Escolar Documentos

Profissional Documentos

Cultura Documentos

De Super Heater

Enviado por

gateauxboyDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

De Super Heater

Enviado por

gateauxboyDireitos autorais:

Formatos disponíveis

A100 Desuperheater Valve

...put the pressure drop to work

for better steam conditioning.

The A100 combines pressure and temperature control in one easily

installed and compact unit. It achieves its outstanding results by using

the pressure drop velocities to make high initial absorption of cooling

spray water. The expansion chamber and diffuser plate complete the

mix and allow the use of accurate sensitive controls. The valve

responds quickly to load changes of 50 to 1 and so contributes to the

economic management of energy in a wide range of power and process

systems.

Reliable and accurate temperature control on dry steam.

Diffuser plate and expansion chamber minimise noise.

Pneumatic actuation and control as standard.

Air failure closes valve in standard mode.

Incorporates design features of A100 Control Valve including

cage trim.

8 sizes: some to 1000 psi and 1000F.

PRESSURE CONTROL AND SAFETY VALVES

A100 DESUPERHEATER VALVE

DESIGN

The high pressure steam on entering the reducing valve

passes through the cage trim between the valve seat and lid,

expanding and so lowering the pressure. At the valve seat the

cooling water is injected into the high velocity turbulent steam

causing the water to be atomised and flashed to steam. This

process absorbs energy from the total heat of the superheated

steam and so produces a mixture of increased weight at a

lower temperature.

3/8" BSP PRESSURE

D

3/4" BSP

TEMPERATURE

The mixture passes from the control valve into a tapered

expansion chamber which reduces the gas velocity to a value

compatible with normal piping practice and from the expansion

chamber through a diffuser plate past the sensing elements for

the pressure and temperature controllers and so out of the

unit.

B

G

C

1/2" BSP DRAIN TAPPING

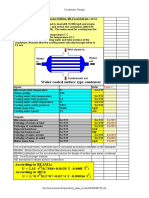

DATA TABLE

The diffuser plate prevents any water droplets adhering to the

side of the pipe from escaping downstream. It also ensures

excellent fluid mixing of the steam and water vapour so

eliminating any risk of stratification and thus permitting the use

of sensitive and accurate controls.

INSTALLATION

The drawing below shows the equipment supplied by Auld.

Items shown but not supplied are the small bore piping and

the air filter regulators. The filter regulators are recommended

because the majority of instrument faults are traced to dirt.

Equipment not shown but should be considered include stop

valves, strainer and steam trap (essential) and safety valve.

The water must be supplied at approximately 45 psi above the

outlet pressure of the steam valve. It is recommended that the

whole system be duplicated in continuous process plants.

Valve size

10"

12"

C/L to bottom

C 11" 11" 11" 13" 15" 20" 21"

22"

C/L to top

26"

Steam valve F/F

9"

Chamber

(approx)

20"

20"

28

58

Cv for steam valve

2"

2"

3"

4"

27" 29" 29"

6"

8"

33"

38"

38"

38"

14"

17"

22"

24"

30"

20"

24"

30"

36"

42"

48"

80

120

210

380

520 700

11" 11"

Dimensions for B, F and G calculated at time of quotation

SIZING

The data table shows the rated Cv for the

A100 Desuperheater valve. It is essential that

sizing is confirmed by Auld. The following

information is necessary:

inlet pressure and temperature.

outlet pressure and temperature.

maximum and minimum flow rates.

pressure, temperature and quantity of

water.

FOR MORE INFORMATION

Auld Valves Ltd

Cowlairs Industrial Estate

Finlas Street

Glasgow G22 5DQ, Scotland

Tel: +44 (0)141 557 0515

Fax: +44 (0)141 558 1059

E-mail: sales@auldvalves.com

Web: www.auldvalves.com

Auld Valves Ltd 08.07

PRESSURE CONTROL AND SAFETY VALVES

Você também pode gostar

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsAinda não há avaliações

- Pur-15-02 - Air Purger Type PurDocumento4 páginasPur-15-02 - Air Purger Type PurAnderson Giovanny Herrera DelgadoAinda não há avaliações

- VAD Variable Area Desuperheaters: Desuperheater OverviewDocumento6 páginasVAD Variable Area Desuperheaters: Desuperheater OverviewLucasZanaAinda não há avaliações

- DesuperheatersDocumento8 páginasDesuperheatersmuhdrijasmAinda não há avaliações

