Escolar Documentos

Profissional Documentos

Cultura Documentos

Nitotile 489

Enviado por

Venkata RaoDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Nitotile 489

Enviado por

Venkata RaoDireitos autorais:

Formatos disponíveis

Nitotile 489*

Epoxy tile adhesive and grout

Uses

Instructions for use

As a chemical resistant adhesive and grout for bonding quarry

and ceramic tiles to concrete or steel. Also suitable as a

multi-purpose adhesive for bedding and repairs.

Preparation

n Easy to apply

n Easy to clean up during application - can be washed off

with water

n Long working life

n Waterproof

Mixing

n High resistance to a wide range of industrial chemicals

The base and hardener components should be individually

stirred to re-disperse any settlement. The base and hardener

should then be mixed together until a uniform grey paste is

obtained. The filler should then be incorporated using a slow

speed drill and paddle.

n Good adhesion to steel, concrete and tiles

Standards compliance

Nitotile 489 meets the requirements of ANSI specification

A118.3 E5.5.

Description

Nitotile 489 is a three component solvent free epoxy resin

based adhesive consisting of a white base, a black hardener

and specially selected filler. The components are mixed

together to give a smooth non-slump paste adhesive and

grout.

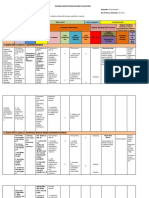

Properties

Compressive strength

:

(BS 1881, Pt 116)

Tensile strength

:

(ASTM C307-61)

Bond shear strength

:

(ANSI A118.3 E5.5)

Slant Shear Bond Strength :

(BS 6319: Pt 4)

Flexural strength

:

(ASTM C580)

Specific gravity

Pot life

Open time

Adjustability time

Initial set

Initial cure

Nitotile 489

All surfaces should be clean and free from dust, loose particles

and grease. Oil and grease contaminated concrete surfaces

should be treated with proprietary chemical degreaser and

then washed well with clean water. Steel surfaces should be

grit blasted to SA 21/2 and the adhesive applied within 3 hours

of blasting.

:

:

:

:

:

:

Application

The mixed adhesive should be spread over the surface using

a serrated trowel or comb. Tiles should be placed within the

open time of the adhesive.

Cleaning

The tile adhesive can be removed from tiles, tools and mixing

equipment before initial set using a damp rag. After initial set

the use of Fosroc solvent 102* and / or mechanical removal

will be necessary.

Limitations

83 N/mm2

Application should not commence if the temperature is below

5C or if the substrate is affected with either frost or ice. Nitotile

489 should not be applied to damp or wet surfaces nor should

it be exposed to moving water during application. If any doubts

arise concerning substrate or temperature consult your local

Fosroc office.

16.6 N/mm2

7.0 N/mm2

35.0 N/mm

32 N/mm

Technical support

@ 20C

@ 35C

2.0

2 hours

2 hours

3 hours

8 hours

24 hours

2.0

1 hour

1 hour

90 min

4 hours

18 hours

Fosroc offers a comprehensive technical support service to

specifiers, end users and contractors. It is also able to offer

on-site technical assistance, an AutoCAD facility and

dedicated specification assistance in locations all over the

world.

Estimating

Additional Information

Supply

Fosroc manufactures a wide range of complementary

products which include :

Nitotile 489

10 litre packs

5.0 m2 @ 2 mm thickness

n waterproofing membranes & waterstops

Coverage

Nitotile 489

n joint sealants & filler boards

Storage

n cementitious & epoxy grouts

When stored at 300C in dry conditions in the original, unopened

packs, Nitotile 489 will have a shelf life of 12 months.

n specialised flooring materials

Precautions

Health and safety

Fosroc additionally offers a comprehensive package of

products specifically designed for the repair and refurbishment

of damaged concrete. Fosrocs Systematic Approach to

concrete repair features the following :

Some people are sensitive to epoxy resin systems and

solvents. Ensure adequate ventilation and avoid inhalation of

vapours. Wear suitable protective clothing, gloves and eye

protection.

n hand-placed repair mortars

Direct contact with eyes will cause irritation and may cause

serious damage if left untreated. Any eye contamination

should be washed thoroughly with water and immediate

medical attention sought.

n chemically resistant epoxy mortars

Gloves and barrier creams such as Kerodex 71 or Rozalex 9

should always be used when handling Nitotile 489. If contact

with skin occurs a resin removing cream such as Kerocleans

22 or Rozalex 42 should be used followed by washing with

soap and water. Do not use solvent. If swallowed, do not

induce vomiting. Seek medical advice immediately.

