Escolar Documentos

Profissional Documentos

Cultura Documentos

Welding QC 3 - Weld Procedures

Enviado por

Exsan OthmanDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Welding QC 3 - Weld Procedures

Enviado por

Exsan OthmanDireitos autorais:

Formatos disponíveis

TWI

vo[t

THE \4LDINC NSTN'UTE

SECTION3

TWI

Vr7-/F

l, lllN

THE W:LDI\C I\ST. 1'II

T H EW E L D I N GP R O C E D U R E

The task of col ectingthe data and draftrngthe oocumeniation

is oftenrefei.i-ed

to as w ting a weld procedure.In many ways tnis is an unfofiunate

term as

the writingof documentsts the lasr in a sequenceof tasks.

Producinga weld procedureinvolves:

o

.

.

.

.

.

.

planningthe tasks

collectingihe data

writing a procedurefor use or for trial

makingtest welds

evaluatingthe resultsof the tests

approvingthe procedureof the relevantCode

preparingthe documentation

In each Code referenceis made to how the proceduresare to be devisedand

whether approvalof these proceduresis required. In most Codes approvalis

mandatoryand tests to coniirmthe skill of the welder are specified. Detailsare

also given of acceptancecriteriafor the finishedjoint.

The approachused dependson the Code,for example:

BS 2633 : (Class I arc weldingoi ferritjcsteel pipeworkfor carryingfluids)

pfovroesgeneralcommentson various$pects of a suitableweld

procedure.

AWS D.1.1 (Structural

weldingcode - steel)favoursmore specific

instructionsfor differentjoints and processeswhich are, in effect,pre_

qualifiedprocedures.

Other Codes do not deal specificallywith the detailsof the weld procedure

but referto publisheddocumentation,

e.g. BS 5135 ,processof arc weldinq

carbonand carbonmaneanesesteels,.

? *(s

,r pd.rz-

,t

,^_P_5

"/..VX

Ur-o4!,-.v FTJ

=--1----+-_--+:-j

r,'-\,{

\,r-W

WELDING TECHNOLOGY

I s s u e0 1 9 1

T\MI

7[Or

TIIE \ll-j:)tNc

INSTfijTE

COMPONENTS

OF A WELDPROCEDURE

Items to be includedin the procedurecan be some of the following:

1. Parentmetal

1.1

1.2

1.3

1.4

Type

Thickness(for pipe this includesoutsidediameter)

Surfacecondition

ldentifyingmarks

;-_-2. Welding process

2.1 Type of process(MMA, TlG, MAG etc)

2.2 EouiDment

2.3 Make, brand,type of weldingconsumables

2.4 When appropriatethe temperatureand time adoptedfor

drying and bakingof electrode/consumables

3. Joint design

3.1

3.2

3.3

3.4

3.5

3.6

Weldingposition

Edge preparation

Methodof cleaning,degreasingetc

Fit up of joint

Jiggingor tackingprocedure

Type of backing

4. Weldingposition

4.1 Whethershop or site welding

4.2 Arrangementof runs and weld sequence

4.3 Filler material,compositionand size (diameter)

4.4 Weldingvariables- voltage,currenttravel speed

4.5 Weld srze

4.6 Back gouging

4.7 Any specificfeatures,e.g. heat input control,run-out length

5. Thermal treatment

5.1 Preheatand interpas-s

temperaturesincludingmethod and

control

5.2 Post weld treatmentincludingmethod and control

3.2

WELDING TECHNOLOGY

Issue 0191

i

TWI

THE W LD INC INSTIILITE

APPROVING

THE PROCEDURE

When the data has been co ected, the proceduremust be varidatedby

producingand testinga trial weld.

lf the procedureis to be usedon a fabrication

whichnas beendesiqnedto

meetthe requirements

of a code, the test werdis done underthe s-upervision

of an independent

witness.The detairedarrangements

for the testare subiect

to agreementbetweenthe contracting

parties.

