Escolar Documentos

Profissional Documentos

Cultura Documentos

MSS SP-97 2012 Integrally Reinforced Forged Branch Outlet Fittings - Socket Welding, Threaded and Buttwelding Ends

Enviado por

JuliusMaximus12Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

MSS SP-97 2012 Integrally Reinforced Forged Branch Outlet Fittings - Socket Welding, Threaded and Buttwelding Ends

Enviado por

JuliusMaximus12Direitos autorais:

Formatos disponíveis

MSS SP-97 -2012

Integrally Reinforced Forged

Branch Outlet Fittings Socket Welding, Threaded,

and Buttwelding Ends

08 OCT 2012

I

(

SISTEMA DE GESnOH

SGC I SGA I SST

Nombnr y Fi",,~

"S

COPIA CONTROi..ADA

Standard Practice

Developed and Approved by the

Manufacturers Standardization Society of the

Valve and FIttings Industry, Inc.

127 Park Street, NE

Vienna, Virginia 22180-4602

Phone: (703) 281-6613

Fax: (703)281-6671

E-mail: standards@mss-hq.org

www.mss-hq.org

Sc*I to;l*OAIAATlON HAHDLIG SfAvas, Ol aatl'

2OIVWlII8:IU . QMT

M SS

ST ANDARD P R ACTICE

SP-9 7 I

This MSS Standard Practice was developed under the consensus of MSS Technical Committees 105 and the

MSS Coordinating Committee. The content of this Standard Practice is the resulting efforts of competent and

experienced volunteers to provide an effective, clear, and non-exclusive standard that will benefit the industry

as a whole. This MSS Standard Practice describes minimal requirements and is intended as a basis for common

practice by the manufacturer, the user, and the general public. The existence of an MSS Standard Practice does

not in itself preclude the manufacture, sale, or use of products not conforming to the Standard Practice.

Mandatory conformance to this Standard Practice is established only by reference in other documents such as a

code, specification, sales contract, or public law, as applicable. MSS has no power, nor does it undertake, to

enforce or certify compliance with this document. Any certification or other statement of compliance with the

requirements of this Standard Practice shaH not be attributable to MSS and is solely the responsibility of the

certifier or maker of the statement.

"Unless otherwise specifically noted in this MSS Standard Practice, other standards documents

referred to herein are identified by the date of issue that was applicable to this Standard Practice

at the date of issue of this Standard Practice (see Annex C). This Standard Practice shall remain

silent on the applicability of those other standards of prior or sllbsequent dates of issue even

though applicable provisions may not have changed. ..

By publication of this Standard Practice, no position is taken with respect to the validity of any potential

claim(s) or of any patent rights in connection therewith. MSS shaH not be held responsible for identifying any

patent rights. Users are expressly advised that determination of patent rights and the risk of infringement of

such rights are entirely their responsibility.

In this Standard Practice, all text, notes, annexes, tables, figures, and references are construed to be essential to

the understanding of the message of the standard, and are considered normative unless indicated as

"supplemental". AH appendices, if included, that appear in this document are construed as "supplemental".

Note that supplemental information does not include mandatory requirements.

The SI (metric) units and U.S. customary units in this Standard Practice are regarded separately as the standard;

each should be used independently of the other. Combining or converting values between the two systems may

result in nonconformance with this Standard Practice.

This Standard Practice has been substantiaHy revised from tbe previous edition. It is

suggested tbat if tbe user is interested in knowing what changes have been made, that

direct page by page comparison should be made of tbis document.

Non-toleranced dimensions in the Standard Practice are nominal, and, unless otherwise specified, shaH be

considered "for reference only".

Excerpts of this Standard Practice may be qlloted with permission. Credit lines sholiid read 'Extracted

from MSS SP-97-20J 2 with permission of the publisher, Manufacturers Standardization Society of the

Valve and Fittings Industry'. Reproduction and/or electronic transmission or dissemination is prohibited

IInder copyright convention unless written permission is granted by the Manufacturers Standardization

Society of the Valve and Fittings Industry Inc. All rights reserved.

OriginaHy Published: June 1987

Current Edition Approved: September 20 II

Current Edition Published: May 2012

MSS is a registered trademark of the Manufacturers Standardization Society of the Valve and Fittings Industry, Inc.

Copyright @, 2012 by

Manufacturers Standardization Society

of the

Valve and Fittings Industry, Inc.

Printed in U.S.A.

SoIc:Ito:1HFOAMATION HANDUNQ Sf:AVlCES. Ot82tllilti

2Ot2N2tl t8; t5:11 QMI'

ST ANDARD PRACTICE

MSS

SP-97

TABLE OF CONTENTS

PAGE

SECTION

2

3

4

5

6

7

SCOPE ..................................................................................................................................................... 1

SERVICE DESIGNATION ..................................................................................................................... 1

SIZE ......................................................................................................................................................... 2

MARKING .............................................................................................................................................. 2

MATERIAL ............................................................................................................................................. 2

DESIGN AND DIMENSION .................................................................................................................. 3

TESTS ..................................................................................................................................................... 3

TABLE

2

3

4

5

6

7

A2

A3

A4

A5

A6

A7

Correlation of Fittings Class with Schedule Number or Wall

Designation of Run Pipe for Calculation of Ratings ............................................................................... 1

90 Branch Outlets - Buttwelding. U.S. Customary Units .................................................................... ..4

90 Branch Outlets - Threaded. U.S. Customary Units .......................................................................... 5

90 Branch Outlets - Socket Welding. U.S. Customary Units ................................................................ 6

45 Branch Outlets - Buttwelding. U.S. Customary Units ...................................................................... 7

45 Branch Outlets - Threaded, U.S. Customary Units .......................................................................... 8

45 Branch Outlets - Socket Welding. U.S. Customary Units ................................................................ 9

90 Branch Outlets - Buttwelding. SI (Metric) Units ........................................................................... 10

90 Branch Outlets- Threaded, SI (Metric) Units ............................................, ................................... 11

90 Branch Outlets - Socket Welding. SI (Metric) Units ...................................................................... 12

45 Branch Outlets - Buttwelding. SI (Metric) Units ........................................................................... \3

45 Branch Outlets - Threaded, SI (Metric) Units ................................................................................ 14

45 Branch Outlets- Socket Welding. SI (Metric) Units ...................................................................... 15

FIGURE

Fitting Consolidation Gap Allowance ..................................................................................................... 2

ANNEX

A SI (Metric) Tables A2 through A7 ......................................................................................................... 10

B Design Proof Test .................................................................................................................................. 16

C Referenced Standards and Applicable Dates ......................................................................................... 17

ii

. . ~NFOMIATION~ RfMCU.Ol1i211111

2\)1ZN2811:1S:S1GMT

STANDA RD PRACTI CE

M SS

SP- 97

INTEGRALLY REINFORCED FORGED BRANCH OUTLET FITTINGS SOCKET WELDING, THREADED, AND BUTTWELDING ENDS

\. SCOPE

2. SERVICE DESIGNATION

J.1

This Standard Practice covers essential

dimensions, finish, tolerances, testing,

marking, material, and minimum strength

requirements for 90 and 45 degree integrally

reinforced forged branch outlet fittings of

buttwelding, socket welding, and threaded

types.

2.1 These fittings are designated by their

size, type, and class, as shown in Table I.

2.2 Design temperature and other service

conditions shall be limited as provided by the

applicable piping code or regulation for the

material of construction of the fitting. Within

these limits, the maximum allowable pressure

of a fitting shall be that computed for straight

seamless run pipe of equivalent material (as

shown by comparison of composition and

mechanical properties in the respective

material specifications). The wall thickness

used in such computation shall be that

tabulated in ASME 836.1 OM for the size and

applicable schedule of pipe reduced by

applicable manufacturing tolerances and other

allowances (e.g., threaded allowances).