- Desuperheater: Variable Nozzle Desuperheater - VND FeaturesDocumento4 páginasDesuperheater: Variable Nozzle Desuperheater - VND FeaturesNutthakarn WisatsiriAinda não há avaliações

- Flash Steam SystemDocumento4 páginasFlash Steam SystemAnonymous CX51waIAinda não há avaliações

- Level Gauges Definition Types Measuring Range Ordering InformationDocumento3 páginasLevel Gauges Definition Types Measuring Range Ordering Informationkamala 123Ainda não há avaliações

- Helical Oil SeparatorsDocumento6 páginasHelical Oil SeparatorsGauravAinda não há avaliações

- Best Practices For Steam Control Valve InstallationDocumento4 páginasBest Practices For Steam Control Valve InstallationBen MusimaneAinda não há avaliações

- Positioning of Air Cooled CondensersDocumento9 páginasPositioning of Air Cooled CondensersAlexAinda não há avaliações

- PRO 810124 12 A1-Steam-Traps enDocumento30 páginasPRO 810124 12 A1-Steam-Traps enZulfadli RaniAinda não há avaliações

- Prof Ir Dr. Ab Saman B. Abd Kader, Peng, Miem, Mcit Faculty of Mechanical Engineering, UtmDocumento21 páginasProf Ir Dr. Ab Saman B. Abd Kader, Peng, Miem, Mcit Faculty of Mechanical Engineering, UtmakusuperAinda não há avaliações

- Heller System PPT 3 Cooling SystemsDocumento34 páginasHeller System PPT 3 Cooling SystemsShrey DattaAinda não há avaliações

- Deaerator TypesDocumento4 páginasDeaerator TypesMuhammad Fakhriy Indallah0% (2)

- Unesco - Eolss Sample Chapters: Vacuum Creating EquipmentDocumento7 páginasUnesco - Eolss Sample Chapters: Vacuum Creating Equipmentahmed nawazAinda não há avaliações

- Exp 1 Refrigeration CycleDocumento23 páginasExp 1 Refrigeration CycleAnonymous T7vjZG4otAinda não há avaliações

- Float Board Level GaugeDocumento6 páginasFloat Board Level GaugeanaismariaAinda não há avaliações

- 6.vapour Power CyclesDocumento18 páginas6.vapour Power CyclesJayneel GajjarAinda não há avaliações

- Instrument Air Dryer and Instrument Air ReceiverDocumento4 páginasInstrument Air Dryer and Instrument Air ReceiverAzizul HakimAinda não há avaliações

- Controlling Heat ExchangersDocumento11 páginasControlling Heat ExchangersgermanaponteAinda não há avaliações

- De Super HeaterDocumento27 páginasDe Super HeaterShivam Mannan MishraAinda não há avaliações

- Reducing Steam Header PressureDocumento1 páginaReducing Steam Header Pressuresj_scribdAinda não há avaliações

- Kettle Reboilers Chemical Engineering Design Ray SinnoyDocumento6 páginasKettle Reboilers Chemical Engineering Design Ray SinnoyFederico BogettiAinda não há avaliações

- 880 Series Inverted Bucket Steam TrapsDocumento2 páginas880 Series Inverted Bucket Steam TrapsCherbee FerrerAinda não há avaliações

- AERCO Boiler Benchmark 3.0Documento129 páginasAERCO Boiler Benchmark 3.0hfdadl100% (1)

- Condensate System PresentationDocumento24 páginasCondensate System Presentationмing junAinda não há avaliações

- Refrigeration: Refrigerant CompressorDocumento88 páginasRefrigeration: Refrigerant CompressorKhalidAinda não há avaliações

- Gorter r200Documento6 páginasGorter r200Manish SaraswatAinda não há avaliações

- Liquid Recirculation System-2Documento7 páginasLiquid Recirculation System-2Behnam AshouriAinda não há avaliações

- Jet Pump Technical DataDocumento11 páginasJet Pump Technical DataIdelia Cutipa Yauri100% (1)

- Orifice Plate BrochureDocumento39 páginasOrifice Plate Brochureronzies100% (1)

- Pressure Measuring InstrumentsDocumento7 páginasPressure Measuring Instrumentspaves007Ainda não há avaliações

- APCO Air Valve 613Documento4 páginasAPCO Air Valve 613jones0055Ainda não há avaliações

