Escolar Documentos

Profissional Documentos

Cultura Documentos

WP Dry Transformer

Enviado por

avinashpratapTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

WP Dry Transformer

Enviado por

avinashpratapDireitos autorais:

Formatos disponíveis

PROCEDURE FOR INSTALLATION, TESTING & COMMISSIONING

OF DRY TYPE DISTRIBUTION TRANSFORMER

VOPAK TERMINAL KANDLA

VTKN CAPEX UP GRADATION PROJECT

Doc. No. : VTKN/9001/TE/004

DATE

05.12.2014

DETAILS OF REVISION

Rev No. : 00

REV

00

Issued for Review & Approval

Page 1 of 7

PROCEDURE FOR INSTALLATION, TESTING & COMMISSIONING

OF DRY TYPE DISTRIBUTION TRANSFORMER

VOPAK TERMINAL KANDLA

VTKN CAPEX UP GRADATION PROJECT

Doc. No. : VTKN/9001/TE/004

TABLE OF CONTENTS

1.0

SCOPE

2.0

PURPOSE

3.0

REFERENCE DOCUMENTS

4.0

RESPONSIBILITIES

5.0

PROCEDURE

6.0

FORMATS

7.0

DOCUMENTATION

8.0

GENERAL

9.0

SAFETY

Page 2 of 7

Rev No. : 00

PROCEDURE FOR INSTALLATION, TESTING & COMMISSIONING

OF DRY TYPE DISTRIBUTION TRANSFORMER

VOPAK TERMINAL KANDLA

VTKN CAPEX UP GRADATION PROJECT

Doc. No. : VTKN/9001/TE/004

Rev No. : 00

1.0 SCOPE

This Procedure describes guidelines for Installation & Testing of Dry Type Distribution Transformer included

in ELECTRICAL WORKS for VTKN CapEx up gradation Project, at Vopak, CRL Terminal Pvt. Ltd., Old

Kandla.

2.0 PURPOSE

The purpose of this procedure is to provide guidelines for Installation, Testing and Commissioning of Dry

Type Distribution Transformer at Vopak, CRL Terminal Pvt. Ltd. Old Kandla.

3.0 REFERENCE DOCUNENTS

i.

Approved SOR.

ii.

Latest AFC Drawing.

iii. Approved Vendor Drawing.

iv. Tender Documents.

v.

OEM Erection Manuals

vi. TCE Specifications

If there is any contradiction between contract specifications and this procedure, the Tender Documents

shall prevail.

4.0 RESPOSIBILITIES

The responsibilities of implementation of this procedure lie with Project Manager, AFCONS A/c VTKN

CAPEX UP GRADATION PROJECT

5.0 PROCEDURE

5.1

MATERIALS

After receipt of material at site, IMIR shall be made & material shall be inspected as per approved ITP.

5.2

PRE INSTALLATION CHECKS

i.

Ensure the received material is as per approved vendor drawings / documents.

ii.

Check foundation its level, centrelines, anchor bolts / insert plates. In case of rail mounted type checks

centre line & level of rails. Check Transformer to be placed on foundation as per approved AFC GA drawing

for Dry Type Distribution Transformer.

iii. Check the Serial no. and Rating of Transformer as per specification / AFC drawing.

iv. Inspect for availability of all accessories.

v.

Inspect any physical damages, missing or short supplied items for insurance claim.

vi. Check completion of Civil works, get the clearance from Civil and cleanliness of area.

Page 3 of 7

PROCEDURE FOR INSTALLATION, TESTING & COMMISSIONING

OF DRY TYPE DISTRIBUTION TRANSFORMER

VOPAK TERMINAL KANDLA

VTKN CAPEX UP GRADATION PROJECT

Doc. No. : VTKN/9001/TE/004

Rev No. : 00

vii. Availability of Tested, Calibrated & Standard Tools & Tackles, skilled manpower for Shifting & Lifting of

equipment.

viii. Check the size of terminal box suitable for Incoming Cables.

