Escolar Documentos

Profissional Documentos

Cultura Documentos

Improve Reliability and Reduce Your Costs

Enviado por

RAMKUMARTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Improve Reliability and Reduce Your Costs

Enviado por

RAMKUMARDireitos autorais:

Formatos disponíveis

ESSENTIAL ASSET MONITORING

Improve Reliability and Reduce Your Costs

Up to 5 percent of production

availability is lost annually

due to unscheduled

slowdowns and shutdowns.

Just nine asset classes account

for the majority of this loss.

Your critical business challenges are all interdependent. A single unplanned shutdown or slowdown

can have a cascading effect, whether you manage a refinery, or chemical or petrochemical facility.

If equipment reliability suffers, so will throughput, costs, and margins. Poor reliability can even

cause safety and environmental incidents. On top of all of this, experienced staff is retiring.

Your operations are complex and variable, and the regulatory world today is volatile. You are

doing all you can to maintain or increase your profit margins, but it isnt easy. You certainly dont

want to add to your challenges by running your plants inefficiently.

Reliability and efficiency suffer not because critical assets are unmonitored. Its often because less

What if you could...

... mitigate production

losses caused by

unplanned shutdowns

and slowdowns

sometimes worth

millions per year?

... use predictive diagnostics

to reduce your

maintenance costsup

to 50% per incident?

... identify accelerated

heat exchanger fouling

and improve fired heater

efficiencysaving

millions from your fuel

bill?

critical, but still essential assets lack adequate monitoring. Issues with these assets can cause a

slowdown, shutdown, or HSE incident, while also draining efficiency and reliability across your facility.

UNPLANNED SHUTDOWNS AND SLOWDOWNS SACRIFICE VALUABLE PRODUCTION

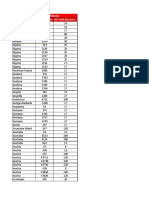

Studies have shown that up to 5 percent of production is lost annually due to equipment being

unavailablewith just seven asset classes accounting for the majority of the loss. The majority of these essential assets are only periodically monitored due to the perception that online,

real-time measurement is expensive. This leaves operators and maintenance personnel without

sufficient insight into the health of their equipment. The situation is becoming more of a concern

as experienced personnel retire and take their vast stores of knowledge with them.

MAINTENANCE COSTS ARE

INCREASING

Maintenance of these same seven

asset classes can consume close to 60

percent of the total maintenance

budget. These assets are usually

maintained using preventive

maintenance where the asset is

repaired on a routine basis

whether it needs it or not. If the

equipment does fail, repair costs are

typically 50 percent higher than if

the problem had been addressed

Critical Assets

Essential Assets

Already monitored

Higher probability of

failure and higher impact

Medium probability,

medium-to-high

impact failure risk

Could cause slowdown,

shutdown, or HSE

incident

Unmonitored or

monitored with periodic

manual rounds

Seven Essential Assets

Air cooled heat exchangers Heat exchangers

Blowers

Pipes and vessels

Cooling towers

Pumps

Non-critical compressors

prior to failure.

RELIABILITY ISSUES MAY CAUSE ENVIRONMENTAL AND SAFETY INCIDENTS

People are put in harms way during trips to hazardous areas for preventive maintenance or

diagnostic data collection. Equipment reliability problems can lead to leaks and fires, and

operators lack the information they need to identify abnormal operations and avoid incidents.

ESSENTIAL ASSET MONITORING

Integrated Solutions for More Effective Decision Support

Historically, many plants were built with the minimum instrumentation needed to safely operate.

Additional measurements are often required to optimize and monitor asset health. However,

the refining, chemical, and petrochemical industries have changed in the last 20 years, making

automated monitoring more affordable. With affordable monitoring, plants no longer have to just

accept unplanned shutdowns, high maintenance costs, and decreased reliability.

INCREASE PROCESS AVAILABILITY

Give your operations and maintenance personnel the full picture so they know when statistically

significant changes occur in the process and the equipment. Automatically capture key operating

parameters over the operating range of the equipment and identify before something goes

wrong, gaining access to expertise for evaluating data, resulting in better-informed and corrective

actions.

