency variation

10%

D.C. Supply voltage variation :i)

Closing device

- 15% to + 10%

ii)

Tripping device

- 30% to + 10%

1.5.3

Two sources of each of the above supplies i.e. 240 volts AC, 110 volts DC will be made

available by the purchaser at one terminal point. The vendor shall include adequately

rated control transformers for any other voltage levels are required. Vendor's scope shall

include distribution beyond the points of supply including interconnecting cables,

terminal blocks etc.

1.5.4

Reference temperature for design of electrical equipment / devices:

50 Deg C for tropical regions, all marine conditions and polluted industrial atmosphere

with 100 percent humidity. However, the maximum temperature and humidity shall be

assumed not occurring simultaneously.

1.5.5

SCOPE OF WORK:

This specification covers design, manufacturing, fabrication, assembly, cleaning, painting,

testing, packing and supply of 33 KV MRSS HT Switch Board as per the enclosed

Technical Specification & Single Line Diagram.

1.5.6

SCOPE OF SUPPLY:

Any item not specifically mentioned above but is essentially required for proper

successful operation of the systems shall be included in the scope of the bidder.

1.5.7

and

SCOPE OF SERVICES:

For Supervision of erection, testing and commissioning of the equipment of the equipment

will be done by the supplier, if required.

RASHMI METALIKS LTD

TECHNICAL SPECIFICATION OF 33KV IN DOOR SWITCH BOARD

FOR 350 CUM MBF AT KHARAGPUR

2. TECHNICAL SPECIFICATION FOR 33 kV SWITCHBOARD

2.1

Introduction

2.1.1

This specification covers the design, manufacture, supply & supervision of

erection, pre-commissioning & commissioning of 33 kV indoor type

switchboard incorporating draw out vacuum circuit breakers.

2.1.2

The 33 kV switchboard shall be capable of continuous and reliable

operation at the full load rating specified where continuity of operation is

of prime importance. Workmanship shall be the highest grade and the

entire construction in accordance with the best modern practice. The HT

switchboard shall be capable of withstanding the severest stresses likely to

occur in actual service and of resisting rough handling during transport.

2.1.3

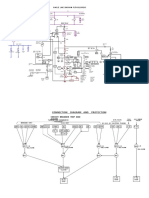

The HT switchboards shall have incoming and outgoing feeders as

specified elsewhere in the enclosed single line diagram.

2.1.4

Circuit breaker shall be suitable to withstand inrush magnetising currents

of transformers and capacitor bank ON and OFF. Also circuit breakers

shall be used for synchronizing applications as specified.

Specific Requirements:

HT Switchboard:

2.2

2.2.1

Rated voltage

Rated frequency

Fault level

Degree of Protection

Highest System Voltage

One

minute

Power

Frequency

Withstand voltage

1.2/50 micro second impulse

Clearance in air

Busbar Material

:

:

:

:

:

:

33 kV, 3 phase

50 Hz

31.5 kA for 3 sec

IP4X

36 kV

70 kV(rms)1

: 170kV (peak)1

: As per IS/IEC

: High Conductivity Electrolytic

grade Copper

Busbar Rating under natural cooled : 2000A

condition

1

The insulation level of the synchronization breakers shall be as recommended by IEC:61936-1:2002 and

IEC:60694:2001

RASHMI METALIKS LTD

TECHNICAL SPECIFICATION OF 33KV IN DOOR SWITCH BOARD

FOR 350 CUM MBF AT KHARAGPUR

Design Ambient

Maximum Busbar Temperature

Cable Entry for Outgoing feeder

Cable Sizes

Class & VA Burden rating for CT/ PT

2.2.2

Communication protocol for Relays

Communication protocol for meters

Earthing System

Breaker Requirements:

Description

Design ambient

Natural Cooling Condition

Forced Cooling Condition

Rated Voltage

Rated frequency

Fault level

Circuit Breaker Type

Highest System Voltage

One

minute

Power

Frequency

Withstand voltage

1.2/50 micro second impulse

Clearance in air

Operating Duty

Rated short circuit breaking capacity

Dynamic Rating

Rated short circuit making capacity

DC current

Rated Asymmetrical breaking capacity

Control Voltage

2.3

:

:

:

:

45 C

As per IEC

Bottom of the panel

As specified in the SLD.

Shall be as specified in the

SLD.

: IEC61850

: PROFIBUS / IEC61850

: Resistance Earthed / Unearthed

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

Outgoing Feeder Circuit

Breaker

45 C

Shall not be less than 2000 A

of in panel rating

Not applicable

33 kV, 3 phase

50 Hz

31.5 kA for 3 sec

Vacuum

36 kV

70 kV (rms)2

170 kV (peak)2

As per IS/IEC

O-0.3s-CO-3 min-CO

31.5 kA

78.75 kA

78.75 kA

14.25 kA (minimum)

34.57 kA

110 V DC, with

independent source

single

Standards

The design, manufacture and testing of various equipments covered by

this specification shall comply with the latest issue of the following

standards:

The insulation level of the synchronization breakers shall be as recommended by IEC:61936-1:2002 and

IEC:60694:2001

RASHMI METALIKS LTD

TECHNICAL SPECIFICATION OF 33KV IN DOOR SWITCH BOARD

FOR 350 CUM MBF AT KHARAGPUR

IS:375

Marking and arrangement of switchgear busbars

IS:694

PVC insulated cable with copper conductor for

voltages upto 1100 V

IS:722

Integrating meters

IS:1248

Electrical indicating instruments

IS:13118

General requirements of circuit breaker for

voltages above 1000V.

IS:2705

Specifications for current transformers

IS:3156

Specifications for voltage transformers

IS:3231

Electrical relays for power system protection

IS:3427

Metal enclosed switchgear and control gear (1 kV

to 52 kV)

IS:6865

Control switches and push buttons

IEC 44

Instrument Transformers

IEC 255

Electric Relays

IEC 1036

Static Meters

IEC 60044-1 -

Current Transformers

IEC 60041-2 -

Potential Transformers

IEC 62271-200-

Circuit Breakers

RASHMI METALIKS LTD

TECHNICAL SPECIFICATION OF 33KV IN DOOR SWITCH BOARD

FOR 350 CUM MBF AT KHARAGPUR

2.4

2.4.1

General Requirements

Construction

2.4.1.1

The switchgear shall be metal clad, free floor standing, totally enclosed, dust and vermin

proof with draw out type circuit breakers. Vertical units shall be assembled to form a

continuous line up of uniform height.

2.4.1.2

The panel structure shall house the components contributing to the major weight of the

equipment such as circuit breaker, main horizontal busbars and other of the

components is adequately supported without deformation or loss of alignment during

transit or during operation.

Each unit of the switchgear shall have necessary internal sheet metal barrier to form

separate compartments for buses, instruments, relays, cable connections etc.

2.4.1.3

2.4.1.4 Adequate barriers shall permit personnel work safely within an empty compartment

with the busbars energised.

Checking and removal of components shall be

possible without disturbing the feeder. All auxiliary equipment shall be easily

accessible to facilitate their operation and maintenance.

It shall be possible to

set all relays and measuring instruments without de-energising the switchgear.

2.4.1.5 All doors and openings shall be fitted with dust excluding neoprene gaskets with

fasteners designed to ensure proper compression of the gaskets.

2.4.1.6 When covers are provided in place of doors, generous overlap shall be assured

b e t w e e n sheet steel surfaces with closely spaced fasteners to preclude the entry

of dust.

