Escolar Documentos

Profissional Documentos

Cultura Documentos

RKM Details

Enviado por

Durairaj.NDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

RKM Details

Enviado por

Durairaj.NDireitos autorais:

Formatos disponíveis

1

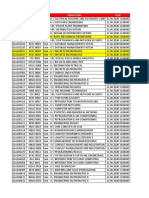

RKM DETAILS

9/12/2003

COMPARISON BETWEEN TENSORAPID AND TENSOJET

SL.NO

DETAILS

UTR 3

UTJ

1.

Testing speed

Lower (5mpm)

Higher (400mpm)

2.

No of test per sample

100 tests

10,000 tests

3.

Clamp distance

50 cm

4.

RKM

Lower

Higher

(11.4% Higher RKM than

Higher

Lower

(3.3% lower Elongation%

50 cm

UTR3)

5.

Elongation %

than UTR3)

Recommended Testing RH 65% + 2 DB 27 +2 C (81+4 F)

Recommended conditioning time of samples 24 Hrs

UTR 3 and UTJ machines are working constant Rate of Elongation (CRE)

principle.

UTJ. A compact scatter plot pattern indicates a uniform yarn with low tensile

property variation. An abnormally shaped scatter plot indicates abnormal yarn

variation and potential problems in subsequent processing.

A yarn that has a good average breaking strength, but a high number of weak

places will not perform as well as another yarn that has a lower average

breaking strength but fewer weak place.

Breaks occur in weak place.

Weak values are more important than average value of yarn.

For avoiding critical area (1) RKM & Elongation CV % to be reduced (2)

Mean RKM value to be increased (3) Loom Tension to be reduced.

Higher Humidity more than 65% giving Higher RKM and Elongation.

YCP yarn giving higher RKM and Elongation.

Weak yarn having less than 60% of the average value.

UTJ weak yarn breaking force less than 4X count in text (CN) and Elongation

less than 2.5%.

UTJ percentile value P.01 (10 breaks out of 10,000 were x grams force and

lower or 0.1% of all test) value should be minimum 60% of the average value.

BREAKING FORCE

The maximum amount of force required causing the test sample to be

carried to rupture. Expressed as grame force (gf).

Breaking force CN = Breaking force gf x 0.981

ELONGATION %

It is the Ratio of the increase in length over the original length

express as percentage for a given test length.

Length at break - Length at initial

Elongation % = ------------------------------------------------ X 100

Length at initial

TENACITY

A break force value expressed as force per unit of linear density.

Breaking force in CN

Tenacity = -------------------------------Yarn count in Tex

590.5

Tex yarn count = ---------------Count in Ne

RKM = Tenacity (CN/tex) X 1.02

Tenacity eliminates the influence of yarn count.

BREAK WORK

Break work is a product of force and elongation.

unit gf x cm or CN x cm

MINIMUM REQUIREMENT OF WEAVING YARN

a. Lowest Breaking Tenacity - 11 RKM

b. CV% of RKM

- 9%

c. Elongation

- 5%

d. CV% of Elongation

- 9%

e. Weak place

- 1 per 1 Lakh meter

FACTORS AFFECTING RKM VALUE

A. RAW MATERIAL COTTON

1. Fibre strength

2. Fibre elongation

3. Fibre length

4. Short fibre content

5. Trash content in cotton

6. Fibre fineness

7. Fibre maturity

B. YARN

1. Yarn TPI

2. Yarn count CV%

3. Yarn evenness

4. Yarn Imperfection

5. Periodic fault

6. Drafting waves

7. Classimate thin faults(H1, H2, I 1 & I 2 )

8. Winding

9. Singeing

10.Dyeing

11.Temperature and Humidity

TO INCREASE RKM VALUE IN YARN

1. Oil and water to be added in the mixing. Oil 100ml & Water 2500ml per

bale to Oil 200ml & water 5000ml.

