Escolar Documentos

Profissional Documentos

Cultura Documentos

Itp FBSB Moc Fibreoptic 005 Final

Enviado por

Victor BiacoloDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Itp FBSB Moc Fibreoptic 005 Final

Enviado por

Victor BiacoloDireitos autorais:

Formatos disponíveis

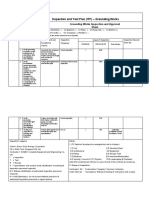

Provision of Engineering, Procurement, Construction, Activity :

Installation, Commissioning (EPCIC) of Long Term Power

Solution at Bintulu Onshore Receiving Facility (BORF) ITP No:

Seq No.

1.0

Description/ Activity

Controlling Procedure Form to

record results of compliance

Inspection & Test Plan

Contract No: PB/1302

FIBRE OPTICAL CABLE

Principal: MOC

FBSB/MOC/ITP-005

Location: BORF

Specification Acceptance Criteria

Reference

Holding Point

Contractor

(FBSB)

3rd Party

(SESCO)

Principal

(MOC)

Operation

Material Receiving Inspection

1.1

Material Received InspectionReport

Visual inspection

ITU-T Standard for fiber Optic (series

G.600-G699)

Material Deficiency Report

2.0

2.1

Check Quantity/ Condition

(Cables/Drum)

Material Verification

Visual Inspection Report

Type of material Cable size, type and

rating conform to specification, insulation

jacket

notspecification

to damaged

Correct

F-I-03

ITU-T Standard for fiber Optic (series

G.600-G699)

Material Received InspectionReport

Method Statement

On the drum test

Material Deficiency Report

Verify damage Material

Visual Inspection Report

Storage

3.1

Correct tagging number

F-I-03

ITU-T Standard for fiber Optic (series

G.600-G699)

Cleanliness

Material Received InspectionReport

Quantity

Material Deficiency Report

Refer to drawing 06001-MGP1-EG-ICDW-0060-08 "Instrument Cable

Schedule Fibre Optic".

INSTALATION AND LAY FO CABLE

4.1

Fiibre Optic Cable Type

Check Trenching size (width and depth)

and condition

W/R

W/R

W/R

Refer to drawing 06001-MGP1-EG-ICDW-0060-08 "Instrument Cable

Schedule Fibre Optic".

3.0

4.0

ITU-T Standard for fiber Optic (series

G.600-G699)

F-C-01

Prevent Bending Radius less than 15D

Refer to Drawing MOM-SK309-64-ICDW-0061-(Sheet 1 to 3) Fiber Optic

Cable Routing (Murphy BORF to SESCO

33KV Substation)

Handle with care the cable drum not to

damage the FO cable

Cable laying into trench and cable laying

by fix drum

Verify and ensure before starting under

ground placing work, all personnel shall

know the communication signal that will be

used. Personnel shall be stationed at the

reel location during cable pulling activities

to maintain proper reel rotation.

Roller shall be arranged within or on

ground surface along trench line.

Manual Cable pulling and assign

designated personnel to guide the FO

cable

Refer to Drawing MOM-SK309-64-ELDW-0085-(Sheet 1 to 3) 33kV

Underground Cable & Fiber Optic Overall Routing Plan

F-I-03

Method Statement

Refer to drawing 06001-MGP1-EG-ICDW-0060-08 "Instrument Cable

Schedule Fibre Optic".

Verify the Spacing between the HV cable

and FO as per AFC

Page 1 of 6

Comments/Remarks

Preserve both end of cable using end

cap

Page 2 of 6

Provision of Engineering, Procurement, Construction, Activity :

Installation, Commissioning (EPCIC) of Long Term Power

Solution at Bintulu Onshore Receiving Facility (BORF) ITP No:

Seq No.