1.2 Fittings manufactured to this Standard

Practice are designed to make a fully

reinforced branch connection in accordance

with applicable piping code requirements,

when attached, at an opening in a run pipe by

means of a full penetration weld.

1.3 Fittings may be made to special

dimensions, size, shape, tolerances, or of other

wrought material by agreement between the

manufacturer and the purchaser.

1.4 Standard Units Tables 2 through 7

show the fitting's dimensional requirements in

customary units or inches (decimal). Tables

A2 through A7 show the fitting' s dimensional

requirements in SI (metric) units (e.g.,

millimeters). The values stated in either

customary or SI (metric) units are to be

regarded separately as the Standard. Within

the body text, the SI (metric) units are shown

in parenthesis. Combining values from the two

systems may result in non-conformance with

the Standard Practice. The values stated in

each option are not exact equivalents;

therefore, each measurement system must be

used independently of the other.

2.3 Any corrosion allowance and any

variation in allowable stress due to

temperature or other design factors shall be

applied to the pipe and fitting alike. The pipe

wall thickness corresponding to each Class of

fitting, for rating purposes only, is shown in

Table I.

TABLE 1

Correlation of Fittings Class with Schedule Number or

Wall

of Run

for Calculation of Ratings

NPS 1/8-24

Extra Strong

NPS 112-6

Schedule 160

3000

NPS 1/8-4

Extra Strong

NPS 112-2

160

Note: (a) The use of run or branch pipe wall thickness either thinner or thicker than shown in Table 1

constitutes a deviation from this Standard Pmctice and is provided for in Section 1.3.

Extra Strong

Schedule 160

Buttwelding

Buttwelding

Threaded & Socket Welding

',' -,

.-..... ' ..,'-'. ,. ...

SOld IIIdIHfON,IAnoH HANCIUN3 SlRVlCIS, 1)1""

aol ~ 18:1S:M 0tI1'

ST ANDAR D P R AC TICE

M SS

c) C/flSS The Fitting Class "STD"

(Standard), "XS" (Extra Strong), "SCH 160"

(Schedule

160), "3000" or "6000".

Alternatively, the designation 3M or 6M, as

applicable, may be used where "M" stands

for 1,000.

3. SIZE

3.1 The 90 and 45 degree branch outlet sizes

considered in this Standard Practice are shown

in Table I. Size on size fittings shall be

limited to outlet sizes NPS 112 (ON 15) and

larger.

d) Size The nominal size of the pipe that

the fitting's marking identifiesRun (or consolidated range)

NPS (ON) x Outlet NPS (ON).

3.2 The run (header) pipe size is limited

only by the pipe size range listed for each type

fitting class.

3.3 The manufacturer has the option to

consolidate run sizes for a given branch size

for economic reasons, provided the designated

consolidation gap distance between the run

pipe radius and the fitting inlet radius does not

exceed 1116" (1.6 mm). See Figure I.

4.

e) SP 97 This marking indicates compliance

wah MSS SP97.

4.3 Where size and shape of fittings do not

permit all of the above markings, they may be

omitted in the reverse order given above.

MARKING

5. MATERIAL

4.1 Each fitting shall be permanently

marked with the required identification by

raised lettering, and/or by stamping. electroetching or vibro tool.

5.1 The material for fittings, under this Standard

Practice, shall consist of forging. bar, and

seamless .tubular products. 1be materials shall

conform to the requirements of the WP Grade

seamless construction materials in ASTM Fitting

Specifications A234/A234M, A403/A403M,

A420/A420M, or A815IA815M; or the ASTM

Specifications

AI051AI05M,

Forging

AI 821AI 82M, or A3501A350M.

4.2 The marking shall include (but it is not

limited to) the following:

a) Mflnu!flcturer's nflme or trfldemflrk.

b) Mflterifl/ Identijicfltion The material

shall be identified in accordance with the

marking requirements of the applicable

ASTM Specifications, including Heat

Identification.

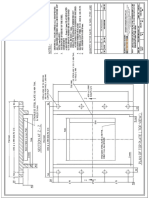

C_o::==I=__i2"'F.~

5.2 All other forging, bar,' and seamless

tubular products listed in ASME B 16.34 Table

I; including the applicable "notes" of ASME

B 16.34 Table I, Table 2, or Appendix VII

tables, may be used.

1/18 Max.

(1.6 mm)

CONTOUR

RADIUS

RUN RADIUS

CONTOUR

RADIUS

_

....

RUN RADIUS

SKIRT GAP

CROTCH GAP

SP-97

FIGURE 1

Fitting Consolidation Gap Allowance

(Illustrative Only)

Applicable to 90 and 45 Branches

2

.. '- ,', .. -.....

'

.. '-"

~e.,-Hl.....,~wIh.ess

8otI1O.1J#CIRUATION HAHOlHJ SSMCCS. Gllalt,

No~ot'~~ wIfIOUI ""lIIOrnlHS

2012iW2t t8:t&:18 OMT

---

ST ANDARD PRACTICE

MSS

SP-9 7

6.4 Socket Weld Socket Weld fittings shall

meet the minimum socket depth. minimum

socket wall thickness and socket diameter of

ASME B 16.11 for the appropriate class.

6. DESIGN AND DIMENSION

6.1 A run pipe having a branch connection is

weakened by the opening made in it The

branch connection must reinforce the opening

and restore the original strength of the run

pipe. It is the intent of this Standard Practice

that these integrally reinforced branch outlet

fittings and the deposited weld metal used to

attach the fittings to run pipes contain all the

reinforcement required by the applicable

pressure vessel or piping codes without the

addition of saddles or pads.

6.5 The contour weld bevel angle on the

longitudinal section of the fittings shall be a

minimum of 35 degrees. The weld bevel angle

on the transverse section of the fitting is based

on the manufacturer's specification.

7. TESTS

7.1 Hydrostatic testing of wrought fittings is

not required by this Standard Practice. All

fittings shall be capable of withstanding.

without

leakage

or

impairment

of

serviceability. a pressure equal to that

prescribed in the applicable code or

regulation for seamless pipe of equivalent

material and schedule listed in Table I.

6.1.1 The adequacy of the design of branch

connection fittings may be established by

mathematical analyses contained in pressure

vessel or piping codes. or. at the

manufacturer's option. by proof testing in

accordance with Section 7 and Annex B.

Records of design or proof tests shall be

available at the manufacturer's facility for

inspection by the purchaser.

7.2 Proof testing is not required, but when

performed to meet the requirements of Section

6.1.1. the testing shall be conducted in

accordance with Annex B.

6.1.2 The pressure vessel or piping codes

referred to in Section 6.1.1 permit a variety of

attachment welds for these fittings. Typical

branch attachments are shown in ASME

B31.1 and B31.3.

6.1.3 Fittings shall be contoured to provide

a good fit at the opening in the run pipe. The

run attachment weld bevel angle design will

vary with the size and type of fitting and with

the manufacturer. The size of the run opening

is dependent on the manufacturer's

specification.

08 OCT 2012

SISTEMA DE GESTION

SGC I SGA I SST

Nomtl,.. y Anna

6.2 Buttwelding Buttwelding end finishes

shall comply with the standard welding bevel

and root face of ASME BI6.25.

COPIA CONTROLADA

6.3 Threads Threads in threaded fittings

ASME

B 1.20.1

shall

comply with

requirements for NPT.

6.3.1 The minimum wall thickness at the

root of the thread at the hand tight plane shall

be equal to or greater than the nominal wall

of the pipe schedule for the appropriate

fitting class. as shown in Table I.