2. Lower beater speed apporx less than 600 RPM (TRUMAC).

3. Lower Licker-in speed 1050 to 960 to 860 RPM (DK 740).

4. Wider Licker-in to feed plate setting (DK 740) 40 Thou to 44 Thou.

5. Higher comber Noils giving higher RKM.

6. Higher TPI/TM in Ring frame gives Higher RKM.

7. Lesser Ring frame speed gives Higher RKM.

8. Wider spacer in Ring frame gives Higher RKM.

9. Lesser winding speed gives Higher RKM.

10.Lesser winding tension gives Higher RKM.

11.Lesser Assembly winder speed gives Higher RKM.

TO REDUCE RKM CV% IN THE YARN

1. Higher TPI/TM to be given for simplex Roving.

2. Lesser Ring frame speed.

3. Ring frame spinde Tape width to be increased 10mm to 11mm& Doubling

spindle Tape width to be increased 12.5mm.

4. Spindle Tape Tension & Width to be checked in the machine and to be

changed.

5. Spindle Tape life maximum 18 months.

6. All spindle tapes are to be measured excluding joining portion before

mounting.

Ex = 2356 x 11mm Allowable Tolerence +4mm, -16mm.

Actual length = 2340 to2360mm

7. Damaged spindles Buttons & Spring to be checked once in 9 months

during Ring centering and to be changed.

8. Auto tex bobbin holders are to be used 3gms spring force for 30 & 40 .

2gms spring force for 50 and above.

9. Simplex Roving stretch to be maintained below 0.9.

10.Creel sliver stretch and sliver feel off to be avoided.

11.Smx flyer hole chocking to be removed.

12.Smx Bobbin wheel Double pin to be used.

13.Smx Top arm pressure to be maintained 22 kgs.

14.RF Top arm pressure to be maintained minimm 18 kgs.

15.RSB 851 T &G Pressure Minimum 120 kgs to be maintained.

16.Autoconer Splice strength should be Minimum 90% of the Single yarn

strength.

17.Autoconer Long Thin setting to be reduced.

18.RSB 851 sliver monitor setting 1%. 2 seconds to be provided.

19.RSB 851 Sliver Hank tolerace 0.001 to be maintained.

20.Elite Ring Frame Spindle wise speed to be checked, Tolerance -Average

Spindle speed 200 RPM to be maintained.

RECOMMENDED YARN RKM FOR INDIAN COTTON

UTR3

UTJ

CSP(approx)

Carded Warp

16

18

2500

Combed Warp

18

20

2900

Carded Hosiery

15

16.5

2300

Combed Hosiery

16

18

2600

RECOMMENDED YARN TM FOR INDIAN COTTON

Carded Warp

4.1 to 4.4

Combed Warp

3.9 to 4.2

Carded Hosiery

3.7 to 3.9

Combed Hosiery

3.5 to 3.8

Higher TM in fine counts producing snarls in further process.

Imported cotton require lesser TM.

70% of single yarn TPI used for double yarn Doubling warp count. Hosiery

count TPI according to party specification.

Double yarn RKM 10% Higher than single yarn RKM for warp counts.