For further information on any of the above, please consult

your local Fosroc office - as below.

n spray grade repair mortars

n fluid micro-concretes

n anti-carbonation/anti-chloride protective coatings

n chemical and abrasion resistant coatings

Fire

Fosroc Solvent 102 is flammable. No smoking. Ensure

adequate ventilation. Do not use near a naked flame.

Flash points

Fosroc Solvent 102

33C

For further information, refer to the Product Material Safety

Data Sheet.

REGIONAL SALES OFFICES IN :

Al Gurg Fosroc LLC

P. O. Box 657

Dubai

United Arab Emirates

TEL : (04) 285 8606

FAX : (04) 285 9649

* Denotes the trademark of Fosroc International Limited

DUBAI

ABU DHABI

BAHRAIN

KUWAIT

OMAN

QATAR

Al Gurg Fosroc

Al Gurg Fosroc

YBA Kanoo

Boodai

GETCO

Tadmur

TEL : 285 8787

TEL : 673 1779

TEL : 738200

TEL : 481 7618

TEL : 771 5080

TEL : 441 3628

FAX : 285 2023

FAX : 673 1449

FAX : 732828

FAX : 483 2124

FAX : 771 7554

FAX : 444 0812

Important note

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard terms and conditions of sale, copies of which

may be obtained on request. Whilst Fosroc endeavours to ensure that the technical information on this data sheet is correct at the time of printing, it is the

customers responsibility to satisfy himself, by checking with the company that this information is still current at the time of use, that the product is suitable for

the intended application, and that the actual conditions of use are in accordance with those recommended. Because Fosroc has no control over the conditions of

use of its products, all recommendations or suggestions regarding the use of these products are made without guarantee.

www.fosrocgulf.com

UAE/0303/01/B

Você também pode gostar

- Pindyck TestBank 7eDocumento17 páginasPindyck TestBank 7eVictor Firmana100% (5)

- Nitotile 489Documento2 páginasNitotile 489Balasubramanian AnanthAinda não há avaliações

- Nitotile 489 : Constructive SolutionsDocumento2 páginasNitotile 489 : Constructive SolutionsmilanbrasinaAinda não há avaliações

- Nitobond Ep..Documento4 páginasNitobond Ep..budhikurniawanAinda não há avaliações

- Conbextra Ep300Documento4 páginasConbextra Ep300Venkata RaoAinda não há avaliações

- Nitoseal 290Documento4 páginasNitoseal 290Venkata RaoAinda não há avaliações

- Conbextra EP10Documento2 páginasConbextra EP10MuhammedHafis100% (1)

- Nitomortar TC2000Documento3 páginasNitomortar TC2000MuhammedHafis100% (1)

- Nitocote Et550Documento4 páginasNitocote Et550Venkata RaoAinda não há avaliações

- Nitoseal 105: Uses PropertiesDocumento2 páginasNitoseal 105: Uses PropertiesVenkata RaoAinda não há avaliações

- Nitoseal 220Documento4 páginasNitoseal 220Venkata RaoAinda não há avaliações

- Cicol EtslurryDocumento4 páginasCicol EtslurryVenkata RaoAinda não há avaliações

- Nitobond EP : Constructive SolutionsDocumento4 páginasNitobond EP : Constructive SolutionsmilanbrasinaAinda não há avaliações

- Fosroc Nukote ST: Constructive SolutionsDocumento4 páginasFosroc Nukote ST: Constructive SolutionsRaj PatelAinda não há avaliações

- Nitocote Ep403Documento4 páginasNitocote Ep403pravi3434Ainda não há avaliações

- Nitoprime ZincrichDocumento4 páginasNitoprime ZincrichVenkata RaoAinda não há avaliações

- Nitotile Ep GroutDocumento2 páginasNitotile Ep GroutBalasubramanian AnanthAinda não há avaliações