5.3

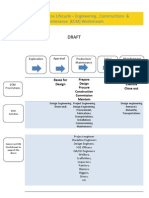

INSTALLATION METHODOLOGY

5.3.1 INSTALLATION CHECKS OF DRY TYPE DISTRIBUTION TRANSFORMER.

i.

Check sequence of installation as per installation flow chart / Erection Manual.

ii.

Check bushing cracks, chips or presence of paint or dirt. Bushing should be cleaned as per vendors

instruction.

iii. Phasing & Orientation of Transformer to be checked as per AFC drawings.

iv. Install of Cable boxes / Bus-duct as per approved drawings.

v.

Install foundation bolts / Stoppers

vi. Install / Grout the anti-earthquake plate as mentioned in the specifications & approved drawings.

vii. Check healthiness of all accessories of transformer.

viii. Install all accessories of transformers as per approved GA / Installation manual.

ix. Install marshalling box as per approved GA and fix the all control cables routes to Marshalling box.

x.

Ensure cable connection at the cable & box, their colour coding & tightness (if required use of spring and flat

washers on the appropriate faces to be confirmed) and cleanliness of lapping surfaces. For multiple cable

connection, check for correctness of phasing.

xi. Check the connection of Space heaters & Thermostat in Marshalling box & Control Cabinet.

xii. Dressing of all power and control cables to be checked.

xiii. Ensure the construction of earth pits and earth grid for Transformer Body & Neutral is as per AFC drawing,

xiv. Ensure the earthing connection of Transformer body, Marshalling panel, HV Cable Box. LV terminal box,

Transformer neutral is as per AFC drawing.

xv. The equipment earthling connections tightness and earth resistance value to be checked.

xvi. If required or specified, Dry-out of Transformer to be done.

xvii. Ensure the tightness of cables at HV & LV sides and control cables in Marshalling panels.

xviii. Installation completion certificate and hand over for Testing & Commissioning.

5.3.2

i.

TESTING OF DRY TYPE DISTRIBUTION TRANSFORMER

Measure winding resistance at each tap. Test Vector group, polarity, magnetizing current, magnetic

balancing.

ii.

Test Insulation Resistance & PI.

Page 4 of 7

PROCEDURE FOR INSTALLATION, TESTING & COMMISSIONING

OF DRY TYPE DISTRIBUTION TRANSFORMER

VOPAK TERMINAL KANDLA

VTKN CAPEX UP GRADATION PROJECT

Doc. No. : VTKN/9001/TE/004

Rev No. : 00

iii. Test Transformation Ratio at each tap points.

iv. Check WTI, Thermostat settings.

v.

Simulation test of thermostats, WTI for alarm and trip signals.

vi. Check tightness of wire connection at NCT terminals and marshalling terminals.

vii. Simulation test for all external interface connection alarms, annunciation and trip circuits checking.

viii. Check Tap Changer Control Operation without Energizing Transformer.

ix. Check the CT Ratio & Polarity. Ensure all earthing connections.

x.

Check the knee point voltage of CL PS C.T. (if any)

xi. Check the Door switch operation.

xii. Ensure the tightness of Transformer body & Neutral earthing connections.

xiii. Adopt relay settings as per Relay Setting diagram & Test Transformer Relay Protection as per approved

scheme.

5.3.3

MEGGAR TEST

The Transformer & its cable shall be check for insulation resistance by using suitable rating of Meggar.

Suitable rating of Meggar as per Equipment Voltage

5.3.4

Equipment

Voltage (AC)

Minimum Test Voltage (DC)

230-500V

500V

6600V

5000V

POST INSTALLATION AND TESTING CHECKS

i.

Transformer & Relay testing results to be reviewed prior to commissioning.

ii.

Check & attend all points mentioned in the commissioning checklist.

iii. Check the IR / PI and keep record for energisation.

iv. Check mechanical operation of Tap-changer including indicator.

v.

HT, LT & Bus duct connections to be checked for tightness & phasing.

vi. Tightness of winding lead connection to Bushing terminals.

vii. Connection & Tightness of all Jumpers / Bus-bar at HV & LV side.

