Escolar Documentos

Profissional Documentos

Cultura Documentos

24-01 Pij

Enviado por

betanzos5000-2Descrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

24-01 Pij

Enviado por

betanzos5000-2Direitos autorais:

Formatos disponíveis

Oil States Industries,

HydroTech Division

GPS-24-01

General Product Specification for

Pipe Insulating Joint (PIJ)

1

0

A

Revision

Issue for Use

Issue for Review and Comment

28-July-98

01-May-97

22-Apr-98

GRD

GRD

JEG

ODT

ODT

JEG

LAD

LAD

JEG

Rev

Origination ( 0 ) Revision ( )

Date

Prepared

Reviewed

Approved

Oil States Industries,

HydroTech Division

Date: 28-July-98

Pipe Insulating Joint

GSP-24-01

Rev: 1

Page 2 of 5

ON O

General Product Specification, GPS-24-01, defines the specifications for

HydroTech systems standard Pipe Insulating Joints. Pipe Insulating Joints

with alternate requirements can be designed and manufactured but are

outside the scope of this document, although this Specification may be

referenced in part.

1. GENERAL DESCRIPTION

A Pipe Insulating Joint (PIJ), illustrated in Figure 1, is a high resistance

monolithic or monoblock fitting used to electrically isolate sections of a

pipeline. The primary purpose of electrical isolation is to improve the

effectiveness of cathodic protection systems and to reduce ground loop

currents. Unlike insulating flanges or flange kits which are usually field

assembled and tested, the PIJ is factory assembled, electrical tested at five

different stages of manufacturing and hydrostatically tested. The PIJ is

provided with Extension Nipples, matching the pipeline wall and grade, of

sufficient length to eliminate any possibility of thermal damage to the

Fitting during field welding.

The monolithic design of the PIJ results in a pipe fitting having high cyclic

bending strength integrity. This aspect is particularly important for

offshore pipeline riser applications where cyclic loading is common. The

integrity of the PIJ is further enhanced by the use of high temperature

fluorocarbon (Viton) seals and insulation of high pressure glass filled

structural epoxy laminate. The clean monolithic profile will not trap

moisture and reduces the possibility of crevice corrosion. This is an

additional advantage of the monolithic design over conventional insulating

flanges in offshore pipeline applications.

HydroTech Systems maintains an inventory of Pipe Insulating Joints up to

900 ANSI ratings in nominal sizes from 4 inch to 8 inch with schedule 80

bores and API 5L Grade B pipe Extension Nipples. Pipe Insulating Joints

can be designed and manufactured for any size pipeline.

2. DESIGN REQUIREMENTS

Pipe Insulating Joints designed to this General Product Specification are in

accordance with the ASME Pressure Vessel Code, Section VIII, Division 1,

unless another recognized code is specified by the purchaser. A PIJ is

designed to be at least as strong as a comparable rated pipeline when

subjected to external loads.

Oil States Industries,

HydroTech Division

Date: 28-July-98

Pipe Insulating Joint

GSP-24-01

Rev: 1

Page 3 of 5

ON O

The electrical resistance, leakage current and breakdown voltage is a

function of the insulating material, insulator thickness and capacitance.

The electrical resistance of the PIJ is at least 40 megohms with 1000 VDC

applied potential and the maximum leakage current, with 2500 VAC (60

Hz) applied potential, is 5 mA. The dielectric strength (breakdown voltage)

of the PIJ is designed to be in excess of 20,000 volts.

3. MATERIALS AND COATINGS

Standard materials for Pipe Insulating Joints are tabulated below along

with the appropriate HydroTech Material Specification (HMS). The

appropriate standard material for a particular PIJ End Flange, Retainer

Flange and Hub is based on the matching pipeline material grade. The PIJ

Assembly is externally protected by three coats of high build epoxy per

HydroTech Coating Specification, HCS-4. Bare internal surfaces and buttweld preparations are coated with a temporary rust preventive per HCS-6.

