Escolar Documentos

Profissional Documentos

Cultura Documentos

Ns-Es-0250 Cfsi

Enviado por

sekharsamyTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Ns-Es-0250 Cfsi

Enviado por

sekharsamyDireitos autorais:

Formatos disponíveis

Nuclear Services / Engineering Services

Preventing Intrusion of Counterfeit,

Fraudulent and Suspect Items into the

Nuclear Supply Chain

Background

For many years, the nuclear industry

regulators have been concerned about

preventing the intrusion of counterfeit,

fraudulent and suspect items (CFSI) into

the nuclear supply chain. This issue is

not receding, and it is incumbent on all

stakeholders, including suppliers, to stay

current on this evolving issue and to provide

appropriate processes in order to prevent

introduction of CFSI into the nuclear supply

chain.

GL 89-02 puts forth three characteristics of

procurement and dedication programs that are

effective in detecting counterfeit or fraudulently

marked products. The three characteristics are:

1. The involvement of engineering staff in the

procurement and product acceptance process

2. Effective source inspection, receipt inspection

and testing programs

3. Thorough engineering-based programs to

review and test the suitability of commercialgrade products for use in safety-related

applications

Description

Westinghouse processes and initiatives regarding

CFSI are in alignment with pertinent regulatory

guidelines, which include:

yy The 1989 U.S. Nuclear Regulatory Commission

(NRC) Generic Letter (GL) 89-02, Actions

to Improve the Detection of Counterfeit and

Fraudulently Marked Products

yy The 2008 NRC Information Notice 2008-04,

Counterfeit Parts Supplied to Nuclear Power

Plants

yy The 2011 NRC SECY-11-0154, An Agencywide

Approach to Counterfeit, Fraudulent and

Suspect Items

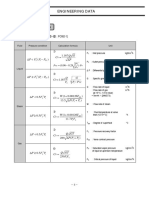

NLP 7300 cards, original (back)

and redesigned (front)

June 2013

NS-ES-0250

2014 Westinghouse Electric Company LLC. All Rights Reserved

Benefits

Processes and Initiatives

Position

Westinghouse implements processes and

initiatives, including those to identify and prevent

nonconformances, increase organizational learning,

and minimize the frequency and severity of events, all

of which help detect and prevent CFSI. Westinghouse

implements business-specific initiatives to detect and

prevent CFSI.

Westinghouse believes that a robust quality assurance

program and processes that address the three

characteristics identified in GL 89-02 are effective

in detecting and preventing CFSI. To this point, the

Westinghouse Quality Management System and lowertier procedures align with the three characteristics

identified in GL 89-02.

The involvement of

engineering staff in the

procurement and product

acceptance process

Effective source inspection,

receipt inspection and

testing programs

Thorough Engineeringbased programs for review,

testing and dedication of

commercial-grade products

for suitability for use in

safety-related applications

Suspect and Counterfeit Items

Supplier Qualification

and Assessment

Procedure for Control

of Purchased Items

and Services

Quality Oversight at

Supplier Facilities

Receipt Inspection

Procedure for

Dedication of

Commercial-grade

Items

Test Control

Certificate of Conformance

Westinghouse Quality Assurance procedures and alignment with GL 89-02

Receipt Inspection

Process

QC Inspector

Training

Empirical testing of

products / material and

use of PMI (positive

material identification)

techniques

Inspectors trained to

identify counterfeit parts

XRF (X-Ray

Fluorescence) analysis

and Sim Scope

Training materials

incorporate guidance

from NRC-SECY-11-0154,

EPRI 1021493 and

EPRI 1019163

Design

Engineering

Knowledge

Detailed design

knowledge by virtue of

Westinghouse OEM

design ownership

Initiatives to detect and prevent CFSI

Você também pode gostar

- Punch List: Guy Wire Support Flare Stack System Piping DetailDocumento1 páginaPunch List: Guy Wire Support Flare Stack System Piping DetailMuhammad SaifAinda não há avaliações

- HAZOP Study MethodologyDocumento5 páginasHAZOP Study MethodologyRonak MotaAinda não há avaliações

- Human Factor and Reliability Analysis to Prevent Losses in Industrial Processes: An Operational Culture PerspectiveNo EverandHuman Factor and Reliability Analysis to Prevent Losses in Industrial Processes: An Operational Culture PerspectiveAinda não há avaliações

- Structured What If Technique A Complete Guide - 2020 EditionNo EverandStructured What If Technique A Complete Guide - 2020 EditionAinda não há avaliações

- CTL Brochure-Storage Tanks & TerminalsDocumento7 páginasCTL Brochure-Storage Tanks & TerminalsSameer BawaAinda não há avaliações

