Escolar Documentos

Profissional Documentos

Cultura Documentos

SWMS - Air Leakage Test - Rev.00

Enviado por

Syerifaizal Hj. MustaphaTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

SWMS - Air Leakage Test - Rev.00

Enviado por

Syerifaizal Hj. MustaphaDireitos autorais:

Formatos disponíveis

SAFE WORK METHOD STATEMENT DOCUMENT

Document Title (to be completed by the Contractor)

Project: Menara Public Mutual

SWMS No: 0166

SWMS Title: Air Leakage Test for Underfloor Air Plenums

This SWMS will be reviewed: ____________ (Date)

OR earlier if conditions and/or circumstances change that introduce

new hazard/s.

Contractor / Service Provider: Daewoo E&C

Document Status (to be completed by Contractor)

Rev

No

00

Date

25/5/2015

Comments

1st submission

Sub-Contractor

review by

Syerifaizal

Main Contractor

review by

MHR/BN/RN

PAB / Lend Lease

verification by

TM

Contractor Review, Verification & Endorsement

REVIEW

I have reviewed all aspects of this SWMS and am satisfied to the best of my knowledge that it meets all Lend Lease acceptance criteria.

Main Contractor Supervisor / Engineer (print name): ...Signed: .. Date: ././.

VERIFICATION

I have verified all aspects of this SWMS and am satisfied to the best of my knowledge that it meets all Lend Lease acceptance criteria.

Main Contractor Main EH&S Team Head (print name): Signed: Date: ././.

ENDORSEMENT

I have verified all aspects of this SWMS and am satisfied to the best of my knowledge that it meets all Lend Lease acceptance criteria.

Main Contractor Project / Construction Leader (print name): Signed: Date: ././.

Enter SWMS No and Version here

Page 1 of 10

SWMS REVIEW CHECKLIST (to be completed by Contractor)

NOTE:

Each Contractor / Service Provider, before commencing work, must provide written Safe Work Method Statement/s (SWMS) for the work to be

carried out. The following checklist is to be completed and reviewed by Main Contractor, and assessed to have met the EH&S Requirements as

per the Contract acceptance criteria in compliance with the requirements outlined in the checklist and any relevant EH&S Legislation, Codes and

Specifications.

This SWMS must be reviewed on a regular basis. When new information on EH&S risks surface, changes occur or after any inspection, incident /

accident that impact on the agreed method of work, the SWMS must be revised accordingly.

Section 1: Compliance Checklist

SWMS Criteria

1.

Sets out step by step how the work activity will be carried out.

2.

Identifies the aspects/hazards associated with each step of the work activity.

3.

Assesses the impacts / risks associated with each step of the work activity.

4.

Defines the controls to manage risks associated with each step of the work activity based

on the hierarchy of controls Eliminate, Substitute, Isolate, Engineer, Administrate and

PPE.

5.

Provides a description of the plant / equipment that will be used in carrying out the work

activity (including equipment maintenance and inspection requirements, certification by

qualified person and / or registration, etc.).

6.

Describes the qualifications and training of personnel carrying out the work activity,

including supervisors experience, competency, licenses, operators certification, etc.

7.

Refers to and confirms compliance with relevant EH&S Legislation, Standards, Codes,

Regulations and / or Lend Lease SMR as per the Contract.

8.

Includes design requirements, engineered details or certification for both temporary and

permanent structures, platforms or access ways / ladders.

9.

Where PPE is nominated, the type of PPE is specifically listed and when it is required.

10.

Defines who is responsible to ensure that the work activity is monitored and carried out in

accordance with the SWMS.

11.

Defines the process and frequency of reviews and methods for ensuring the work

complies with the SWMS controls.

12.

Identifies where any Contractor / Service Provider will be used, who is responsible to

monitor and supervise the works, and how impacts/hazards arising from interaction

between trades will be communicated and managed (e.g. induction into more than 1

SWMS).

13.

For complex or high risk work activities (where appropriate), uses photos / diagrams /

sketches / summary to enhance the SWMS.

14.

Includes the name and signature of the person who developed the SWMS, a current date

and revision number.

15.

The SWMS includes specific EH&S controls for key high risk activities (refer to Planning &

Delivery GMR 4.2 High Risk Activities).