- AX5 Vaporizer Electric Water Bath Type LPG VaporizerDocumento2 páginasAX5 Vaporizer Electric Water Bath Type LPG VaporizerRicky DermawanAinda não há avaliações

- Varioasept: Microbiological Safety For Your ProductsDocumento6 páginasVarioasept: Microbiological Safety For Your Productsمصطفى- القرقعيAinda não há avaliações

- Alia AFC365 Flow ComputerDocumento4 páginasAlia AFC365 Flow ComputerRexCrazyMindAinda não há avaliações

- Cooling TowerDocumento10 páginasCooling TowerKeshav Rao100% (1)

- Fluid Flow Basiics of Throttliing ValvesDocumento56 páginasFluid Flow Basiics of Throttliing Valvesdanne_eAinda não há avaliações

- By Pass RotameterDocumento6 páginasBy Pass Rotameterkrishna kumarAinda não há avaliações

- Hitachi S-4700 InstructionsDocumento19 páginasHitachi S-4700 InstructionssuperheoAinda não há avaliações

- Refrigeration Liquid Recirculation SystemsDocumento7 páginasRefrigeration Liquid Recirculation Systemsgoodspeed_phAinda não há avaliações

- Design of Air IDocumento5 páginasDesign of Air IInvedeAinda não há avaliações

- StallDocumento16 páginasStallbhalchandrak1867100% (1)

- High Pressure BoilersDocumento18 páginasHigh Pressure BoilersVivek VardhanAinda não há avaliações

- Model 5 Operating and Maintenance Manual - Low Water VolumeDocumento120 páginasModel 5 Operating and Maintenance Manual - Low Water VolumeJuan C FrancoAinda não há avaliações

- Khan 2000Documento18 páginasKhan 2000HIMANSHU YADAVAinda não há avaliações

- G Temperature Glide MF EN PDFDocumento14 páginasG Temperature Glide MF EN PDFKanaga RajAinda não há avaliações

- Steam Trap TesterDocumento4 páginasSteam Trap TesterISMAEL RAMIREZAinda não há avaliações

- SMST-Tubes Product Range en 2010 WebDocumento16 páginasSMST-Tubes Product Range en 2010 Webalbejo_r9Ainda não há avaliações

- Steam Nozzle ProblemsDocumento5 páginasSteam Nozzle ProblemsGopinath Narayanan100% (1)

- Unvented Calorifiers Installation & Commissioning GuideDocumento10 páginasUnvented Calorifiers Installation & Commissioning GuidePaul KwongAinda não há avaliações

- 3.2. Water Coagulation PlantDocumento4 páginas3.2. Water Coagulation PlantRaul IlieșAinda não há avaliações

- Effect of Fin SpacingDocumento12 páginasEffect of Fin SpacingAnkit LonareAinda não há avaliações

- File 1428726206Documento8 páginasFile 1428726206Rizwanahmad Khan Rizwanahmad KhanAinda não há avaliações

- 57-62 1m809 - Eng72dpiDocumento6 páginas57-62 1m809 - Eng72dpiAbhinav TewariAinda não há avaliações

- Practica CDocumento2 páginasPractica CAlejandroCalleRuizAinda não há avaliações

- Vaccum Pump PDFDocumento1 páginaVaccum Pump PDFsaa6383Ainda não há avaliações

- Fixed Nozzle DesuperheatersDocumento16 páginasFixed Nozzle DesuperheatersChan PhingAinda não há avaliações

- Tank BlankettingDocumento6 páginasTank BlankettingBaskar KannaiahAinda não há avaliações

- Viking Series 90 Operating & Maintenance Instructions: FiltersDocumento15 páginasViking Series 90 Operating & Maintenance Instructions: FiltersninatenaAinda não há avaliações

- What Has Changed in API 521 6EDDocumento19 páginasWhat Has Changed in API 521 6EDgateauxboy100% (1)

- BMW Comparion 320d THDocumento1 páginaBMW Comparion 320d THgateauxboyAinda não há avaliações

- BMW Comparion 325d M THDocumento1 páginaBMW Comparion 325d M THgateauxboyAinda não há avaliações

- DW144 Smacna 2005Documento32 páginasDW144 Smacna 2005Angel Daniel GarciajoyaAinda não há avaliações

- Vibration Signals of Reciprocating Compressor Valves: Paweł Białek, Piotr BielawskiDocumento7 páginasVibration Signals of Reciprocating Compressor Valves: Paweł Białek, Piotr BielawskigateauxboyAinda não há avaliações