- Qa-Qc Plan For Sharq R-0aDocumento163 páginasQa-Qc Plan For Sharq R-0akbldamAinda não há avaliações

- Materials Handling Chapter 1 and 2Documento9 páginasMaterials Handling Chapter 1 and 2Edel Quinn Madali100% (1)

- PWHT Tech Roles and ResponsibilitiesDocumento2 páginasPWHT Tech Roles and ResponsibilitiesGuna Raj50% (2)

- Risk Based Inspection A Complete Guide - 2020 EditionNo EverandRisk Based Inspection A Complete Guide - 2020 EditionAinda não há avaliações

- CRMS ItpDocumento2 páginasCRMS Itparockiyathass100% (1)

- TPIP ManualDocumento53 páginasTPIP ManualMurugananthamParamasivamAinda não há avaliações

- Process Safety: Are There Proven Tools For ATEX Risk Assessment?Documento1 páginaProcess Safety: Are There Proven Tools For ATEX Risk Assessment?SARFRAZ ALIAinda não há avaliações

- EIA Complaints and AppealsDocumento19 páginasEIA Complaints and AppealscankawaabAinda não há avaliações

- MP Information Sheet - Planned Maint.Documento2 páginasMP Information Sheet - Planned Maint.joydeepAinda não há avaliações

- Blanking and Blinding PracticeDocumento8 páginasBlanking and Blinding PracticeBabyface888100% (1)

- ADOR Booklet F Web FDocumento132 páginasADOR Booklet F Web FbadesharamkAinda não há avaliações

- CVMCDocumento4 páginasCVMCAzhar HussainAinda não há avaliações

- Client: BMT India Document: Terms of References For Quantitative Risk Assessment StudyDocumento10 páginasClient: BMT India Document: Terms of References For Quantitative Risk Assessment StudyAnurag BholeAinda não há avaliações

- Hazardous Liquid Pipelines: ABC Company ABC Chemical Complex Engineering SpecificationDocumento47 páginasHazardous Liquid Pipelines: ABC Company ABC Chemical Complex Engineering Specificationanac_math100% (1)

- Unit I Algorithmic Problem Solving 9Documento21 páginasUnit I Algorithmic Problem Solving 9Mars KokilaAinda não há avaliações

- Pre-Commissioning and Commissioning Manual: Mellitah Oil & Gas BVDocumento13 páginasPre-Commissioning and Commissioning Manual: Mellitah Oil & Gas BVThirukkumaranBalasubramanianAinda não há avaliações

- Hazid RecordDocumento21 páginasHazid Recordavanish.vAinda não há avaliações

- ISO 18001 - Process Safety IndicatorsDocumento22 páginasISO 18001 - Process Safety IndicatorsStephen Groves100% (1)

- BGAS-CSWIP Log Book & Stamp (Overseas)Documento1 páginaBGAS-CSWIP Log Book & Stamp (Overseas)hahah100% (2)

- Jacking Procedurefor Construction of Tanks OLDDocumento10 páginasJacking Procedurefor Construction of Tanks OLDVikram RangasamyAinda não há avaliações

- ADL 16 Total Quality Management V4ADocumento8 páginasADL 16 Total Quality Management V4Asolvedcare0% (2)

- 7100 XXXX HDPEDocumento2 páginas7100 XXXX HDPEIgor IvanovskiAinda não há avaliações

- 8.5.5 Post Delivery ActivitiesDocumento2 páginas8.5.5 Post Delivery ActivitiesMaricris Napigkit Serrano100% (1)

- MGT613 Online Quiz 1 Lecture 1to13Documento31 páginasMGT613 Online Quiz 1 Lecture 1to13khalidhussaincheemaAinda não há avaliações

- MOG-HSEQ-P-005 Rev A3 Corporate HSE Training Awarness and Competence ProcedureDocumento18 páginasMOG-HSEQ-P-005 Rev A3 Corporate HSE Training Awarness and Competence ProcedureSamerAinda não há avaliações

- ML 07 WeldingDocumento11 páginasML 07 WeldingDeepakAinda não há avaliações

- EACOP - Resettlement Policy Framework PDFDocumento214 páginasEACOP - Resettlement Policy Framework PDFrahul nagareAinda não há avaliações

- M2007-005 TranskorMTM TBv2011 012412Documento2 páginasM2007-005 TranskorMTM TBv2011 012412daniel_silabanAinda não há avaliações

