Escolar Documentos

Profissional Documentos

Cultura Documentos

Bullheading Well Control Method

Enviado por

ivan villabona0 notas0% acharam este documento útil (0 voto)

347 visualizações3 páginascementacion forzada

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

DOCX, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentocementacion forzada

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOCX, PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

347 visualizações3 páginasBullheading Well Control Method

Enviado por

ivan villabonacementacion forzada

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOCX, PDF, TXT ou leia online no Scribd

Você está na página 1de 3

Bullheading Well Control Method

by D RI LLI NG FO R MUL AS .C O M on JUNE 22, 2014

Bullheading is one of the well control methods which may be utilized

in some occasions in order to control the well. Concept of bullheading

is to pump kicks back into formations by using kill weight fluid. People

usually use this method when normal circulation is impossible and

volumetric method is not feasible to perform.

When May You Consider Using the Bullheading

Well Control Method?

When the kick size is very big so you may not be able to control

the excessive volume coming to the surface.

When you need to reduce surface pressure in order to start

further well control operations.

When there is a possibility to exceed surface pressure and

volume gas on the surface if the conventional methods (drillers

method, wait and weight and volumetric) are performed.

When there is no pipe in the hole while taking influx.

The influx contains high level of H2S which can cause safety of

personnel on the rig.

When there is no feasible way to strip back to the bottom in order

to kill in the flux below.

For every drilling operation, decision to perform bullheading must be

discussed because if the well is shut in and wait for a long time before

making decision to bullhead the well, it might be very difficult to perform

because the surface pressure at that time may increase so high due to

gas migration. The chance of pushing the kick back into reservoir

becomes smaller.

Note: Bullheading may or may not fracture formations.

There are some factors affecting the feasibility of

bullheading as listed below;

Reservoir permeability pumping fluid back into low permeability

reservoir takes longer time than pumping into high permeability zone. It

might require breaking the formation in order to successfully

bullheading the well.

Surface pressure rating rating of surface equipment as BOP,

wellhead, casing, etc will limit the maximum allowable pumping

pressure.

Type of influx Gas influx will migrate and it will increase surface

pressure, however, liquid influx (oil or water) will not cause increasing

in surface pressure because it will not migrate.

Procedure of Bullheading (Example)

This procedure below will give you only overview of how to perform

bullheading therefore you must need to add the site specific

information before conducting the actual work.

1.

2.

3.

4.

5.

6.

Determine surface pressure limitation of surface equipment.

Calculate surface pressure which will fracture formation during

bullheading operation.

Prepare a bullheading pressure chart representing strokes

pumped vs pumping pressure.

Ensure correct line up.

Bring the pump to speed at low rate to overcome surface

pressure.

Slowly increase pump rate to the planned pump rate.

7.

Closely monitor tubing, casing pressure to ensure that pressures

will not exceed the equipment limitation at any stage of operation.

8.

Slow down pump rate when the kill fluid close to reservoir. You

will see surface pressure decrease over time while pumping kill mud

into the well because the kill weight mud will increase hydrostatic

pressure.

9.

Observed pressure increase when the kill weight fluid is pushed

into formation.

10. Shut the pump down and shut in the well.

11. Monitor pressure. Bleed trapped pressure if required.

We wish you would get more understanding about the bullheading well

control. Additionally, we will demonstrate some calculations related to

this topic. Please feel free to leave any comments.

Você também pode gostar

- Well Control FdreDocumento27 páginasWell Control FdreKhairi OmarAinda não há avaliações

- StrippingDocumento17 páginasStrippingGhavban David0% (1)

- Hydra-Jar AP Double-Acting Hydraulic Drilling Jar: Jarring DownDocumento4 páginasHydra-Jar AP Double-Acting Hydraulic Drilling Jar: Jarring DownpendexxAinda não há avaliações

- Well Control EquationsDocumento13 páginasWell Control EquationsShaho Abdulqader Mohamedali100% (1)

- Note On Kick ToleranceDocumento4 páginasNote On Kick TolerancePrasad100% (1)

- 2003 SPE/IADC Drilling ConferenceDocumento66 páginas2003 SPE/IADC Drilling Conferenceadityamdutta0% (1)

- Well CompletionDocumento82 páginasWell CompletionFlorian Ananias ByarugabaAinda não há avaliações

- 19 Well ControlDocumento133 páginas19 Well ControlAvazdordi SadriAinda não há avaliações

- 03 Shut-In ProcedureDocumento15 páginas03 Shut-In Proceduresitemaster60Ainda não há avaliações