A numberof Britishstandardsmakecrossreference

to anotherstandard

whichcoversapprovaltesting.

OtherCodesof practiceincludetheirown weldprocedureA,velder

aDoroval

information.

In generarthey incrudea standardformatwhichcan be usedto report

the

resultsof an approvaltest.

Exle'rF $

Ayln'.---t

) /o' 4

Y,,l)" \tvl

-/2t""W)

(t'*"c";"

D-"*x4

Q

\ft

3.3

T'wI

7[O{

TlS \!LDINC

INSTTFLFIE

M A N U F A C T U R E RW' SE L D I N G

P R O C E D U RSCP E C I F I C A T I O

NP S )

rw

(so EN 2e-2)

Loc.llon: .......TWI

TFAJNTNG

WOnKSHOp

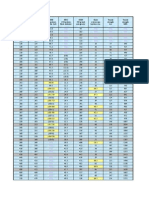

M:nulrcturr/! Wctdtngproc.durt: .......pwpS

m1/A._.

Rcl.r.nc. Ho: ........{1920...

WPARNo: ........0223........

M:nul:ctrJ.!r : ...-....FnED

BLOGGStNOUSTRIES.

W.lde/.

Errmln.r o. t.3t bo<ba......8.O.1

LTD.....

OEGREASE&

Hotho<tot Prspr.r on .nd CI..nlng:......MACHINE...

Prr!nt t{eterirt Spctftcr on: ..316L STANLESS STEEL

c . c o % c . 1 7 % M n 1 . 5 %M o 2 5 %

Nam.: .-......_A

N OTHER...,..

Ni 1l% Si 0.5% + Resrdualg

welding Proca..; ....-..141C|cROOT)/1

r 1(rt4^ ;t,-l a Copt................... ll.t.rial Thlcknr..

{lnm):.-....15mm

Jolnt Typ.: ........StNG1:

gUT;....-..

VE=

Outsld. Otrm.t.r (lnm):......

155mrn_........-,,._,..............

W.ldlog Poiltlon: ..-...HLO45....,..-...-.,.,................-...-_-.

Wcld Pr!p.r.

on O.trtttJotnt O.3tgn (Sk.tch).

W.ldlng O.t.ltr

ltUn

Procast

t4t

a

10

SE. ot

Rll.? H.trl

AUTOGENEOUS

lll

C{rr?ani

60-70

Voltrg.

l0-t2

Typ. ol

cuftanU

Polr,tty

Wl.. F..d

Sp..d

DCEN

110-120

Traval

Sp..d.

H.at

Inpur

l|o.nnvmn

l.C]|(Ymrn

l{Ornm FIOL

1.o.(yritn

95-l t0

DCEP

l30.nm ROL

1.ol(Yrnm

Ill

70-90

OCEP

tmrnm ROL

l.(}(Yrnrn

70-90

OCEP

t@rnm ROL

LoKYmrn

coanpruoar

Zsftm

Flu.r u.trt ct:3rlttc. on .nd t rd. nrh.:._--.souooMETAL

supEFICROM3l6L to tSO 3581-E19123:t-Rzt....-_..-..._-,_.-.__---._..

anv_sjxclrt 8.r|no o? orytag: ......oRy AT roo.c FoR

2 HOURSOUtyR AT 75.C.......--....___-_-__.

irgFlux: tht.tdtng: .....-Aflcoa.l_ COMMERCLALpURtTy

.-............

Orh.. Inlo.hr on.:...

D.cllng : .--..IAGON - COMMERCTALpURtTy

....,..-.......-.-.-...-...-...

..g.

G.3 Ro- R:t. - sht.tdtng: ._.-.8LITRESA|rNfrfa.....,........._..._...--_:..-.._.:' w.rung (nr,tlmum rtdrh ol .un): _2 x a......

6:ottetton: tmputud., Ir|qq.nca, dw.( Um.: ....!:1requir<l

B.cl|ns: .-.... UTREsa.{'**.......-.......-.....-...........--.-jil.l

-ungslon

Pu|3 w.rdtnc d.trIs ......NoT REoUtRED ....._.--...

