Escolar Documentos

Profissional Documentos

Cultura Documentos

Rules of Thumb Steel Design

Enviado por

vDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Rules of Thumb Steel Design

Enviado por

vDireitos autorais:

Formatos disponíveis

North American Steel Construction Conference

Rules of Thumb for Steel Design

with factored loads and LRFD or service

I n earlier times when computers

were neither available nor essential, one

loads and ASD in the final design.

Structural Depths:

objective of the structural design process

was to discover a computational method, Inevitably, a question raised in a pro-

which was elegant, simple and appropri- ject concept meeting is what will be the

ately accurate. When such a process was structural depth? Regularly, the partici-

identified it was recorded as an expedient pants are impressed by the response of

approach to solving a recurring structural the structural engineer and that positive

design problem. Thus, quick “Rules of impression lasts if the actual depths

Thumb” became essential resources for designed fall within the range of these

the structural engineer. As computer soft- early predictions. Therefore, it is impor-

ware has proliferated, become very com- tant to have established rules of thumb,

prehensive, and been made very user which allow structural depth predictions.

friendly, the importance of “Rules of The depth of the structural system is

Thumb” and approximate methods has influenced by the span of the elements as

been diminished. It has been argued that, well as such variables as the spacing of

with the computational speed and ease of elements, loads and loading conditions,

Socrates A. application of computer methods, the continuity, etc. Nonetheless, ratios of

Ioannides, need for approximations and “Rules of span to depth can often be relied upon to

Ph.D., S.E., Thumb” no longer exists. However, provide a guide and a starting point from

is President equally imposing arguments can be made which further refinement can be made.

for the value of these quick approaches With the caution that variables other

and John L. such as: than span need to be considered, the

Ruddy, P. E., information in Table 1 is presented.

is Chief • The structural engineer should have

tools to make on-the-spot intelligent It is convenient to remember that ser-

Operating decisions, viceable steel section depths are in the

Officer, of • A reasonable solution is often required range of ½” of depth for each foot of

Structural as computer input, span (L/24). Some people might find it

Affiliates • The validity of the computer output easier to remember the following simpli-

International, should be verified with rational fied rule where the length is expressed in

approximations. feet and the depth of the member in

Inc., in inches:

Nashville. So, with the objective of fostering con-

This article is tinued development, use and enthusiasm Depth of Roof Beams, Roof Joists =

for “Rules of Thumb” and approximate 0.5*Length

based on a methods, several steel framing “Rules of

paper sched- Thumb” are presented in this paper. In Depth of Floor Beams, Floor Joists

uled to be general, these rules of thumb are service- = 0.6*Length

presented at load based, which simplifies their applica- Depth of Composite Beams =

the 2000 tion. Formal checks can then be made 0.55*Length

North

American

Steel Construction Conference in Las

Table 1: Structural Depths

Vegas. System L/ds Span Range

Steel Beam 20 to 28 0’ to 75’

Steel Joist

Floor Member 20 8’ to 144’

Roof Member 24

Plate Girder 15 40’ to 100’

Joist Girder 12 20‘ to 100’

Steel Truss 12 40’ to 300’

Space Frame 12 to 20 80’ to 300’

Modern Steel Construction / February 2000

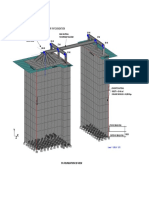

Section Properties Consider a beam spanning 30 feet Roof Systems

supporting a 10 foot width of floor with a A common approach to economy in

Wide flange steel section properties total supported load of 140 psf, resulting

can be estimated with reasonable accura- steel roof systems of single story buildings

in a moment of 157.5 foot-kips. For an is to cantilever girders over the columns.

cy when the member depth, width and 18” deep beam, the equation yields 43.75

foot-weight are known. Recalling that The ends of the cantilever support a

pounds per foot. A W18x50 is the pre- reduced span beam. When this system is

the density of steel is 490 pcf, the rela- dicted section and the actual moment

tionship between cross section area and subjected to a uniform load and multiple

capacity is 176 foot-kips. If a beam equal spans are available, a cantilever

foot-weight can readily be derived as: depth of 21” is assumed, the equation length approximately equal to 15%

yields 37.5 suggesting a W21x44, which

Wt (0.146) of the span length will result in

A= has a moment capacity of 162 foot-kips. the maximum moment in any span being

3.4 A similar formulation for steel having equal to 1/16 wL2. For end spans, nega-

Fy = 50 ksi produces: tive and positive moments can be bal-

The strong axis moment of inertia can anced using a cantilever length equal to

be approximated using: For an 18” deep beam, the equation 25% of the first interior span.