3

:opyrigMMSS

PfOicIId by IHS unci ... _ _ 'IIIIIh MSS

SOld to:lNFOAMATlON HANOUHG SERVICES, 01828810

.., I'Iproductlon ot nltWOrkIng pemllMd wtIhout IlcenN kom IHS

2012N2'le:I5;580MT

ST ANDARD PRACTICE

MSS

SP-97 I

TABLE 2

90 Branch Outlets - Buttweldlng, U.S. Customary Units

I

Dimensions are in inches.

Outlet

(NPS)

StaDdard

ReduclDg

1/8

0.62

1/4

0.62

3/8

0.75

0.75

112

0.88

3/4

1.06

1

1.25

14

1~

1.31

2

1.50

1.62

2~

3

1.75

1.88

3A

4

2.00

2.25

5

2.38

6

2.75

8

10

3.06

12

3.38

14

3.50

16

3.69

18

3.81

20

4.00

24

4.56

.03 In.

Tolerances. I:t, - J~.

1 - 4 .06 in.

5 -12 .12 in.

14 -24 .19 in.

Full

0.75

0.88

1.06

1.25

1.31

1.50

1.62

1.75

2.00

2.00

2.25

2.38

2.75

3.06

3.38

3.50

3.69

4.06

4.62

5.38

A

(Face of FlItID& to Crotch)

Extra StroDg

Full

ReduciDg

0.62

0.62

0.75

0.75

0.75

0.88

0.88

1.06

1.06

1.25

1.25

1.31

1.31

1.50

1.50

1.62

1.62

1.75

1.75

1.88

2.00

2.00

2.00

2.25

2.25

3.06

3.06

3.88

3.88

3.69

3.50

4.06

3.94

3.94

4.12

4.18

4.44

4.38

4.69

4.69

5.00

5.50

5.50

Schedule 160

Full

ReduciD&

"~

.. '.

1.12

1.25

1.50

1.75

2.00

2.18

2.44

2.88

3.31

3.69

4.12

3.31

3.69

4.12

','

.~

..,"--

SoId ~TlONHAHDlNlSlAYlCU. Ol""

20121W2t 1Ik":56OMT

1.12

1.25

1.50

1.75

2.00

2.18

2.44

2.88

'

--

SP-97

ST ANDARD PRACTI CE

MSS

TABLE 3

90 Branch Outlets - Threaded, U.S. Customary Units

NPT THREADS PER B1.20.1

I

AN om.

'"'-

-/

Dimensions are in inches.

Outlet

(NPS)

118

114

3/8

112

3/4

1

1:1,

1 :-'2

2

2:-',

3

4

Tolerances:

A Nom.

(Face of FlttiDg to Crotch)

Threaded

Class 6000

Class 3000

0.75

0.75

0.81

1.25

1.00

1.44

1.06

1.56

1.31

1.62

1.31

1.69

1.38

2.06

1.50

1.81

2.00

2.25

I;, - ';.

.03 in.

1- 4 .06in.

5

Capyrtght MS8

PIOYIdecI by IHS under 1IcI_ willi MIS

No replOducIIon or nIbwofkIng PIIrmlllMi 'IfIIIhout lice,... from IHS

SoIdIO;INFORMATlON HANOUNG SERVICES, OI_It

201211128 tI!:15:580MT

ST ANDARD PRACTICE

MSS

SP-97

TABLE 4

90 Branch Outlets - Socket Welding, U.S. Customary Units

I

I

1,---I

Oude!

(NPS)

"'--

Dimensions are in inches

CMaL

BMln.()

118

0.38

114

0.38

0.38

318

112

0.38

314

0.50

1

0.50

1

0.50

1'1,

0.50

2

0.62

2'1,

0.62

3

0.62

0.75

4

Note: (a) "B" Minimum Socket Depth per ASME BI6.1\

v.

Class 3000

o_6000

0.41

0.41

0.50

0.63

0.63

0.88

0.88

0.94

0.94

1.00

1.19

1.19

0.94

1.00

1.13

1.19

1.25

1.44

_

....

P-'OIOby IHS UI'dIII . . . . "'" lollS

HI) ~ or

/WhIOIWno pemWIIO ..,.,.,. bNe IJom IHS

6otd ~T1ON HAHDUl RJMCES. 0'.."

201ZWl81 8:1S:5I OMT

STANDARD PRACTICE

MSS

SP-97

TABLES

45 Branch Outlets - Buttwelding, U.S. Customary Units

i are

A

(TOpOl

Outlet

(NPS)

to Run Pipe)

lilt.nA -r<\ 1 Extra

A Min.

A Max.

I

I.

I.

.500

2.750

3.500

1/4

~.

1'2

~.87S

....... .- .

, ','

'.

,,--- ...

in inches.

STANDARD PRACTICE

MSS

SP-97

TABLE 6

45 Branch Outlets - Threaded, U.S. Customary Units

I are

(ToP of:

Outlet

(NPS)

Class 1000 A

1----:-:7-+----'A7.MiJ1.

A MaL

1/4

1500

I~

.500

..681

in inches.

A

: to RUD PI~

Class ~ 000 A

A MiD.

A.M!'L

1.531

1.87~S_-I

.&ll.

r-~~--r---TS~OO---+---7~---+---7~--~--~~~~

..812

.125

2.106

2. iOO

3.100

.50(

:.406

1.001

1.001

3.31

:.~

,3

3 .~

14

o

8

SOIdto:JNFOl'NAT1OH HANOUHO RVICES. 01_'.

2012/Wa 11:15:51

our

4.12!

ST ANDARD PRACTI CE

M SS

SP-97

TABLE 7

45 Branch Outlets - Socket Weldin&. U.S. Customary Units

are in inches.

A

Outlet

(NPS)

1/4

3/8

112

3/4

I

(Top or I'ImDI to RUD Pipe)

BMin.(a)

~.

1.3

1.3

~3000

ClusliOOO

AI

.51

.750

:.000

00

.8

.1

t.41

IV.

:.s()

0.50

0.62

.00

Note: (8) "B" Minimum Socket Depth per ASME B16.11

IV,

2

' .~.'

",',""-' - 't,'

~~

I ;3

I

3.0

3 .~

9

SOIcIIO:WCRloIATIOH HANOl.HQ SOM eD ,

2012NZ8 Ia:l5:5e our

01_1,

AMu.

..8

.8

.1:

2.

2.

3,

3.375

4.125

SP-97

STANDARD PRACTICE

MSS

ANNEXA

SI (Metric) Tables A2 through A7

TABLEA2

90 Branch Outlets - Buttwelding, SI (Metric) Units

I

I

A

Dimensions are in millimeters.

A

Oudet

(Fa~e

Oudet

(NPS)

of Flttioa to Crot~bl

Extra StroOI

Red.clog

Fun

15.7

15.7

19.1

19.1

19.1

22.4

22.4

26.9

26.9

31.8

31.8

33.3

33.3

38.1

38.1

41.1

41.1

44.4

44.4

47.8

50.8

50.8

50.8

57.2

57.2

77.7

77.7

98.6

98.6

93.7

88.9

103.1

100.1

100.1

104.6

112.8

106.2

111.2

119.1

127.0

119.1

139.7

139.7

Staodard

(DN)

Reducblg

F.n

lIB

15.7

6

1/4

15.7

8

10

3/8

19.1

112

19.1

IS

19.1

20

3/4

22.4

22.4

25

26.9

26.9

I

31.8

31.8

32

IY.

40

33.3

33.3

I Y2

50

2

38.1

38.1

41.1

41.1

65

2'h

44.4

80

3

44.4

90

3Y.