- ANSI B16.5 FlangesDocumento24 páginasANSI B16.5 Flangesgateauxboy100% (2)

- Annular VelocityDocumento2 páginasAnnular VelocitygateauxboyAinda não há avaliações

- Hit A ChiDocumento46 páginasHit A ChigateauxboyAinda não há avaliações

- Overseas Business 1Documento2 páginasOverseas Business 1gateauxboyAinda não há avaliações

- The Use of QRA To Inform The Design of A High-Pressure Onshore PipelineDocumento12 páginasThe Use of QRA To Inform The Design of A High-Pressure Onshore PipelinehpmonAinda não há avaliações

- Branch Reinforcement Per Asme B31.4 PipelineDocumento1 páginaBranch Reinforcement Per Asme B31.4 PipelinegateauxboyAinda não há avaliações

- Piping and Pipe Support SystemsDocumento5 páginasPiping and Pipe Support SystemsgateauxboyAinda não há avaliações

- Pipe Design Basic MaterialDocumento1 páginaPipe Design Basic MaterialpandiangvAinda não há avaliações

- Case Study-Steam Jet EjectorDocumento21 páginasCase Study-Steam Jet Ejectorgateauxboy60% (5)

- ASME Joint EfficiencyDocumento49 páginasASME Joint Efficiencygateauxboy95% (39)

- Equivalent Material List For Standards: Ref. No. EML-001Documento3 páginasEquivalent Material List For Standards: Ref. No. EML-001gateauxboy100% (5)

- Efficient Industrial Heat Exchangers - Seminar ReportDocumento67 páginasEfficient Industrial Heat Exchangers - Seminar ReportdaemonohAinda não há avaliações

- 6th Central Pay Commission Salary CalculatorDocumento15 páginas6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- United States PatentDocumento7 páginasUnited States PatentDouglas TondelloAinda não há avaliações

- Ammonia: Concept and ApplicationDocumento40 páginasAmmonia: Concept and ApplicationSapna AndyaniAinda não há avaliações

- CH 206 Tutorial 7 SolutionsDocumento14 páginasCH 206 Tutorial 7 SolutionspushkalAinda não há avaliações

- UHP-MADINA Contract 180002 Rev 3 SignedDocumento8 páginasUHP-MADINA Contract 180002 Rev 3 SignedFarhan KhanAinda não há avaliações

- Boiler ControlDocumento38 páginasBoiler ControlTharun JagadeeshAinda não há avaliações

- Uni Mac ProgrammingDocumento166 páginasUni Mac ProgrammingEnrique HeroAinda não há avaliações

- Thermon Steam Tracing PDFDocumento4 páginasThermon Steam Tracing PDFCarlos SopasAinda não há avaliações

- Trouble Shooting and Problems of A CFBC Unit PDFDocumento72 páginasTrouble Shooting and Problems of A CFBC Unit PDFgangaraoAinda não há avaliações

- Thermodynamics 2: 2.0 Rankine Cycle As A Two-Phase Power SystemDocumento23 páginasThermodynamics 2: 2.0 Rankine Cycle As A Two-Phase Power SystemMarianne DevillenaAinda não há avaliações

- Energy Savings From Steam Losses On An Oil RefineryDocumento11 páginasEnergy Savings From Steam Losses On An Oil RefineryidigitiAinda não há avaliações

- Project Proposal On Sesame OilDocumento28 páginasProject Proposal On Sesame OilMohamed Asherif100% (1)

- TD-XT-D004-003 V2.00 20131204 XG1.UCD-135M185M300M Operation Manual PDFDocumento47 páginasTD-XT-D004-003 V2.00 20131204 XG1.UCD-135M185M300M Operation Manual PDFStan TC100% (1)

- FLOWIRL 8400 BrochureDocumento12 páginasFLOWIRL 8400 BrochureRavi RAinda não há avaliações

- Industrial Power Plant Design ElementsDocumento25 páginasIndustrial Power Plant Design ElementsFernan MacusiAinda não há avaliações

- Uhde Nitric Acid Process BrochureDocumento0 páginaUhde Nitric Acid Process BrochureGopiAinda não há avaliações

- Plant Commissioning Start Up ProcedureDocumento100 páginasPlant Commissioning Start Up ProcedureJean Dejardin100% (2)

- Ejector PrincipleDocumento13 páginasEjector Principlekhoshya7100% (1)