Check

Yes

No

Remarks

Where an exclusion zone is required, the SWMS must clearly state the detail of the required exclusion zone,

including the person responsible for implementation and supervision.

Enter SWMS No and Version here

Page 2 of 10

APPLICATION (to be completed by Contractor / Service Provider)

Section 1: Scope of Works

Tasks / Activities:

- Pre-start requirements & work location set up

- Raised Floor Installation

- Installation of Testing Equipment

- Air Leakage Test

Work Location (Attach Site Plan): No

Duration: From 1/6/2015 (Date) to 15/6/2015 (Date)

Remarks:

Section 2: Plant / Machinery / Equipment (Attach Inspection Certificates)

1

Type of Plant / Machinery / Equipment

Raised Floor

Is this equipment inspected?

Yes

No

PVC Pipes

Yes

No

Flexible Hose

Yes

No

Testing equipment (DPM Micro manometer/Airflow Duct

Leakage Test Rig)

Yes

No

Remarks

Material to be approved

Calibration Cert and sticker

Section 3: Key Personnel / Qualified Persons (Attach Training Qualification Certificates)

Name

1

Mr. Lee Un Dal

Appointment / Designation

Construction Manager

Mr. Syerifaizal

QAQC Manager

Mr. Khairin

Architectural Coordinator

Mrs. Ain

Safety Officer

Enter SWMS No and Version here

Remarks

Page 3 of 10

Section 4: Work Processes & Procedures

Inventory of Work Activities

Key Job Steps

These steps are to be copied to:

C Section 2: Risk Assessment &

C Section 3: Safe Work Procedures

1

Pre-start requirements & work location set up

Key Job Step breakdown (if required)

Step breakdowns are to be copied to:

C Section 3: Safe Work Procedures

Material Handling & Storage

SWMS briefing

Mobilising of material

Safety Pre-Start Session

Install task lighting (if required)

Install exclusion zone (if required)

Shifting material to storage area & works location

Raised Floor Installation

Installation of testing equipment

Air Leakage Test

To refer approved SWMS Ref. No.PMB/DEC/P2/SF/0639 Installation of Access Raised Floor (Rev.02)

To refer Attachment 1 which consisting Category 1 and category 2

Completed raised floor shall be completely sealed off.

To refer attached layout for proposed area for leakage test.

Measurement will be taken and properly recorded base on flowrate

value.

Special Instructions/Remarks:

To refer attachment for technical Method Statement

Enter SWMS No and Version here

Page 4 of 10

RISK ASSESSMENT (to be completed by Contractor / Service Provider)

Section 1: General Information

PREPARED BY:

REVIEWED / APPROVED BY:

Name:

Signed: .

Name:

Signed: .

Designation: .

Date: . /. /.

Designation: .

Date: . /. /.

Applicable Environment, Health & Safety (EH&S)

Legislation

Approved Code of Practice (COP) and/or GMR

Risk Assessment Team

Name

Designation

Signature

________________________

________________________

________________________

________________________

________________________

________________________

________________________

________________________

________________________

________________________

________________________

________________________

________________________

________________________

________________________

________________________

________________________

________________________

Enter SWMS No and Version here

Page 5 of 10

Consequence Table

IMPACT

Very Small - 1

Unlikely injury or ill-health, or

onsite first aid treatment.

Onsite environmental impact

with straightforward clean-up

or remedy with available site

equipment and controls.

No regulatory notification

required.

Small - 2

Offsite medical treatment.

Onsite and/or offsite

environmental damage

taking 0-3 months to clean

up or remedy.

No regulatory notification

required.

Some community concerns

raised but no impact.

LIKELIHOOD

Medium - 3

Lost Time Injury or

Occupational Illness.

Onsite and/or offsite

environmental damage

taking 3-6 months to clean

up or remedy.

Regulatory notification may

be required.

Limited impact on community

with minor concerns raised.

Large - 4

Permanently Disabling Injury

or Occupational Illness.

Onsite and/or offsite

environmental damage

taking 6-12 months to clean

up or remedy.

Regulatory notification

compulsory but no public

investigation likely.

Major impact on local

community leads to

community protests.

Very Large - 5

Fatality due to Injury or

Occupational Disease.

Evacuation of employees

due to threat of fatality.

Irreversible onsite and/or offsite environmental damage;

or clean-up or remedy from

damage lasting > 12 months.

Regulatory notification

compulsory with public

investigation likely.