ELONGATION %

FACTORS AFFECTING ELONGATION %

a. Raw material cotton

1. Fibre elongation

2. Fibre length

3. Fibre maturity

4. Short fibre content

b. Yarn

1. Yarn TPI

2. Classimate thin faults (H1, H2, I 1 & I 2)

Fibre Elongation value 4.0 to 9.0 %

FIBRE ELONGATION DROP DEPARTMENT WISE

Department

%

Blow Room

4

Card sliver

1

Comber

6

Drawing

3

Simplex

2

Ring frame

24

Total

40%

Fibre to yarn elongation Drop from Blow room to winding 25%

Fibre to yarn Elongation Rcalisation %

Ratio of yarn elongation to fibre elongation expressed as percentage

Fibre to yarn Elongation Realisation 65 to 85%

TO INCREASE ELONGATION % AND REDUCE ELONGATION CV %

1. Higher TPI/TM in Ring frame

2. Lesser Ring frame speed

3. Higher TPI/TM in simplex

4. Lighter Traveller in Ring frame

5. Lesser winding speed

6. Lesser yarn tension in winding

7. Lesser micronaire cotton

8. Higher crimp cotton giving Higher yarn elongation%

RECOMMENDED YARN ELONGATION FOR INDIAN COTTON

30 to 40 - 5.0

50 to 60 - 4.5

70 to 100 - 4.0

Cone yarn having lesser elongation than cop

Double yarn having 10% Higher yarn elongation..

USTER TENSO JET REPORT

a) Weak place of weaving yarn.

1.Minimum RKM value

- Less than 11 RKM.

2.Minimum Elongation value (E) - Less than 2.5%

3.Minimum Breaking Force(F)

- Less than 4 X count in tex.

For 60cw 4 X 9.83= 39.33 CN.

b) Severe weak place of weaving yarn for 60cw.

1. Force and Elongation

F- Force less than 39.33 CN &

E - Elongation less than 2.5%

F & E -Reading should be Nil (0) for Good yarn.

b) General:

1. PO.1 Breaking Force value should be minimum 60% of the

average value.

2. RKM and Elongation CV% should be less than 9%

d)Scatter Diagram:

1.Compact oval shape plot indicate good yarn quality.

2.Upnormal shape with elongated tail indicates Bad yarn quality

and potential problem of breaks in the weaving process.

Você também pode gostar

- Yarn Faults and ClearingDocumento8 páginasYarn Faults and Clearingsitu_tex8594100% (7)

- LRTDocumento5 páginasLRTAnish akAinda não há avaliações

- BITRA NormsDocumento9 páginasBITRA Normsselvapdm100% (17)

- Speed Frame PDFDocumento9 páginasSpeed Frame PDFKazi Tanvirul Islam50% (2)

- Process Parameters in SimplexDocumento3 páginasProcess Parameters in SimplexTanvir Alam100% (5)

- Calculation of Draft ConstantDocumento10 páginasCalculation of Draft ConstantVinay Kumar Tripathi100% (4)

- CV CalculationDocumento7 páginasCV CalculationNirbhay Sharma71% (7)

- Impact of Cotton Parameters On Yarn QualityDocumento4 páginasImpact of Cotton Parameters On Yarn Qualityغلام جیلانی100% (6)

- Classimat Yarn Fault AnalysisDocumento4 páginasClassimat Yarn Fault AnalysisMitu Chowdhury75% (4)

- Cotton Process ParametersDocumento54 páginasCotton Process ParametersBhaskar Mitra100% (9)

- Simplex FrameDocumento38 páginasSimplex Framedrskathirrvelu0% (1)

- Clearer Cuts Summary ReportDocumento34 páginasClearer Cuts Summary ReportTowfic Aziz Kanon100% (1)

- Spinning Production & Other CalculationDocumento5 páginasSpinning Production & Other Calculationamar924786% (7)

- Auto Levelling in SpinningDocumento81 páginasAuto Levelling in SpinningArihara Sudhan73% (11)

- HVI Measurement Principles - by - AbuBakkar MarwatDocumento33 páginasHVI Measurement Principles - by - AbuBakkar MarwatAbu Bakkar100% (6)

- Spin Plan For A Cotton MillDocumento10 páginasSpin Plan For A Cotton MillRobotrix84% (19)

- Control Startup BreakageDocumento4 páginasControl Startup BreakageAnish ak100% (5)

- USTER AFIS PRO 2 The Fiber Process Control SystemDocumento24 páginasUSTER AFIS PRO 2 The Fiber Process Control Systembub1234567875% (8)

- TPMDocumento2 páginasTPMVijay Shirole83% (6)

- Ring Spinning Machine LR 6/S Specification and Question AnswerDocumento15 páginasRing Spinning Machine LR 6/S Specification and Question AnswerPramod Sonbarse100% (3)