3.5per

M foot, therefore, a

yields 30.6 ≈

Wtpounds Another approach to economical roof

W18x35 is predicted.D The actual capacity

Wt systems is the use of plastic analysis.

I x ≈ D2

of a W18x35 beam with Fy=50 ksi is 158

foot kips. Although not as critical for this system,

20 splice locations in the plastically designed

For common composite beam floor continuous beams are usually chosen so

The radius of gyration is an important systems (e.g. 5½” slabs with 3” composite that they are close to the point of zero

cross section property when considering deck, 4½” slab with 2” composite deck, moment.

column buckling. Both the strong axis etc.), the simplified equations yield rela-

and weak axis radius of gyration can be tively accurate foot weights if 70% to Hinge or splice location for can-

estimated using the member depth (D) 75% of the simple span moment is used tilever or continuous roof systems

and width (b) as: for M. Following are two more “Rules of is 15% to 25% of span length

Thumb” relating to composite construc-

ry ≈ 0.26 b tion and Fy=36:

In ASD Number of shear studs

required for Full Composite Action Trusses

rx ≈ 0.45 D = 1.1*Wt The foot weight of trusses utilizing

Fy=36 ksi steel can be calculated by

In LRFD Number of shear studs assuming Fa=22 ksi. The Chord Force

required for Full Composite Action (Fch) is then equal to the moment (M) in

= 1.25*Wt foot-kips divided by de (center of top

chord to center of bottom chord) in feet,

Beams resulting in a chord area of M/22de. By

The rapid determination of a steel recognizing that Wt = A*3.4, converting

section size can be made without refer- COLUMNS de to inches and assuming that de = 0.9D

ence to a steel manual using a very sim- When the column axial capacity is and that the total truss weight is equal to

ple equation. If the moment capacity, plotted as a function of Kl/r, an approxi- 3.5 times the chord weight then:

depth and foot weight of the economy mate linear relation can be observed.

steel beams listed in the AISC 6M

Specification are tabulated with moment

Certainly, the column curve is not linear,

however an accurate approximation of

Wt ≈

divided by the depth as the independent column capacity for Fy=36 ksi can be

D

variable and foot weight as the depen- calculated using:

dent variable, a linear regression analysis The same formulation using steel with

results in a rather simple equation for Fy=50 ksi produces the following

Fy=36 ksi. Kl approximation:

P ≈ A 22.0 − 0.10

Wt ≈

5M r 4.5 M

D Wt ≈

A similar formulation for steel having D

Fy = 50 ksi produces:

The closest economy section of the These weight approximations include

depth used in the equation that has a truss joint connection material weight.

foot weight greater than predicted by the

Kl

equation indicates the beam that will sus- P ≈ A 30.0 − 0.15

tain the moment. This equation was con- r

firmed by the author using an alternate

approach, coined “Visual Semi-rigorous Thus, using the section property Rigid Frame Analysis

Curve Fitting”3. If all the beam sections approximations in conjunction with a Approximations:

are included, a slope value in the linear member foot-weight, width, depth and

The following “Rules of Thumb” are

equation of 5.2 yields closer approxima- unsupported length, the capacity of a col-

useful in determining preliminary sizes

tions for Fy=36 ksi. umn can be approximated.

for Rigid Moment Frames resisting

Modern Steel Construction / February 2000

Lateral loads. They are based on the tra-

ditional “Portal Frame” approach modi-

Table 2: Tall Building Structural Systems

fied from the authors’ experiences with Stories Lateral Load Resisting System

“real” frames.

<30 Rigid frame

1.2 H V story

M col ≈ • 30 to 40 Frame – shear truss

2 ncol 41 to 60 Belt truss

61 to 80 Framed tube

M

M beam ≈ col Interior Columns at Roof

2 81 to 100 Truss – tube w/ interior columns

101 to 110 Bundled tube

M beam ≈ M col Interior Columns Not at Roof 111 to 140 Truss – tube without interior columns

The moments in beams framing Tall Building Structural Systems l = Column Length (inches)

into exterior columns are half of the The late Fazlur Khan hypothesized L = Length (ft)

above values that the appropriate structural system to

resist lateral loads was directly related to M = Bending moment (foot-kips)

building height. He predicted that struc- Mbeam = Design Moment for Beam

tural economy could be realized using

Steel Weight Estimates the appropriate system shown in Table 2. Mcol = Design Moment for Column