2.4.1.7 The panels shall have a rear cable chamber housing the cable and connections

the design shall ensure generous availability of space for easy installation and

maintenance. Cabling and adequate safety for working in one section without coming

into accidental contact with live part in an adjacent section.

2.4.1.8 HT switchboard shall be constructed only of materials capable of withstanding the

mechanical, electrical and thermal stresses, as well as the effects of humidity, which are

likely to be encountered in normal service. All insulating materials used in construction

of the equipment shall be non-hydroscopic material, duly treated to withstand the

effects of high humidity high temperature tropical ambient service conditions. Creepage

distances shall comply to those specified in relevant standards.

2.4.1.9 Each panel shall be provided with space heater to prevent condensation and the same

shall be equipped with differential thermostat to automatically cut in and cut

out the heater so as to maintain interior temperature of 5 Deg.C. above the ambient

and should have manual disconnect switch.

2.4.1.10 The height of the panel shall not be more than 2700 mm. The total depth of the panel

shall be adequate to cater for proper cabling space.

RASHMI METALIKS LTD

TECHNICAL SPECIFICATION OF 33KV IN DOOR SWITCH BOARD

FOR 350 CUM MBF AT KHARAGPUR

2.4.1.11

Provision shall be made for permanently earthing the frames and other

metal parts of the HT switchboard through a copper earth busbar running

throughout the full length of the switchboard at the bottom. Drawout type

switching units shall have sliding ground contact. It shall be possible to

earth the switchboard at two independent points on either ends for

connections to the external earthing network of the plant.

2.4.1.12

The panel shall have provision to extend on either direction of the board at

a future date (2 Feeders on LHS & 2 Feeders on RHS). The Ends of

busbars shall be suitably drilled for this purpose.

2.4.1.13

Suitable eye bolt for lifting of panel shall be provided. On removing the

eye bolts no holes offering access to panel shall be provided.

2.4.1.14

Circuit breaker closing, tripping, control and indication power will be

connected from single sources of 110V DC supply.

2.5

Busbars

2.5.1

The busbars shall be epoxy moulded sleeved.

2.5.2

2.5.3

The busbar chamber shall be totally maintenance free.

The switchboard shall comprise 3 phase main busbars which shall extend

through all units of the switchgear line up. The busbar mating surface

shall be tinned. High tensile bolts and spring washers shall be provided at

all busbar joints and busbar joints shall be silver plated. The busbar shall

be of uniform section throughout and shall be sized to continuously carry

the rated current without exceeding the maximum temperature rise, as

recommended by IEC over the maximum ambient temperature as

specified. Busbars shall be colour coded for easy identification of

individual phases. The SUPPLIER shall submit temperature rise test

report for the substantiating the selected size of busbars.

2.5.4

Busbars shall be supported at regular intervals and both, busbars and

supports shall be adequately sized and braced to withstand short circuit

level without deformation. All bus supports shall be non-carbonizing

material resistant to acid alkalies and shall have non-hydroscopic

characteristics.

For long busbars suitable expansion joints shall be provided. Thermal

design of the busbars shall be based on the installation of the switchgear in

poorly ventilated condition as per IS Thermal Design.

2.5.5

RASHMI METALIKS LTD

TECHNICAL SPECIFICATION OF 33KV IN DOOR SWITCH BOARD

FOR 350 CUM MBF AT KHARAGPUR

2.5.6

Busbars shall be housed in a separate chamber which shall be accessible

for inspection only with special tools.

2.5.7

Insulated busbars for control supply of 110V DC & 220V AC through out

the panel shall be provided.

2.6

2.6.1

Circuit Breakers

Circuit breakers shall be triple pole, vacuum circuit breaker, drawout type.

2.6.2

The breakers shall have motor operated spring charged mechanism with

anti-pumping contactor. The control circuit shall be suitable for local as

well as remote control. Provision for manual operation shall also be

available.

2.6.3

The power supply voltage for the spring charge motor shall be 110V DC.

2.6.4

The breaker sockets and plugs should be heavily silver plated. The

breaker shall have adequate auxiliary contacts required by plant control

schematics. Additional 30% spare contacts (Minimum 10NO + 10NC) for

future use shall be provided and wired upto Terminal Boxes. Auxiliary

relays should be used to multiply the contacts.

2.6.5

All spare contacts of breakers shall be wired upto terminal blocks.

2.6.6

The operating mechanism shall be robust design with a minimum number

of linkages to ensure maximum reliability. The operating mechanism

shall be such that the breaker is at all times free to open immediately the

trip coil is energised. It is to be ensured that all the three poles open/close

in unison to avoid any eventuality of single phase operation of the

generator. All controls shall be suitable for 85 % to 110 % for closing of

110VDC and 70% to 110 % for tripping of 110 V DC supply.

2.6.7

Two (2) numbers of tripping coils shall be used for tripping the circuit

breaker and shall be planned with 110V DC supply along with capacitor

tripping unit for all breakers. The DC tripping circuit shall be provided

with capacitive tripping device additionally to facilitate positive operation

of the DC tripping coil in the event of failure of DC supply to the tripping

circuit.

2.6.8

Breaker shall be tripped through any of the trip coils available in the

breaker through TNC switch / remote tripping impulse / master trip

operated signal during normal operation.

RASHMI METALIKS LTD

TECHNICAL SPECIFICATION OF 33KV IN DOOR SWITCH BOARD

FOR 350 CUM MBF AT KHARAGPUR

2.6.9

The breaker shall have the distinct positions indicating:

`Service ' position:

`Test' position

With main auxiliary contacts connected

:

With power contacts fully disconnected and control

circuit contacts connected

`Isolated' position:

2.6.10

2.6.11

With both power and control circuit contacts

fully disconnected

The trolleys of the circuit breaker shall be so inter-locked that,

-

It shall not be possible to isolate it from the inserted position or

to insert it in from the isolated position with the breaker closed.

The circuit breaker can be closed only when it is in one of the three

positions or when it is fully out of the panel.

It shall not be possible to open the breaker compartment door

unless the breaker is drawn to the isolated position or test position.

Inadvertent 'pushing in' of the drawout circuit breaker in service

position, with auxiliary circuit plug not in the position shall be

prevented.

2.6.13

The breaker shall be able to function even under condition of phase

opposition that may arise due to totally out phase synchronisation as per

relevant IS or IEC standard.

The tips of the main contact shall be adequately silver plated to withstand

arcing.

The operating mechanism shall be electrically controlled spring operated.

2.6.14

Mechanism shall have anti pumping and trip free circuitry.

2.6.15

Local arrangement for operating the breakers both electrically and

mechanically shall be provided.

2.6.16

The breaker trolley shall remain inside the cubicle even in the draw out

position.

2.6.17

Automatic safety shutters shall be provided to ensure the inaccessibility of

live parts after the breaker is drawn out.

2.6.12

RASHMI METALIKS LTD

TECHNICAL SPECIFICATION OF 33KV IN DOOR SWITCH BOARD

FOR 350 CUM MBF AT KHARAGPUR

2.6.18

The circuit breaker trolley shall be provided with a heavy duty self

aligning earth contact which shall make before and break after the main

isolating contacts during insertion into and withdrawal from the service

position of the breaker. Even in the isolated position positive earthing

contact should exist.

2.6.19

Circuit breakers of identical rating shall be inter-changeable.