- Spinning Formula FinalDocumento29 páginasSpinning Formula FinalMKA Gaming YT100% (3)

- Uster Classimat Fault ChartDocumento7 páginasUster Classimat Fault Chartstylish eagle100% (3)

- Standard Parameters of Cotton Yarns of Different TypesDocumento3 páginasStandard Parameters of Cotton Yarns of Different TypesRezaul Karim Tutul80% (5)

- LRT HandbookDocumento41 páginasLRT HandbookAshok Kumar60% (5)

- IPI Stands For Imperfection Index of YarnsDocumento1 páginaIPI Stands For Imperfection Index of YarnsShoreless Shaikat100% (5)

- Common Spinning FormulasDocumento38 páginasCommon Spinning FormulasDeanna ChapmanAinda não há avaliações

- Automation in Ring Spinning Machines-KTTMDocumento24 páginasAutomation in Ring Spinning Machines-KTTMkathirvelus94080% (1)

- Interpretation of SpectrogramDocumento48 páginasInterpretation of SpectrogramPrakash Chavali100% (6)

- Auto Cone ComparisonDocumento8 páginasAuto Cone ComparisonMuhammad Talha100% (1)

- FormulasDocumento20 páginasFormulasRishit MevadaAinda não há avaliações

- Spin PLanDocumento3 páginasSpin PLanntunewspoint100% (4)

- Classification of Yarn Faults and Possible SourceDocumento4 páginasClassification of Yarn Faults and Possible SourceNagarajan Sivathanu Pillai50% (2)

- Project Report - Breakage in RingframeDocumento16 páginasProject Report - Breakage in RingframeSushmita KushwahaAinda não há avaliações

- Spinning CalculationDocumento5 páginasSpinning CalculationKarthik Manic100% (1)

- Ring Spinning NTPELDocumento92 páginasRing Spinning NTPELCraig Martin67% (3)

- Fiber RuptureDocumento16 páginasFiber RuptureNessre Zeine100% (1)

- Spinning CalculationDocumento178 páginasSpinning Calculationamboklate69% (16)

- Uster Tester 5Documento11 páginasUster Tester 5Ashique100% (3)

- Winding 1Documento16 páginasWinding 1Siddhesh Pradhan67% (3)

- Spinning CalculationsDocumento40 páginasSpinning Calculationsrajasekarmca100% (2)

- CONSTANTS AND CALCULATIONS - Textile SpinningDocumento8 páginasCONSTANTS AND CALCULATIONS - Textile SpinningLolla Ravi100% (16)

- Calculation of Draft and Twist in Ring SpinningDocumento3 páginasCalculation of Draft and Twist in Ring Spinningbmsali100% (2)

- Investigation Yarn Count Variation of Ring FrameDocumento63 páginasInvestigation Yarn Count Variation of Ring FrameYeasin Arafat100% (1)

- Finisher Draw Frame AutolevellerDocumento30 páginasFinisher Draw Frame AutolevellerRuhi gnext100% (1)

- Prevailing 40s Conversion FactorsDocumento17 páginasPrevailing 40s Conversion FactorsNitin Chaudhary100% (6)

- Investigative Study of Periodic Yarn Faults and Its Removal by Using Gearing AnalysisDocumento59 páginasInvestigative Study of Periodic Yarn Faults and Its Removal by Using Gearing AnalysisJuan Cubas100% (1)

- Process Control in SpinningDocumento31 páginasProcess Control in Spinningapi-2649455553% (15)

- Textilecalculations 131030144207 Phpapp01Documento15 páginasTextilecalculations 131030144207 Phpapp01jazzlovey100% (1)

- Assignment 165022 Adv YarnDocumento7 páginasAssignment 165022 Adv YarnMd Ariful IslamAinda não há avaliações

- Low Frequency EvaluationDocumento13 páginasLow Frequency EvaluationthrillerxAinda não há avaliações