Cost is generally the basis for confirm- ncol = Number of Columns (not bays) in

ing a structural system since safety and the story of the Frame

functions are essential for any options

considered. Economy is related to the P = Column Axial Capacity

weight of the structural steel although

r x = Strong Axis Radius of Gyration

costs are influenced by many other para-

meters. Yet, weight can be a valuable

Miscellaneous (inches)

indicator of cost and Rules of Thumb are End rotation of a simple beam = 0.2 r y = Weak Axis Radius of Gyratio

useful in establishing an expectation for radians (inches)

steel weight. A quick assessment of Deflection of simple span beam (reduc-

anticipated weight serves as a check of S = Elastic Section Modulus (in3)

tion due to connections) = 80% of calcu-

the reliability of the weight determined lated Vstory = Total Story Shear for the Frame

by more involved investigations.

Roof Framing Systems Wt = Foot weight of the steel beam

Bracing is a cost-effective means of (pounds per foot)

providing lateral load resistance for low For Cantilevered or continuous roof

to medium rise buildings. As the building beams : Wt(psf) = Weight of steel structure (psf)

height increases, the unit steel weight

increases since columns are subjected to • Run beams in short direction

larger loading at the lower floors and lat- • Optimum bay size is 30’ x 40’

eral load resisting components are sub- For Truss Joist and Joist roof systems:

jected to greater loads for greater heights. • Run Girders in Long direction

Thus, one parameter influencing the

• Optimum bay size is 40’ x 40’

steel weight is building height. A rough

approximation for steel weight per square

foot in a braced building using steel with

Fy = 50 ksi is:

Wt(psf) = stories/3 + 7

A three-story building would have a Nomenclature

steel weight in the range of 8 psf and a

27-story building would require 16 psf.

Certainly, this relationship is an over A = Area (in2)

simplification. Yet, it provides a value,

which can be used to confirm that the b = Nominal member width (inches)

results of a more detailed analysis are D = Nominal member depth (inches)

reasonable.

ds = System depth (ft)

Fy = Yield strength of steel

H = Story Height

I = Moment of Inertia (in4)

Modern Steel Construction / February 2000

Você também pode gostar

- Beam Deflection FormulaeDocumento2 páginasBeam Deflection Formulae7575757575100% (6)

- IS13920 Explanatory+Examples+3Documento9 páginasIS13920 Explanatory+Examples+3Kiran Raju Alluri100% (1)

- Fema 454 PDFDocumento392 páginasFema 454 PDFAnna SanchezAinda não há avaliações

- 2 Concept of Limit State DesignDocumento3 páginas2 Concept of Limit State DesignVinoth KumarAinda não há avaliações

- Understanding The Mass Participation FactorDocumento7 páginasUnderstanding The Mass Participation FactorDavid RajAinda não há avaliações

- Seismic Behavior Retaining WallsDocumento29 páginasSeismic Behavior Retaining WallsSaeedAinda não há avaliações

- 1 Dynamic Analysis of Machine Foundation Using AnsysDocumento7 páginas1 Dynamic Analysis of Machine Foundation Using AnsysVivek DhutAinda não há avaliações

- Tower Design SheetDocumento41 páginasTower Design Sheet14pcashAinda não há avaliações

- Zeds & Cees: Users GuideDocumento40 páginasZeds & Cees: Users GuideTee Bun PinAinda não há avaliações

- Structural Design of Steel Bins and SilosDocumento36 páginasStructural Design of Steel Bins and Silosyoussefayay92% (12)

- Calculation of Blast Loads For Application To Structural ComponentsDocumento92 páginasCalculation of Blast Loads For Application To Structural ComponentsAgam Bichman HarahapAinda não há avaliações

- Cold Formed Steel Joints and Structures - A ReviewDocumento14 páginasCold Formed Steel Joints and Structures - A ReviewGabriel MacedoAinda não há avaliações

- Reducing Torque&Drag, New Drilling Tech (A, 12)Documento12 páginasReducing Torque&Drag, New Drilling Tech (A, 12)bolerjeffAinda não há avaliações

- An Explanatory Handbook On Is 875 Part 1987Documento108 páginasAn Explanatory Handbook On Is 875 Part 1987SourabhAdikeAinda não há avaliações