2.6.20

Circuit breaker shall have provision for manual re-charging.

2.6.21

ON / OFF indicator and number of operation centre shall be provided.

2.6.22

Mechanical lock along with cover shall be provided for closing lever /

knob for the circuit breaker, which are identified for synchronising

purpose.

2.7

Earthing Trolleys

2.7.1

Bus earthing and cable earthing trolleys (one number each per rating) shall

be provided along with each switchboard. Necessary safety interlocking

shall be incorporated in the bus earthing trolley to avoid insertion of

trolley, when the bus is live. Similarly, suitable interlock shall be

provided to avoid insertion of cable earthing trolley, when the cable side is

live (i.e.) supply is extended from remote for incomer feeders. These

interlocks shall be of electro-mechanical type. Closing of the source

incomer breakers shall be inhibited when the Bus earthing trolley is in

inserted position by providing a suitable mechanical key interlock.

2.8

2.8.1

Current Transformers

The current transformer shall be cast-resin insulated type of adequate

capacity and proper characteristics on secondary as specified. The current

density should not be more than 1000 amps/sq.inch.

2.8.2

CTs shall withstand stresses originated from short circuit. They shall have

ratios, output and accuracy as specified in the drawings. Single core type

CTs shall be provided for 2000 Amps rating breaker feeders. CTs in other

feeder shall be of multicore type.

2.8.3

CTs shall be preferably of bar primary type, they shall be mounted on the

switchboard stationary part and suitable approach for maintenance shall be

provided.

RASHMI METALIKS LTD

TECHNICAL SPECIFICATION OF 33KV IN DOOR SWITCH BOARD

FOR 350 CUM MBF AT KHARAGPUR

2.8.4

The secondary CT leads from all panels should be terminated on the front

of the board on easily accessible shorting type terminal connectors so that

operation and maintenance can be carried out when the panels are in

service.

2.8.5

CTs shall be suitable for continuous loading of 120% of rated current.

2.8.6

CTs shall be subjected to heat run test, if the same has not been type tested

in the last three years.

2.8.7

Single CBCT shall be considered in at incoming / outgoing feeders

covering all runs of cables as indicated in the single line diagram.

2.8.8

The Burden indicated for the current transformers shall be at lowest

tappings.

Potential Transformer

The potential transformer shall be cast-resin insulated type. It shall be

draw out type and easily accessible so that the same can be attended to or

replaced when the panels are in service condition.

2.9

2.9.1

2.9.2

The potential transformers shall be protected through HRC fuses on

primary side and MCBs on secondary side. They shall have ratios,

outputs and accuracies specified.

2.9.3

The draw out mechanism shall disconnect the primary connection before

the PT or its primary fuses become accessible.

2.9.4

All PTs shall be single phase type. The voltage factor shall be 1.2 times

continuous and 1.9 times for 8 hours.

2.9.5

The Line PTs will be mounted on the top of the respective panel and

separate cubicle will be provided for bus PT.

2.10

2.10.1

Integrating Meters

Integrating meters of the Trivector or equivalent types capable of

indicating all phase instantaneous parameters and recording kWH,

kVARH and kVAH directly shall be provided.

2.10.2

These shall be suitable for 3 phase, 4 wire 50 Hz circuits with unbalanced

loading and with two sets of elements connected to current and potential

transformers of specified ratio.

RASHMI METALIKS LTD

TECHNICAL SPECIFICATION OF 33KV IN DOOR SWITCH BOARD

FOR 350 CUM MBF AT KHARAGPUR

2.10.3

The trivectormeter shall be of digital type, class 0.2 or better with

communication port, RS485 interface with the protocol as specified in

the specific requirement of the switchboard, for hooking up to PC /

DCS.

2.10.4

The Trivector meters available all the incoming and outgoing feeders shall

have import/export facility.

Indicating Lamps

Indicating lamps shall be of cluster LED type low watt consumption,

provided with series resistor where necessary and with translucent lamp

covers. Bulbs and lenses shall be easily replaceable from the front.

2.11

2.11.1

2.11.2

2.11.3

2.11.4

Following indicators are required on the panel having lens colours as

follows:

Breaker ON

:

RED

Breaker OFF

GREEN

Auto trip

AMBER

Trip Circuit healthy

WHITE

Spring Charged

BLUE

Breaker in Test position

WHITE

Breaker in Service Position

RED

Potential Free contacts for the following function shall be provided in the

synchronising breaker panels for hooking up to synchronisation panel:

a)

Breaker ON

b)

Breaker OFF

c)

Spring Charged

d)

Auto Trip

Live line indications with proven design shall be provided at incoming

and outgoing sides of all the feeders and bus bars. No PT supply shall be

used for the above purpose.

RASHMI METALIKS LTD

TECHNICAL SPECIFICATION OF 33KV IN DOOR SWITCH BOARD

FOR 350 CUM MBF AT KHARAGPUR

2.12

Relays

2.12.1

All protective relays shall be back connected, draw out type, suitable for

flush mounting and fitted with dust tight covers. All relays shall be

mounted on the front of the panel and shall be specified as per

requirement. The current and the voltage coils shall be rated as specified.

2.12.2

All relays shall have built-in flag / indicator to indicate operation. All

tripping relays shall be suitable to operate on the specified DC voltage.

2.12.3

Feeder & transformer protection relays shall be of numeric /

microprocessor type with self diagnostic facility, RS 485 communication

port with protocol as specified for interfacing with PC / DCS, software for

data downloading & configuration. Feeder / transformer protection relays

shall have IDMT / highset overcurrent & earth fault elements. Alpha

numeric display shall be available for the relays and all fault data

shall be displayed in natural language, without needing to refer codes

/ manuals.

2.12.4

Separate sensitive earth fault relay shall be provided for the feeders as

called for in the single line diagram. Any case this relay can not be

combined with the main protection of the feeders.

2.12.5

Master trip relay, trip circuit supervision relays and auxiliary relays shall

be provided, wherever specified. All the auxiliary relays shall be

electromagnetic type.

2.12.6

All spare contacts of relays shall be wired up to Terminal Blocks.

2.13

Control Switches and Push Buttons

2.13.1

Control switches shall be of the heavy duty rotary type with name plates

clearly marked to show the operation. They shall be semi-flushed

mounting with only the front plate and operating handle projecting.

2.13.2

Circuit breaker control switches shall be of the spring return to neutral

type, while local / remote selector switches and instrument selector

switches shall be of the stay-put type.

2.13.3

Emergency push button shall be provided for each circuit Breaker in the

panel

2.13.4

Mush-room type emergency push button shall be provided.

RASHMI METALIKS LTD

TECHNICAL SPECIFICATION OF 33KV IN DOOR SWITCH BOARD

FOR 350 CUM MBF AT KHARAGPUR

2.14

Internal Wiring

2.14.1

Internal wiring and inter-panel wiring for all circuits shall be carried out

with 1100/660 V grade, single core, multi strand, PVC insulated copper

conductor wire of minimum 2.5 Sq.mm for other control circuit.

2.14.2

The wiring shall be neatly bunched adequately supported and properly

routed and terminated in the respective terminals with suitable lugs. There

shall not be more than two wires connected at a terminal.

2.14.3

Wires shall be identified by numbered ferrules at each end. The ferrules

shall be of ring type and non deteriorating material.

2.14.4

All control circuits shall have MCBs mounted in front of the panel and

shall be easily accessible.