Impact on local community

leads to community outrage.

5 (Very High) - A Very High Likelihood:

1) Almost certain to occur; 2) Almost certain to re-occur due to past trends from

reported incidents / issues; 3) Quantified very high exposure to the risk without

any controls in place.

Minor

Moderate

Significant

Significant

Critical

4 (High) - A High Likelihood:

1) Strong evidence to likely occur; 2) Highly likely to re-occur due to past trends

from reported incidents / issues; 3) Quantified high exposure to the risk without

any controls in place.

Minor

Minor

Moderate

Significant

Significant

3 (Medium) - A Medium Likelihood:

1) May occur or known to occur; 2) Infrequent number and regularity of reported

incidents / issues; 3) Quantified moderate exposure to the risk without any

controls in place.

Minor

Minor

Moderate

Moderate

Significant

Negligible

Minor

Minor

Minor

Moderate

Negligible

Negligible

Minor

Minor

Minor

2 (Low) - A Low Likelihood:

1) Could occur at some but not expected; 2) One or two reported incidents /

issues to date; 3) Quantified low exposure to the risk without any controls in

place.

1 (Very Low) - A Very Low Likelihood:

1) Highly unlikely to occur; 2) No evidence of reported incidents / issues in the

past; 3) No quantified and known exposure to the risk without controls in place.

Risk Index

Action

Critical

Operation not permissible; management attention and consultation with Region Head of EH&S required.

Significant

Operation not permissible; risk must be reduced by all possible means (not by interim risk control measures); management attention and consultation with Region Head of EH&S required.

Moderate

Further risk reduction required where possible; remedial action to be taken immediately; frequent review needed to ensure risk level assigned is accurate and does not increase over time;

management attention required.

Minor

Risk tolerable subject to demonstration that risk level is as low as reasonably practicable; remedial action to be taken at appropriate time to further reduce risk level; frequent review needed to ensure

risk level assigned is accurate and does not increase over time.

Negligible

Risk acceptable; discretionary remedial action to be taken.

Enter SWMS No and Version here

Page 6 of 10

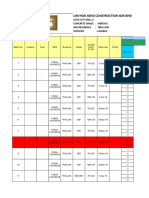

Section 2: Risk Assessment

MANDATORY PPE:No

Unless stated otherwise in this document, ALL WORKERS, will wear (at all times during this activity):1 Hard hat, 2 Safety boots 3 Safety gloves 4 Safety glasses 5 Hi-viz reflective vest

Key Job Steps

Aspect / Hazard

Pre-start requirements &

work location set up

Material Handling &

Storage

Raised Floor Installation

Existing Controls

L

Risk

Rating

Electric shock causing

serious or fatal injury

Moderate

Trips causing minor

injury

Minor back injury

Risk

Rating

Negligible

Minor

Cable management

ELCB

Inspect & tag

Cable management

Negligible

2

2

Manual handling

Dust from sweeping

works causing eye injury

and breathe problems.

Minor back injury

Minor

Two people to carry

Negligible

Moderate

Negligible

Supervisor

workers

Minor

Negligible

Supervisor

Workers

Material movement

Moderate back injury

Minor

Negligible

Supervisor

Workers

Manual handling

Moderate back injury

Minor

Proper posture and ergonomics

Negligible

Supervisor

Workers

Use and handling the Testing

equipment ( Test Rig) in proper posture

and ergonomics

Cable management

ELCB

Inspect & tag

Negligible

Supervisor

Workers

Negligible

Surface preparation

Installation of testing

equipment

Manual handling

Minor back injury

Minor

Air Leakage Test

Electricity

Electric shock causing

serious or fatal injury

Moderate

Provide mask and all workers

should wear the 5 PPEs

Pre-wet the area

Use and handling the wheelbarrow/

Pallet Jack in proper posture and

ergonomics

Using of pallet truck/wheel barrow to

move materials

Section 3: Safe Work Procedures

Enter SWMS No and Version here

Page 7 of 10

Risk

Rating

Accountable

person/s & if

applicable follow

up date

Supervisor

Workers

Electricity

Risk Control

Further improvement (if required)

L

I

Risk Control

Manual handling

Uncontrolled

Risk & Impact

Supervisor

Workers

Workers

Supervisor

Workers

MANDATORY PPE:-

Unless stated otherwise in this document, ALL WORKERS, will wear (at all times during this activity):1 Hard hat, 2 Safety boots 3 Safety gloves 4 Safety glasses 5 Hi-viz reflective vest

Key Job Steps

(Copy from B Section 4)

Pre-start requirements & work location set

up

Key Job Step breakdown

(Copy from B Section 4)

Safe Work Procedures

(include images / sketches if required for further clarity)

Permits Required

Additional Equipment /

PPE

Hold Point

Responsible

SWMS briefing

The supervisor will ensure that all workers have been briefed into

the SWMS PRIOR to the work commencing. This will be verified by

signatures on the document.