Description/ Activity

5.0

BACKFILLING

5.1

Check spacing between cable

Controlling Procedure Form to

record results of compliance

Soil Compaction

Concrete slabs lining

Inspection & Test Plan

Principal: MOC

FBSB/MOC/ITP-005

Location:

Specification Acceptance Criteria

Reference

Holding Point

Contractor

(FBSB)

Refer to MOM-SK309-64-EL-DW-008601

F-C-01

Contract No: PB/1302

FIBRE OPTICAL CABLE

3rd Party

(SESCO)

Principal

(MOC)

Operation

Comments/Remarks

Cable route maker should be placed

Backfilling

6.0

FIBRE OPTIC TERMINATION

6.1

Correct tagging number.

ITU-T Standard for fiber Optic (series

G.600-G699)

F-I-03

Verify that only approved cleaving tools

and test equipment use for FO.

DEP 32.71.00.11 sec. 2.2.1

Certified personnel to Terminate the FO

FO cable is clean and dust free

Competency certificate

Refer to MOM-SK309-64-IC-DS-001900 "Instrument Datasheet for Indoor

Fiber Optic Patch Panel"

Equipment Certificate

Refer to MOM-SK309-64-IC-DS-002000 "Instrument Datasheet for High

Speed Fiber Optical Modem"

H/R

Correct Splicing and Equipment tools

Wave length test OTDR (Optical Time

Domain Reflectometer)

*Inspection and test mark-up legend: I = Inspect/Test, M=Monitor or surveillance, W = Witness, H = Hold Point, R = Document Review, A = Document Approval, SCE = Safety critical Item, 5 % V - 5 % Principal Verifi

required

Inspection and testing activities completed

3rd Party (SESCO)

Contractor (FBSB)

Signature :

Print Name :

Date :

Page 3 of 6

Operation

Contract No: PB/1302

Principal: MOC

Location: BORF

Comments/Remarks

Page 4 of 6

Page 5 of 6

Contract No: PB/1302

Principal: MOC

Location:

Comments/Remarks

ess, H = Hold Point, R = Document Review, A = Document Approval, SCE = Safety critical Item, 5 % V - 5 % Principal Verification

Principal (MOC)

Page 6 of 6

Você também pode gostar

- 1939 1708 Data Link Fault TracingDocumento16 páginas1939 1708 Data Link Fault TracingAyoub Ayoub100% (1)

- Section 05-05 Fiber Optic NetworkDocumento24 páginasSection 05-05 Fiber Optic NetworkYusuf AbdinasirAinda não há avaliações

- Calibration InstrumnetDocumento14 páginasCalibration InstrumnetDwi Mulyanti DwimulyantishopAinda não há avaliações

- Work Methodolgy For The Installation of Video-WallDocumento17 páginasWork Methodolgy For The Installation of Video-WallDani SalimiAinda não há avaliações

- Method Statement For LV Cables & Wires InstallationDocumento6 páginasMethod Statement For LV Cables & Wires InstallationUmaira ZainalAinda não há avaliações

- Inter Company Employee Transfer Letter FormatDocumento2 páginasInter Company Employee Transfer Letter FormatVictor Biacolo100% (1)

- Dokgoro K1785 Method StatementDocumento6 páginasDokgoro K1785 Method StatementJackie van SchalkwykAinda não há avaliações

- Script Das Cores Iqoption ScriptDocumento2 páginasScript Das Cores Iqoption ScriptStallkie67% (3)

- Method Statement For Installation of MDB, SMDB, DB, MCC & Capacitor BankDocumento7 páginasMethod Statement For Installation of MDB, SMDB, DB, MCC & Capacitor Bankadeniyi abiolaAinda não há avaliações

- Slope Stability Manual 8Documento12 páginasSlope Stability Manual 8YawgmothAinda não há avaliações

- Method Statement Forwater Tank FixingDocumento12 páginasMethod Statement Forwater Tank FixingJAMES neelAinda não há avaliações

- Alfanar Low Voltage Control Cables CatalogDocumento52 páginasAlfanar Low Voltage Control Cables CatalogAhmed H. HassanAinda não há avaliações

- Inspection & Test Check ListDocumento1 páginaInspection & Test Check ListPRAKTISIAinda não há avaliações