- Safety Training Presentations: Process Safety Management of Highly Hazardous Chemicals 29 CFR 1910.119 (PSM) EH&S 3-13Documento22 páginasSafety Training Presentations: Process Safety Management of Highly Hazardous Chemicals 29 CFR 1910.119 (PSM) EH&S 3-13Billel Hichem HitacheAinda não há avaliações

- 0301e - Guidebook For Inspectors - 2018-3Documento6 páginas0301e - Guidebook For Inspectors - 2018-3FranciscoAinda não há avaliações

- TPS QA KA AA 001 (C01) Welding Tank ProcedureDocumento10 páginasTPS QA KA AA 001 (C01) Welding Tank ProcedureTouil HoussemAinda não há avaliações

- Written Schemes of Examinations Example Template - Course DownloadDocumento9 páginasWritten Schemes of Examinations Example Template - Course Downloadgamil2Ainda não há avaliações

- Risk Based Inspection Best Practice-The Technical Specification Ron Selva PP Simtech Keynote Paper-1 13th Icpvt 2012 LondonDocumento20 páginasRisk Based Inspection Best Practice-The Technical Specification Ron Selva PP Simtech Keynote Paper-1 13th Icpvt 2012 LondonRichard KoehlerAinda não há avaliações

- QM-QA-QC Basic Infos, LinksDocumento8 páginasQM-QA-QC Basic Infos, LinksbehringerzsoltAinda não há avaliações

- Consultancy in Mechanical Integrity RBI, RCM, FFS, NDT & Vibration Analysis Services Training Based On API ASME and Other StandardsDocumento6 páginasConsultancy in Mechanical Integrity RBI, RCM, FFS, NDT & Vibration Analysis Services Training Based On API ASME and Other StandardsShahbaz KhanAinda não há avaliações

- Structural Integrity ManagementDocumento22 páginasStructural Integrity Managementonnly1964100% (1)

- Sa 6717Documento1 páginaSa 6717biplabpal2009Ainda não há avaliações

- Saudi Aramco Inspection Checklist: Manhole Receiving, Handling, Storage and Preservation SAIC-S-4001 30-Apr-13 PlumbDocumento1 páginaSaudi Aramco Inspection Checklist: Manhole Receiving, Handling, Storage and Preservation SAIC-S-4001 30-Apr-13 Plumbbiplabpal2009Ainda não há avaliações

- Scale of Professional ChargesDocumento26 páginasScale of Professional Chargesfazal1988Ainda não há avaliações

- How To Cost Load A ScheduleDocumento3 páginasHow To Cost Load A ScheduleInaam Ullah MughalAinda não há avaliações

- Unit Gas Leak ChecklistDocumento1 páginaUnit Gas Leak Checklistfathul syaafAinda não há avaliações

- Switch GearDocumento7 páginasSwitch GearpanduranganraghuramaAinda não há avaliações

- Intro To DMAICDocumento40 páginasIntro To DMAICsamfisher8989Ainda não há avaliações

- PSBR 1 TemplateDocumento2 páginasPSBR 1 TemplatesathishAinda não há avaliações

- Foam Hose Reel Testing ProcedureDocumento26 páginasFoam Hose Reel Testing ProcedureVijil JohnrajAinda não há avaliações

- Inspection DocumentDocumento3 páginasInspection DocumentNaiyer KarimiAinda não há avaliações

- 1godwin A. Udoakan CV.Documento7 páginas1godwin A. Udoakan CV.Godwin A.udo-akanAinda não há avaliações

- FM200 KiddeDocumento37 páginasFM200 KiddeNguyen Van TuanAinda não há avaliações

- DNV Certification: Customer CommunicationsDocumento4 páginasDNV Certification: Customer Communicationsindika_kumara70Ainda não há avaliações

- 23 Tecnimont ChiaruttiniDocumento16 páginas23 Tecnimont ChiaruttiniRsn786Ainda não há avaliações

- Methodology Tapping Methodology of WaterlineDocumento15 páginasMethodology Tapping Methodology of WaterlineBryAinda não há avaliações

- Esmat CVDocumento8 páginasEsmat CVعصمت ضيف اللهAinda não há avaliações

- Simón and Gosson-Quality Control Reporting RequirementsDocumento3 páginasSimón and Gosson-Quality Control Reporting RequirementsJacqueline Andrea Orias CarrascoAinda não há avaliações

- JT AssignmentDocumento13 páginasJT AssignmentDarshanAinda não há avaliações

- Flow of Fluids - Morris PDFDocumento62 páginasFlow of Fluids - Morris PDFsekharsamyAinda não há avaliações

- Pure Nickel Special, Nuclear Grade: Never SeezDocumento2 páginasPure Nickel Special, Nuclear Grade: Never SeezsekharsamyAinda não há avaliações