Gain insight into process health

Alert your operators to process condition changes so they can take action to avoid slowdowns or

shutdowns.

IMPROVE ASSET RELIABILITY

Receive online updates about equipment health, enabling operators to know when equipment

has reached a warning stage, or has escalated to critical, without being overwhelmed by

nonessential alarms. Determine the root causes of bad actors to reduce repeat failures.

Easily gather fault-alert data about equipment so repeat failures can be analyzed and addressed.

Ensure equipment is not run to failure.

Know when to perform condition-based maintenance before asset failure

Only perform turnarounds and maintenance on equipment that needs maintenance. See the

trend of an assets health and know when the cost to operate exceeds the cost to maintain.

Maintain equipment on the most cost-effective schedule. Avoid periodic, preventive maintenance

by measuring equipment health using predictive diagnostics.

MITIGATE SAFETY AND ENVIRONMENTAL RISKS

Receive early warnings on degrading equipment to prevent leaks before causing a hazardous

incident. Minimize trips into hazardous areas that put your people in harms way.

Reduce trips to the field

Reduce periodic, schedule-based rounds to monitor equipment health. Conduct maintenance

safely and efficiently.

Manual monitoring

only catches about 2

seconds of data every

month. It is worth

making sure that your

important equipment

has continuous

monitoring.

Sr. Machinery Reliability Lead

Major Global Refiner

ESSENTIAL ASSET MONITORING

Detect abnormal situations, spot imminent failure, and be alerted to potentially hazardous situations involving your equipment in a timely

manner, with Emersons Essential Asset Monitoring Suite.

AIR COOLED HEAT EXCHANGERS

Avoid cooling-constrained operations caused by:

High vibration and bearing temperature

Operating near known resonance frequency

Louver/pitch actuator mechanical defects

Exchanger fouling and excessive cooling

Fan icing

BLOWERS

Ensure fired heaters and boilers dont trip due to blower failure as a result of:

High vibration and bearing temperature

Low differential pressure

Operating near known resonance frequency

Louver mechanical defects

Plugged suction filter

NON-CRITICAL COMPRESSORS

Receive early warnings to avoid unexpected compressor outages as a result of:

High vibration

Low differential pressure

High differential temperature

Instability

Control vane defect

Plugged suction filter

COOLING TOWERS

Prevent limited cooling tower capacity caused by:

High and low cooling tower efficiency

Excessive and insufficient makeup and blowdown flow

High and low cycles of concentration

Scaling and corrosion potential

Pumps and fans faults

HEAT EXCHANGERS

Avoid unit turndown and improve the cleaning strategy of heat exchangers by monitoring conditions such as:

High fouling rate

High lost-energy cost

Optimal time to clean

PUMPS

Prevent pump damage and failure (even on second-tier pumps) resulting from:

High vibration and bearing temperature

Low differential pressure

Pre-cavitation and cavitation

Seal flush faults

Hydrocarbon leaks

Plugged suction strainer

PIPES AND VESSELS

Combine continuous monitoring of your corrosion devices with monitoring and detection of process conditions that

lead to corrosion. EAM for Pipes and Vessels determines system corrosion health and detects high corrosion from:

Combination of temperature, flow, sulfur, and acid number Desalter malfunction

Dew point

pH balance

ESSENTIAL ASSET MONITORING

Ready to Explore Essential Asset Monitoring at Your Facility?

Improved Asset Reliability

An effective essential asset monitoring program has been shown to save up

to 13 percent of maintenance costs, reclaim 0.9 percent of lost production,

Millions in

Savings

Increased Process Availability

and save up to 2 percent of preheat energy costs every year.