- CRD - PracticeDocumento10 páginasCRD - PracticeHarshGuptaAinda não há avaliações

- yarn-II NoteDocumento118 páginasyarn-II NoteMoshiur Rahman Kayes100% (1)

- Rotor Spinning Process: Md. Mazbah Uddin Bangladesh University of Textiles Yarn Engineering Departmet Batch 08Documento61 páginasRotor Spinning Process: Md. Mazbah Uddin Bangladesh University of Textiles Yarn Engineering Departmet Batch 08TKK-TEXTILE PSG CT100% (1)

- SIMpull Cable Pull Calculator 4.2Documento6 páginasSIMpull Cable Pull Calculator 4.2John ElyAinda não há avaliações

- A Guide To Low Frequency Vibration Measurement IrdDocumento13 páginasA Guide To Low Frequency Vibration Measurement IrdPIRATASANTANAAinda não há avaliações

- Tensile Calculation PDFDocumento2 páginasTensile Calculation PDFWendimagen Meshesha FantaAinda não há avaliações

- 160-Article Text-84-1-10-20181128Documento6 páginas160-Article Text-84-1-10-20181128Ravi KumarAinda não há avaliações

- Guincho Didatico CWG-30375,30565,30750,31500,34000 OkDocumento20 páginasGuincho Didatico CWG-30375,30565,30750,31500,34000 OkthiricycAinda não há avaliações

- M 3 FaqDocumento11 páginasM 3 FaqSubburaj KarthickAinda não há avaliações

- Bunchesin CardingDocumento2 páginasBunchesin CardingDurairaj.NAinda não há avaliações

- Apsa 80 - Spinning MillDocumento4 páginasApsa 80 - Spinning MillDurairaj.NAinda não há avaliações

- Fibre Testing PDFDocumento16 páginasFibre Testing PDFDurairaj.NAinda não há avaliações

- Hairiness - I PDFDocumento4 páginasHairiness - I PDFDurairaj.NAinda não há avaliações

- Fiber Length PDFDocumento2 páginasFiber Length PDFDurairaj.NAinda não há avaliações

- MESDAN AQUA Splicer 4923ADocumento4 páginasMESDAN AQUA Splicer 4923ADurairaj.NAinda não há avaliações

- PPP-B-676 e PDFDocumento34 páginasPPP-B-676 e PDFffincher4203Ainda não há avaliações

- EE 411-Digital Signal Processing-Muhammad TahirDocumento3 páginasEE 411-Digital Signal Processing-Muhammad TahirQasim FarooqAinda não há avaliações

- Buffers Notes1Documento3 páginasBuffers Notes1Lara MonevaAinda não há avaliações

- Mits Chocolates: Let The Life Be More Sweet'Documento30 páginasMits Chocolates: Let The Life Be More Sweet'Azaz NathaniAinda não há avaliações

- 765 p1+2+3 Guide Limta Mock 2022Documento8 páginas765 p1+2+3 Guide Limta Mock 2022Théophile MbameAinda não há avaliações

- Nanotechnology ApplicationsDocumento11 páginasNanotechnology ApplicationsDivya DivyachilaAinda não há avaliações

- Glamour Secrets Prices For Products and ServicesDocumento1 páginaGlamour Secrets Prices For Products and ServiceslocalintheknowAinda não há avaliações

- MalachiteDocumento2 páginasMalachiteAkhil KumarAinda não há avaliações

- Curvature CorrectionDocumento7 páginasCurvature CorrectionE J SAinda não há avaliações

- 34 Plaza Newsletter 101317 FINALDocumento4 páginas34 Plaza Newsletter 101317 FINALJosef SzendeAinda não há avaliações

- Definition of Logistics ManagementDocumento4 páginasDefinition of Logistics ManagementzamaneAinda não há avaliações

- Catalogue Mp200Documento33 páginasCatalogue Mp200Adrian TudorAinda não há avaliações