El.ctrod. Typ.6ur: ..-...2% THof,tuM

2.5 0................-..-..*.... st nd ott dtstrnc.: .._...NoT REoutREo ._....--._.---...

).lrll.^ot B..l4c.rd.a8.cttng:

...-..BETAJN

Uml nUlr s Or.rw^nO_.

;hr.n. wltdtng d.r.tt* ....-.NOTREOutREo .---.....

Intarpa3iTcmp.rrtura: ......150.CMAX|MUM.................-o3t-W.ld Ho:t T..rtm.nt rn.t/or Ag.tn9: ......NONE..................-..................

l.mpcrrlur.. l{.thod: ......NOTREOU|REO..--...........-.....-...

..r.n.,

H.allng .nct Coo ng R:t..: .-...-ASpROCEDURe..-,..................._...-......:

'nu:ctuilr

Nltna

o:t. .ct3-co-| 99_

Etamrnaaoa ta3t body

N.tn. ,.....1.C.

O:t.

Slgnrtu.a

'ab,.,*ge

? A

WELDINGTECHNOLOGY:

lssue 0191

TWI

VOOT

IHE WELDTNG N.IS?NIN:E ' '

W E L D I N GP R O C E D U RAEP P F O V A LR E C O R OF O R M( w P A R )

TO EN 288

WELDINGPROCEOURE

APPROVAL- TEST CERTIFICATE

H anul.ctursf s W6ldIng Procedu.o

ReterencoNo. _........._.-.................41920/m1/A...................

Errmlnor or test body 8Dl L;0...

R . l o r o n c oN o . . 9 0 17 1 0 O O ? 5

......_.....,..

Manulacturo|:...FREDELOGGSINOUSTRIES

Addre3i ....375 LONDON ROAD. CA 4BRIOGE UK

;od^estlng St.nd.rd:......EN298

-at6 o{ Woldlng:......@-0O-199-

EXTENTOF APPROVAL

weldlng process:...-.l4 t T1GROOT t1l MMA FILL&CAp

Joint Typ: ....^NY EUTTJO|NI tN ptpE OR PLATEF-IET WELOStN ptpApLATE& T BUTTwErts

Par60rmerat(s):....AUsrENt'IIc srAJNLEsssrEELs................

conditionsot ro.npred:

.Nor AppucAaLE...-.-...

Mt:l thlcknGs {mm}: ......t2mm - l6.5mm

Oqt3ld. Dlrmot.r (mm):.....78rnm- 3tOmm

Flllc. llet.l typ.:......3i6L SOUOOME-,ALSUPERCROM

TO tSO EtqtA3:L R 23 ONLY

S hlelding Gt tFlur

.....l,RGON

Typo ol Woldlng Curront ......O|FiECT

CURFTENTt4l

OCEN I l1 rcEp ....___.

tldlng Posltlons: ...,.1LL pOStTIONS EXCEFr p.c. MEFrIIC& mWN)

Oih6r Inlorrn.tlon: ......TACKWELDtNG NOT PERM|TTED UNE Up CLA!,tpS ONLY

c'illll6d thrt te3t ?eld3 p,aPaaad, waldad and tostod satislacto.lly In accordanco *lth tha rcqulrsmnta

ol th. codanoaflng atandard

Indic:ted abovo.

Loc:tlon

Drt. ol lssuo .00-@-199-

El(rmlnor or l6st body

Nrrn6-- El:It EID;

t.c. tTcrNBE

Prg. 1 ol3

WELDINGTECHNOLOGY

lssue 0191

+!.c

T\VI

700t

Tre \I,ELDINCrr-STmJTE

DETAILSOF WELD TEST

Loc:tlon: ......,SHOP- TWt TFAINING WORKSHOP

Menulectur./a Wrtdlng ploc.dur'

Rloroncr No.: ...,._41

920

Ej(rmlner or tsst body.-._..8.D.1.

l_TD....-_

wpanNo:......wpAn

col/A......