Page 5 of 7

PROCEDURE FOR INSTALLATION, TESTING & COMMISSIONING

OF DRY TYPE DISTRIBUTION TRANSFORMER

VOPAK TERMINAL KANDLA

VTKN CAPEX UP GRADATION PROJECT

Doc. No. : VTKN/9001/TE/004

Rev No. : 00

viii. Water tightness of all covers of Transformer, Bus ducts, Marshalling Panel etc.

ix. All control wires tightness to be checked.

x.

Relay settings to be checked as per approved settings.

xi. Preparation of Marked up drawings.

xii. Installation completion certificate and handing over to commissioning.

5.3.5

POST ENERGISATION CHECKS

i.

The inrush magnetizing current and No Load Current

ii.

Alarm, if any relay flag operated

iii. Voltage and current of all three phases.

iv. Note the Winding Temperature

v.

Transformer humming sounds and vibrations.

vi. Cable box for heating and any abnormal sounds.

GENERAL CHECKS

i.

Fire Alarm, Sand bucket & Fire Extinguisher shall be provided as specified near Transformer.

ii.

Sand filling shall be done in the cable trench as per the drawing. Cable trench shall be covered after the

cable laying is carried out in accordance with the specifications.

iii. Cable trays shall be covered, where ever required, as per the project specifications.

iv. Unused holes should plugged with suitable plug.

v.

After testing the J/B shall be properly closed to avoid any unauthorized changes.

vi. Proper sealing shall be provided at the cable entry into the control room, cable room.

5.3.6

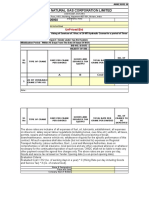

INSPECTION AND TEST PLAN

Inspection and test plan for Installation / Erection & Testing of Dry type Distribution Transformer for

Electrical Work

6.0 FORMATS

i.

Installation / Erection & Testing of Transformer Testing & Meggar readings test Record.

ii. Installation / Erection & Testing of Transformer Check list.

Page 6 of 7

PROCEDURE FOR INSTALLATION, TESTING & COMMISSIONING

OF DRY TYPE DISTRIBUTION TRANSFORMER

VOPAK TERMINAL KANDLA

VTKN CAPEX UP GRADATION PROJECT

Doc. No. : VTKN/9001/TE/004

Rev No. : 00

7.0 DOCUMENTATION

i.

Documents shall be prepared in approved formats at all stages of Installation / Inspection as per approved

ITP and maintained, duly signed by AFCONS / TCE.

ii.

As Built Drawings.

iii. OEM Drawings / Manuals

iv. Test Reports

8.0 GENERAL

i.

All inspection shall be carried out as per approved ITP.

ii.

House keeping shall be carried out everyday after completion of work.

iii. Scaffolding shall be erected wherever required.

9.0 SAFETY

i.

All safety precautions shall be taken as per SHE requirements of the project.

ii.

Related JSA shall be prepared and to be approved from PMC before starting any activity.

iii. Tool box meeting shall be conducted before starting any job.

iv. Full care and precaution shall be taken by the field management for the safety and sanitation of workmen in

the field to prevent accidents during the execution of works

v.

During execution, the electrical equipment shall be placed so as to give no obstruction for traffic and proper

measures shall be taken to prevent damage due to falling bodies etc. and decrease in insulation

performance due to water penetration etc.

Page 7 of 7

Você também pode gostar

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (120)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Engineering - PresentationDocumento23 páginasEngineering - PresentationIdp Vadodara100% (1)

- Hydraulic IndustrialDocumento56 páginasHydraulic IndustrialKuni Faizah100% (1)

- Lecture 4 Pumps Pumping SystemsDocumento42 páginasLecture 4 Pumps Pumping SystemsKeith Tanaka MagakaAinda não há avaliações

- Presentation On BOPDocumento27 páginasPresentation On BOPRatnakar Patil100% (2)

- Project Report On King Chilli Processing UnitDocumento39 páginasProject Report On King Chilli Processing UnitPrakash Pokhrel0% (1)