- Land Rig INTEGRATED PERFORMANCE TEST PROCEDUREDocumento38 páginasLand Rig INTEGRATED PERFORMANCE TEST PROCEDUREAboozar FathinejadAinda não há avaliações

- Stripping OperationsDocumento4 páginasStripping Operationshosam aliAinda não há avaliações

- Using Hi-Vis Sweep To Clean Hole While DrillingDocumento5 páginasUsing Hi-Vis Sweep To Clean Hole While DrillingSAMIRAinda não há avaliações

- Surface BOP Stack Operations SI - Vertical Well Kill SheetDocumento0 páginaSurface BOP Stack Operations SI - Vertical Well Kill Sheetjosesito_amoroso2005Ainda não há avaliações

- Wait and Weight MethodDocumento2 páginasWait and Weight MethodMubin Ashraf Sheikh100% (1)

- DAY 6 - Loss Circulation & Stuck Pipe Sharing SessionDocumento27 páginasDAY 6 - Loss Circulation & Stuck Pipe Sharing SessionReza Syahputra MulyanaAinda não há avaliações

- 01-Section 02 Drilling Fluids Functions PDFDocumento11 páginas01-Section 02 Drilling Fluids Functions PDFLazharAinda não há avaliações

- Annular Velocity TheoryDocumento2 páginasAnnular Velocity TheoryMohitTagotraAinda não há avaliações

- Overpressure Mod-2Documento72 páginasOverpressure Mod-2Antonio Jose da CostaAinda não há avaliações

- Dual Gradient DrillingDocumento72 páginasDual Gradient DrillingJosue FishAinda não há avaliações

- Tech/drilling/Casing Design ExDocumento43 páginasTech/drilling/Casing Design ExSohaib RashidAinda não há avaliações

- Microsoft Word - Exercise 1Documento27 páginasMicrosoft Word - Exercise 1KRAinda não há avaliações

- Helical Buckling of Coiled Tubing in Directional Oil Wellbores 2009Documento1 páginaHelical Buckling of Coiled Tubing in Directional Oil Wellbores 2009SIMULIACorpAinda não há avaliações

- Drilling FluidsDocumento19 páginasDrilling FluidsBenjamin HaganAinda não há avaliações

- 1.10 Abnormal PressureDocumento48 páginas1.10 Abnormal PressurezemabderAinda não há avaliações

- Relief Well Planning ChecklistDocumento9 páginasRelief Well Planning Checklistbyed100% (2)

- Guidelines For Volumetric Stripping Rev.1 Feb.2004Documento27 páginasGuidelines For Volumetric Stripping Rev.1 Feb.2004Yuri KostAinda não há avaliações

- Drilling 1 AutoRecoveredDocumento52 páginasDrilling 1 AutoRecoveredKhaled AdelAinda não há avaliações

- Drilling With Casing Promises Major BenefitsDocumento12 páginasDrilling With Casing Promises Major BenefitsRaul Alberto Miranda LoayzaAinda não há avaliações

- Smith Rotating Control DevicesDocumento8 páginasSmith Rotating Control DevicesDon BraithwaiteAinda não há avaliações

- Spe 196232 MSDocumento18 páginasSpe 196232 MShijoetigreAinda não há avaliações

- Drilling EngineeringDocumento167 páginasDrilling EngineeringLudovic NietzscheAinda não há avaliações

- Top Squeeze or Top FillDocumento5 páginasTop Squeeze or Top Filldrilling moneytreeAinda não há avaliações

- Side TrackDocumento121 páginasSide TrackSlesh S. Campero AramayoAinda não há avaliações

- Job Description - Drilling AssistantDocumento1 páginaJob Description - Drilling AssistantYougchu LuanAinda não há avaliações

- 00087167Documento11 páginas00087167JohnSmith100% (1)

- Fundamentals and Applications of Bionic Drilling FluidsNo EverandFundamentals and Applications of Bionic Drilling FluidsAinda não há avaliações

- Drilling Fluid QuestionsDocumento2 páginasDrilling Fluid QuestionsMunsef AL-juroshyAinda não há avaliações

- Quiz AITDocumento4 páginasQuiz AITazizsarshoghAinda não há avaliações

- Rig Stuck Pipe Assessment FormDocumento13 páginasRig Stuck Pipe Assessment FormBalkis FatihaAinda não há avaliações

- Rules of Thumb To Improve High-Angle Hole CleaningDocumento29 páginasRules of Thumb To Improve High-Angle Hole CleaningjalalAinda não há avaliações