;;i;;';;;;;.;;;j;;;;;

;;;.;;;,...;iC i. jiCnerse

ptrent Mater{.|Specific2uon:..316L

STAJNLESS

STE:L

ManuractuEr _.._.

F;iFD Br oc.:c tunr rerorEa

lry.ldln9 S.qu.nc.

ttun

ProcGr

l4t

SE! ot

Flller tlotat

Cunant

AUTOGENEOUS

lll

Volt.g.

Typc ot crJ..!nv

Pohrtty

lt

oceN

WI.! F .d

Sprod

Tr:val

Sp.d.

45mm

115

tO to

' 1

-alnprqton

80

H.rt lnpqt.

Kymtn

21

150mm

0.96

lsornrr

0.84

I lomm

0.96

1lornm

0.96

FIlle. M.trt Ct.3rflc.tjon .nd tnd. n.m.: ....SOUDOMET&

SUpERCAOM 3t6L

Any Specl.t B.ktr|g o. Orytn!:....CRtED AT lm.C _

2 HRS.

/Flux:

q[.ldlng: ....-.8OC AFTGON-..........-........,_.--..........-.-,

G.t

Olhaa Inlormstloni

b.cktng:.-....BOC

AtcON......-..........-.....................

..9. wo.vlng (Ltrxtmurn wtdth ot nrh): .-NONE-.

G:s FlowRat. - Shr.tdtng:.......6

UTFTESA{1N...................._.........:

Osclllatlon:

a.nplttuda, tnquoncyr dw. um.

B.cllng: ......aurREs/MtN....--......--..............................

_

Puls. w.tdlng dtalt( --.NONE_-..-.-.-.-.

TungstonElsct.o{t.Typ.6&.i .--...2%

fHOnrUUZS.^.........-.........'

Stand oft < 3tznc.:..-.NONE....-............

Oot.ll3 oa&cting: _-.-.RFIAINED

UNnL FUN 6--Plrimr weldl.g d.t.lt!: ...NONe-..--_..

Pt!hGat tomp.r.tur.: .......NoNEAppL1ED......................................._...

To.ch .ngt.: .-..ASREOUTREO............

Int.rpasa Tcmp.dtur.: ...-...MAX|MUM

t30.C

Post-W.ld H.et T.strn.nt rnd/o?Ag.|ng:......NONE

I rm., I emprrtur.,l,t.thod:..-.......NONE...-......_----_

Hratlng .nd Coo(ng Brto.i .........NONE-.................

UATIUFACTURER

N.m.: .-.......FREDERlCK

O.t!: .-.-......m-OO-199_ .-.._...

Slgnrtur:

Errmln.. or trst body

Nrmr:..........1

C

qa,ner)

Slgnrtura:

:a n' b ri6)

J.b

P.gr 2 ol 3

WELDINGTECHNOLOdY

- --

I<<t ta n7 01

TWI

voor

TI{E WEI'ING U.]STMUTE

DOCUMENTATION

The objectivesof a procedureor welder approvaltest are:

a) to prove the proceduremeets the necessaryrequirementswith referenceto

feasibiiity,mechanrcalstrengthetc

b) to prove the weldersare competentto work in a particularjob

lf a customerqueriesit, evidencecan and would be suppliedto prove validity,

even though the approvaltests might have been some considerabletime ago.