Yes

Supervisor

Mobilising of material

The supervisor will ensure the mobilisation of material has been

carried out in safe manners.

Yes

Supervisor

Safety Pre-Start Session

The supervisor, team leader OR Safety Officer/Supervisor will lead

a daily pre-start session at the work location immediately prior to the

work commencing. This session will cover hazards & risk

associated with todays activity.

Yes

Supervisor

Install task lighting

The Electrical Engineer will ensure the cable management has

been done in correct manner.

Yes

Supervisor

Install exclusion zone

The Supervisor will brief the workers on the safe method of works

prior commencing of works.

Yes

Supervisor

Material Handling & Storage

Hoisting works

Shifting material to storage area & works

location

The Engineer shall brief to all workers at the work location prior

commencement of works which will cover the safe works procedure,

tools inspection and also potential hazard & risk to the activity.

Yes

Engineer

Raised Floor Installation

To refer approved SWMS Ref.

No.PMB/DEC/P2/SF/0639 - Installation of

Access Raised Floor (Rev.02)

The supervisor, team leader OR Safety Officer/Supervisor shall brief

to all workers at the work location prior commencement of works

which will cover the safe works procedure, tools inspection and also

potential hazard & risk to the activity.

Yes

Supervisor

To refer Attachment 1 which consisting

Category 1 and category 2

Completed raised floor shall be

completely sealed off.

To refer attached layout for proposed

area for leakage test.

Measurement will be taken and properly

recorded base on flowrate value.

The supervisor, team leader OR Safety Officer/Supervisor shall brief

to all workers at the work location prior commencement of works

which will cover the safe works procedure, tools inspection and also

potential hazard & risk to the activity.

Installation of testing equipment

Air Leakage Test

Enter SWMS No and Version here

The supervisor, team leader OR Safety Officer/Supervisor shall brief

to all workers at the work location prior commencement of works

which will cover the safe works procedure, tools inspection and also

potential hazard & risk to the activity.

Page 8 of 10

Yes

Supervisor

Yes

Supervisor

Section 4: Instruction & Communication

This Safe Work Method Statement has been developed through consultation with the following crew members and has been instructed through induction, read and understood, and signed by all employees undertaking

the works.

Name

Designation

Remarks / Comments

Signature

Date

Section 5: Verification

I have provided, accurate and sufficient information and instructions pertaining to this Safe Work Method Statement - the aspects / hazards associated with each work process and activity, the type of potential impact,

incident or accident, and the risk controls / practicable measures to be taken in the course of work and during an emergency - to ensure its / their safe undertaking.

Instructed by (print name): .. Signed: ..

Enter SWMS No and Version here

Date: ..../...../ Time: .............. am / pm

Page 9 of 10

Enter SWMS No and Version here

Page 10 of 10

Você também pode gostar

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Issue No - 4 - Cream E-MagDocumento34 páginasIssue No - 4 - Cream E-MagSyerifaizal Hj. MustaphaAinda não há avaliações

- Notes - The Most Common Irregular VerbsDocumento1 páginaNotes - The Most Common Irregular VerbsSyerifaizal Hj. MustaphaAinda não há avaliações

- Filing Labeling - Sample RoomDocumento1 páginaFiling Labeling - Sample RoomSyerifaizal Hj. MustaphaAinda não há avaliações

- Guide To Performance Management - 2023Documento43 páginasGuide To Performance Management - 2023Syerifaizal Hj. MustaphaAinda não há avaliações

- CREAM E-Magazine - Issue 1, January 2023Documento24 páginasCREAM E-Magazine - Issue 1, January 2023Syerifaizal Hj. MustaphaAinda não há avaliações