- 2 BDocumento13 páginas2 BSonali PriyadarshiniAinda não há avaliações

- Bme Answer KeyDocumento13 páginasBme Answer KeyS A ABDUL SUKKURAinda não há avaliações

- Global Review Solar Tower Technology PDFDocumento43 páginasGlobal Review Solar Tower Technology PDFmohit tailorAinda não há avaliações

- Tech Tip #51: Everyday Helpful Facts and FormulaeDocumento1 páginaTech Tip #51: Everyday Helpful Facts and FormulaeMohamed MeeranAinda não há avaliações

- 1 s2.0 S1877050917322299 Main PDFDocumento8 páginas1 s2.0 S1877050917322299 Main PDFJoi GirishAinda não há avaliações

- Combined Cycle Power Plant OperationDocumento21 páginasCombined Cycle Power Plant OperationEgit Bobyarta100% (5)

- Flash and Condensate Savings CalculatorDocumento2 páginasFlash and Condensate Savings CalculatorHiranthaAinda não há avaliações

- Chapter 5 Inspection and Maintenance: 5.1 List of Consumables and Regular Replacement PartsDocumento16 páginasChapter 5 Inspection and Maintenance: 5.1 List of Consumables and Regular Replacement PartsГоран ГорановAinda não há avaliações

- Rich Artha Kalla Fix NewwDocumento21 páginasRich Artha Kalla Fix NewwIndra GaAinda não há avaliações

- Condenser DesignDocumento2 páginasCondenser DesignRahul ChandrawarAinda não há avaliações

- Pruss ValveDocumento36 páginasPruss ValveSatyasheel TyagiAinda não há avaliações

- Thailand LAWI Reference List - Master - 190620Documento16 páginasThailand LAWI Reference List - Master - 190620Manoj SinghAinda não há avaliações

- Construction Manager - Caligiore CarmeloDocumento7 páginasConstruction Manager - Caligiore CarmeloMạnh CườngAinda não há avaliações

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterNo EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterAinda não há avaliações

- Electric Motors and Drives: Fundamentals, Types and ApplicationsNo EverandElectric Motors and Drives: Fundamentals, Types and ApplicationsNota: 4.5 de 5 estrelas4.5/5 (12)

- Electric Motor Control: DC, AC, and BLDC MotorsNo EverandElectric Motor Control: DC, AC, and BLDC MotorsNota: 4.5 de 5 estrelas4.5/5 (19)

- Introduction to Power System ProtectionNo EverandIntroduction to Power System ProtectionNota: 5 de 5 estrelas5/5 (1)

- Solar Energy: Survive Easily on Solar Power Off the GridNo EverandSolar Energy: Survive Easily on Solar Power Off the GridAinda não há avaliações

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesNo EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesNota: 4.5 de 5 estrelas4.5/5 (21)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentNo EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentNota: 4.5 de 5 estrelas4.5/5 (21)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialAinda não há avaliações

- Shorting the Grid: The Hidden Fragility of Our Electric GridNo EverandShorting the Grid: The Hidden Fragility of Our Electric GridNota: 4.5 de 5 estrelas4.5/5 (2)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsAinda não há avaliações

- Building Energy Management Systems and Techniques: Principles, Methods, and ModellingNo EverandBuilding Energy Management Systems and Techniques: Principles, Methods, and ModellingAinda não há avaliações

- Handbook on Battery Energy Storage SystemNo EverandHandbook on Battery Energy Storage SystemNota: 4.5 de 5 estrelas4.5/5 (2)

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsNo EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsNota: 4.5 de 5 estrelas4.5/5 (2)

- Well Control for Completions and InterventionsNo EverandWell Control for Completions and InterventionsNota: 4 de 5 estrelas4/5 (10)

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ANo EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AAinda não há avaliações

- Power Electronics Diploma Interview Q&A: Career GuideNo EverandPower Electronics Diploma Interview Q&A: Career GuideAinda não há avaliações

- Flow Analysis for Hydrocarbon Pipeline EngineeringNo EverandFlow Analysis for Hydrocarbon Pipeline EngineeringAinda não há avaliações

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideNo EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideNota: 2 de 5 estrelas2/5 (1)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsAinda não há avaliações

- Photovoltaic Solar Energy: From Fundamentals to ApplicationsNo EverandPhotovoltaic Solar Energy: From Fundamentals to ApplicationsAinda não há avaliações