Reduced Energy Consumption

You can achieve a low risk, but effective solution to improve reliability and

reduce costs with an expert assessment from Emerson. Bringing decades of

DISCOVER

Preliminary assessment

EVALUATE

Technical evaluation

Economic evaluation

experience solving complex problems at plants across the globe, our experts

can help you identify and justify asset monitoring improvements that will

reduce unplanned shutdowns, slowdowns, and maintenance costs. You will

be able to deliver quantifiable and lasting improvements to give you a proven

edge over your competitors.

After your assessment, you can choose which steps to take to begin improving

your plant availability and reliability immediately. We can identify where

DEFINE

Functional specification

IMPLEMENT

Detailed engineering

Commissioning support

automation would have the most significant benefits, including reducing your

risk exposure and giving you access to more effective decision support.

You can trust that your solution will be scaled to meet your needs and that

you will be supported from project justification to installation and beyond.

ACT NOW

Take steps to improve your Refining, Chemical, or Petrochemical facilities

OPERATE

today by contacting us at: www.EmersonProcess.com/Explore-EAM

Post implementation audit

Solution support

Improvement program

2013 Emerson Process Management. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co.

www.EmersonProcess.com/

AssetMonitoring

D352140X012 / Printed in USA / 8-13

The contents of this publication are presented for information purposes only, and while effort has been made to ensure their accuracy, they are not to

be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales

are governed by our terms and conditions, which are available on request. We reserve the right to modify or improve the designs or specifications of

our products at any time without notice.

Você também pode gostar

- Reduce Shutdowns and Fulfill Production Goals: Compressor Health MonitoringDocumento4 páginasReduce Shutdowns and Fulfill Production Goals: Compressor Health Monitoringpeach5Ainda não há avaliações

- BE Overview Chillers PlannedMaintenanceDocumento2 páginasBE Overview Chillers PlannedMaintenanceEdmund YoongAinda não há avaliações

- MaintenanceDocumento89 páginasMaintenancelp mishra100% (5)

- Preventive Maintenance PresentationDocumento15 páginasPreventive Maintenance Presentationabhinav2018100% (2)

- Chemical IndustriesDocumento10 páginasChemical IndustriessunliasAinda não há avaliações

- Root Cause Failure Analysis Rev 2Documento69 páginasRoot Cause Failure Analysis Rev 2clcoolleo100% (1)

- Plant We Bops MaintDocumento18 páginasPlant We Bops MaintNam SanchunAinda não há avaliações

- Hydraulic Systems Failure, Maintenance and ReparationDocumento10 páginasHydraulic Systems Failure, Maintenance and ReparationHaidar HeroAinda não há avaliações

- MaintenanceDocumento34 páginasMaintenancerashm006ranjan100% (3)

- Ers Allar0702e EcmmagDocumento3 páginasErs Allar0702e EcmmagthetroubleshooterAinda não há avaliações

- CalibrationDocumento155 páginasCalibrationdarrel_julio100% (1)

- Introduction To Reliability Excellence RX 197Documento15 páginasIntroduction To Reliability Excellence RX 197HamdanAinda não há avaliações

- Ams - Asset Management SystemDocumento5 páginasAms - Asset Management SystemcleitonmoyaAinda não há avaliações

- Making The Case For Plant-Wide Condition MonitoringDocumento8 páginasMaking The Case For Plant-Wide Condition MonitoringAbdulrahman Alkhowaiter100% (1)

- Planned MaintenanceDocumento17 páginasPlanned MaintenanceAnand Dubey100% (1)

- Unit 2 Maintenance EnggDocumento46 páginasUnit 2 Maintenance EnggVenkadeshwaran KuthalingamAinda não há avaliações

- LEM The Power of Prep EPM GuideDocumento17 páginasLEM The Power of Prep EPM GuideAgus MulyanaAinda não há avaliações

- GAPS Guidelines: Emergency Engine MaintenanceDocumento4 páginasGAPS Guidelines: Emergency Engine MaintenanceAsad KhanAinda não há avaliações

- Document 7Documento4 páginasDocument 7bernardAinda não há avaliações

- Maintenance of Equipment: Philippine Society of Mechanical Engineers Professional Development CourseDocumento23 páginasMaintenance of Equipment: Philippine Society of Mechanical Engineers Professional Development CourseAngel Silva VicenteAinda não há avaliações