- Method Statement For Pulling Belt On With A Winch PDFDocumento1 páginaMethod Statement For Pulling Belt On With A Winch PDFFajar Sodiq100% (1)

- SGS - MS - Installation of LED FloodlightsDocumento8 páginasSGS - MS - Installation of LED FloodlightsomarqasimAinda não há avaliações

- TG085 Placing Fiber Optic Cable Into An Underground DuctDocumento11 páginasTG085 Placing Fiber Optic Cable Into An Underground DuctNaiem JalalyAinda não há avaliações

- 01 - PVC Conduits InstallationDocumento11 páginas01 - PVC Conduits InstallationRaju ManojAinda não há avaliações

- FTTH Network Installation Guide and Mobile Requirements: January 2013Documento56 páginasFTTH Network Installation Guide and Mobile Requirements: January 2013khaledhajjAinda não há avaliações

- Method Statement For Earthing & Bonding System InstallationDocumento9 páginasMethod Statement For Earthing & Bonding System InstallationThulani Dlamini100% (1)

- Method Statement Lamps, Switches and Socket Outlets InstallationDocumento2 páginasMethod Statement Lamps, Switches and Socket Outlets InstallationVõ Khắc GhiAinda não há avaliações

- Method of Statement For Installation of Wires and Cables PDF FreeDocumento6 páginasMethod of Statement For Installation of Wires and Cables PDF Freetristan guarinoAinda não há avaliações

- History of Owners of Handy House - Smith and TrippDocumento17 páginasHistory of Owners of Handy House - Smith and TrippwestporthistoricalAinda não há avaliações

- Cryofuge 5500i Sorvall RC4 120 200 208 EnglishDocumento90 páginasCryofuge 5500i Sorvall RC4 120 200 208 EnglishAndrew Holmes100% (5)

- QA/QC Responsibilities: InspectionsDocumento1 páginaQA/QC Responsibilities: InspectionsVenkata Suresh MandavaAinda não há avaliações

- Inspection and Test Plan (ITP) - Grounding WorksDocumento2 páginasInspection and Test Plan (ITP) - Grounding WorksElisco Pher SalmasanAinda não há avaliações

- Method Statement - Installation CCTVDocumento1 páginaMethod Statement - Installation CCTVMuhammad Syadham100% (1)

- Pre-Commissioning and CommissioningDocumento25 páginasPre-Commissioning and CommissioningVictor BiacoloAinda não há avaliações

- Erection Methodoly Electrical 50 MWPDocumento21 páginasErection Methodoly Electrical 50 MWPInaam Ullah MughalAinda não há avaliações

- Tecon Method Statement Lcs Rev-3Documento9 páginasTecon Method Statement Lcs Rev-3Nithin SudarshanAinda não há avaliações

- Table OF: Method Statement FOR Wires AND Cables InstallationDocumento235 páginasTable OF: Method Statement FOR Wires AND Cables InstallationMuhammad Jamil Khan100% (1)

- Plexo Catalog PDFDocumento20 páginasPlexo Catalog PDFMeylia RodiawatiAinda não há avaliações

- Ms For Indoor Ligthing InstallationDocumento6 páginasMs For Indoor Ligthing InstallationJoe_AverageAinda não há avaliações

- CHECKLIST For Installation of MICC CableDocumento2 páginasCHECKLIST For Installation of MICC CableTHEOPHILUS ATO FLETCHERAinda não há avaliações

- Combustion TheoryDocumento44 páginasCombustion TheoryyaidragonAinda não há avaliações

- Plumbing Method of StatementDocumento2 páginasPlumbing Method of Statementgvs rao100% (1)

- Guide To Fiber Optic InstallationDocumento20 páginasGuide To Fiber Optic InstallationdaybsAinda não há avaliações

- Tps OHLDocumento88 páginasTps OHLNaseem AhmedAinda não há avaliações

- Method statment-Underground-Cables-Laying-of-MV-LV-Street-Lighting-External-WorksDocumento9 páginasMethod statment-Underground-Cables-Laying-of-MV-LV-Street-Lighting-External-WorksUET MAIN100% (1)