- 10 CFR 50.59 ExampleDocumento40 páginas10 CFR 50.59 Examplesekharsamy100% (1)

- Mathematical Modelling Numerical Investigations Coanda EffectDocumento32 páginasMathematical Modelling Numerical Investigations Coanda EffectsekharsamyAinda não há avaliações

- Thermal Stresses GatewoodDocumento248 páginasThermal Stresses Gatewoodsekharsamy100% (2)

- Stresstel Fasteners PDFDocumento46 páginasStresstel Fasteners PDFsekharsamyAinda não há avaliações

- Adiabatic Compression of OxygenDocumento242 páginasAdiabatic Compression of OxygensekharsamyAinda não há avaliações

- Screws Thread Forces DerivationDocumento3 páginasScrews Thread Forces DerivationsekharsamyAinda não há avaliações

- Calculations of Real-Gas Effects in NozzlesDocumento9 páginasCalculations of Real-Gas Effects in NozzlessekharsamyAinda não há avaliações

- Compressible Flow at High Pressure With Linear Equation of StateDocumento63 páginasCompressible Flow at High Pressure With Linear Equation of StatesekharsamyAinda não há avaliações

- Steamtab ManualDocumento44 páginasSteamtab Manualali_kntuAinda não há avaliações

- Shell To Head Stress ConcentrationDocumento1 páginaShell To Head Stress ConcentrationsekharsamyAinda não há avaliações

- Differentiating Under The Integral SignDocumento23 páginasDifferentiating Under The Integral SignsekharsamyAinda não há avaliações

- Flow AnalysisDocumento99 páginasFlow AnalysissekharsamyAinda não há avaliações

- Peruvian Aji Sauce: Time - Serves 10Documento1 páginaPeruvian Aji Sauce: Time - Serves 10sekharsamyAinda não há avaliações

- Control Valve Flow Theory-DeFillippis-1974Documento22 páginasControl Valve Flow Theory-DeFillippis-1974sekharsamyAinda não há avaliações

- PDF Upload Commentsonallowablestresses Jun04Documento2 páginasPDF Upload Commentsonallowablestresses Jun04Fahmi AliAinda não há avaliações

- The Rigidity of Rib-Reinforced Cover PlatesDocumento13 páginasThe Rigidity of Rib-Reinforced Cover PlatessekharsamyAinda não há avaliações

- Development and Testing of Vortex GeneratorsDocumento45 páginasDevelopment and Testing of Vortex GeneratorssekharsamyAinda não há avaliações

- Thread CalculationsDocumento2 páginasThread CalculationsilyaskureshiAinda não há avaliações

- Geometry Flashcards PDFDocumento59 páginasGeometry Flashcards PDFsekharsamyAinda não há avaliações

- Thermo MathDocumento8 páginasThermo MathskluxAinda não há avaliações

- Development of A Multi-Stage Choke Valve SizingDocumento221 páginasDevelopment of A Multi-Stage Choke Valve SizingsekharsamyAinda não há avaliações

- Optimum Design of Wind Tunnel Contractions MikhailDocumento7 páginasOptimum Design of Wind Tunnel Contractions MikhailsekharsamyAinda não há avaliações

- Bolting Force Analysis RelaxationDocumento160 páginasBolting Force Analysis RelaxationsekharsamyAinda não há avaliações

- Manifold-To-Orifice Turning Angle On Sharp-Edge Orifice Flow CavitationDocumento21 páginasManifold-To-Orifice Turning Angle On Sharp-Edge Orifice Flow CavitationsekharsamyAinda não há avaliações

- Lecture No7 Pipeline SystemsDocumento4 páginasLecture No7 Pipeline SystemsMuhammadUsmanAinda não há avaliações

- MIR - LML - Markushevich A. I. - Complex Numbers and Conformal MappingsDocumento68 páginasMIR - LML - Markushevich A. I. - Complex Numbers and Conformal Mappingsavast2008100% (3)

- Development of A Multi-Stage Choke Valve SizingDocumento221 páginasDevelopment of A Multi-Stage Choke Valve SizingsekharsamyAinda não há avaliações

- Calculation of Natural Gas Isentropic ExponentDocumento8 páginasCalculation of Natural Gas Isentropic ExponentsekharsamyAinda não há avaliações

- Dakshin Dinajpur TP ListDocumento5 páginasDakshin Dinajpur TP ListDeb D Creative StudioAinda não há avaliações

- PTS Controller: Over Fuel Dispensers and ATG Systems For Petrol StationsDocumento161 páginasPTS Controller: Over Fuel Dispensers and ATG Systems For Petrol StationsdawitAinda não há avaliações