47.8

50.8

50.8

100

4

50.8

125

5

57.2

57.2

ISO

6

60.4

60.4

200

8

69.8

69.8

250

10

77.7

77.7

12

85.9

300

85.9

350

14

88.9

88.9

400

16

93.7

93.7

450

18

96.8

103.1

20

500

101.6

117.3

600

24

115.8

136.6

Tolerances: 6 - 20 0.8 mm

25-100 1.6mm

125-300 3.2mm

350 - 600 4.8 mm

&bedule 160

Full

Redacma

10

Sold ICIdNfOfIIMAT1OH twClUNQ IIJMCH.

2OtZ/ll'llll:tl:5e OMT

Ot_,.

28.4

28.4

31.8

38.1

44.4

50.8

55.4

62.0

73.2

31.8

38.1

44.4

50.8

55.4

62.0

73.2

84.1

93.7

104.6

84.1

93.7

104.6

--

MSS

ST ANDARD PRACTICE

SP-97

ANNEX A (Continued)

SI (Metric) Tables A2 through A7

TABLEA3

90" Branch Outlets - Threaded, SI (Metric) Units

NPT THREADS PER 81.20.1

I

ANom.

"'--

-...r

Dimensions are in millimeters

Outlet

(DN)

6

S

10

15

20

25

32

40

50

65

SO

100

Tolerances: 6 - 20 O.S mm

25-100 1.6mm

" ,'.-,C ,~yrtglll MIS

"'"-dldby tIS undIr llc1nMwIIh was

No I'IProduCIlon or nIlwoIkIng PlrmIbd wIII'IOIIt IIcIM IIOtI'IIHS

A Nom.

(Face of FittiDI! to Crotch)

Threaded

Class 3000

Class 6000

19.0

19.0

20.6

25.4

31.S

26.9

36.6

39.6

33.3

33.3

4 1.1

35.0

42.3

52.3

3S.1

46.0

50.S

57.2

Outlet

(NPS)

",

........-" .,.,

liS

114

3/S

112

3/4

I

I Y.

I Y,

2

2Y,

3

4

',.,

11

SaId kl:INFORMATlON HANDLING SERVICES, 0182801a

2012/8128115:15:5150MT

MSS

SP-97

ST ANDARD PRACTICE

ANNEX A (Continued)

SI (Metric) Tables A2 througb A7

TABLEA4

90 Brancb Outlets - Socket Welding, SI (Metric) Units

L,----

-.7

"'-

O.det

(DN)

Oudet

(NPS)

B MiII.()

6

118

9.5

8

9.5

114

3/8

9.5

10

112

9.5

15

20

3/4

12.5

12.5

25

I

32

12.5

IX.

I Y,

40

12.5

50

16.0

2

65

16.0

2~

80

16.0

3

4

19.0

100

Note: (a) "B" Minimum Socket Depths per ASME B16.11

o

12

Dimensions are in millimeters

CMaL

Class 3000

Class 6000

11

11

13

16

16

23

23

24

24

26

31

31

24

26

29

31

32

37

STANDARD PRACTI CE

M SS

SP-97

A NNEX A (Continued)

SI (Metric) Tables Al through A7

TABLEA5

45 Braoch Outlets - Buttweldlog. SI (Metric) Uoits

Dimensions are in millimeters

Oudet

A

(Top of FJttiJIg to R8D Pipe)

(ON)

StaDdard I Extra StroDI

8

10

15

20

25

32

40

50

AMiD.

38.1

38.1

38.1

44.5

54.0

54.0

63.5

73.0

A MaL

42.9

42.9

42.9

50.8

65.1

65.1

69.9

88.9

\3

ScId IO: ~TIOH HANDL.Jr.a

201ZN28 to;t5M OMT

S&MCU. 0'_"

ST ANDARD PRACTICE

M SS

SP-97

ANNEX A (Continued)

SI (Metric) Tables A2 through A7

TABLEA6

45 Branch Outlets - T hreaded, SI (Metric) Units

o

Dimensions are in millimeters

A

(Top of Fittiug to RUB Pipe)

Outlet

(DN)

8

10

IS

20

25

32

40

SO

Clau3000

AMiD.

38. 1

38.1

38.1

46.0

54.0

61.1

63.5

76.2

Clau6000

AMu.

42.9

42.9

44.5

50.8

63.5

76.2

76.2

84.1

AMiD.

38.9

38.9

46.0

54.0

61. 1

65.1

78.6

78.6

_

....

~."

.. "'*' .... wlth MSS

No ~or ~g PlfT'lll*lwIIhoIa IcInM 1l'0III ItS

14

SoId trx_OAMATlON HANOUNO IlERVICES, 01828811)

2012N21 10;11:M 0..,.

A Max.

47.6

47.6

55.6

63.5

73.0

77.8

85.7

104.8

SP-97

STANDARD PRACTICE

MSS

ANNEX A (Continued)

SI (Metric) Tables A2 through A7

TABLEA7

45 Branch Outlets - Socket Welding, SI (Metric) Units

Dimensions are in millimeters

A

Outlet

(DN)

B Min.(I)

(Top of Fitting to Run Pipe)

Class 6000

Class 3000

A Min.

A Max.

9.5

38.1

42.9

8

9.5

42.9

10

38.1

IS

9.5

38.1

44.5

20

12.5

46.0

50.8

54.0

25

12.5

63.5

12.5

61.1

76.2

32

40

12.5

63.5

76.2

SO

16.0

76.2

84.1

..

Note: (a) "B" MinImum Socket Depth per ASME B16.11

15

AMiD.

38.9

38.9

46.0

54.0

61.1

65.1

78.6

78.6

......,.".,., ..,

Sold Io:INFORWATlON HANDUNQ SERVICES, Ot tztl,O

20121W2& le~I$;HGMT

A Max.

47.6

47.6

55.6

63.5

73.0

77.8

85.7

104.8

ST ANDARD PRACTICE

MSS

SP-97

ANNEXB

Design Proof Test

B I. Proof Test AdminisJ':I'Iion

Alternately, the test is considered successful if the

assembly withstands, without rupture, a test

pressure of 105 percent (105%) of the computed

test pressure defined above.

B 1.1

Proof tests shall be made as set forth

herein as evidence of the adequacy of branch

connections employing these outlet fittings.

B3. It is not necessary to conduct an individual test

of fittings in all combinations of sizes, wall thickness,

and pressute class. A successful proof test on one

prototype fitting may represent other similarly

proportioned fittings to the extent described herein.

B2. Proof Test Procedure

B2.l Fittings selected for testing shall be

representative of production fittings, shall be

identified as to material, grade, and class, and shall

be inspected for compliance with this Standard

Practice.

B3.l A successful test on a full size fitting may be

used to quality other full sized fittings no smaller

than one-half nor larger than two-times the size of

the test fitting.

B2.2 Run and branch pipe sections, assembled

with a fitting for test, shall be of equivalent

material to the fitting and shall have nominal wall

thicknesses corresponding to the fitting in

accordance with Table 1, and shall meet all

requirements of the pipe specification.

B3.2 A successful test on a reducing fitting

qualifies:

B3.2.l All similar fittings of the same bnmch

pipe size which fit larger run pipes than the test

fitting.

B2.3 The test bnmch outlet fitting shall be welded

to the run pipe. The diameter of the bnmch opening

in the run pipe shall not be less than the inside

diameter of the bnmch pipe. The length of run pipe

on either side of the weld intersection shall be at

least twice the pipe outside diameter or a suitable

length to ensure the reinforcing effect of the weld

does not affect the proof test The bnmch outlet

pipe extension shall have a length at least twice its

diameter. The run pipe shall have a bursting

strength at least as great as the computed proof test

pressure as calculated in Section B2.4.