- Electrical & Wiring METHOD STATEMENTDocumento4 páginasElectrical & Wiring METHOD STATEMENTAfiq JamalAinda não há avaliações

- Distribution Conductor StringingDocumento21 páginasDistribution Conductor Stringingmadhava_srinivasan174Ainda não há avaliações

- Method Statement For GIDocumento9 páginasMethod Statement For GIAleen Gamal Al-DinjiAinda não há avaliações

- Brochure Explosion Protection enDocumento45 páginasBrochure Explosion Protection enpramodtryAinda não há avaliações

- FEWA LV Joints & TerminationsDocumento13 páginasFEWA LV Joints & TerminationsMuhammad RazaAinda não há avaliações

- Method Statement For InstallationDocumento5 páginasMethod Statement For InstallationAriel CatapalAinda não há avaliações

- CHECKLIST For Installation of Electrical UPVC DuctsDocumento1 páginaCHECKLIST For Installation of Electrical UPVC DuctskevinAinda não há avaliações

- Duct Bank InformationDocumento19 páginasDuct Bank InformationGaneshAinda não há avaliações

- Electrocution Risks When Working Near Overhead Power Lines: Case No. 1 (One Person Serious Injured)Documento1 páginaElectrocution Risks When Working Near Overhead Power Lines: Case No. 1 (One Person Serious Injured)ken azuraAinda não há avaliações

- Quality Control Procedure For HVDocumento9 páginasQuality Control Procedure For HVVIKRAM DESAIAinda não há avaliações

- Corrosion Control InspectionDocumento6 páginasCorrosion Control InspectionAutumn SimonAinda não há avaliações

- Minor Electrical Installation Works - RedDocumento2 páginasMinor Electrical Installation Works - RedSeby SebastianAinda não há avaliações

- Method Statement FOR Testing and Commissioning: Grounding SystemDocumento3 páginasMethod Statement FOR Testing and Commissioning: Grounding SystemNon Etabas Gadnatam100% (1)

- Havells Combined Price List Modular SwitchDocumento12 páginasHavells Combined Price List Modular SwitchRakesh VermaAinda não há avaliações

- Release Notes - Instrument Inspector 2 - 0 - 2 - 0Documento8 páginasRelease Notes - Instrument Inspector 2 - 0 - 2 - 0Adrian ReyesAinda não há avaliações

- Termostato AKM 446 PDFDocumento4 páginasTermostato AKM 446 PDFPaulo RebeloAinda não há avaliações

- RFA of Method Statement For MV Cable Termination WorkDocumento2 páginasRFA of Method Statement For MV Cable Termination Workquynhanh2603Ainda não há avaliações

- Slave Clocks Commissioning 2Documento18 páginasSlave Clocks Commissioning 2badruddojamohdAinda não há avaliações

- 26076-110-GPP-GCX-00094 Work Method Statement For Loading Unloading GeneratorDocumento10 páginas26076-110-GPP-GCX-00094 Work Method Statement For Loading Unloading Generatorbangun0% (1)

- Check List For: Screed Works: Subcontractor Contractor Section of Work: Civil LOCATION: Parcel 18, Plot 405 LevelDocumento6 páginasCheck List For: Screed Works: Subcontractor Contractor Section of Work: Civil LOCATION: Parcel 18, Plot 405 LevelAminovic PlusAinda não há avaliações

- Method Statement For GCBDocumento6 páginasMethod Statement For GCBkamil0% (1)

- ITP Plan - FF PDFDocumento7 páginasITP Plan - FF PDFAltaf KhanAinda não há avaliações

- Index Final Data BookDocumento2 páginasIndex Final Data Booksajadsadeghi123100% (1)

- KMTC Advert For September 2021 and March 2022 IntakesDocumento2 páginasKMTC Advert For September 2021 and March 2022 IntakesNjoroge MainaAinda não há avaliações