- Render CureDocumento2 páginasRender CureVenkata RaoAinda não há avaliações

- Nitoseal 280Documento2 páginasNitoseal 280shanon33Ainda não há avaliações

- Nitocote HT120Documento4 páginasNitocote HT120Venkata Raju KalidindiAinda não há avaliações

- Proofex GPXDocumento2 páginasProofex GPXVenkata RaoAinda não há avaliações

- Conbextra EP300Documento4 páginasConbextra EP300Venkata Raju KalidindiAinda não há avaliações

- Nitoseal 130Documento2 páginasNitoseal 130Venkata RaoAinda não há avaliações

- Nitoseal 290Documento4 páginasNitoseal 290shanon33Ainda não há avaliações

- Nitoseal® 200Documento4 páginasNitoseal® 200Venkata Raju KalidindiAinda não há avaliações

- Nitotile LM GroutDocumento2 páginasNitotile LM GroutVenkata RaoAinda não há avaliações

- Fosroc Nukote JF80Documento3 páginasFosroc Nukote JF80Balasubramanian AnanthAinda não há avaliações

- Nitoseal 200Documento4 páginasNitoseal 200shanon33Ainda não há avaliações

- Nitomortar SSDocumento2 páginasNitomortar SSBalasubramanian AnanthAinda não há avaliações

- ReebolDocumento2 páginasReebolVenkata RaoAinda não há avaliações

- Protection BoardDocumento2 páginasProtection BoardVenkata Rao0% (1)

- (PDS) Conbextra EP300Documento4 páginas(PDS) Conbextra EP300Faizal HaziziAinda não há avaliações

- Nitomortar TC2000Documento3 páginasNitomortar TC2000grtunaAinda não há avaliações

- Nitokit Surface SealantDocumento2 páginasNitokit Surface SealantBalasubramanian AnanthAinda não há avaliações

- Nitoseal 280: Heavy Duty Epoxy Urethane Joint SealantDocumento2 páginasNitoseal 280: Heavy Duty Epoxy Urethane Joint SealantVenkata Raju KalidindiAinda não há avaliações

- Nitotile UW: Tropical Grade Ceramic Tile Adhesive Suitable For Damp and Totally Submerged ConditionsDocumento2 páginasNitotile UW: Tropical Grade Ceramic Tile Adhesive Suitable For Damp and Totally Submerged ConditionsBalasubramanian AnanthAinda não há avaliações

- Nitoseal PU 280 PDFDocumento2 páginasNitoseal PU 280 PDFhelloitskalaiAinda não há avaliações

- Nitomortar FCDocumento2 páginasNitomortar FCManish SonowaneAinda não há avaliações

- Fosroc Nitotile 489: Constructive SolutionsDocumento2 páginasFosroc Nitotile 489: Constructive SolutionsVincent JavateAinda não há avaliações

- Nitomortar FCDocumento3 páginasNitomortar FCBalasubramanian AnanthAinda não há avaliações

- Nitotile GroutDocumento2 páginasNitotile GroutBalasubramanian AnanthAinda não há avaliações

- Nitocote cm210Documento4 páginasNitocote cm210Venkata RaoAinda não há avaliações

- Nitoflor Eu50Documento4 páginasNitoflor Eu50Venkata RaoAinda não há avaliações

- Nitocote EPW100: Water Dispersed Epoxy Coating and SealerDocumento2 páginasNitocote EPW100: Water Dispersed Epoxy Coating and SealerVenkata Raju KalidindiAinda não há avaliações

- Proofex GPDocumento2 páginasProofex GPSyed ShahbazAinda não há avaliações

- Dekguard FillerDocumento2 páginasDekguard FillerVenkata RaoAinda não há avaliações

- Conbextra EP75Documento4 páginasConbextra EP75Venkata Raju KalidindiAinda não há avaliações

- Nitocote RiDocumento2 páginasNitocote RiVenkata Rao0% (1)

- Conbextra EP10Documento4 páginasConbextra EP10Venkata Raju KalidindiAinda não há avaliações

- 136Documento4 páginas136Mohamed ShehataAinda não há avaliações

- Nitocote Et402Documento4 páginasNitocote Et402Venkata Rao100% (1)

- TDS Nitomortar TC2000 Saudi ArabiaDocumento3 páginasTDS Nitomortar TC2000 Saudi ArabiaHarry BawingAinda não há avaliações