- SH - Shop Drawings Tracking ListDocumento6 páginasSH - Shop Drawings Tracking ListSyerifaizal Hj. MustaphaAinda não há avaliações

- ShoringDocumento1 páginaShoringSyerifaizal Hj. MustaphaAinda não há avaliações

- Davco Grout 280 Eco Sds en MyDocumento9 páginasDavco Grout 280 Eco Sds en MySyerifaizal Hj. MustaphaAinda não há avaliações

- BC Bitumen CoatingDocumento3 páginasBC Bitumen CoatingSyerifaizal Hj. MustaphaAinda não há avaliações

- Control of RC WorksDocumento52 páginasControl of RC WorksSyerifaizal Hj. MustaphaAinda não há avaliações

- Master List of Construction DrawingsDocumento94 páginasMaster List of Construction DrawingsSyerifaizal Hj. MustaphaAinda não há avaliações

- BC Bitumen Coating SDS en MYDocumento8 páginasBC Bitumen Coating SDS en MYSyerifaizal Hj. MustaphaAinda não há avaliações

- Mos - P.U InjectionDocumento1 páginaMos - P.U InjectionSyerifaizal Hj. MustaphaAinda não há avaliações

- PMP Audit ChecklistDocumento6 páginasPMP Audit ChecklistSyerifaizal Hj. MustaphaAinda não há avaliações

- MOS UnloadingDocumento3 páginasMOS UnloadingSyerifaizal Hj. MustaphaAinda não há avaliações

- RWTP-GB-AMS-L-000263-2023 - Proposal of Test Frequency For Site ImplementationDocumento3 páginasRWTP-GB-AMS-L-000263-2023 - Proposal of Test Frequency For Site ImplementationSyerifaizal Hj. MustaphaAinda não há avaliações

- Green Building Index (Gbi)Documento22 páginasGreen Building Index (Gbi)Gholai KhocezkhoAinda não há avaliações

- QMS Audit ChecklistDocumento4 páginasQMS Audit ChecklistSyerifaizal Hj. MustaphaAinda não há avaliações

- Jadual Minggu Orientasi SRIAZA 2023 Tahap 1Documento1 páginaJadual Minggu Orientasi SRIAZA 2023 Tahap 1Syerifaizal Hj. MustaphaAinda não há avaliações

- SH Audit ChecklistDocumento5 páginasSH Audit ChecklistSyerifaizal Hj. MustaphaAinda não há avaliações

- EMS Audit ChecklistDocumento4 páginasEMS Audit ChecklistSyerifaizal Hj. MustaphaAinda não há avaliações

- Take Stocks QSHE Monthly Dashboard GBU - KPI July 2022.rev.00Documento43 páginasTake Stocks QSHE Monthly Dashboard GBU - KPI July 2022.rev.00Syerifaizal Hj. MustaphaAinda não há avaliações

- ESG ScreenshotDocumento1 páginaESG ScreenshotSyerifaizal Hj. MustaphaAinda não há avaliações

- QSHE Dashboard GBU 2018.09Documento218 páginasQSHE Dashboard GBU 2018.09Syerifaizal Hj. MustaphaAinda não há avaliações

- Two Component Semi-Rigid Foam: NCL Pu Flex-2Documento2 páginasTwo Component Semi-Rigid Foam: NCL Pu Flex-2Syerifaizal Hj. MustaphaAinda não há avaliações

- Excavation Along Jalan Belfield: Method Statement ForDocumento37 páginasExcavation Along Jalan Belfield: Method Statement ForSyerifaizal Hj. Mustapha100% (1)

- Excavation Along Jalan Belfield: Method Statement ForDocumento37 páginasExcavation Along Jalan Belfield: Method Statement ForSyerifaizal Hj. Mustapha100% (1)

- Section 1 Key QSHE Issues and Risks (Current or Forecast) : KPI Score (Append Every Month's Score Horizontally)Documento4 páginasSection 1 Key QSHE Issues and Risks (Current or Forecast) : KPI Score (Append Every Month's Score Horizontally)Syerifaizal Hj. MustaphaAinda não há avaliações

- Cube Strength - Concrete Trend Analysis - SCM2-Not UpdateDocumento49 páginasCube Strength - Concrete Trend Analysis - SCM2-Not UpdateSyerifaizal Hj. MustaphaAinda não há avaliações