- VDA Volume Assessment of Quality Management Methods Guideline 1st Edition November 2017 Online-DocumentDocumento36 páginasVDA Volume Assessment of Quality Management Methods Guideline 1st Edition November 2017 Online-DocumentR JAinda não há avaliações

- Crossroads in Time Philby and Angleton A Story of TreacheryNo EverandCrossroads in Time Philby and Angleton A Story of TreacheryAinda não há avaliações

- AD 256 - Design Considerations For The Vibration of Floors - Part 3Documento3 páginasAD 256 - Design Considerations For The Vibration of Floors - Part 3symon ellimacAinda não há avaliações

- GATE RCC & Steel Structures BookDocumento12 páginasGATE RCC & Steel Structures BookMims120% (1)

- Thumb Rules For Steel DesignDocumento3 páginasThumb Rules For Steel Designpranit_rai100% (1)

- Analysis of Prestressed Concrete Girder For BridgesDocumento8 páginasAnalysis of Prestressed Concrete Girder For BridgesEditor IJTSRDAinda não há avaliações

- AD 338 - Guidance On The Use of Stainless SteelDocumento2 páginasAD 338 - Guidance On The Use of Stainless Steelsymon ellimacAinda não há avaliações

- Tata Steel Advance To Eurocodes Jun 13Documento60 páginasTata Steel Advance To Eurocodes Jun 13s9904055Ainda não há avaliações

- Seismic Behavior & Design of Gusset PlatesDocumento41 páginasSeismic Behavior & Design of Gusset PlateswilfredAinda não há avaliações

- Inelastic Lateral-Torsional Buckling of Beam-Columns Proc. ASCEDocumento70 páginasInelastic Lateral-Torsional Buckling of Beam-Columns Proc. ASCEbauemmvssAinda não há avaliações

- Lateral Loads of 4 Level Shelving, With Hilti Anchorage, Based On ASCE 7-16Documento12 páginasLateral Loads of 4 Level Shelving, With Hilti Anchorage, Based On ASCE 7-16kosdsdsAinda não há avaliações

- Specific Instuctions To BiddersDocumento37 páginasSpecific Instuctions To BiddersShahed Hussain100% (1)

- Factors Affecting Strength of Epoxy Repaired TimberDocumento15 páginasFactors Affecting Strength of Epoxy Repaired TimberJosé PeAinda não há avaliações

- Model Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNo EverandModel Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionAinda não há avaliações

- 1983 (Q2) - Design of Headed Anchor BoltsDocumento13 páginas1983 (Q2) - Design of Headed Anchor BoltsCesar RjszvlAinda não há avaliações

- Column Design Procedure PDFDocumento26 páginasColumn Design Procedure PDFTamilAinda não há avaliações

- Concrete-Filled Double-Skin Steel Tubular Columns: Behavior and DesignNo EverandConcrete-Filled Double-Skin Steel Tubular Columns: Behavior and DesignAinda não há avaliações

- IBC 2006 Seismic CalculationDocumento1 páginaIBC 2006 Seismic CalculationMonotobo X MakinaAinda não há avaliações

- Review of Handbook For Blast Resistent Design of BuildingsDocumento3 páginasReview of Handbook For Blast Resistent Design of BuildingsNaz KalamAinda não há avaliações

- Assignment On Porters Generic StrategiesDocumento12 páginasAssignment On Porters Generic StrategiesGeetinder Singh78% (9)

- Analysis of Non Prismatic Beams in BridgeDocumento7 páginasAnalysis of Non Prismatic Beams in BridgeNafeez AhmedAinda não há avaliações

- Crane Wheel Load EccentricityDocumento2 páginasCrane Wheel Load Eccentricitypranit_rai0% (1)

- TVL-SMAW 12 - Week 4 - Lesson 1 - Concept of Welding Codes and StandardsDocumento9 páginasTVL-SMAW 12 - Week 4 - Lesson 1 - Concept of Welding Codes and StandardsNelPalalonAinda não há avaliações

- Floor Vibration Serviceability - Tips and Tools For Negotiating A Successful DesignDocumento8 páginasFloor Vibration Serviceability - Tips and Tools For Negotiating A Successful Design_at_to_Ainda não há avaliações

- İsrail Deprem Yönetmeliği EkiDocumento18 páginasİsrail Deprem Yönetmeliği EkiErol Eylemci KaplanAinda não há avaliações