- Fosroc Renderoc CS PuneDocumento2 páginasFosroc Renderoc CS Punealdred_chezkaAinda não há avaliações

- Nitocote NT550Documento4 páginasNitocote NT550Venkata Raju KalidindiAinda não há avaliações

- Nitobond EPDocumento3 páginasNitobond EPArun KumarAinda não há avaliações

- Conbextra EP10TGDocumento2 páginasConbextra EP10TGBambang SasikiranaAinda não há avaliações

- Nitocote EN901Documento4 páginasNitocote EN901kalidindivenkatarajuAinda não há avaliações

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionAinda não há avaliações

- GRP and Buildings: A Design Guide for Architects and EngineersNo EverandGRP and Buildings: A Design Guide for Architects and EngineersAinda não há avaliações

- TDS - Mastertile 530 - RbgroutDocumento1 páginaTDS - Mastertile 530 - RbgroutVenkata RaoAinda não há avaliações

- TDS - Mastertile 40Documento2 páginasTDS - Mastertile 40Venkata RaoAinda não há avaliações

- TDS - Mastertile 30 - WPMDocumento2 páginasTDS - Mastertile 30 - WPMVenkata RaoAinda não há avaliações

- Rheofinish 202: Solvent Based Chemical Release AgentDocumento2 páginasRheofinish 202: Solvent Based Chemical Release AgentVenkata RaoAinda não há avaliações

- Tds - Waboflex SRDocumento3 páginasTds - Waboflex SRVenkata RaoAinda não há avaliações

- TDS - Mastertile 550 - DgroutDocumento3 páginasTDS - Mastertile 550 - DgroutVenkata RaoAinda não há avaliações

- TDS - Mastertile 540 - WjgroutDocumento2 páginasTDS - Mastertile 540 - WjgroutVenkata RaoAinda não há avaliações

- TDS - Rheomix 141Documento4 páginasTDS - Rheomix 141Venkata RaoAinda não há avaliações

- TDS - Wabocrete IIDocumento2 páginasTDS - Wabocrete IIKingshuk SarkarAinda não há avaliações

- TDS - Masterkure 106Documento2 páginasTDS - Masterkure 106Venkata RaoAinda não há avaliações

- 3696 2Documento7 páginas3696 2Venkata RaoAinda não há avaliações

- TDS - Masterkure 107Documento2 páginasTDS - Masterkure 107Venkata Rao100% (1)

- TDS - Masterkure 161Documento2 páginasTDS - Masterkure 161Venkata Rao0% (1)

- TDS Rheomix 121Documento3 páginasTDS Rheomix 121Tanzeel Liaqat100% (1)

- PlastisealDocumento4 páginasPlastisealVenkata RaoAinda não há avaliações

- Reebol WBDocumento2 páginasReebol WBVenkata RaoAinda não há avaliações

- Fosroc Acid EtchDocumento2 páginasFosroc Acid EtchVenkata RaoAinda não há avaliações

- Brush BondDocumento4 páginasBrush BondVenkata RaoAinda não há avaliações

- Proofex GPXDocumento2 páginasProofex GPXVenkata RaoAinda não há avaliações

- Render CureDocumento2 páginasRender CureVenkata RaoAinda não há avaliações

- Conbextra Cable GroutDocumento4 páginasConbextra Cable GroutVenkata RaoAinda não há avaliações

- Trafficguard UrDocumento2 páginasTrafficguard UrVenkata RaoAinda não há avaliações

- ReebolDocumento2 páginasReebolVenkata RaoAinda não há avaliações

- Nitomortar SDocumento4 páginasNitomortar SVenkata RaoAinda não há avaliações

- Nitoprime ZincrichDocumento4 páginasNitoprime ZincrichVenkata RaoAinda não há avaliações

- Elastic Modulus SFRCDocumento9 páginasElastic Modulus SFRCRatul ChopraAinda não há avaliações

- Instructions For Microsoft Teams Live Events: Plan and Schedule A Live Event in TeamsDocumento9 páginasInstructions For Microsoft Teams Live Events: Plan and Schedule A Live Event in TeamsAnders LaursenAinda não há avaliações

- Jerome4 Sample Chap08Documento58 páginasJerome4 Sample Chap08Basil Babym100% (7)