- Power - Distribution Transformers @2020V2Documento34 páginasPower - Distribution Transformers @2020V2Musfiqul AzadAinda não há avaliações

- Fill in The Table by Determining The Functions of The Following ItemsDocumento6 páginasFill in The Table by Determining The Functions of The Following ItemsJessabel CandidatoAinda não há avaliações

- 7 Stages of NafsDocumento7 páginas7 Stages of NafsLilyAinda não há avaliações

- Shadow UAV HandbookDocumento57 páginasShadow UAV HandbookGasMaskBob100% (2)

- Jerms B 2109 - 0BDocumento10 páginasJerms B 2109 - 0BNothing is ImpossibleAinda não há avaliações

- Oertel - Extracts From The Jāiminīya-Brāhma A and Upanishad-Brāhma A, Parallel To Passages of TheDocumento20 páginasOertel - Extracts From The Jāiminīya-Brāhma A and Upanishad-Brāhma A, Parallel To Passages of Thespongebob2812Ainda não há avaliações

- 020 Basketball CourtDocumento4 páginas020 Basketball CourtMohamad TaufiqAinda não há avaliações

- The Fat CatsDocumento7 páginasThe Fat CatsMarilo Jimenez AlgabaAinda não há avaliações

- Fast Track Pro Drivers Read MeDocumento3 páginasFast Track Pro Drivers Read MeMatt JerniganAinda não há avaliações

- Curriculum Jaime Alvarado (Jaime Alvarado)Documento3 páginasCurriculum Jaime Alvarado (Jaime Alvarado)yuly aldanaAinda não há avaliações

- Brewing With New Hop VarietiesDocumento70 páginasBrewing With New Hop VarietiesFelipe BaronyAinda não há avaliações

- SDS Super PenetrantDocumento5 páginasSDS Super Penetrantaan alfianAinda não há avaliações

- Staff Code Subject Code Subject Data FromDocumento36 páginasStaff Code Subject Code Subject Data FromPooja PathakAinda não há avaliações

- Electro-Mechanical SectorDocumento22 páginasElectro-Mechanical SectorKen LeeAinda não há avaliações

- Mensuration Practice SheetDocumento1 páginaMensuration Practice SheetSonia SabuAinda não há avaliações

- Big Fat Lies - How The Diet Industry Is Making You Sick, Fat & PoorDocumento212 páginasBig Fat Lies - How The Diet Industry Is Making You Sick, Fat & PoorangelobuffaloAinda não há avaliações

- O221771s - Mil Pipe Pro 450 RFC PDFDocumento84 páginasO221771s - Mil Pipe Pro 450 RFC PDFJavier Isaac Berrocal Torres100% (1)

- Acc05 SCG116Documento42 páginasAcc05 SCG116Hilal HazaaAinda não há avaliações

- Swatch This, 3000+ Color Palettes for Success: Perfect for Artists, Designers, MakersNo EverandSwatch This, 3000+ Color Palettes for Success: Perfect for Artists, Designers, MakersNota: 3.5 de 5 estrelas3.5/5 (3)

- Edward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsNo EverandEdward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsAinda não há avaliações

- House Rules: How to Decorate for Every Home, Style, and BudgetNo EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetAinda não há avaliações

- The Martha Manual: How to Do (Almost) EverythingNo EverandThe Martha Manual: How to Do (Almost) EverythingNota: 4 de 5 estrelas4/5 (11)

- Crochet Southwest Spirit: Over 20 Bohemian Crochet Patterns Inspired by the American SouthwestNo EverandCrochet Southwest Spirit: Over 20 Bohemian Crochet Patterns Inspired by the American SouthwestNota: 5 de 5 estrelas5/5 (2)

- Treasure Bookmaking: Crafting Handmade Sustainable JournalsNo EverandTreasure Bookmaking: Crafting Handmade Sustainable JournalsAinda não há avaliações

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiNo Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiNota: 5 de 5 estrelas5/5 (2)