Approval Test Specifications

call for a paper recordwhich can be know as

either:

procedure/welderapprovalcertificate

procedure/welderapprovalrecord

procedure/welderapprovaireport

The followingrecordsshouldalso be kept:

a) NDT reports

b) records of visual examinationor mechanicaltesting

c) test pieces from destructivetesting

Other recordswhich are equallyimportantare:

a) PROOF of regularemployment

on a job

b) for schedulingre-tests

c) to avoid duplicationon procedureapproval

TEST CERTIFICATE

Should state clearlythat it is a welderapproval;and not a pROCEDURE

approval,and, dependingon the particularStandard,should containthe

following:

a) welder's name and identitynumber- could be his/herclock or payroll

number, or possiblya photograph

b) date of the test

c) Standard of Code in tutt,i.e. BR|TISHSTANDARD4872 pT 1 : 1sB2

d) testpiecedetailsincludingmaterialspecification

e) equipmentand consumabledetails:weldingequipment,type of filler etc

0 e):tent of approval

g) sketch of run sequence,preparationand dimensions

WELDINGTECHNOLOGY

IssueO19l

3l.z

T\VI

vgot

,ITfE WELDiNG

D{STI I'LTrE

h) otherfactors,operatingparameters

etc

i) the test results(visual,NDT,DT etc)

j) remarks

k) witnessed

by

l) testsupervisof

m) locatron

Most Standardsgivean exampleof the test certificate.

SIGNATURES

ON CERTIFICATES

MUSTBE ENDORSED

WITHCOMPANY

STAMP.

STORAGEAND RETRIEVAL

Mostcompaniespreferto storethe recordsin a conventional

filingsystem.

Wth largerccmpaniesit may be usefulto use a computerfilingsystemor

registerwhichcouldautomatically

givean indicationof re-approval.

.]'.(J

WELDINGTECHNOLOGY

Issue0191

i

TWI

wot

r.q.!r.{,!rB.r

iarorrrcr

!0d

//ir.rrt

crr. d

or.r.r:

Eho o,r.

ftisrl.:

arri,nd.

o. rri: 41

A6i.rdN. tur

. . . . . . .p A S S P ' O a r

1r r.lrutrd)

30' iia::3

.. ....

...

Nci aaou R0

.. ..:5 0EcEf.raan i05!BLCCG3 iNOUSTR]ES

iqs rnt srluro

C&i

5b

. ;FD

. . . . 1r C 2 a

5p<.-lor...

.. C::l

rit.r4.

cE'

THE \ILDING L.-ST[T'UTE

FEdLrd

trl.r.ro.Ld)

.r !a.

W E L D E R A P P R O V A LT E S T C E R T I F I C A T E

Ex ?s;

kcoobl.r*<!'d

(o.r.r.

G no!!4l

mG)

STNGLE!E AL|ft

A^IYzuTT OA FIILET WELD

v'OIl,{o?

Frf.. tu@ rtrD.3EMuon

r 5 0 3 5 ! r Ero : r2 l : ! f { 2 1

rOl/1^/O,.1^o I t/

AAOVE PPROVAL IJSING5PCIFISO F|(LER

AAGOfT

^AGC$r EACKING

T.!

pr-.

(.ml

hEr.os

Plp. o@d.

d1a-.16r

5M

(|Ml

AAO GAEATER

GAE IEF T}IAN 0.5 t

aL Posmoa.JsExcPTvEatc

NOr AEOr-/rAaO

&roo.rd

6rolfuu6

r. .d

R:OU|AO o,J oqraLE PneS

.,.Er.E

p@.6d.

,p.chcr0o^ ^lo.:

n d.

dor. sn ,gi!r.

1M6..

o. r.rr r.dy

t@uon

ftobrEdro^

ror h.

,or.ppavil

'Eionrrl

2 yia

sa.r t rkrjr.a

by .rshd

lrlilr

d r.n

b.6i/

ro lO2)

WELDINGTECHNOLOGY

Issue0191

t/ c- -fualte

Lc rTc-aNaE

8cr LID

l\41 lr{^rNrNG \4or\xsfiop

v:Jnrry or !rp@

/\0p.. 3.!srr.

L OO!'N

6ur

Proh.E:!o^ ro. .!pova/

ro. !l. ronorrE

@-e-r99-

by ..rDloFr/@1tu(x

6 donsu (,.i.r ro to:r

T\VI

THE \\'?L-DING bTSTmUTE

OUESTIONS

WELD PROCEDURE

& WELDERAPPROVAL

Q1.