B3.2.2 All similar fittings with a bnmch pipe size

no smaller than one-half nor larger than two times

the test fitting provided the run pipe to branch

pipe size ratio is equal to or greater than the test

fitting.

B3.3 The untested fitting must have a bnmch pipe

tID ratio, not less than one-half, nor more than

three times the test fitting.

B3.4 The pre5Sute retaining capacity of a fitting

made of various grades of material with similar

mechanical properties will be essentially directly

proportional to the tensile properties of the various

grades. Hence it is necessary to test a prototype in

only a single grade to prove the geometric design

of fittings.

B2.4 Hydrostatic pressute shall be applied to the

assembly. The acrua1 test pressure prior to rupNre

must be at least equal to the computed proof test

pressure defined below:

P=2St

where:

The manufacNrer shall be able to demonstrate that

fittings prodllCed from materials with significantly

different mechanical properties (i.e., carbon vs.

stainless steel) are considered essentially

proportional to the tested grade, or additional

testing may be required.

P - Proof Test Pressure (PSig)

S - The acrua1 tensile strength of the run pipe to

be used, psi, (determined on a specimen

representative of the pipe)

B3.5 Proof tests which have been conducted prior

to the issuance of this Standard Practice, and that

are equivalent to the above requirements, shall be

considered as fulfilling the requirements of this

Standard Practice provided they are adequately

documented .

- Nominal run pipe wall thickness, inches

D - Specified outside diameter of the run pipe,

inches

.. .. ,

.....

'.-

... , ,'-.

16

ST ANDARD PRACT I CE

MSS

SP-97

ANNEXC

Referenced Standards and Applicable Dates

This Annex is an integral part of this Standard Practice and is placed after main text for convenience.

Standard Name

Description

ASME; ANSIIASME

B1.20.1 -1983 (R2006)

B16.34-2009

B36.IOM-2004 (R2010)

BI6.11 -2011

B 16.25-2007

B31.\-2010

B31j-2010

ASTM

Pipe Threads, General Purpose (Inch)

Valves Flanged, Threaded and Welding End; including 2010 Supplement

Welded and Seamless Wrought Steel Pipe

Forged Fittings, Socket-Welding and Threaded

Buttwelding Ends

Power Piping

Process Piping

Standard Specification for:

A I05/AI05M- l la

AI82/AI82M- I la

A234/A234M-I la

A3501A350M-1I

A403/A403M-II

A4201A420M-lOa

A815/A815M-IOa

Carbon Steel Forgings for Piping Applications

Forged or RoHed Alloy and Stainless Steel Pipe Flanges, Forged Fittings, and

Valves and Parts for High-Temperature Service

Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and

High Temperature Service

Carbon and Low-AHoy Steel Forgings, Requiring Notch Toughness Testing

for Piping Components

Wrought Austenitic Stainless Steel Piping Fittings

Piping Fittings of Wrought Carbon Steel and Alloy Steel for LowTemperature Service

Wrought Ferritic, FerriticlAustenitic, and Martensitic Stainless Steel Piping

Fittings

The foHowing Organizations appear on the above list:

ANSI

American National Standards Institute, Inc.

25 West 43 ni Street, Fourth Floor

New York, NY 10036-7406

ASME

American Society of Mechanical Engineers (ASME International)

Three Park Avenue

New York, NY 10016-5990

ASTM

ASTM International

100 Bar Harbor Drive, P.O. Box C700

West Conshohocken, PA 19428-2959

17

COpytIQIIt MIS

PfooIoII:tId by IHS ulldlt IoINI "

_I

No~Of~~~

_ _ 1ronI1HS

SOld 1O.1NFOI'VtoIIATION HAHDUNQ SERVICU, 0112"1'

.'iNa

11:15:&1GMT

LUnUty 01 MOO OU:ltJU_IU rn.\O.ucw:. \tlD VI IVltlYI LV 1'1

TITLE

SP6-2012

SP.,.2008

SP252008

SP-422009

SP-432OOI

SP....2010

SP-45-2003

SP5120I~

sP5).1999

SM.I999

SP55-2011

Stondatd Finishes forContDCI Faces of Pipe FlAnaeslll'ld ConnmlnaEnd FIonSCS ofVDlvCl and Flttlnp

Spot Fatlna for Bronze. Iron tnd SIecI Flslges

StandIrd M.ki1lJ System for Volves. RUin... FIqcs. ond Unions

COfTOIIon RcsisWnt Gat~ Globe. Anale Dnd Check ValvCl with FlInacd and Buu Weld Ends (CIasscI15o. 300 A 6(0)

Wroupt Dnd Fabrk:.tcd ButtWeldinaFlttinp for Low Pmsun. COITOIion RalIIant Applications (Inc!. 2010 ErrMo Sheet)

SkelPipeUneflan&cs(IncI.2011 EmtaSheet)

(R 200B) Bypas ood Dram Cooocctions

CIao 150l W Coon>oIon RaItIIaI FI_ .... Call FIaopd Flnlnp

(R2OO7)QuoIiIySlandonl lOrs...ICoIIinp ..... .,....... lOr V.....,.,....... ..... .,............ 0dIcr ........ ~ - M..,-_

--..M_

r"

f.""" -....

(R 2007) QuoIiIy SIandonI lOr Sled Cald".. ood faIna> C.. V _ fIonaa, ood fInIoss ond 0Ihcr PiJ*'I CompononIs Qualhy SWMiard fot Steel Catlnp far Valves, Flanau, Fll1lnp., and Ckhcr Pipins Componenu - VisuAl Method far EvDluldan af

MctIoocI

SP96-2011

SP972012

SP982012

SP.I)9.2010

SPlDO-2009

SPI 0 11989

SpI021989

SPI()4..2(l12

SpI052010

Surf,," Inqul..ttic:s (ANSI.pprwed ~ N. . . .I SCaadard)

Pipe Hqen and Supports - MaIeria1s. Oesip. MAnufoccute. Sclec:tion, Applic:Dtion. InClIMtillMlon (1nc0lp0f1ltC:t CAntent ofSP.69. n. 89. and 90)

(ANS11ppnrved ~ NadMW Staaclard)

Connectina Flanae Joints between T appina S1eevcslUld T"",ina Volva

Prcuure Tatlna of Valva

Hlp PrcssUfe Chemical Industry Flanaes and lbrcadcd Stubs for Use with Lens Gaskets

BldlctfIy Volva

Hip Prasure BldlctfIy Volva with OffICI DcsJan

Pipe Hangen and Supports - Selection and AppUca&lon (ANSI..pproved America. Nadoul Sea.clanl)

Gray Iron Gate VDlva. FlIIf1pd and Threaded Ends

Oro)' Iron Swina Check VDlvCl. Filltged and Threaded Ends

BoD Volveswith Flonpd or Butt.Weldina Ends fat General Servlc:e

SpocIIIcootIon Cor H1pTest, WroooahI. B...W.. d... Fl.....

Groy Iron PI. Valva, FlInpdtnd Thraded Ends

Socket WeldlllJ Rcduc:erlnsertl

Bronze Gate. Globe, Angle, tnd Check Valves

SIIInlc:u Sled. Bonnetless, FlInpd Knife Ga&c Valves

Class 3000 Steel ~ Unions Socket Welding tnd 1lutad.d

Gnoy 10... Globe & """" VoI_ FIaopd ..... 1Iwadod Eoob

Guidellnel fot Metrie Doll in St.ndMb for Valves. f1Inps. Flttfnp, Ind ACCUIIkIn (tnc:l1011 Emta Shccl)

(R 1996 - ............. 2011) FiiCICXy-Madc B... WcIdinIJ Flu .... C.. a-I_Pipin.App6........