- FEA-Secant Pile Wall InstallationDocumento12 páginasFEA-Secant Pile Wall InstallationAlwin Antony100% (1)

- IS 1852-1985 Rolling & CuttingTolerance For Hot Rolled Ste 1 - RDocumento28 páginasIS 1852-1985 Rolling & CuttingTolerance For Hot Rolled Ste 1 - RvaideehAinda não há avaliações

- Analyzing The Seismic Behavior of Set Back Buildings by Using E-TABSDocumento9 páginasAnalyzing The Seismic Behavior of Set Back Buildings by Using E-TABSrock_musicAinda não há avaliações

- TSLAB V3.0 User GuidanceDocumento68 páginasTSLAB V3.0 User GuidanceJohn R100% (1)

- TN005 - Guidelines For Designing To As 4100 When Imported Materials Are InvolvedDocumento7 páginasTN005 - Guidelines For Designing To As 4100 When Imported Materials Are InvolvedAndy AcousticAinda não há avaliações

- Design of Vertical Bracing Connections For High Seismic DriftDocumento12 páginasDesign of Vertical Bracing Connections For High Seismic DriftvAinda não há avaliações

- Columns and SlabsDocumento142 páginasColumns and Slabsk. mohan brothersAinda não há avaliações

- Mathcad - 2019 SNI 1726 Static Equivalent Forces PDFDocumento9 páginasMathcad - 2019 SNI 1726 Static Equivalent Forces PDFDiego KevinAinda não há avaliações

- Driven Steel Piling - BBGEDocumento2 páginasDriven Steel Piling - BBGEmasterumAinda não há avaliações

- Steel Bridges: Publication No. 34/02Documento98 páginasSteel Bridges: Publication No. 34/02Starla HillAinda não há avaliações

- Slim Floor: Long Carbon Europe Sections and Merchant BarsDocumento36 páginasSlim Floor: Long Carbon Europe Sections and Merchant BarstankeanleongAinda não há avaliações

- Bending Under Seated ConnectionsDocumento5 páginasBending Under Seated ConnectionsSaeedAinda não há avaliações

- Research On Steel Plate Shear Wall Past, Present, FutureDocumento50 páginasResearch On Steel Plate Shear Wall Past, Present, FutureAlexander Vega VásquezAinda não há avaliações

- Splicing of Precast Prestressed Concrete Piles Part I - Review and Performance of Splices PDFDocumento28 páginasSplicing of Precast Prestressed Concrete Piles Part I - Review and Performance of Splices PDFSid KhanAinda não há avaliações

- How To Design A Transfer FloorDocumento4 páginasHow To Design A Transfer Flooreplim60100% (1)

- Design Code For IndonesiaDocumento3 páginasDesign Code For IndonesiaAmol GoleAinda não há avaliações

- Fan Foundation Frequency CheckDocumento4 páginasFan Foundation Frequency CheckdantevariasAinda não há avaliações

- Composite Beam IIDocumento27 páginasComposite Beam IIStefan-Raluca AsavoaeAinda não há avaliações

- Probabilistic Analysis of Soil - Diaphragm Wall FrictionDocumento11 páginasProbabilistic Analysis of Soil - Diaphragm Wall FrictionDiego Alejandro Flores OrtízAinda não há avaliações

- Rules of Thumb For Steel Design: Orth Merican Teel Onstruction OnferenceDocumento1 páginaRules of Thumb For Steel Design: Orth Merican Teel Onstruction OnferencebagmassAinda não há avaliações

- Thumb Rules Steel DesignDocumento7 páginasThumb Rules Steel DesignQazi Abdul MoeedAinda não há avaliações

- Construction and Building Materials: Reza MasoudniaDocumento18 páginasConstruction and Building Materials: Reza MasoudniaMazenMowafyAinda não há avaliações

- Comparison of Design Calculations of Deep Beams Using Various International CodesDocumento10 páginasComparison of Design Calculations of Deep Beams Using Various International CodesIgor BarcelosAinda não há avaliações

- Comparison of Design Calculations of Deep Beams Using Various International CodesDocumento10 páginasComparison of Design Calculations of Deep Beams Using Various International CodesHabibur RahmanAinda não há avaliações

- Conference Preview: What Makes A Good Design Drawing?Documento2 páginasConference Preview: What Makes A Good Design Drawing?Yami YugiAinda não há avaliações