- Business Environment Analysis - Saudi ArabiaDocumento24 páginasBusiness Environment Analysis - Saudi ArabiaAmlan JenaAinda não há avaliações

- PeopleSoft Application Engine Program PDFDocumento17 páginasPeopleSoft Application Engine Program PDFSaurabh MehtaAinda não há avaliações

- Arduino Based Voice Controlled Robot: Aditya Chaudhry, Manas Batra, Prakhar Gupta, Sahil Lamba, Suyash GuptaDocumento3 páginasArduino Based Voice Controlled Robot: Aditya Chaudhry, Manas Batra, Prakhar Gupta, Sahil Lamba, Suyash Guptaabhishek kumarAinda não há avaliações

- Appendix - 5 (Under The Bye-Law No. 19 (B) )Documento3 páginasAppendix - 5 (Under The Bye-Law No. 19 (B) )jytj1Ainda não há avaliações

- A Review Paper On Improvement of Impeller Design A Centrifugal Pump Using FEM and CFDDocumento3 páginasA Review Paper On Improvement of Impeller Design A Centrifugal Pump Using FEM and CFDIJIRSTAinda não há avaliações

- Simoreg ErrorDocumento30 páginasSimoreg Errorphth411Ainda não há avaliações

- Daraman vs. DENRDocumento2 páginasDaraman vs. DENRJeng GacalAinda não há avaliações

- American AccentDocumento40 páginasAmerican AccentTimir Naha67% (3)

- Module 5 Data Collection Presentation and AnalysisDocumento63 páginasModule 5 Data Collection Presentation and AnalysisAngel Vera CastardoAinda não há avaliações

- Low Cost Building ConstructionDocumento15 páginasLow Cost Building ConstructionAtta RehmanAinda não há avaliações

- Cs8792 Cns Unit 1Documento35 páginasCs8792 Cns Unit 1Manikandan JAinda não há avaliações

- Squirrel Cage Induction Motor Preventive MaintenaceDocumento6 páginasSquirrel Cage Induction Motor Preventive MaintenaceNishantPareekAinda não há avaliações

- Interruptions - 02.03.2023Documento2 páginasInterruptions - 02.03.2023Jeff JeffAinda não há avaliações

- Feasibility Study of Diethyl Sulfate ProductionDocumento3 páginasFeasibility Study of Diethyl Sulfate ProductionIntratec SolutionsAinda não há avaliações

- CNC USB English ManualDocumento31 páginasCNC USB English ManualHarold Hernan MuñozAinda não há avaliações

- Sample Annual BudgetDocumento4 páginasSample Annual BudgetMary Ann B. GabucanAinda não há avaliações

- WEEK6 BAU COOP DM NextGen CRMDocumento29 páginasWEEK6 BAU COOP DM NextGen CRMOnur MutluayAinda não há avaliações

- Weekly Learning PlanDocumento2 páginasWeekly Learning PlanJunrick DalaguitAinda não há avaliações

- FIRE FIGHTING ROBOT (Mini Project)Documento21 páginasFIRE FIGHTING ROBOT (Mini Project)Hisham Kunjumuhammed100% (2)

- Fidp ResearchDocumento3 páginasFidp ResearchIn SanityAinda não há avaliações

- MMC Pipe Inspection RobotDocumento2 páginasMMC Pipe Inspection RobotSharad Agrawal0% (1)

- What Is Retrofit in Solution Manager 7.2Documento17 páginasWhat Is Retrofit in Solution Manager 7.2PILLINAGARAJUAinda não há avaliações

- XgxyDocumento22 páginasXgxyLïkïth RäjAinda não há avaliações

- Strobostomp HD™ Owner'S Instruction Manual V1.1 En: 9V DC Regulated 85maDocumento2 páginasStrobostomp HD™ Owner'S Instruction Manual V1.1 En: 9V DC Regulated 85maShane FairchildAinda não há avaliações

- Fernando Salgado-Hernandez, A206 263 000 (BIA June 7, 2016)Documento7 páginasFernando Salgado-Hernandez, A206 263 000 (BIA June 7, 2016)Immigrant & Refugee Appellate Center, LLCAinda não há avaliações

- Securitron M38 Data SheetDocumento1 páginaSecuritron M38 Data SheetJMAC SupplyAinda não há avaliações