- PT. Anugerah Cahaya Cemerlang Lestari Directur (Zahren Mohamed) Jl. Minangkabau Ruko 6E, Jakarta Selatan 12970Documento1 páginaPT. Anugerah Cahaya Cemerlang Lestari Directur (Zahren Mohamed) Jl. Minangkabau Ruko 6E, Jakarta Selatan 12970Zamri MahfudzAinda não há avaliações

- 1st Hydrocarbon Processing 09 2010Documento165 páginas1st Hydrocarbon Processing 09 2010Iulian BarascuAinda não há avaliações

- Previews 2195353 PreDocumento9 páginasPreviews 2195353 PrelexloxAinda não há avaliações

- NJ Exemption CertificatesDocumento19 páginasNJ Exemption CertificatesKeith LeeAinda não há avaliações

- University Question Unit WiseDocumento8 páginasUniversity Question Unit WiseAbdul AsifAinda não há avaliações

- Oakridge Reactive PowerDocumento95 páginasOakridge Reactive Powerrazvan_nAinda não há avaliações

- ABB Surge Arrester POLIM-I - Data Sheet 1HC0075858 E01 ABDocumento5 páginasABB Surge Arrester POLIM-I - Data Sheet 1HC0075858 E01 ABRadu Sergiu CimpanAinda não há avaliações

- 3G3MX2 A4022 OmronDocumento13 páginas3G3MX2 A4022 Omronsareluis2727Ainda não há avaliações

- Problems and SolutionsDocumento14 páginasProblems and SolutionsAsif Iqbal DawarAinda não há avaliações

- Notes PPC Case StudyDocumento160 páginasNotes PPC Case StudyMike LassaAinda não há avaliações

- Industry ProfileDocumento5 páginasIndustry ProfileProsenjit RoyAinda não há avaliações

- PremiLine Specification1Documento2 páginasPremiLine Specification1Naty FleitesAinda não há avaliações

- Unit Conversion: LengthDocumento35 páginasUnit Conversion: LengthBhupesh MulikAinda não há avaliações

- Plumbing Arithmetic RefresherDocumento80 páginasPlumbing Arithmetic RefresherGigi AguasAinda não há avaliações

- Smart Grid and Energy Management PDFDocumento19 páginasSmart Grid and Energy Management PDFEng_Mennat_AllahAinda não há avaliações

- PETROM Asset IntegrityDocumento18 páginasPETROM Asset Integrityghostforever0Ainda não há avaliações

- SIEMENS 33 KV GIS ManualDocumento68 páginasSIEMENS 33 KV GIS ManualAnonymous kielG2Ainda não há avaliações

- Annexure V Bidder Response SheetDocumento2 páginasAnnexure V Bidder Response SheetAshishAinda não há avaliações

- Kedar - MMUP Engineering License Exam DTD 08th December 2014Documento4 páginasKedar - MMUP Engineering License Exam DTD 08th December 2014Abdul Rahman A RAinda não há avaliações

- Poster 'I Want To Be ' - Rev0Documento4 páginasPoster 'I Want To Be ' - Rev0hafizahmad84Ainda não há avaliações

- UNIDO Methodologies, Tools And: Networks For Partnership PromotionDocumento19 páginasUNIDO Methodologies, Tools And: Networks For Partnership PromotionMauro MLRAinda não há avaliações

- Rapport Annuel Cosumar 2019 Web en - ReduceDocumento58 páginasRapport Annuel Cosumar 2019 Web en - ReduceVyrax FalconAinda não há avaliações

- Invitation Letter Petrolida 2021Documento91 páginasInvitation Letter Petrolida 2021Stephen ZhengAinda não há avaliações

- Dominic Cole's IELTS Blog: Index of Sample IELTS Essays Houses and ApartmentsDocumento7 páginasDominic Cole's IELTS Blog: Index of Sample IELTS Essays Houses and Apartmentssheneen_abdullaAinda não há avaliações

- Catalogue of JSV-FF100 PDFDocumento80 páginasCatalogue of JSV-FF100 PDFRonak Patel0% (1)