- Modern Crochet Style: 15 Colourful Crochet Patterns For You and Your HomeNo EverandModern Crochet Style: 15 Colourful Crochet Patterns For You and Your HomeNota: 5 de 5 estrelas5/5 (1)

- Crochet Impkins: Over a million possible combinations! Yes, really!No EverandCrochet Impkins: Over a million possible combinations! Yes, really!Nota: 4.5 de 5 estrelas4.5/5 (10)

- Amigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)No EverandAmigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)Ainda não há avaliações

- Textiles Transformed: Thread and thrift with reclaimed textilesNo EverandTextiles Transformed: Thread and thrift with reclaimed textilesAinda não há avaliações

- Crochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsNo EverandCrochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsNota: 4.5 de 5 estrelas4.5/5 (10)

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiNo EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiNota: 4 de 5 estrelas4/5 (3)

- Harter's Picture Archive for Collage and IllustrationNo EverandHarter's Picture Archive for Collage and IllustrationNota: 4.5 de 5 estrelas4.5/5 (3)

- Hello Hexie!: 20 Easy Crochet Patterns from Simple Granny HexagonsNo EverandHello Hexie!: 20 Easy Crochet Patterns from Simple Granny HexagonsNota: 5 de 5 estrelas5/5 (3)

- Upcycling: 20 Creative Projects Made from Reclaimed MaterialsNo EverandUpcycling: 20 Creative Projects Made from Reclaimed MaterialsAinda não há avaliações

- 250 Japanese Knitting Stitches: The Original Pattern Bible by Hitomi ShidaNo Everand250 Japanese Knitting Stitches: The Original Pattern Bible by Hitomi ShidaNota: 5 de 5 estrelas5/5 (7)

- Crochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeNo EverandCrochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeNota: 5 de 5 estrelas5/5 (2)

- Basic Black: 26 Edgy Essentials for the Modern WardrobeNo EverandBasic Black: 26 Edgy Essentials for the Modern WardrobeNota: 4 de 5 estrelas4/5 (10)

- Edward's Menagerie: Dogs: 50 canine crochet patternsNo EverandEdward's Menagerie: Dogs: 50 canine crochet patternsNota: 3 de 5 estrelas3/5 (5)

- Euphoria Tapestry Quilts: 40 Appliqué Motifs & 17 Flowering ProjectsNo EverandEuphoria Tapestry Quilts: 40 Appliqué Motifs & 17 Flowering ProjectsAinda não há avaliações

- Radical Sewing: Pattern-Free, Sustainable Fashions for All BodiesNo EverandRadical Sewing: Pattern-Free, Sustainable Fashions for All BodiesAinda não há avaliações

- Shetland Fine Lace Knitting: Recreating Patterns from the Past.No EverandShetland Fine Lace Knitting: Recreating Patterns from the Past.Nota: 2 de 5 estrelas2/5 (1)

- Crochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastNo EverandCrochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastNota: 5 de 5 estrelas5/5 (1)

- The New Crochet Stitch Dictionary: 440 Patterns for Textures, Shells, Bobbles, Lace, Cables, Chevrons, Edgings, Granny Squares, and MoreNo EverandThe New Crochet Stitch Dictionary: 440 Patterns for Textures, Shells, Bobbles, Lace, Cables, Chevrons, Edgings, Granny Squares, and MoreNota: 5 de 5 estrelas5/5 (20)

- Crochet Cute Dolls with Mix-and-Match Outfits: 66 Adorable Amigurumi PatternsNo EverandCrochet Cute Dolls with Mix-and-Match Outfits: 66 Adorable Amigurumi PatternsNota: 4 de 5 estrelas4/5 (5)

- Fairytale Blankets to Crochet: 10 Fantasy-Themed Children's Blankets for Storytime CuddlesNo EverandFairytale Blankets to Crochet: 10 Fantasy-Themed Children's Blankets for Storytime CuddlesNota: 5 de 5 estrelas5/5 (3)