- Applied Gaseous Fluid Drilling Engineering: Design and Field Case StudiesNo EverandApplied Gaseous Fluid Drilling Engineering: Design and Field Case StudiesAinda não há avaliações

- Formation Integrity TestDocumento1 páginaFormation Integrity Testfad003100% (1)

- Drilling Problems - 1Documento85 páginasDrilling Problems - 1Mohab Ayman0% (1)

- Shallow Gas SummaryDocumento4 páginasShallow Gas SummaryHerbertLansinkAinda não há avaliações

- Kicks IndicatorsDocumento17 páginasKicks IndicatorsGhavban DavidAinda não há avaliações

- Accumulator Sizing - SLBDocumento9 páginasAccumulator Sizing - SLBemmanuelAinda não há avaliações

- Drilling FLUIDDocumento6 páginasDrilling FLUIDsrikantaLeeAinda não há avaliações

- Well ControlDocumento5 páginasWell ControlMostafa IbrahimAinda não há avaliações

- Abnormal PressureDocumento65 páginasAbnormal PressureNana Silvana AgustiniAinda não há avaliações

- Management of Lost CirculationDocumento8 páginasManagement of Lost CirculationKolawole AdisaAinda não há avaliações

- Mud Gas Separator Poor Boy DegasserDocumento3 páginasMud Gas Separator Poor Boy DegasserZain Ul AbdeenAinda não há avaliações

- Shale ShakerDocumento3 páginasShale ShakerkosunlucyAinda não há avaliações

- Drilling Fluids Additives Catalog 2020 (Updated)Documento47 páginasDrilling Fluids Additives Catalog 2020 (Updated)melvinkuriAinda não há avaliações

- Kick Handling Losses HPHT EnvironmentDocumento4 páginasKick Handling Losses HPHT EnvironmentrajkumarfAinda não há avaliações

- Managed Pressure Drilling Modeling & Simulation (A Case Study)Documento8 páginasManaged Pressure Drilling Modeling & Simulation (A Case Study)Mejbahul SarkerAinda não há avaliações

- Pre Recorded Imformation: Davis Family 1-42Documento10 páginasPre Recorded Imformation: Davis Family 1-42scrbdgharaviAinda não há avaliações

- Dynamic Low Choke High Quality PDFDocumento4 páginasDynamic Low Choke High Quality PDFWCGAinda não há avaliações

- Bullheading Calculation ExampleDocumento9 páginasBullheading Calculation Exampleivan villabonaAinda não há avaliações

- 12 Drilling PreventersDocumento82 páginas12 Drilling PreventersDavid Kusuma100% (1)

- With Eng. Ayman Rashad, WSL Eng. Ahmed Hamdy, NWSLDocumento84 páginasWith Eng. Ayman Rashad, WSL Eng. Ahmed Hamdy, NWSLivan villabonaAinda não há avaliações

- Workover Operations and Well Intervention PDFDocumento52 páginasWorkover Operations and Well Intervention PDFShashidhar KasturiAinda não há avaliações

- Workover Operations and Well Intervention PDFDocumento52 páginasWorkover Operations and Well Intervention PDFShashidhar KasturiAinda não há avaliações

- Simulador Well ControlDocumento8 páginasSimulador Well Controlivan villabonaAinda não há avaliações

- Packers Bridge PlugsDocumento119 páginasPackers Bridge Plugsivan villabonaAinda não há avaliações

- Well Control MethodsDocumento4 páginasWell Control MethodsVassilios KelessidisAinda não há avaliações

- Well Control MethodsDocumento4 páginasWell Control MethodsVassilios KelessidisAinda não há avaliações

- Formulation and Evaluation of Vilazodone Sublingual Tablets by Using Lyophilization TechniqueDocumento9 páginasFormulation and Evaluation of Vilazodone Sublingual Tablets by Using Lyophilization Techniquealamia pharmAinda não há avaliações

- The Slope of A PH SensorDocumento17 páginasThe Slope of A PH SensorMehdi SalariradAinda não há avaliações

- Biofoam: Dosage Rate Application InformationDocumento2 páginasBiofoam: Dosage Rate Application InformationDhilAinda não há avaliações

- Isolation of Caffeine From A Tea BagDocumento7 páginasIsolation of Caffeine From A Tea BagShahriman Radzi67% (6)

- Instrumentation & Process ControlDocumento51 páginasInstrumentation & Process ControlChiến Phan Công100% (1)

- Safety Analysis For The Production of MethanolDocumento14 páginasSafety Analysis For The Production of MethanolTauseef Aamere RoseAinda não há avaliações