DiIphntpn Valva

GuideUnes for Manual Opcl'ltion of Valva

MSS Valve U., Guide

QualIty SUndIrd for Steel CutinI' and Forginp for Valves. f1Inaes. Fiftinp. tnd OdIer PiplllJ Componentl - Liquid Penetrw1t

Examinotlon Method

Quality S&andard for Fmitic and Mattenlltle Steel ea.elnp for VDlvCl. Flanges. Fiuinp. and Olher Pipina Componcntl - Ultruonle

Eumlnation Method

Swqo(d) Nippl.. ond Bull Pi....

GuldeUnes on Tenninology for Volves and Flttlnp

IntepDlly Reinforced For;ed Branch Outlet Fialnp .. Socket Woldln" Threaded. and Bunwcldina Ends

ProtectiveCOGIlnp for the lntcriorofVolves. Hydnmtl. and Fhtinp

Instrument VDlves

QuoDfiCQ11on Requirements for Elastomer o;aphrqrnt fat Nuclear Service o;aphragrn Volves

(R 200 I) hitTum VDlvc Actuator Attachment .. Flanae ond DRvin, Component Dimensions and Performance Chamcteristlcs

(R2001) MukiTum Volve ACW8tOt AttDChment .. FllInIC and DrivlnaComponcnt Dimc:nsJons and PerfonnonccChanlclCristics

Wroupt CoppcrSoJder..Joint Pressure Fitdnp

Instrument Valves forCode Appdcaliona

sP I06-20 I 2

CaIIC_AUoy~""'FIaopdFlnlnp,a-I2$.I50.""')oo

SPI()8..2012

SpI09.2012

SpII().2010

Splll2012

SP1122010

RaDIc:nlSeaIodCut Iron Eccc:ntric PILlS Valva

WcJded.Fabricated Copper Solder-joint pretIlft Fitinp

u.u Valves Thteadcd. SockdWeldins.SoIder Joint, Grocwcd InCl FlDred Encb (1ncL20IO E,... Sheet)

Gray.lron Mel Ouc:tik-lron TopplngSlena

QuIIlty SUwtard fot Evaluad~ of Cut Swl'ace Flnbha - Visual and Tactile Method. This SP must be used with a l<kurface. tbfte dimensional Cast

Surface Cocnp.nI&Or. which b 0 noc:enary pan afthc s&anciIrd. Additional Cornpenton OYOilabic tepCItI1Cly.

ConnectI,.Jalnll bctwccn ToppinaMachInes Iftd. Tapplna Valves

Conosion Ralu.tt Pipe Fitttnas Thtcadcd and Sockec WeldinaCla. ISO Ind 1000 (ANSI1PpromI Mteriela N.c&o.ol StaNard)

Excas Flow Valva, 1% NPS and Smaller. for Fuel Gas Sctvlce

Servk:ct-Linc Valves and Flttinp for Drinklna Wacet Systems

BcDaWi Seals for Globe and Gate Volves

Compact Steel Globe & Check Valva - Flanged, FlIIf1aoteu. Threaded & Weldina Ends (Chemical & Petroleum Rcnntty Servlc:e)

FactoryMade Wrought BeUed End Pipe Fitlinp for Sackcl.Weldina

Flexlble Gnaphite Packina System for RUlna SICIft Valvcs - Daian Requirements

Qualification T Cltlna Methods for Stem Packina fat RUina SICIft S&ecl Volves

Plastie Industrial 8411 Volves

(R 2006) NonFetrO\II Threaded and SoJder.Jalnt Union. fat Use with Copper WIterTube

Fabricated Tappina Sleeves

Gray Iron and Ductile Iron InUne. Sprinal.oAded, CenlCT GulcIed Check VDlva

SleeIInUnc Spring.Assistcd Center Guided Check Valves

Brxln,1Or PipillJ Systems Sei.smIcWIndDynarnic OctIan. Scle:ction. Application

Ductile Iron a.tc Volves

(R 2007) C~Nickel Sockee.Weldina FiUlnp tnd UniON

8eUows SeDlt lOt lnstnament VDlves

MetaUle ~uaPy 0pe:nIed Gas DlstriIMaioa Valves

Co...... Woo PacklnsSystems for InstrumcN Valva

Excea Flow Vatva for Low PraMwe FuW Gal AppIlanca

Valva fcwCryogcnIe Service, includina RcquiranattI fot BodyIBonnec Extemions

HJah Prets\Ire Knife Ga&c Volvcs

0uc:tUe Iron SwlllJCheck Valva

Quality S&andard fot Potkive Motcriot Identification of Metal Valves, FI. . . . Flttlnp, and Other PipinaComponentI

QuaUty Standard Prxticc: forOxypn QaIn" afVoIves&: FlU...

Copper Alloy Gate. Globe, Angle. Dnd Check Valves rot Low PreaurelLow TemperatutC Plumbin8 Applicotiont

Quality Stondatd Practice for Preparation of Valva and Flftlnp for SiliCOM-Frce Servic:e

MultiTwn ond Check Valve ModifiCIWon.

Excas Flow VDlvCl for Fuel Gu Service. NPS I~ throuah 12

Uvc-LoGded VolveStem PackinaSystems

SP5&-2009

SP.6I).20 12

SP.06I2009

SP652012

SP.0672011

SPa68-2011

sp~2oo3

Sp7D-20II

sp7120 II

SP7220IOa

sP752001

SP78--2011

SP71).2011

SPao.2008

SP-II20060

SP-I)lOO6

SP-85-2011

SP.a6-2009

SP-87I991

SP ...2010

SP912009

SP922(112

SP932008

SP.94-2OO8

SP952006

Spll)'2012

SPII4-2007

SpII52(l10

SPI 16.201 I

SPI 17201 I

SpII&-2007

SPIII).20IO

SP12D-2011

SP1212006

SpI222012

SpI231998

SP124-2012

SPI252010

SP126-2OO7

Sp1272ool

SP128--2011

SPIlC).2003

SPI)().lOO3

SP1312010

SP13220IO

SP13).2010

SP134-2012

SP135-2010

SP136.2007

SPl)72007

SP1382009

SP131).2010

SP14D-2012

SP1412012

SP'422012

SP,1432012

(R :nAR) Ind6catet year reatllrmed PrIce Liat Av.llllbl. Upon Requ..t MSS .. an ANSI-acaedited Amet1can Ndonll Standard. developer

_"""....

Manufacturers Standardization Society of the Valve and Fittings Induatry, Inc.