2.15

Terminal Blocks

2.15.1

Terminal blocks for the LT connections shall be of 660V grade of stud

type and of adequate current rating with minimum 2.5Sq.mm.

2.15.2

The insulating barriers shall be provided between adjacent terminals.

Provision shall be made for label inscription on terminal block. Cables

should never be terminated directly on components. Provision shall be

made for CT terminals shorting links, remote ON/OFF pushbutton, remote

ON/OFF indication and remote ammeter. 30% spare terminals shall be

provided on each terminal block.

Cable Termination

The HT switchboard shall be designed to facilitate outgoing power

connection through XLPE insulated armoured cables with bottom entry.

2.16

2.16.1

2.16.2

Ample space for connection of these cables shall be provided at the rear of

the switchboard. The cable termination arrangement shall be of adequate

size and design to receive the required number of cables as specified.

Proper cable clamping arrangement shall be provided. Minimum height

of 700mm shall be maintained between gland plate and the terminals

for the HV cables.

2.16.3

Detachable gland plate of adequate thickness shall be provided for the

cable entry into the panel. Sufficient space shall be provided to avoid

sharp bending and easy connection. Gland plates to be made up of nonmagnetic material, wherever single core cable are used.

RASHMI METALIKS LTD

TECHNICAL SPECIFICATION OF 33KV IN DOOR SWITCH BOARD

FOR 350 CUM MBF AT KHARAGPUR

2.16.4

Suitable shrouds shall be provided to prevent accidental contact with live

outgoing terminations of other feeders while carrying out maintenance on

one feeder.

2.17

Labels

2.17.1

Name plates of approved design shall be provided to represent circuit

designation for each feeder. Material for name plates shall be anodised

aluminium. They shall be firmly secured with fasteners.

2.18

Painting

2.18.1

All metal surfaces shall be chemically cleaned, degreased and pickled in

acid to produce a smooth clean surface, free of scale, grease and rust.

2.18.2

After cleaning, phosphating and passivation treatment, the surface shall be

given two coats of zinc rich epoxy primer and baking in the oven.

2.18.3

After primer, it shall be given two coats of epoxy paint, shade RAL 7032,

in semi matt finish. Sufficient quantity of touch up paint shall be

furnished for application at site

2.19

Tests

2.19.1

The 33 kV switchboard shall be tested for routine tests as per the relevant

IS / IEC.

2.19.2

All the panels shall be tested in assembled condition

2.19.3

The routine tests shall be carried out in the presence of PURCHASER /

CONSULTANT.

2.19.4

Type test certificates having conducted in the last three years shall be

submitted for similar rating, type of the switch board and circuit

breakers for review. In case the above is not available, the

SUPPLIER shall have to conduct the type tests as per IEC/IS with out

affecting delivery schedule of the switch board without cost to

PURCHASER.

RASHMI METALIKS LTD

TECHNICAL SPECIFICATION OF 33KV IN DOOR SWITCH BOARD

FOR 350 CUM MBF AT KHARAGPUR

2.20

List of Documents / Drawings to be Submitted

2.20.1

Drawings / Documents required along with the Bid

2.20.1.1

The BIDDER shall submit in their Technical BID, drawings, diagrams

and all such information which are necessary to fully understand the offer

both technically and commercially.

2.20.1.2

As a minimum requirement the following information shall be supplied

with the technical bid in sufficient detail to fully describe the scope of

work and the services offered:

2.20.1.2.1

Filled in Bidder Credentials

2.20.1.2.2

Filled-in data sheets and schedules.

2.20.1.2.3

Feeder wise Dimensioned General Arrangement Drawings showing

the physical location of all the components for HT Switchboard

2.20.1.2.4

Bill of quantities with type references.

2.20.1.2.5

Fish plate details.

2.20.1.2.6

Quality Assurance Plan.

2.20.1.2.7

Catalogues of all equipment.

2.20.1.2.8

List of sub-suppliers.

2.20.2

Drawings and information required from Supplier during Contract

Stage

2.20.2.1

The drawings and documents to be furnished by the SUPPLIER after the

award of the contract shall include but not limited to the following. A

drawing / document submission schedule clearly identifying the

documents to be submitted and the purpose of the submission (for

information, approval etc., as elaborated elsewhere in this document) shall

be furnished after discussions and in consultation with the

CONSULTANT / PURCHASER.

2.20.2.2

Detailed time schedule in the form of network or bar chart for the design,

manufacture, delivery, erection, testing and commissioning period with

critical milestone activities and other important intermediate dates for

uninterrupted progress of the project.

RASHMI METALIKS LTD

TECHNICAL SPECIFICATION OF 33KV IN DOOR SWITCH BOARD

FOR 350 CUM MBF AT KHARAGPUR

2.21.2.1

The following drawings and documents shall be compiled in a single set

and submitted for approval:

Filled-in revised technical data sheets.

Quality Assurance Plan.

List of manufacturers and specification of all standard equipment.

Catalogues of all equipment.

Connection diagram for all units (like incomer, outgoing feeders,

breaker wiring diagrams, etc.).

Schematic diagram for the complete switchboard.

Fish plate details for the busbar connections.

Terminal connection diagram of the main terminal boards.

Temperature Rise test certificates for similar ratings conducted at

any recognised institute.

Sketches of the overall dimensions of the board / busduct - plan,

elevation and section views clearly showing the bus size.

Typical internal arrangement drawings for all types of feeders,

showing clearly the dimensions of components / devices and

clearances.

Plan and sectional layout with detailed bill of quantities for the

busduct and its accessories.

Brand names of all components incorporated in the boards, etc.

Marshalling TB schedule as per the required format.

Guaranteed technical particulars for the critical components.

Certificates of tests giving the results of tests conducted as per the

appropriate standards on similar switchboard and interior

components.

Shipping dimensions of the board / busduct and its weight - gross

and net (without packing).

RASHMI METALIKS LTD

TECHNICAL SPECIFICATION OF 33KV IN DOOR SWITCH BOARD

FOR 350 CUM MBF AT KHARAGPUR

Test certificates and inspection reports of all equipment.

2.21.2.2

Other drawings and documents as indicated in various sections of

this document.

Erection manuals and installation procedures for all equipment.

2.21.2.3

Operation and maintenance manuals for all equipment and systems.

2.21.2.4

'As-Built' drawings.

2.21.2.5

CD containing all final drawings and documents.

RASHMI METALIKS LTD

TECHNICAL SPECIFICATION OF 33KV IN DOOR SWITCH BOARD

FOR 350 CUM MBF AT KHARAGPUR

2.21.2.6

2.21

Each drawing / document shall have a title block consisting of the

following:

Project

Customer

Consultant

Title

Drg. No.

Rev.No. and Details

List of Operational Spares

The scope of supply for this package shall include the items as mentioned

below:

a.

Three (3) Numbers of 110V DC Tripping Coil for each type of

breaker 1 Lot

b.

c.

d.

Two (2) number of spring charging Motor for each type of breaker

1 Lot

One Set of PT Fuses (3 nos) 1 Lot

Five (5) Sets of Indication lamps for each colour 1 Lot

e.

Three (3) Sets of fixed contacts with shrouds in each rating of

breaker 1 Lot

f.

Three (3) sets of main contacts with shrouds in each rating of

breaker 1 Lot

g.