- Attachment E - UPS Checklist PDFDocumento1 páginaAttachment E - UPS Checklist PDFnandaanujAinda não há avaliações

- Android Based Electrical Appliance ControlDocumento5 páginasAndroid Based Electrical Appliance Controlharrysingh100% (1)

- Cable Ladder Method of Statement.Documento4 páginasCable Ladder Method of Statement.Ahmad DagamsehAinda não há avaliações

- ChecklistDocumento35 páginasChecklistShashi Kant Singh100% (1)

- 16126Documento13 páginas16126uddinnadeemAinda não há avaliações

- Procedure Installation of Grounding & Lightning System - LABUAN BAJO PDFDocumento9 páginasProcedure Installation of Grounding & Lightning System - LABUAN BAJO PDFWika Djoko OAinda não há avaliações

- KOM For Instrumentation FOCDocumento28 páginasKOM For Instrumentation FOCnoelAinda não há avaliações

- TOR Electric Utility Annual Preventive MaintenanceDocumento10 páginasTOR Electric Utility Annual Preventive MaintenanceVictor BiacoloAinda não há avaliações

- Genset Base PadDocumento1 páginaGenset Base PadVictor BiacoloAinda não há avaliações

- Weekly Timesheet With Payslip Excel TemplateDocumento4 páginasWeekly Timesheet With Payslip Excel TemplateVictor BiacoloAinda não há avaliações

- Receipt ExpensesDocumento4 páginasReceipt ExpensesVictor BiacoloAinda não há avaliações

- WP20Documento8 páginasWP20Victor BiacoloAinda não há avaliações

- For AccreditationDocumento1 páginaFor AccreditationVictor BiacoloAinda não há avaliações

- Receipt ExpensesDocumento2 páginasReceipt ExpensesVictor BiacoloAinda não há avaliações

- Water Quality AnalyzerDocumento1 páginaWater Quality AnalyzerVictor BiacoloAinda não há avaliações

- Plam - TDSDocumento1 páginaPlam - TDSVictor BiacoloAinda não há avaliações

- June 2021 ExpensesDocumento2 páginasJune 2021 ExpensesVictor BiacoloAinda não há avaliações

- IBS Training ModuleDocumento58 páginasIBS Training ModuleAkhtar Khan100% (1)

- Fice Solution Cons Inc: Organizational ChartDocumento1 páginaFice Solution Cons Inc: Organizational ChartVictor BiacoloAinda não há avaliações

- Continuity/Insulation Resistance Test FormDocumento1 páginaContinuity/Insulation Resistance Test FormVictor BiacoloAinda não há avaliações

- Data SheetDocumento1 páginaData SheetVictor BiacoloAinda não há avaliações

- PVC Foam Data Sheet: Property Test Method Unit Q80Documento1 páginaPVC Foam Data Sheet: Property Test Method Unit Q80Victor BiacoloAinda não há avaliações

- 5 Adca Training - Part 3 5d72288d3b8cfDocumento48 páginas5 Adca Training - Part 3 5d72288d3b8cfVictor BiacoloAinda não há avaliações

- AdcaTraining-2-Rev 02 53b126afc413aDocumento40 páginasAdcaTraining-2-Rev 02 53b126afc413ajoaquin torrano veraAinda não há avaliações

- 6 Adca Training - Part 4 5d7228a93513fDocumento31 páginas6 Adca Training - Part 4 5d7228a93513fVictor BiacoloAinda não há avaliações

- 3 Adca Training - Part 1 5d722ade5d2acDocumento30 páginas3 Adca Training - Part 1 5d722ade5d2acVictor BiacoloAinda não há avaliações

- Large Scale Commercial Solution: Three Phase Grid-Tied Solar InverterDocumento4 páginasLarge Scale Commercial Solution: Three Phase Grid-Tied Solar InverterVictor BiacoloAinda não há avaliações

- Scrapper LAuncher M-840 & Receivers M-850Documento1 páginaScrapper LAuncher M-840 & Receivers M-850Victor BiacoloAinda não há avaliações