- Simulation & Role PlayDocumento10 páginasSimulation & Role Playpreeti sharma100% (2)

- The Complete MARILLION Discography V2 PDFDocumento13 páginasThe Complete MARILLION Discography V2 PDFtotalmenteprovisorioAinda não há avaliações

- Service and Technology Marketing Service and Technology MarketingDocumento27 páginasService and Technology Marketing Service and Technology MarketingVinudeep MalalurAinda não há avaliações

- STIGA - Vue Eclatée Moteur BRIGGS & STRATTONDocumento32 páginasSTIGA - Vue Eclatée Moteur BRIGGS & STRATTONregis.petitjeanAinda não há avaliações

- Intro To RMAN-10g-okDocumento41 páginasIntro To RMAN-10g-okAnbao ChengAinda não há avaliações

- CATEGORY - Green (III) Consent To EstablishDocumento4 páginasCATEGORY - Green (III) Consent To EstablishROOPDIP MUKHOPADHYAYAinda não há avaliações

- Intellectual Property Rights: Indian PerspectiveDocumento20 páginasIntellectual Property Rights: Indian PerspectiveFateh Singh RawatAinda não há avaliações

- Dystopian LiteratureDocumento3 páginasDystopian LiteratureLol LeeAinda não há avaliações

- Report - Roche Pharmaceuticals LTD (Human Resource Planning & Development) 222Documento23 páginasReport - Roche Pharmaceuticals LTD (Human Resource Planning & Development) 222jawwadraja100% (1)

- AIMS Manual - 2021Documento82 páginasAIMS Manual - 2021Randyll TarlyAinda não há avaliações

- Overseas Assignment 18thseptDocumento6 páginasOverseas Assignment 18thseptSuresh VanierAinda não há avaliações

- Student Camps 2022 - Grade 6 Science Curriculum Based Test BookletDocumento58 páginasStudent Camps 2022 - Grade 6 Science Curriculum Based Test Bookletthank you GodAinda não há avaliações

- Engineering Data: 2. CV CalculationDocumento1 páginaEngineering Data: 2. CV Calculationdj22500Ainda não há avaliações

- Lawn-Boy Service Manual 1950-88 CompleteDocumento639 páginasLawn-Boy Service Manual 1950-88 Completemasterviking83% (35)

- Laws of ThermoDocumento13 páginasLaws of ThermofabyunaaaAinda não há avaliações

- Lab Manual 10: Z-Transform and Inverse Z-Transform Analysis ObjectiveDocumento7 páginasLab Manual 10: Z-Transform and Inverse Z-Transform Analysis ObjectiveSyed Waqas ShahAinda não há avaliações

- HTTPHeader LiveDocumento199 páginasHTTPHeader LiveDenys BautistaAinda não há avaliações

- CP2405 Assignment 1 Ontology DesignDocumento8 páginasCP2405 Assignment 1 Ontology DesignFredrick Oduor OmondiAinda não há avaliações

- Important Questions - BlockchainDocumento1 páginaImportant Questions - BlockchainHarsh Varshney100% (1)

- 2020 Sec 4 E Math SA2 Anderson Secondary-pages-DeletedDocumento41 páginas2020 Sec 4 E Math SA2 Anderson Secondary-pages-Deletedregi naAinda não há avaliações

- GNDU Contract Jobs 2013 Advertisement PDFDocumento8 páginasGNDU Contract Jobs 2013 Advertisement PDFAnonymous zwCV8ZAinda não há avaliações

- Surge CounterDocumento2 páginasSurge CounterJavier CuzcoAinda não há avaliações

- Lister Hr3 ManualDocumento119 páginasLister Hr3 ManualRichard Gomez Cueva100% (2)

- Future Christchurch: Solutions. Housing: Biran HeDocumento108 páginasFuture Christchurch: Solutions. Housing: Biran HecamiayoungAinda não há avaliações

- Centennial Tower Promotion 1Documento10 páginasCentennial Tower Promotion 1madeAinda não há avaliações

- Advanced Numerical Modelling of Geogrids and Steel Wire Meshes - Daniele TubertiniDocumento94 páginasAdvanced Numerical Modelling of Geogrids and Steel Wire Meshes - Daniele TubertiniSze Mian KuehAinda não há avaliações

- Research TopicsDocumento15 páginasResearch TopicsmalinksAinda não há avaliações

- Antennas and Wave Propagation - Nov - 2015Documento8 páginasAntennas and Wave Propagation - Nov - 2015Jyothi SamanthulaAinda não há avaliações