Two (2) sets per rating of Auxiliary contacts for breakers 1 Lot

RASHMI METALIKS LTD

TECHNICAL SPECIFICATION OF 33KV IN DOOR SWITCH BOARD

FOR 350 CUM MBF AT KHARAGPUR

2.22

Make of Components

1.

HT Breaker( VCB)

BHEL/Siemens/ABB/Areva/Crompton

2.

Vacuum Contactor

BHEL/Siemens/ABB/Areva/Crompton

3.

HRC Fuse.

L & T /GE/ Siemens

4.

Timer

L & T /GE/ BCH/ Schneider/EAPL

5.

Pushbutton

L & T / Siemens/ BCH/ Vaishnu/ GE

6.

Indication Lamp

Vaishnu/ L&T/ Siemens/ BCH/Emco

7.

Current Transformer

AE / Kappa / PRAGATHI

8.

Indicating Meters

Enercon/AE / Rishav (L&T) / IMP/ SCHNEIDER

9.

Selector Switch- Auto / Manual

Kaycee / Salzer / Vaishnu

10.

Power Terminal

Connectwell / ACDC/Elmex

11.

Control Terminal

Elmex / Connectwell / ACDC

12.

Power & Control wire.

Finolex / KDK

13.

Socket (Crimping type)

Dowells / UML/ Clippon

14.

Transducer

Enercon/AE /ABB

15.

Potential Transformer

AE / Kappa

16.

T N C Switch.

Alstom / Salzer

17.

MCB

MDS / Siemens/ GE

18.

Hooter.

Kheraj / Local

19.

Relay

Alstom / ABB/L&T

RASHMI METALIKS LTD

TECHNICAL SPECIFICATION OF 33KV IN DOOR SWITCH BOARD

FOR 350 CUM MBF AT KHARAGPUR

3.0 CLEANING AND PACKING:

3.1

CLEANING

Surface of all parts shall be cleaned to remove scale, dirt, oil, water, grease and other foreign

objects prior to final assembly of the equipment.

3.2 PACKING

The equipment after acceptance by inspecting agency, if any shall be shipped to site duly

packed in wooden crate. The equipment shall be wrapped in polyethylene sheet before being

placed in crate or wooden box. All crates shall have skid bottom for handling. All lose parts

of the equipment shall be properly boxed. The consignee address to be clearly marked on the

crate. The wooden crate or box shall be sturdy so that it is not damaged during transportation

or handling.

3.3

DELIVERY:

Delivery period of the equipment including all its accessories specified in the specification

shall be strictly follows as per order. Timely delivery of the equipment is the essence of

contract.

3.4

GUARANTEE:

The supplier should be responsible for correctness of rating / workmanship and performance

of the equipment. The supplier / bidder shall provide a guarantee covering rectification of all

detects in the design, materials and workmanship of all items provided under the

specification for a period of 12 months from the date of satisfactory commissioning and 18

months from the date of delivery whichever period is later. During guarantee period any

defects found with the parts or equipment will be free replacement or repairing of the

defective item. The guarantees for performance shall cover individual items and the system

as a whole.

3.5 SPARES:

3.5.1 COMMISSIONING SPARES

All spares required for commissioning of the 33KV H.T. Switch Board and for its efficient

operation until provisional acceptance after demonstration of satisfactory performance in

accordance with the guarantees are in the scope of supply.

3.5.2 SPARES FOR TWO (2) YEARS OF NORMAL WORKING

Bidder are to submit purchaser a list of recommended spares for two years of normal

operation of 33 KV H.T. Switch Board.

RASHMI METALIKS LTD

TECHNICAL SPECIFICATION OF 33KV IN DOOR SWITCH BOARD

FOR 350 CUM MBF AT KHARAGPUR

3. DATA SHEETS AND SCHEDULES

SL.

DESCRIPTION

PAGE NO.

3.1

BIDDER INFORMATION

II.21

3.2

BIDDER CREDENTIAL

(to be submitted along with the offer)

II.22

3.3

33 kV SWITCHGEAR

II.23

3.4

SCHEDULE OF DEVIATIONS

II.26

RASHMI METALIKS LTD

TECHNICAL SPECIFICATION OF 33KV IN DOOR SWITCH BOARD

FOR 350 CUM MBF AT KHARAGPUR

Data Sheet No.

Title :

S.No

3.1

BIDDER INFORMATION

Description

Bidder's complete Company Name and Postal Address

Tender Reference and Date

Proposal Validity (No. of Days)

Whether particulars of past similar experiences

furnished?

Name and particulars of Collaborator, if applicable

Equipment warranty period from the date of

commissioning

Whether furnished offer as per specification?

Whether list of deviations / exclusions taken furnished?

Whether all taxes & duties included in the price

schedule?

10

Whether offer for 2 years' operational spares included?

11

Whether all commissioning spares included in base

offer?

12

Whether a project schedule with commissioning date

is enclosed?

13

Whether equipment guarantee schedule furnished?

14

Whether the drawings required as per specification

enclosed?

15

Whether quality plan enclosed?

Signature Of The Bidder :

Sheet No.: 1 / 1

Unit

RASHMI METALIKS LTD

TECHNICAL SPECIFICATION OF 33KV IN DOOR SWITCH BOARD

FOR 350 CUM MBF AT KHARAGPUR

Data Sheet No.

Title :

S.No

3.2

BIDDER CREDENTIAL (to be submitted along with the offer)

Description

Unit

Manufacturing unit location

No. of years in manufacture of MV / HV Switchboards

Total No of MV / HV Switchboard supplied per year for last three

Years

a. 2007-08

b.2008-09

c.2009-10

Turn-over of MV / HV Switchboard division for last three year

in Rs. Crores

a. 2007-08

b.2008-09

c.2009-10

Whether Type Test Certificate Copies enclosed, conducted

within the last three (3) years ?

Sheet No.: 1 / 1

a.

Temperature rise test certificates for 2000A rating

Yes / No

b.

Short time rating (31.5kA with Idc of min.30%) certificate

Yes / No

In-panel rating for 2000A breaker at ambient of 45 Deg C?

Confirm whether the submitted offer has any Deviations

( if Yes, kindly ensure that the schedule of deviations sheet

is attached with the offer )

Yes / No

Confirmation of circuit breakers for the intended application

as specified in the clause no:2.2.2

Yes/No

Signature Of The Bidder :

RASHMI METALIKS LTD

TECHNICAL SPECIFICATION OF 33KV IN DOOR SWITCH BOARD

FOR 350 CUM MBF AT KHARAGPUR

Data Sheet No.

Title :

S.No

1

Sheet No.: 1 / 3

3.3

33 kV SWITCHGEAR

Description

Unit

Make

Type of switchgear

Voltage rating

kV

Rated Current

Short time current

kA

Short time duration

Sec.

Max. temperature of busbar

Continous current rating of busbars and busbar material

Degree of protection

10

Colour, finish and shade

11

Busbar insulation

12

1.2/50 micro sec.impulse

kV

13

1 min. power frequency

kV

14

Cable Entry

15

o. of Incomer Feeders and Rating

16

No. of Outgoings Feeders and Rating

17

Whether Bus PT panel considered?

18

Whether CTs, PTs, metering and protection provided as

per drawing / specification?

19

Breaker Details:

19.1

Rated Voltage

kV

19.2

Rated short circuit breaking capacity

kA

19.3

Rated current

19.4

Rated short circuit making capacity

Signature Of The Bidder :

Amps

kA

RASHMI METALIKS LTD

TECHNICAL SPECIFICATION OF 33KV IN DOOR SWITCH BOARD

FOR 350 CUM MBF AT KHARAGPUR

Data Sheet No.