- Date GE Tag Description LearningDocumento3 páginasDate GE Tag Description LearningVictor BiacoloAinda não há avaliações

- MaterialsDocumento3 páginasMaterialsVictor BiacoloAinda não há avaliações

- Vibration StudyDocumento2 páginasVibration StudyVictor BiacoloAinda não há avaliações

- Motor PartsDocumento27 páginasMotor PartsVictor BiacoloAinda não há avaliações

- 200ah 12VDocumento2 páginas200ah 12VVictor BiacoloAinda não há avaliações

- Exhibitor 35804 PDFDocumento36 páginasExhibitor 35804 PDFulton1237624Ainda não há avaliações

- Buckling Considerations in Pile Design: October 2005Documento9 páginasBuckling Considerations in Pile Design: October 2005shashank sharmaAinda não há avaliações

- Sonali MondalDocumento2 páginasSonali MondalSonali MondalAinda não há avaliações

- Rohit Bebarta CVDocumento1 páginaRohit Bebarta CVRohit BebartaAinda não há avaliações

- LBS SchneiderDocumento20 páginasLBS SchneiderTien Dang ThanhAinda não há avaliações

- OBIEE 11g Training Details: Contact Name: Rao Contact No: 919948713895Documento7 páginasOBIEE 11g Training Details: Contact Name: Rao Contact No: 919948713895SwapnasaritAinda não há avaliações

- Sample Letters To DEPDocumento7 páginasSample Letters To DEPSJLibraryAinda não há avaliações

- AMIA Definition of Biomedical InformaticsDocumento15 páginasAMIA Definition of Biomedical InformaticsAndre FrancoAinda não há avaliações

- Accounting Information Systems: Basic Concepts and Current Issues 4th Edition Robert L. HurtDocumento29 páginasAccounting Information Systems: Basic Concepts and Current Issues 4th Edition Robert L. HurtJamieAinda não há avaliações

- Result For: Trucks & CV / 4 Wheeler - LCV / Asia Motor Works / AMW 2518 HLDocumento3 páginasResult For: Trucks & CV / 4 Wheeler - LCV / Asia Motor Works / AMW 2518 HLmanoj_doshi_1Ainda não há avaliações

- GROUP 7 - Banksia-SD-SE-T1-Hazard-Report-Form-Template-V1.0-ID-200278Documento5 páginasGROUP 7 - Banksia-SD-SE-T1-Hazard-Report-Form-Template-V1.0-ID-200278Samir Mosquera-PalominoAinda não há avaliações

- Black Box Software Testing: Introduction To Test DocumentationDocumento29 páginasBlack Box Software Testing: Introduction To Test DocumentationMohamed SaleemAinda não há avaliações

- TyresDocumento9 páginasTyresNitesh KotianAinda não há avaliações

- Fruit Recognition Deep LearningDocumento53 páginasFruit Recognition Deep Learningsaran20099Ainda não há avaliações

- ATMega8 UcDocumento40 páginasATMega8 UcnrjchopraAinda não há avaliações

- PPC Porcelain Solid Core Post Insulators and Operating RodsDocumento23 páginasPPC Porcelain Solid Core Post Insulators and Operating RodsCHRISTIANAinda não há avaliações

- OBIEE GuideDocumento306 páginasOBIEE GuideKomal Kandi100% (1)

- The Spring-And-Lever Balancing Mechanism, George Carwardine and The Anglepoise LampDocumento8 páginasThe Spring-And-Lever Balancing Mechanism, George Carwardine and The Anglepoise Lampmg504Ainda não há avaliações

- Chapter 12 Solutions To ExercisesDocumento41 páginasChapter 12 Solutions To ExercisesMuhammad Awais56% (9)

- Newton B CableRackDocumento48 páginasNewton B CableRackjuliocastAinda não há avaliações

- Industrial Public AddressDocumento2 páginasIndustrial Public AddresspradeepAinda não há avaliações

- Frs 3.4.0f 05-31-11Documento467 páginasFrs 3.4.0f 05-31-11SRKAinda não há avaliações