State six (6) essentialvariables

- \ .i ,

i ,

I

\

.

i

meaningof 'extentof ?ppfqv-a]'

and give five (5) examples

Q2.

o4.

Why are proceduresand weldersapproved?

Q5.

Statetwo (2) reasonsfor re-approvalot

a)

A weld procedure- -rr.:,.-.: ,

b)

A welders \.\.j:

_

,'

.-... -

;-c-."-'

k..i^ +

:',

,:i

:

r.Y\'.1 \ar,:'$

t-. ..

'

, ' 4

Você também pode gostar

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- A-Health Advance - Application Form With InstructionsDocumento14 páginasA-Health Advance - Application Form With InstructionsExsan OthmanAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Remote Field Eddy CurrentDocumento4 páginasRemote Field Eddy CurrentExsan OthmanAinda não há avaliações

- A-Health Advance-I Premium RatesDocumento2 páginasA-Health Advance-I Premium RatesExsan OthmanAinda não há avaliações

- Astm C 692 PDFDocumento7 páginasAstm C 692 PDFExsan Othman100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Engineering Your Future PDFDocumento605 páginasEngineering Your Future PDFExsan OthmanAinda não há avaliações

- AWS Weld Symbol ChartDocumento1 páginaAWS Weld Symbol ChartExsan OthmanAinda não há avaliações

- Astm C 871Documento5 páginasAstm C 871Exsan Othman100% (2)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Calculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Documento6 páginasCalculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Exsan OthmanAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Chat For Organization of CodeDocumento1 páginaChat For Organization of CodeExsan OthmanAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Asmt C 795Documento4 páginasAsmt C 795Exsan OthmanAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- AWS Specifications For Filler MaterialDocumento9 páginasAWS Specifications For Filler MaterialExsan OthmanAinda não há avaliações

- Calculation Minimum Required Thickness For Bending Pipe r2Documento11 páginasCalculation Minimum Required Thickness For Bending Pipe r2Exsan OthmanAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- I) Example of Water-Tube Boiler A) Horizontal Straight Tube BoilerDocumento1 páginaI) Example of Water-Tube Boiler A) Horizontal Straight Tube BoilerExsan OthmanAinda não há avaliações

- 300 - F&D Head Design Tool Ver E4.01Documento1 página300 - F&D Head Design Tool Ver E4.01Honey TiwariAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- MaterialsDocumento181 páginasMaterialsExsan OthmanAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Pipeline DataDocumento4 páginasPipeline DataExsan OthmanAinda não há avaliações

- Hemispherical Head Design Tool: Pressure Vessel Engineering LTDDocumento1 páginaHemispherical Head Design Tool: Pressure Vessel Engineering LTDExsan OthmanAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Piping TableDocumento59 páginasPiping TableExsan Othman100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Hardness Conversion For Ferrous AlloysDocumento2 páginasHardness Conversion For Ferrous AlloysExsan OthmanAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Actvities On Boiler Maintenance: I. FurnaceDocumento5 páginasActvities On Boiler Maintenance: I. FurnaceExsan OthmanAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Boiler Feedwater ControlDocumento6 páginasBoiler Feedwater ControlExsan OthmanAinda não há avaliações

- Material ComparisonDocumento1 páginaMaterial ComparisonSetiyo Bayu IndrayanaAinda não há avaliações

- 14 Ga 316 SS HN R1y0 Cert 1938 4 North American Stainless Canada IncDocumento1 página14 Ga 316 SS HN R1y0 Cert 1938 4 North American Stainless Canada IncJennifer FrenchAinda não há avaliações

- EferencesDocumento0 páginaEferenceswearplayAinda não há avaliações

- Besi UNP PDFDocumento2 páginasBesi UNP PDFMuhammad IdrusAinda não há avaliações

- Tabla de Referencia de Materiales: Material Reference ChartDocumento2 páginasTabla de Referencia de Materiales: Material Reference Chartsateesh chandAinda não há avaliações