- (SSOP) : Sanitation Standard Operating ProcedureDocumento6 páginas(SSOP) : Sanitation Standard Operating ProcedureAsrel05100% (1)

- Centigrade Fahrenheit Equivalent Cone Heated at 150C/hr Visual Colour NotesDocumento1 páginaCentigrade Fahrenheit Equivalent Cone Heated at 150C/hr Visual Colour NotesGogu7778 Gogu7778Ainda não há avaliações

- Making Potentiostatic and Potentiodynamic Anodic Polarization MeasurementsDocumento13 páginasMaking Potentiostatic and Potentiodynamic Anodic Polarization MeasurementsPaty ChiluisaAinda não há avaliações

- Exceed™ XP 8358 Series: Performance PolymerDocumento2 páginasExceed™ XP 8358 Series: Performance PolymerMaram YasserAinda não há avaliações

- Pre Combustion CaptureDocumento3 páginasPre Combustion CaptureArooshbabu BabuAinda não há avaliações

- Sadhu Forging Limite1 - 2Documento4 páginasSadhu Forging Limite1 - 2Priya KaleAinda não há avaliações

- Compressor AM2Documento3 páginasCompressor AM2Hendra KurniawanAinda não há avaliações

- SorptionDocumento44 páginasSorptionluckyprimeAinda não há avaliações

- Keep 512Documento17 páginasKeep 512rajaijahAinda não há avaliações

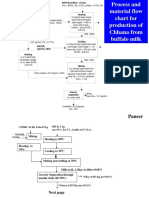

- Process Flow Chart Dairy ProductsDocumento5 páginasProcess Flow Chart Dairy Productslokesh jainAinda não há avaliações

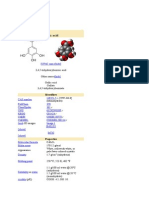

- Gallic AcidDocumento28 páginasGallic AcidDolih GozaliAinda não há avaliações

- Conductivity of Ionic SolutionsDocumento3 páginasConductivity of Ionic SolutionsCristina AreolaAinda não há avaliações

- DDFC Boiler Effeciency AnalysisDocumento21 páginasDDFC Boiler Effeciency AnalysisPublic DemandAinda não há avaliações

- Shrimp: In: Use of Sodium Metabisulfite, AlternativesDocumento3 páginasShrimp: In: Use of Sodium Metabisulfite, Alternativesvalerie rosalind angkawidjajaAinda não há avaliações

- Bahareh Tavakoli - A Review of Preparation Methods For Supported Metal CatalystsDocumento37 páginasBahareh Tavakoli - A Review of Preparation Methods For Supported Metal CatalystsAarón NavarreteAinda não há avaliações

- Chemical Engineering CommunicationsDocumento16 páginasChemical Engineering CommunicationsMichelle Quilaqueo NovoaAinda não há avaliações

- ASTM A674 - Polyethylene Encasement For Ductile Iron Pipe For Water or Other Liquids PDFDocumento7 páginasASTM A674 - Polyethylene Encasement For Ductile Iron Pipe For Water or Other Liquids PDFApolos CastAinda não há avaliações

- Pasteurisation Process Objectives: CFB31103 Food Process Engineering Laboratory 4: Thermal ProcessingDocumento3 páginasPasteurisation Process Objectives: CFB31103 Food Process Engineering Laboratory 4: Thermal Processingnurul nabilah bt khairul anuarAinda não há avaliações

- 2022 - Hyd 443 - 1Documento201 páginas2022 - Hyd 443 - 1api-620585842Ainda não há avaliações

- High Quality Line Fi Lter Elements For All Your Fi Ltration NeedsDocumento2 páginasHigh Quality Line Fi Lter Elements For All Your Fi Ltration NeedsNuc LeusAinda não há avaliações

- Petronas Samur PL PDFDocumento38 páginasPetronas Samur PL PDFJessica Ward100% (1)

- Oxygen Content Using A 14-Mev Neutron Activation and Direct-Counting TechniqueDocumento8 páginasOxygen Content Using A 14-Mev Neutron Activation and Direct-Counting Techniqueruben carcamoAinda não há avaliações

- CPP & Cqa PDFDocumento71 páginasCPP & Cqa PDFanon_695264516100% (1)

- (Alan R. Katritzky, Otto Meth-Cohn, and Charles W.Documento1.287 páginas(Alan R. Katritzky, Otto Meth-Cohn, and Charles W.Ganesh KashinathAinda não há avaliações