Title :

S.No

3.3

33 kV SWITCHGEAR

Description

Sheet No.: 2 / 3

Unit

19.5

Rated short circuit duration

19.6

DC component of rated short circuit breaking current

19.7

Rated assymetrical breaking capacity

kA

19.8

Rated lightning impulse withstand voltage

kV

19.9

Rated power frequency withstand voltage

kV

19.10

Drive

19.11

Rated Operating Duty

19.12

Rated Auto Reclosing Duty

19.13

Rated No. of Operation at Rated Current

19.14

Rated No. of Operation at Rated Short Circuit Current

19.15

Mechanical life of Interrupter

19.16

Mechanical life for Drive

19.17

Operating Times

19.17.1

Closing Time

19.17.2

Spring Charging Time

19.17.3

Opening Time / Contact parting time

19.17.4

Arcing Time

19.17.5

Break Time

19.17.6

Dead Time

19.17.7

Close-open Time

19.17.8

Minimum command duration

a. Opening

b. Closing

Signature Of The Bidder :

m sec

RASHMI METALIKS LTD

TECHNICAL SPECIFICATION OF 33KV IN DOOR SWITCH BOARD

FOR 350 CUM MBF AT KHARAGPUR

Title :

Sl.No.

PRICE SCHEDULE

Description

I.

SWITCHBOARD

1.

Basic price of 33 kV Switchboard complete with CTs/PTs, etc.,

as per enclosed drawings & Ex-works,including packing &

forwarding charges

a.

33 kV Switchgear Panel as per Drg. Titled, "Single Line Diagram

.

for 33 kV Switchboard",

Drg. No: 2-27331-900-0468, Rev.0

b.

c.

e

f.

2.

3

4

5

6

7

II

1.

2.

3.

III

Supply of manufacturers recommended Commissioning Spares.

T

Supply of manufacturers

E recommended Maintenance spares for two

years Normal operation.

N

Busbar EarthingD

Truck with necessary interlocks (2000A)

E

Cable Earthing Truck with necessary interlocks (2000A)

R

Cable Earthing Truck with necessary interlocks (1250A)

D

R

Excise Duty including

A education cess

W

Sales Tax / CST / VAT

I

Freight Charges N

upto Site

Transit InsuranceG

Sub-Total (a to f)

Total (2 to 6)

Site Services

Charges for switchboard commissioning and supervision of

erection, Pre-commissioning and Commissioning

(Minimum four (4) days & two (2) visits)

Configuration & simulation of the numeric relay and training

of plant engineers for operation & maintenance of the numeric

relays (Minimum two (2) days & one (1) visit)

Total (1 to 2)

GRAND TOTAL (I.7 + II.3)

Signature Of The Bidder :

Unit

1 Set

1 Lot

1 No.

1 Lot

1 No.

1 No.

Total Price in Rs.

Você também pode gostar

- 50SDMS01Documento11 páginas50SDMS01amazonia1954Ainda não há avaliações

- Technical Specification OF 11&33 KV Indoor Type Switchgear For Consumer SubstationDocumento12 páginasTechnical Specification OF 11&33 KV Indoor Type Switchgear For Consumer SubstationAhmed JwdhariAinda não há avaliações

- 2012 CALPEC Electrical Basis of DesignDocumento6 páginas2012 CALPEC Electrical Basis of DesignGaurav YadavAinda não há avaliações

- 005-WPL-26-003 - 33kV Line-3 (D3) Control Cable Sch. & Term.Documento4 páginas005-WPL-26-003 - 33kV Line-3 (D3) Control Cable Sch. & Term.priyanka236Ainda não há avaliações

- Vol 2 - C3.4.4 Standard Specifications For Electrical WorksDocumento127 páginasVol 2 - C3.4.4 Standard Specifications For Electrical Worksashutosh ambeyAinda não há avaliações

- D-09 2016 معدات ض.و خارجية قاطع دورة مع صندوق محولات توزيعDocumento8 páginasD-09 2016 معدات ض.و خارجية قاطع دورة مع صندوق محولات توزيعAhmed Al-BaghdadiAinda não há avaliações

- Control Cable ScheduleDocumento25 páginasControl Cable Scheduleshrikanth5singhAinda não há avaliações

- Power House Lighting Outside Lighting Battery Charger Power Point Unit 2 Power Point Unit 1 16A DPDocumento24 páginasPower House Lighting Outside Lighting Battery Charger Power Point Unit 2 Power Point Unit 1 16A DPPritam SinghAinda não há avaliações

- LV Motors Controlcable Schedule CHP - 1.Documento7 páginasLV Motors Controlcable Schedule CHP - 1.superthambiAinda não há avaliações

- Heat DissipationDocumento17 páginasHeat DissipationAsif SajwaniAinda não há avaliações

- Sa3-Ps2, Main Pump House Scale Below Ground Earthing - Location of Lugs Layout, Sections and DetailsDocumento1 páginaSa3-Ps2, Main Pump House Scale Below Ground Earthing - Location of Lugs Layout, Sections and DetailssartajAinda não há avaliações

- Oil Soak PitDocumento1 páginaOil Soak PitSathish KumarAinda não há avaliações

- Battery Sizing 3 Trafo (Latest)Documento20 páginasBattery Sizing 3 Trafo (Latest)jm.mankavil6230Ainda não há avaliações

- Pilot Cable Specs FewaDocumento13 páginasPilot Cable Specs Fewabharat_22nandulaAinda não há avaliações

- Electrical Unpriced BOQ-23 07 2019Documento13 páginasElectrical Unpriced BOQ-23 07 2019Mitesh KhandwalaAinda não há avaliações

- Reference TG - Cable ScheduleDocumento21 páginasReference TG - Cable Scheduleerkamlakar2234Ainda não há avaliações

- Diagram PLTA SLJDocumento4 páginasDiagram PLTA SLJMEi Cuiet Luph-LuPhAinda não há avaliações

- Shazadabagh - Control Cable ScheduleDocumento83 páginasShazadabagh - Control Cable ScheduleAnkur SangwanAinda não há avaliações

- FS4005 Cable TraysDocumento8 páginasFS4005 Cable Traysm_925Ainda não há avaliações

- Technicall Specification of 630 KVA, 11-0.415 KV Dry Type Outdoor Transformers.......... Dated. 31.08.2015Documento25 páginasTechnicall Specification of 630 KVA, 11-0.415 KV Dry Type Outdoor Transformers.......... Dated. 31.08.2015spidervinoAinda não há avaliações

- 11kV SF6Documento6 páginas11kV SF6ahmadgce04Ainda não há avaliações

- Alfanar Low Voltage Power Cables CatalogDocumento106 páginasAlfanar Low Voltage Power Cables Catalogvasanthi8025Ainda não há avaliações

- Transformer PanelDocumento64 páginasTransformer PanelNarayana SwamyAinda não há avaliações

- Transformer ProtectionDocumento19 páginasTransformer ProtectionBassem MostafaAinda não há avaliações

- T Proc Notices Notices 040 K Notice Doc 39826 154073019 PDFDocumento281 páginasT Proc Notices Notices 040 K Notice Doc 39826 154073019 PDFabbastceAinda não há avaliações