- Design of Cellular Beams Against Lateral Torsional Buckling: Notation 1Documento9 páginasDesign of Cellular Beams Against Lateral Torsional Buckling: Notation 1HHTAinda não há avaliações

- Absolute Bending MomentDocumento19 páginasAbsolute Bending Momentpranit_raiAinda não há avaliações

- f10t Bolt PropertyDocumento1 páginaf10t Bolt Propertypranit_raiAinda não há avaliações

- Description TS StaadDocumento1 páginaDescription TS Staadpranit_raiAinda não há avaliações

- 2017 Hu Spence Why Globalization Stalled and How To Restart ItDocumento11 páginas2017 Hu Spence Why Globalization Stalled and How To Restart Itmilan_ig81Ainda não há avaliações

- Course 3 Mathematics Common Core Workbook AnswersDocumento4 páginasCourse 3 Mathematics Common Core Workbook Answerspqdgddifg100% (1)

- RF Based Dual Mode RobotDocumento17 páginasRF Based Dual Mode Robotshuhaibasharaf100% (2)

- Exchange 2010 UnderstandDocumento493 páginasExchange 2010 UnderstandSeKoFieAinda não há avaliações

- PTD30600301 4202 PDFDocumento3 páginasPTD30600301 4202 PDFwoulkanAinda não há avaliações

- Development and Growth of Teeth: Dr. Madhusudhan ReddyDocumento48 páginasDevelopment and Growth of Teeth: Dr. Madhusudhan ReddysiyaAinda não há avaliações

- BPI - I ExercisesDocumento241 páginasBPI - I Exercisesdivyajeevan89Ainda não há avaliações

- Kalitantra-Shava Sadhana - WikipediaDocumento5 páginasKalitantra-Shava Sadhana - WikipediaGiano BellonaAinda não há avaliações

- System Administration ch01Documento15 páginasSystem Administration ch01api-247871582Ainda não há avaliações

- Curriculum Vitae: Educational Background Certification Major Name of Institute PeriodDocumento2 páginasCurriculum Vitae: Educational Background Certification Major Name of Institute PeriodTHEVINESHAinda não há avaliações

- 11 - Chapter 3Documento27 páginas11 - Chapter 3sam000678Ainda não há avaliações

- Maharashtra State Board of Technical Education. Academic Monitoring Department ProfileDocumento14 páginasMaharashtra State Board of Technical Education. Academic Monitoring Department Profilevspd2010Ainda não há avaliações

- GNT 52 60HZ enDocumento4 páginasGNT 52 60HZ enEduardo VicoAinda não há avaliações

- Homelite 18V Hedge Trimmer - UT31840 - Users ManualDocumento18 páginasHomelite 18V Hedge Trimmer - UT31840 - Users ManualgunterivAinda não há avaliações

- Super Gene 1201-1300Documento426 páginasSuper Gene 1201-1300Henri AtanganaAinda não há avaliações

- Hasan Bin Ekram: Career ObjectiveDocumento3 páginasHasan Bin Ekram: Career ObjectiveHasan SarikAinda não há avaliações

- MARKETING STUDY EditedDocumento48 páginasMARKETING STUDY EditedRichard Rhamil Carganillo Garcia Jr.Ainda não há avaliações

- Emulsion LectureDocumento30 páginasEmulsion LectureRay YangAinda não há avaliações

- COE301 Lab 2 Introduction MIPS AssemblyDocumento7 páginasCOE301 Lab 2 Introduction MIPS AssemblyItz Sami UddinAinda não há avaliações

- The Eye WorksheetDocumento3 páginasThe Eye WorksheetCally ChewAinda não há avaliações

- Zanussi Parts & Accessories - Search Results3 - 91189203300Documento4 páginasZanussi Parts & Accessories - Search Results3 - 91189203300Melissa WilliamsAinda não há avaliações

- Vishakha BroadbandDocumento6 páginasVishakha Broadbandvishakha sonawaneAinda não há avaliações

- Opentext Documentum Archive Services For Sap: Configuration GuideDocumento38 páginasOpentext Documentum Archive Services For Sap: Configuration GuideDoond adminAinda não há avaliações

- CD4 12-P374493Documento30 páginasCD4 12-P374493suraj_savant1Ainda não há avaliações

- CV - Mohsin FormatDocumento2 páginasCV - Mohsin FormatMuhammad Junaid IqbalAinda não há avaliações

- Green ChemistryDocumento17 páginasGreen ChemistryAaditya RamanAinda não há avaliações