127 Park Street, NE, Vlenn., VA 22180-46 10 17031 2A1-M13 FAY # 17031 2A1-8671

50Ict IO:lNFOAMATION HANOUNO SIEAVICIES. OIQ2ltI'

PIwIdId by IHS Ul'ld1l11lcWM Will M$S

No~Of~~lIIWIoutIiwlMII'onIHS

MSS.IHL~I.~!!.:~I!.:58OMT

Você também pode gostar

- Socket-Welding Reducer Inserts: MSS SP-79-2018Documento18 páginasSocket-Welding Reducer Inserts: MSS SP-79-2018IRANIAN 23Ainda não há avaliações

- Prefabricated Steel Supports for PipingDocumento9 páginasPrefabricated Steel Supports for PipingMuhammed SulfeekAinda não há avaliações

- F681-82 (2014) Standard Practice For Use of Branch ConnectionsDocumento5 páginasF681-82 (2014) Standard Practice For Use of Branch ConnectionsCarlos Guillermo Somoza AlvarengaAinda não há avaliações

- Piping Engineering Note Nitrogen Purge SystemDocumento20 páginasPiping Engineering Note Nitrogen Purge SystemchrysanthiiiiiiAinda não há avaliações

- Piping Material Specification - Tsmto 99fu M 99 Pt0 001 Rev0!3!65Documento64 páginasPiping Material Specification - Tsmto 99fu M 99 Pt0 001 Rev0!3!65epbamdad100% (1)

- Plug Valve Specification for Carlsberg BreweryDocumento7 páginasPlug Valve Specification for Carlsberg BreweryNarayana MugalurAinda não há avaliações

- Piping Class B31Documento142 páginasPiping Class B31interx00Ainda não há avaliações

- ADG005Documento14 páginasADG005prufino2Ainda não há avaliações

- Daniel Orifice Flanges Provide Accurate Flow MeasurementDocumento45 páginasDaniel Orifice Flanges Provide Accurate Flow MeasurementSammyAinda não há avaliações

- PGHU-CV-LDSTS-000001 R2 Piping Standards DrawingDocumento46 páginasPGHU-CV-LDSTS-000001 R2 Piping Standards DrawingRiyan EsapermanaAinda não há avaliações

- Piping Specifications HarrisDocumento27 páginasPiping Specifications Harrisrensieovi100% (2)

- HTTP WWW - Wermac.org Fittings Buttweld Fittings Part5Documento4 páginasHTTP WWW - Wermac.org Fittings Buttweld Fittings Part5prabu prasad100% (1)

- Pipe Support Design SoftwareDocumento61 páginasPipe Support Design Softwaremuhammad0umar-4Ainda não há avaliações

- Piping Engineering Course OverviewDocumento2 páginasPiping Engineering Course Overviewmayur_lanjewar0% (1)

- Flans Chen Prospekt EngDocumento2 páginasFlans Chen Prospekt Englorenzinho290Ainda não há avaliações

- KIL3012 - WEEK 3 - 24.9.19 (Student Copy)Documento84 páginasKIL3012 - WEEK 3 - 24.9.19 (Student Copy)EdAinda não há avaliações

- Piping Spec C ClassDocumento1 páginaPiping Spec C Classnestor ferrel floresAinda não há avaliações

- Iqwq Ce1092 Qpqac 00 0002 - 0 Quality Control Procedure for Piping管道质量控制程序Documento54 páginasIqwq Ce1092 Qpqac 00 0002 - 0 Quality Control Procedure for Piping管道质量控制程序Ali Majeed100% (1)

- PN03CL1S01Documento4 páginasPN03CL1S01Amreusit SaschimbnumeleAinda não há avaliações

- Thumb RuleDocumento42 páginasThumb RuleShabeer KiblaalamAinda não há avaliações

- PNSMV046Documento8 páginasPNSMV046Mehrdad HosseinzadehAinda não há avaliações

- 01NC0B02Documento4 páginas01NC0B02raobabar21Ainda não há avaliações

- SLR Strainer Data Sheet PDFDocumento7 páginasSLR Strainer Data Sheet PDFKailas NimbalkarAinda não há avaliações

- Branch Connection Fittings (MSS SP-97) - Weldolet®, Sockolet®, Thredolet®, Latrolet®, Elbolet®, Nipolet®, Sweepolet®Documento3 páginasBranch Connection Fittings (MSS SP-97) - Weldolet®, Sockolet®, Thredolet®, Latrolet®, Elbolet®, Nipolet®, Sweepolet®dchz_62Ainda não há avaliações

- 7 090 L03 00001 C 2, Piping Material Specification - 170531Documento85 páginas7 090 L03 00001 C 2, Piping Material Specification - 170531ddddAinda não há avaliações

- Sanitary Waste and Vent Piping 15150Documento15 páginasSanitary Waste and Vent Piping 15150Munir RasheedAinda não há avaliações

- 01LK0F01Documento4 páginas01LK0F01raobabar21Ainda não há avaliações

- 01SD1B01Documento5 páginas01SD1B01Jhonny RinconesAinda não há avaliações

- API STANDARD For PipingDocumento28 páginasAPI STANDARD For PipingsahaAinda não há avaliações

- Swagelok Fitting PDFDocumento16 páginasSwagelok Fitting PDFmattuiffAinda não há avaliações

- SP PI PP 001 (General Piping System)Documento49 páginasSP PI PP 001 (General Piping System)Ari IndrajayaAinda não há avaliações

- EIL - Specification Sheet123Documento1 páginaEIL - Specification Sheet123Dinesh ChouguleAinda não há avaliações

- ECS 3-18-1 - 3 - 8009766fDocumento22 páginasECS 3-18-1 - 3 - 8009766fFlorin Daniel AnghelAinda não há avaliações

- Easyflex Flexible Hose DatasheetDocumento2 páginasEasyflex Flexible Hose DatasheetzassssAinda não há avaliações

- Universal Y StrainerDocumento2 páginasUniversal Y Strainerabdi zakiAinda não há avaliações

- Atirkfch-G Tat Tr4Ri: Standard Specification For Orifice Plates and FlangesDocumento7 páginasAtirkfch-G Tat Tr4Ri: Standard Specification For Orifice Plates and FlangesBharat TrivediAinda não há avaliações

- Ac 036630 001Documento1 páginaAc 036630 001navaronefraAinda não há avaliações

- Pfi ListDocumento3 páginasPfi Listalay2986100% (1)

- 500 SP PIP 018 Rev C (Check Valve)Documento13 páginas500 SP PIP 018 Rev C (Check Valve)anwar01Ainda não há avaliações

- Pip PNSM0105Documento6 páginasPip PNSM0105romerobernaAinda não há avaliações

- To Be A Piping Designer You Should KnowDocumento7 páginasTo Be A Piping Designer You Should KnowQusroo AhmedAinda não há avaliações

- Piping Material Service Index ChartDocumento3 páginasPiping Material Service Index ChartOghenekevwe OrumahAinda não há avaliações

- Project Engineering Deliverables: Functional Responsibility Description Type of Deliverable Cost (L.E.)Documento2 páginasProject Engineering Deliverables: Functional Responsibility Description Type of Deliverable Cost (L.E.)MJ MagdyAinda não há avaliações

- New Standard For FRP PipingDocumento37 páginasNew Standard For FRP PipingKamatchi NathanAinda não há avaliações

- API 5L - 43rd and 44th Ed - Comparison r1Documento68 páginasAPI 5L - 43rd and 44th Ed - Comparison r1gopidhan100% (1)

- Pipeline Equipment and ConstructionDocumento16 páginasPipeline Equipment and ConstructionHansLopezAinda não há avaliações

- 01SA0S02Documento5 páginas01SA0S02raobabar21Ainda não há avaliações

- 8474l 000 JSD 1300 006 0 (Specifications For Equipment Spacing)Documento38 páginas8474l 000 JSD 1300 006 0 (Specifications For Equipment Spacing)Muhammad AhsanAinda não há avaliações

- Piping Project Specification for Mean Pressure Steam and Steam Condensate ServiceDocumento1 páginaPiping Project Specification for Mean Pressure Steam and Steam Condensate Servicehalim_kaAinda não há avaliações

- L&T Aquaseal Butterfly Check ValvesDocumento24 páginasL&T Aquaseal Butterfly Check ValvesSohail PathanAinda não há avaliações

- Piping Design CriteriaDocumento15 páginasPiping Design CriteriaSubash Chandrabose0% (1)

- Company Profile Sicilsaldo-2019Documento59 páginasCompany Profile Sicilsaldo-2019Roberto CuadrosAinda não há avaliações