- Section-7.1, 33KV GISDocumento49 páginasSection-7.1, 33KV GISBRB CABLEAinda não há avaliações

- 4.ES04-DC&UPS SystemDocumento10 páginas4.ES04-DC&UPS SystemMangai NAinda não há avaliações

- Gen All e 0116 - 0Documento1 páginaGen All e 0116 - 0Madhankumar100% (1)

- SLD Aux PDFDocumento6 páginasSLD Aux PDFaviral mishraAinda não há avaliações

- 132KVF 1Documento29 páginas132KVF 1MeenakshiAinda não há avaliações

- Technical Specification of Low Voltage Power CablesDocumento9 páginasTechnical Specification of Low Voltage Power CablesAhmed JaAinda não há avaliações

- D000-EL-701 Rev 4Documento19 páginasD000-EL-701 Rev 4Sardar PerdawoodAinda não há avaliações

- HT Cable ScheduleDocumento2 páginasHT Cable ScheduletceterexAinda não há avaliações

- AMD 4 S-4135E Sep8.2016 PDFDocumento4 páginasAMD 4 S-4135E Sep8.2016 PDFEsmaelyAinda não há avaliações

- Lightening Protection - AssignmentDocumento11 páginasLightening Protection - AssignmentNalaka SiyanthaAinda não há avaliações

- Data Sheet For Cable Glands and LugsDocumento8 páginasData Sheet For Cable Glands and LugsBasabRajAinda não há avaliações

- Additional Main Transformer 230 MVA KeyplanDocumento1 páginaAdditional Main Transformer 230 MVA KeyplanAlanAinda não há avaliações

- SLD For LNG Jetty Area (006) - LatestDocumento2 páginasSLD For LNG Jetty Area (006) - LatestDipayan DasAinda não há avaliações

- DG SetDocumento14 páginasDG Setrahul rAinda não há avaliações

- Check ListDocumento6 páginasCheck ListdevcharuAinda não há avaliações

- Imcc - EtsDocumento7 páginasImcc - EtssutanuprojectsAinda não há avaliações

- 33kV TWIN FEEDER 3&4 - REV-A - 03.06.2013Documento52 páginas33kV TWIN FEEDER 3&4 - REV-A - 03.06.2013ADE mrtAinda não há avaliações

- Design and verification of busway and cable for SMDB to LP loadDocumento10 páginasDesign and verification of busway and cable for SMDB to LP loadAhmed MagdyAinda não há avaliações

- Modified Cable Sizing Strategies - Egemin - Publication 2014 JanuaryDocumento54 páginasModified Cable Sizing Strategies - Egemin - Publication 2014 Januarymirali74Ainda não há avaliações

- Medium Voltage Switchgear Single Line DiagramDocumento1 páginaMedium Voltage Switchgear Single Line DiagramBobby AguirreAinda não há avaliações

- Copper Bonded Steel Earth RodDocumento9 páginasCopper Bonded Steel Earth Rodemmanuel_nyirendaAinda não há avaliações

- Data Sheet - Rev.0Documento4 páginasData Sheet - Rev.0mahesh reddy mAinda não há avaliações

- Emergency oil drain pit plan and sectionDocumento1 páginaEmergency oil drain pit plan and sectionAbhay ThakurAinda não há avaliações

- 40 PDFDocumento20 páginas40 PDFmusleh19Ainda não há avaliações

- Cable Installation Notes - GeneralDocumento6 páginasCable Installation Notes - GeneralraghvendraAinda não há avaliações

- 316Z-GREB-SP-E-82EN003-SIGNED.B - LV SWGR & MCC - Spec PDFDocumento33 páginas316Z-GREB-SP-E-82EN003-SIGNED.B - LV SWGR & MCC - Spec PDFMahmoud ChihebAinda não há avaliações

- Transformer DSDocumento4 páginasTransformer DSjuliyet vAinda não há avaliações

- GTP BatteryDocumento17 páginasGTP Batteryraj_stuff006Ainda não há avaliações

- A-01. Switchyard Layout - CompressedDocumento4 páginasA-01. Switchyard Layout - CompressedBrameswara Yuniarto100% (1)

- FS4005 Cable TraysDocumento8 páginasFS4005 Cable TraysRamesh AnanthanarayananAinda não há avaliações

- TEchnical Specification For DDUGJY and IPDS Scheme by REC, SBD DOCumentsDocumento547 páginasTEchnical Specification For DDUGJY and IPDS Scheme by REC, SBD DOCumentsashutosh2291Ainda não há avaliações

- Earthing Diagram NFL CWDocumento1 páginaEarthing Diagram NFL CWSoumitra GuptaAinda não há avaliações

- Process Automation Factory Automation Terminal AutomationDocumento4 páginasProcess Automation Factory Automation Terminal AutomationRitaban R. BanerjeeAinda não há avaliações

- 1.4 FGD - KPCL - SchedulesDocumento22 páginas1.4 FGD - KPCL - SchedulesKoushik DeyAinda não há avaliações

- Knowledge is "Real Power": Introduction to Power QualityNo EverandKnowledge is "Real Power": Introduction to Power QualityAinda não há avaliações

- 2016DC Code Bill BrooksDocumento166 páginas2016DC Code Bill Brooksyavuz772Ainda não há avaliações

- Instrument QuestionsDocumento71 páginasInstrument QuestionsFA AyAinda não há avaliações

- Ohl TestDocumento5 páginasOhl TestAnonymous ExWAN2xjFJAinda não há avaliações

- Current TransformersDocumento19 páginasCurrent TransformersyugoplodAinda não há avaliações

- Tuning Workshop PID Controllers: Shell Global SolutionsDocumento33 páginasTuning Workshop PID Controllers: Shell Global SolutionsSunil SinghAinda não há avaliações

- Siemens S7 200Documento28 páginasSiemens S7 200Sunil SinghAinda não há avaliações

- Incomer 2,16MVADocumento3 páginasIncomer 2,16MVASunil SinghAinda não há avaliações

- IEC Guideline For Photo Voltaic Power PlantsDocumento13 páginasIEC Guideline For Photo Voltaic Power PlantsSiddhartha Sengupta100% (3)

- K25 - K26 - K27 - K28 - K29 - K30 - K31 - K32: - XT:417 - XT:418 - XT:419 - XT:420 - XT:421 - XT:422 - XT:423 - XT:424Documento1 páginaK25 - K26 - K27 - K28 - K29 - K30 - K31 - K32: - XT:417 - XT:418 - XT:419 - XT:420 - XT:421 - XT:422 - XT:423 - XT:424Sunil SinghAinda não há avaliações

- Orifice Plate Flow MetersDocumento8 páginasOrifice Plate Flow MetersGaurav Dhiman100% (1)

- Instructiuni La SuduraDocumento36 páginasInstructiuni La SuduraAntohi CatalinAinda não há avaliações

- Flowmeter PrinciplesDocumento3 páginasFlowmeter PrinciplesSunil SinghAinda não há avaliações

- 280KW Soft Starter PDFDocumento12 páginas280KW Soft Starter PDFSunil SinghAinda não há avaliações

- 6.6KV Cico VCB Panel Board, Scheme PDFDocumento8 páginas6.6KV Cico VCB Panel Board, Scheme PDFSunil SinghAinda não há avaliações