- QSHE Dashboard GBU 2018.08Documento207 páginasQSHE Dashboard GBU 2018.08Syerifaizal Hj. MustaphaAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Nyamango Site Meeting 9 ReportDocumento18 páginasNyamango Site Meeting 9 ReportMbayo David GodfreyAinda não há avaliações

- Antifraud PlaybookDocumento60 páginasAntifraud PlaybookDani UsmarAinda não há avaliações

- Example of Flight PMDG MD 11 PDFDocumento2 páginasExample of Flight PMDG MD 11 PDFVivekAinda não há avaliações

- 16 Personalities ResultsDocumento9 páginas16 Personalities Resultsapi-605848036Ainda não há avaliações

- Chestionar 2Documento5 páginasChestionar 2Alex AndruAinda não há avaliações

- Catalog Tu ZG3.2 Gian 35kV H'MunDocumento40 páginasCatalog Tu ZG3.2 Gian 35kV H'MunHà Văn TiếnAinda não há avaliações

- DLI Watchman®: Vibration Screening Tool BenefitsDocumento2 páginasDLI Watchman®: Vibration Screening Tool Benefitssinner86Ainda não há avaliações

- UBMM1011 Unit Plan 201501Documento12 páginasUBMM1011 Unit Plan 201501摩羯座Ainda não há avaliações

- BA 4722 Marketing Strategy SyllabusDocumento6 páginasBA 4722 Marketing Strategy SyllabusSri GunawanAinda não há avaliações

- 2.1 DRH Literary Translation-An IntroductionDocumento21 páginas2.1 DRH Literary Translation-An IntroductionHassane DarirAinda não há avaliações

- Nse 2Documento5 páginasNse 2dhaval gohelAinda não há avaliações

- Pontevedra 1 Ok Action PlanDocumento5 páginasPontevedra 1 Ok Action PlanGemma Carnecer Mongcal50% (2)

- Rab Sikda Optima 2016Documento20 páginasRab Sikda Optima 2016Julius Chatry UniwalyAinda não há avaliações

- Lifting PermanentmagnetDocumento6 páginasLifting PermanentmagnetShekh Muhsen Uddin Ahmed100% (1)

- P1 Chp12 DifferentiationDocumento56 páginasP1 Chp12 DifferentiationbobAinda não há avaliações

- Key Performance Indicators - KPIsDocumento6 páginasKey Performance Indicators - KPIsRamesh Kumar ManickamAinda não há avaliações

- Cheerios Media KitDocumento9 páginasCheerios Media Kitapi-300473748Ainda não há avaliações

- Lotus Exige Technical InformationDocumento2 páginasLotus Exige Technical InformationDave LeyAinda não há avaliações

- Remedy MidTier Guide 7-5Documento170 páginasRemedy MidTier Guide 7-5martin_wiedmeyerAinda não há avaliações

- Revised Corporation Code - Non Stock Close and Special CorporationsDocumento19 páginasRevised Corporation Code - Non Stock Close and Special CorporationsVenziel PedrosaAinda não há avaliações

- What Are The Advantages and Disadvantages of UsingDocumento4 páginasWhat Are The Advantages and Disadvantages of UsingJofet Mendiola88% (8)

- FKTDocumento32 páginasFKTNeeraj SharmaAinda não há avaliações

- Em FlexicokingDocumento8 páginasEm FlexicokingHenry Saenz0% (1)

- Corporate Tax Planning AY 2020-21 Sem V B.ComH - Naveen MittalDocumento76 páginasCorporate Tax Planning AY 2020-21 Sem V B.ComH - Naveen MittalNidhi LathAinda não há avaliações

- PR Earth Users Guide EMILY1Documento2 páginasPR Earth Users Guide EMILY1Azim AbdoolAinda não há avaliações

- For ClosureDocumento18 páginasFor Closuremau_cajipeAinda não há avaliações

- Flip The Coin - EbookDocumento306 páginasFlip The Coin - EbookAjesh Shah100% (1)

- Cosmic Handbook PreviewDocumento9 páginasCosmic Handbook PreviewnkjkjkjAinda não há avaliações

- Modified Airdrop System Poster - CompressedDocumento1 páginaModified Airdrop System Poster - CompressedThiam HokAinda não há avaliações

- ProjectDocumento33 páginasProjectPiyush PatelAinda não há avaliações