- Welding Map & NDE Map JTBDocumento7 páginasWelding Map & NDE Map JTBFarhan PutraAinda não há avaliações

- Record of Welder Performance Qualification: PictureDocumento2 páginasRecord of Welder Performance Qualification: PictureRhannie GarciaAinda não há avaliações

- Classification of SteelsDocumento29 páginasClassification of SteelsjanakAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Kuliah 6 - 7 - Mampu KerasDocumento36 páginasKuliah 6 - 7 - Mampu KerasEsti Nur AmaliaAinda não há avaliações

- 04 Steam TrapsDocumento8 páginas04 Steam TrapsJoshua Balaram RaoAinda não há avaliações

- Staircase Design: For Landings Span at Right Angles To The Stairs, Ie. Landings Become The Supporting MembersDocumento45 páginasStaircase Design: For Landings Span at Right Angles To The Stairs, Ie. Landings Become The Supporting MembersvivekAinda não há avaliações

- Assembly2 Caster Complete 1Documento1 páginaAssembly2 Caster Complete 1lianaAinda não há avaliações

- Thyssen Krup Stainlesssteel - BrochurenewDocumento23 páginasThyssen Krup Stainlesssteel - BrochurenewthomasAinda não há avaliações

- 20 Sandvik Welding Handbook - 30 September, 2015 - CHAPTERDocumento403 páginas20 Sandvik Welding Handbook - 30 September, 2015 - CHAPTERahmadAinda não há avaliações

- Page 0014Documento1 páginaPage 0014has sasAinda não há avaliações

- Procedure Qualification RecordDocumento10 páginasProcedure Qualification Recordlamia97Ainda não há avaliações

- Rab Tower Water Splash BanjarmasinDocumento5 páginasRab Tower Water Splash BanjarmasinTriwi JokoAinda não há avaliações

- Carbon & Alloy Steels Nomenclatura AISI SAEDocumento51 páginasCarbon & Alloy Steels Nomenclatura AISI SAEbs2002Ainda não há avaliações

- Steel and Cement Price List December 2010 GO RT No 72Documento1 páginaSteel and Cement Price List December 2010 GO RT No 72Vizag RoadsAinda não há avaliações

- SS Pipe Price List, SS 316 Pipe Price List, SS 304 Pipe Price List - PDFDocumento11 páginasSS Pipe Price List, SS 316 Pipe Price List, SS 304 Pipe Price List - PDFsaif asqalanyAinda não há avaliações

- Worldwide Material 3 EditionDocumento1 páginaWorldwide Material 3 Editionhabtsh studioAinda não há avaliações

- Swing MillDocumento6 páginasSwing MillalphatoolsAinda não há avaliações

- UTP Bestseller PDFDocumento28 páginasUTP Bestseller PDFdaha333Ainda não há avaliações

- Osm Monitoring Format - 2Documento13 páginasOsm Monitoring Format - 2Theodore Palmares ArellanoAinda não há avaliações

- Welding Discontinuity TableDocumento1 páginaWelding Discontinuity TablekapsarcAinda não há avaliações

- Denominacion Perfiles MelDocumento19 páginasDenominacion Perfiles Melrgp_ing_civil0% (1)

- Material Translation TableDocumento6 páginasMaterial Translation TableFaruk Ekinci100% (3)

- Qualified Welders ListDocumento3 páginasQualified Welders ListRaghavan VenkatramanAinda não há avaliações

- Assembly2 Caster Complete 1Documento1 páginaAssembly2 Caster Complete 1lianaAinda não há avaliações

- Density of Steel For Ultrasonic TestingDocumento3 páginasDensity of Steel For Ultrasonic TestingGaurav ChopraAinda não há avaliações

- Waste: One Woman’s Fight Against America’s Dirty SecretNo EverandWaste: One Woman’s Fight Against America’s Dirty SecretNota: 5 de 5 estrelas5/5 (1)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionNo EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionNota: 3 de 5 estrelas3/5 (1)