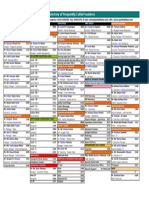

Component

End Flange

Hub

Retainer Flange

Material

ASTM

A105

(HMS-1)

matching pipe grades up to

including API 5L-X42

ASTM A694 Gr F46 or Gr

(HMS-16, CL 1 or 2)

matching pipe grades above

5L-X42

ASTM

A105

(HMS-1)

matching pipe grades up to

including API 5L-X42

ASTM A694 Gr F46 or Gr

(HMS-16, CL 1 or 2)

matching pipe grades above

5L-X42

ASTM

A105

(HMS-1)

matching pipe grades up to

including API 5L-X42

ASTM A694 Gr F46 or Gr

(HMS-16, CL 1 or 2)

for

and

F52

for

API

for

and

F52

for

API

for

and

F52

for

Oil States Industries,

HydroTech Division

Date: 28-July-98

Pipe Insulating Joint

GSP-24-01

Rev: 1

Page 4 of 5

ON O

matching pipe grades above API

5L-X42

API 5L-Grade to match pipeline

Glass filled epoxy laminate,

NEMA Gr G10

Aluminum oxide filled resin

Insulation Epoxy

Molded Viton (HMS-14)

O-Ring Seals

When the pipeline has an uncommon wall thickness, grade or special

material requirements, pipe for the Extension Nipples intended to match

the pipeline, must be supplied by the purchaser.

Extension Nipples

Insulator Rings

4. QUALITY ASSURANCE

The part and heat number of each PIJ End Flange, Hub, Retainer Flange

and Extension Nipple

are steel stamped. Each Assembly also has a unique serial number

stamped on the outside

diameter of the Retainer Flange for complete material traceability.

Dimensional inspection

reports and material test reports for each component are maintained on

file.

The welds to the Extension Nipples are 100% radiographically examined

per ASME Section

VIII, Division 1, Part UW-51 and the End Flange-to-Retainer Flange weld is

ultrasonically

examined per ASME Section VIII, Division 1, Appendix 12.

In accordance with HydroTech Quality Assurance Procedure, HQA-496, the

insulating

characteristics of each PIJ is tested before welding, after welding and after

injecting with epoxy.

Each PIJ is then hydrostatically tested to 1.5 times the design pressure for

a minimum of 1 hour

and the insulating characteristics are tested twice more per HydroTech

Quality Assurance

Oil States Industries,

HydroTech Division

Date: 28-July-98

Pipe Insulating Joint

GSP-24-01

Rev: 1

Page 5 of 5

ON O

Procedure, HQA-489. The final two tests of the insulating characteristics

are conducted after

hydrostatically testing and finally after coating.

Upon request, up to two sets of Quality Assurance documentation will be

provided for all Pipe

Insulating Joints. The documentation shall consist of the following:

Certificate of Conformance

Material Test Reports for pressure containing components

NDE Reports for radiography of welds

NDE Report for ultrasonic examination of weld

PIJ Epoxy Injection Procedure, HQA-496

Acceptance Test Procedure, HQA-489, and Test Chart

Heat Sketch for each pressure containing component identifying:

Part number

H number (traceable to vendor heat number)

Serial number

HydroTech purchase order number

HydroTech sales order number

5. ORDERING INFORMATION

The following minimum information must be specified on any request for

quotation or purchase order for a PIJ intended to meet this General

Product Specification, GPS-24-01.

Nominal pipe size

Pipe wall thickness or bore

Pipe grade

Design rating

Revision Record

Oil States Industries,

HydroTech Division

Date: 28-July-98

Pipe Insulating Joint

GSP-24-01

#

Revision

1

Date

July 1998

Page

Page 2,

Section 2,

Second

Paragraph

Rev: 1

Page 6 of 5

Revision Detail

Replace

2500

5000

ON O

with

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Journalize The Following Transactions in The Journal Page Below. Add Explanations For The Transactions and Leave A Space Between EachDocumento3 páginasJournalize The Following Transactions in The Journal Page Below. Add Explanations For The Transactions and Leave A Space Between EachTurkan Amirova100% (1)

- Health 6 Q 4 WK 6 Module 6 Version 4Documento16 páginasHealth 6 Q 4 WK 6 Module 6 Version 4Kassandra BayogosAinda não há avaliações

- Solids Level Measurement Application Guide en 78224 PDFDocumento144 páginasSolids Level Measurement Application Guide en 78224 PDFwalcalAinda não há avaliações

- Sigma monitor relayDocumento32 páginasSigma monitor relayEdwin Oria EspinozaAinda não há avaliações