- By Group 5: Sintu Kumar Sharma 0017 Avishek Mukherjee 0018 MD Ashraf Alam Khan 0019 Dali Das 0020Documento13 páginasBy Group 5: Sintu Kumar Sharma 0017 Avishek Mukherjee 0018 MD Ashraf Alam Khan 0019 Dali Das 0020Sunil SinghAinda não há avaliações

- Flowmeter Piping RequirementsDocumento11 páginasFlowmeter Piping RequirementskarthipetroAinda não há avaliações

- 4core Copper Xlpe ArmouredDocumento1 página4core Copper Xlpe ArmouredMohit Chowdary NAinda não há avaliações

- Process Controller For Temperature, Flow, Pressure Etc: ProlificDocumento23 páginasProcess Controller For Temperature, Flow, Pressure Etc: Prolifictricky777Ainda não há avaliações

- Busbar Sizing For 50ka For 1 Sec PDFDocumento1 páginaBusbar Sizing For 50ka For 1 Sec PDFSunil SinghAinda não há avaliações

- Copper and Aluminum Busbars GuideDocumento5 páginasCopper and Aluminum Busbars Guidenicolasgimenez1984Ainda não há avaliações

- Is Iec 61725 1997Documento10 páginasIs Iec 61725 1997vijay_rainaAinda não há avaliações

- Process Controller For Temperature, Flow, Pressure Etc: ProlificDocumento23 páginasProcess Controller For Temperature, Flow, Pressure Etc: Prolifictricky777Ainda não há avaliações

- Electrical Design PDFDocumento20 páginasElectrical Design PDFSoe Min TunAinda não há avaliações

- 01.4TB.053 Hardware For Bus ConnectionsDocumento2 páginas01.4TB.053 Hardware For Bus ConnectionsSunil SinghAinda não há avaliações

- 160xx STR Enertia Sunpower 100.2 KW GaDocumento1 página160xx STR Enertia Sunpower 100.2 KW GaSunil SinghAinda não há avaliações

- Disclosure To Promote The Right To InformationDocumento18 páginasDisclosure To Promote The Right To InformationRatnakumarChittoorAinda não há avaliações

- Fab Drawing of MMS Mplus Rooftop Rev-00!1!9Documento1 páginaFab Drawing of MMS Mplus Rooftop Rev-00!1!9Sunil SinghAinda não há avaliações

- Comparison of Design Procedures For Pre Engineering Buildings PEB A Case StudyDocumento5 páginasComparison of Design Procedures For Pre Engineering Buildings PEB A Case StudyfauziahAinda não há avaliações

- Ga Drawing For Ballast Structure 30kwDocumento1 páginaGa Drawing For Ballast Structure 30kwSunil SinghAinda não há avaliações

- Playing With Fire: Talking PointDocumento3 páginasPlaying With Fire: Talking PointSunil SinghAinda não há avaliações

- Hold Time Studies 1Documento10 páginasHold Time Studies 1Jesus Fernando Sotelo ChavezAinda não há avaliações

- Sabp A 074 PDFDocumento26 páginasSabp A 074 PDFWalid MegahedAinda não há avaliações

- Document Title: Application Interfaces User GuideDocumento79 páginasDocument Title: Application Interfaces User Guidedipak1304Ainda não há avaliações

- MSRP C3 07 PDFDocumento666 páginasMSRP C3 07 PDFAnonymous jXP3ykqHWAinda não há avaliações

- New Civil Structural Permit FormDocumento2 páginasNew Civil Structural Permit FormRodolfo NidoyAinda não há avaliações

- Job Offer 1184273338Documento21 páginasJob Offer 1184273338dodiyaashishAinda não há avaliações

- SSPC SP7 PDFDocumento5 páginasSSPC SP7 PDFMelissa Edith Vega Reynoso100% (1)

- Srs On Online Booking System PDFDocumento9 páginasSrs On Online Booking System PDFZeeshan AbbasAinda não há avaliações

- EQPA Tool Box Checklists Batch DispositionDocumento13 páginasEQPA Tool Box Checklists Batch DispositionBlueSagaAinda não há avaliações

- STD-02-0860 Rev 5.0 Part Cleanliness StandardDocumento8 páginasSTD-02-0860 Rev 5.0 Part Cleanliness StandardCARLOS A.N. LANZILLOTTOAinda não há avaliações

- Cargo Bed Cover, Type IV (M923, 5 Ton Cargo Truck/M1083, 5 Ton Medium Tactical Vehicle (MTV) / M1082, 5 Ton MTV Trailer)Documento12 páginasCargo Bed Cover, Type IV (M923, 5 Ton Cargo Truck/M1083, 5 Ton Medium Tactical Vehicle (MTV) / M1082, 5 Ton MTV Trailer)Ahmad Zubair RasulyAinda não há avaliações

- Astm A810-01Documento4 páginasAstm A810-01ditherAinda não há avaliações

- Addis Ababa Institute of Technology Center of Information Technology and Scientific Computing Department of Software EngineeringDocumento37 páginasAddis Ababa Institute of Technology Center of Information Technology and Scientific Computing Department of Software EngineeringhabibAinda não há avaliações

- B 327 - 16 PDFDocumento4 páginasB 327 - 16 PDFHongHaiDuongAinda não há avaliações

- National CAD Standards - V5Documento28 páginasNational CAD Standards - V5krristinAinda não há avaliações

- Maintaining Boeing 737 Aircraft: A Guide to Maintenance DocumentationDocumento16 páginasMaintaining Boeing 737 Aircraft: A Guide to Maintenance Documentationphuoc vanAinda não há avaliações

- Shipping Company SystemDocumento9 páginasShipping Company System3bdelr7man z3z3Ainda não há avaliações

- Important ErectionDocumento15 páginasImportant ErectionVino Sankar100% (1)

- Paper Title: Author NameDocumento1 páginaPaper Title: Author NameshubhAinda não há avaliações

- Case 1: Frito-Lay Salt Test: Here (Links To An External Site.)Documento3 páginasCase 1: Frito-Lay Salt Test: Here (Links To An External Site.)Đức Minh ChuAinda não há avaliações

- Operations Manual Template SpecificationsDocumento6 páginasOperations Manual Template Specificationsshaggy hopkinsAinda não há avaliações

- Specs 5mva-10mva MsedclDocumento22 páginasSpecs 5mva-10mva Msedclgauravgarg1123Ainda não há avaliações

- Contoh ITP Dan ChecklistDocumento21 páginasContoh ITP Dan Checklistandy100% (5)

- Wa0002Documento3 páginasWa0002Shashivendra ShuklaAinda não há avaliações

- Read, Interpret and Apply Specifications and ManualsDocumento55 páginasRead, Interpret and Apply Specifications and ManualsClayton Mark Cadampog100% (2)

- Appendix-C-level 4 PDFDocumento52 páginasAppendix-C-level 4 PDFengrrahman3135Ainda não há avaliações

- Stainless Steel Flap Gate SpecificationDocumento4 páginasStainless Steel Flap Gate SpecificationreluAinda não há avaliações

- General Requirements For Qualification and PCN Certification of NDT PersonnelDocumento26 páginasGeneral Requirements For Qualification and PCN Certification of NDT PersonnelPedro OliveiraAinda não há avaliações

- Chp0600 Design of The PavementDocumento78 páginasChp0600 Design of The Pavementangelbarba100% (1)

- Vector Webinar CANoeDiVa 20200612 PDFDocumento29 páginasVector Webinar CANoeDiVa 20200612 PDFAnup KumarAinda não há avaliações