- Autopipe TutorialDocumento198 páginasAutopipe TutorialMuhammad Nashir100% (1)

- Smith Fibercast Green Thread Performance Plus Fiberglass Pipe Piping BrochureDocumento8 páginasSmith Fibercast Green Thread Performance Plus Fiberglass Pipe Piping BrochureWong Chung MengAinda não há avaliações

- Flange AS4087 AS2129 BS Table DEDocumento2 páginasFlange AS4087 AS2129 BS Table DEadamAinda não há avaliações

- Pipeline and Energy Plant Piping: Design and TechnologyNo EverandPipeline and Energy Plant Piping: Design and TechnologyNota: 5 de 5 estrelas5/5 (2)

- All-in-One Manual of Industrial Piping Practice and MaintenanceNo EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceNota: 5 de 5 estrelas5/5 (1)

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionNo EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionAinda não há avaliações

- Integrally Reinforced Forged Branch Outlet Fittings - Socket Welding, Threaded, and Buttwelding EndsDocumento22 páginasIntegrally Reinforced Forged Branch Outlet Fittings - Socket Welding, Threaded, and Buttwelding Endsssnair85Ainda não há avaliações

- MSS SP-104-2018Documento14 páginasMSS SP-104-2018Денис Пекшуев0% (1)

- Thermowell Calculation Guide V1.3Documento19 páginasThermowell Calculation Guide V1.3AymanelorbanyAinda não há avaliações

- MuestreoDocumento13 páginasMuestreoJuliusMaximus12Ainda não há avaliações

- 133 Series Direct-Operated Regulators: Bulletin 71.1:133Documento24 páginas133 Series Direct-Operated Regulators: Bulletin 71.1:133JuliusMaximus12Ainda não há avaliações

- Verification Coriolis Flow Meter Calibration 2015 0164Documento12 páginasVerification Coriolis Flow Meter Calibration 2015 0164tetioAinda não há avaliações

- UltrasonicDocumento26 páginasUltrasonicJuliusMaximus12Ainda não há avaliações

- Consolidated Relief Valves SRVDocumento498 páginasConsolidated Relief Valves SRVHitesh PanchalAinda não há avaliações

- Berne, F. and Cordonnier, J. - 1995 - Refining, Petrochemical and Gas Processing Techniques - Industrial Water Treatment PDFDocumento256 páginasBerne, F. and Cordonnier, J. - 1995 - Refining, Petrochemical and Gas Processing Techniques - Industrial Water Treatment PDFJuliusMaximus120% (1)

- Bolt UpDocumento2 páginasBolt UpJuliusMaximus12Ainda não há avaliações

- Pipe Fittings PDFDocumento164 páginasPipe Fittings PDFjlvega18Ainda não há avaliações

- AUGI - AutoCAD Its A 3D World After AllDocumento54 páginasAUGI - AutoCAD Its A 3D World After AllJuliusMaximus12Ainda não há avaliações

- Trim Number Chart API ValveDocumento2 páginasTrim Number Chart API ValveJuliusMaximus12Ainda não há avaliações

- Catalogo MariposaDocumento19 páginasCatalogo MariposaJuliusMaximus12Ainda não há avaliações

- TN 25Documento8 páginasTN 25paulo_linanAinda não há avaliações

- Polylac® Pa-747Documento3 páginasPolylac® Pa-747vicenteAinda não há avaliações

- Comparison of RCC and RBC Slab System.Documento1 páginaComparison of RCC and RBC Slab System.Saleem MughalAinda não há avaliações

- Experiment 5 Pressure Distribution On Circular Cylinder and AirfoilDocumento8 páginasExperiment 5 Pressure Distribution On Circular Cylinder and AirfoilMarilynYunLing50% (2)

- Basement Level (1) Plan: ProposedDocumento20 páginasBasement Level (1) Plan: ProposedParth DaxiniAinda não há avaliações

- OPSS - PROV 903 Apr16Documento24 páginasOPSS - PROV 903 Apr16Mark PermaulAinda não há avaliações

- Sizing and Selection Chart 25T, 25TE, 25E, 25PT, 25PTE: How To Select and SizeDocumento2 páginasSizing and Selection Chart 25T, 25TE, 25E, 25PT, 25PTE: How To Select and SizePaul Andre Cruz MolinaAinda não há avaliações

- Sterilizing Filter Integrity Test ServicesDocumento2 páginasSterilizing Filter Integrity Test ServicesLam TranAinda não há avaliações

- Mid If ItDocumento4 páginasMid If ItsncomputerAinda não há avaliações

- Hublit Limphaire Leaflet India PDFDocumento2 páginasHublit Limphaire Leaflet India PDFAkshay RaiAinda não há avaliações

- PRODUCT RANGE GATE VALVEDocumento6 páginasPRODUCT RANGE GATE VALVETanmoy DuttaAinda não há avaliações

- Home Interior Design Presentation For Mr. Piyush Arya and Mrs. Garima AryaDocumento38 páginasHome Interior Design Presentation For Mr. Piyush Arya and Mrs. Garima AryaKalpana GuptaAinda não há avaliações

- Electrical Tools and Materials WITH QUIZDocumento53 páginasElectrical Tools and Materials WITH QUIZJeann OlaytaAinda não há avaliações

- Refresh Refresh (Dynamic - Bypass - Reload) Click Here If You Are Not Automatically Redirected. For Assistance, Contact Your Network Support Team.Documento10 páginasRefresh Refresh (Dynamic - Bypass - Reload) Click Here If You Are Not Automatically Redirected. For Assistance, Contact Your Network Support Team.Kelvin LimAinda não há avaliações

- Main panel single line diagramDocumento15 páginasMain panel single line diagramEr.AROCKIA STEPHAN VSGAinda não há avaliações

- Summary of DPWH Standard Specs and Min Test RequirmentDocumento34 páginasSummary of DPWH Standard Specs and Min Test Requirmentcharlee_05Ainda não há avaliações

- CP203 Schindler Interior DesignDocumento22 páginasCP203 Schindler Interior DesignLABO MRT-KOTAAinda não há avaliações

- Building Timber StepsDocumento5 páginasBuilding Timber StepstrancalinaAinda não há avaliações

- Asad - Utilization of FAC As Lightweight Filler in Cement-Based CompositesDocumento12 páginasAsad - Utilization of FAC As Lightweight Filler in Cement-Based CompositesShan RatnayakeAinda não há avaliações

- Consistent Deformations - Fouad FanousDocumento18 páginasConsistent Deformations - Fouad FanousCut Meutia RatagAinda não há avaliações

- Limo GaugeDocumento3 páginasLimo Gaugeajaysharma19686191Ainda não há avaliações

- 1007 Top PlateDocumento1 página1007 Top PlateAanand SinghiAinda não há avaliações

- Acceptance Criteria for Welds Visual and Radiographic ExaminationDocumento3 páginasAcceptance Criteria for Welds Visual and Radiographic ExaminationerboalAinda não há avaliações

- 03 24 00magDocumento3 páginas03 24 00magMorris AlcantaraAinda não há avaliações

- Plant Location and Plant LayoutDocumento11 páginasPlant Location and Plant LayoutShalini C GAinda não há avaliações

- Brochure Sugar IndustryDocumento2 páginasBrochure Sugar Industrykamals55Ainda não há avaliações

- Sa 20 PDFDocumento46 páginasSa 20 PDFmr.aghelAinda não há avaliações

- Quality Assurence Büscher 2006Documento71 páginasQuality Assurence Büscher 2006mustafAinda não há avaliações

- 01 Properties of SteamDocumento35 páginas01 Properties of SteamDeepanshu Sehgal100% (1)