- Piping Material Classes GuideDocumento98 páginasPiping Material Classes GuideLuis Pottozen VillanuevaAinda não há avaliações

- 2.assessment of Dental Crowding in Mandibular Anterior Region by Three Different MethodsDocumento3 páginas2.assessment of Dental Crowding in Mandibular Anterior Region by Three Different MethodsJennifer Abella Brown0% (1)

- ERS M22 PC4 FerryDocumento2 páginasERS M22 PC4 FerryouakgoodAinda não há avaliações

- Introduction To Animal Science For Plant ScienceDocumento63 páginasIntroduction To Animal Science For Plant ScienceJack OlanoAinda não há avaliações

- Operating Instructions: Katflow 100Documento52 páginasOperating Instructions: Katflow 100Nithin KannanAinda não há avaliações

- Role of Family and Society in The Rehabiloitation of Offenders PDFDocumento4 páginasRole of Family and Society in The Rehabiloitation of Offenders PDFDevlika DasAinda não há avaliações

- Insects, Stings and BitesDocumento5 páginasInsects, Stings and BitesHans Alfonso ThioritzAinda não há avaliações

- 2.1. Pharmacological Therapeutics. 2.2. Basic Cardiac Life Support (BCLS) and Advanced Cardiac Life Support (ACLS) in Neonates and ChildDocumento3 páginas2.1. Pharmacological Therapeutics. 2.2. Basic Cardiac Life Support (BCLS) and Advanced Cardiac Life Support (ACLS) in Neonates and Childclint xavier odangoAinda não há avaliações

- Directory of Frequently Called Numbers: Maj. Sheikh RahmanDocumento1 páginaDirectory of Frequently Called Numbers: Maj. Sheikh RahmanEdward Ebb BonnoAinda não há avaliações

- Growing Turmeric: Keys To SuccessDocumento4 páginasGrowing Turmeric: Keys To SuccessAnkit ShahAinda não há avaliações

- Clinical Case Report No 2Documento11 páginasClinical Case Report No 2ملک محمد صابرشہزاد50% (2)

- of Types of Nuclear ReactorDocumento33 páginasof Types of Nuclear Reactormandhir67% (3)

- Genetics ProblemsDocumento50 páginasGenetics ProblemsTasneem SweedanAinda não há avaliações

- Merit of RatingDocumento1 páginaMerit of RatingRaidasAinda não há avaliações

- Emission of Volatile Organic Compounds (Vocs) From Dispersion and Cementitious Waterproofing ProductsDocumento16 páginasEmission of Volatile Organic Compounds (Vocs) From Dispersion and Cementitious Waterproofing ProductsKrishna KusumaAinda não há avaliações

- Grade 3 science syllabus 1st and 2nd semesterDocumento2 páginasGrade 3 science syllabus 1st and 2nd semesterelyzabeth SibaraniAinda não há avaliações

- Request For Review FormDocumento11 páginasRequest For Review FormJoel MillerAinda não há avaliações

- Very Easy Toeic Units 7 - 12 (Q1)Documento39 páginasVery Easy Toeic Units 7 - 12 (Q1)Minh KhaiAinda não há avaliações

- How To Practice Self Care - WikiHowDocumento7 páginasHow To Practice Self Care - WikiHowВасе АнѓелескиAinda não há avaliações

- Impact of Energy Consumption On The EnvironmentDocumento9 páginasImpact of Energy Consumption On The Environmentadawiyah sofiAinda não há avaliações

- wch13 01 Rms 20230817Documento24 páginaswch13 01 Rms 20230817halcieeschAinda não há avaliações

- Growth Developt Pearl MilletDocumento17 páginasGrowth Developt Pearl MilletdarmaAinda não há avaliações

- Thee Correlational Study of Possittive Emotionons and Coping Strategies For Academic Stress Among CASS Studentts - updaTEDDocumento23 páginasThee Correlational Study of Possittive Emotionons and Coping Strategies For Academic Stress Among CASS Studentts - updaTEDJuliet AcelAinda não há avaliações

- Perforamance Based AssessmentDocumento2 páginasPerforamance Based AssessmentJocelyn Acog Bisas MestizoAinda não há avaliações

- A&P 2 - Digestive System Flashcards - QuizletDocumento1 páginaA&P 2 - Digestive System Flashcards - QuizletMunachande KanondoAinda não há avaliações