- Exp 05Documento6 páginasExp 05Sayali PatilAinda não há avaliações

- Mill Maintenance: Maintenance Can Be Defined As The Activity Undertaken To Allow Continued Use of Buildings andDocumento5 páginasMill Maintenance: Maintenance Can Be Defined As The Activity Undertaken To Allow Continued Use of Buildings andNijam JabbarAinda não há avaliações

- Power Generation: Combined Cycle: Bently Nevada Asset Condition MonitoringDocumento12 páginasPower Generation: Combined Cycle: Bently Nevada Asset Condition Monitoringa_mohid17Ainda não há avaliações

- 10 Rules For Condition Monitoring.Documento8 páginas10 Rules For Condition Monitoring.Zegera MgendiAinda não há avaliações

- High Availability ProcessDocumento8 páginasHigh Availability ProcessasotozuazuaAinda não há avaliações

- Guidelines for Asset Integrity ManagementNo EverandGuidelines for Asset Integrity ManagementNota: 5 de 5 estrelas5/5 (1)

- Maintaining Your Switchgear: You Can Prevent Switchgear Failure With Proper MaintenanceDocumento3 páginasMaintaining Your Switchgear: You Can Prevent Switchgear Failure With Proper MaintenanceممشطAinda não há avaliações

- FLUKE - PDM OverviewDocumento5 páginasFLUKE - PDM OverviewofedulloAinda não há avaliações

- GAPS Guidelines: Steam Turbine Loss Prevention InspectionDocumento5 páginasGAPS Guidelines: Steam Turbine Loss Prevention InspectionحيدرالركابيAinda não há avaliações

- BHCS34337A Sugar Refinery Brochure R6Documento8 páginasBHCS34337A Sugar Refinery Brochure R6hudaAinda não há avaliações

- Fundamentals of VibrationDocumento99 páginasFundamentals of Vibrationjide.atolagbe3737Ainda não há avaliações

- CalibrationDocumento155 páginasCalibrationBhegz Escalona100% (3)

- Breakdown MaintenanceDocumento4 páginasBreakdown MaintenanceSankalp Sharma0% (1)

- Chiller Service 2Documento8 páginasChiller Service 2VENKATAinda não há avaliações

- Pel Water MV FlyerDocumento2 páginasPel Water MV FlyerquinteroudinaAinda não há avaliações

- Guide for Asset Integrity Managers: A Comprehensive Guide to Strategies, Practices and BenchmarkingNo EverandGuide for Asset Integrity Managers: A Comprehensive Guide to Strategies, Practices and BenchmarkingAinda não há avaliações

- UPS MaintenanceDocumento8 páginasUPS MaintenanceElcha Pardana SAinda não há avaliações

- Building Analytics BrochureDocumento8 páginasBuilding Analytics BrochureVinzoKei100% (1)

- Aircraft Maintenance: MD Jalal Uddin Rumi Assistant Professor, AE Dept. MISTDocumento26 páginasAircraft Maintenance: MD Jalal Uddin Rumi Assistant Professor, AE Dept. MISTMd Jalal Uddin RumiAinda não há avaliações

- Maintenance of Hydraulic Systems-10Documento13 páginasMaintenance of Hydraulic Systems-10hermansyah hermanAinda não há avaliações

- Ueeneee110A Develop and Implement Energy Sector Maintenance Programs Assessment1 Maintenance Program DevelopmentDocumento3 páginasUeeneee110A Develop and Implement Energy Sector Maintenance Programs Assessment1 Maintenance Program Developmentamrit palasaurAinda não há avaliações

- Operation and Maintenance SystemsDocumento13 páginasOperation and Maintenance SystemsJill de Luna100% (1)

- How Can We Improve The Trust in Process Analzers?Documento19 páginasHow Can We Improve The Trust in Process Analzers?Andres FlorezAinda não há avaliações

- Condition Monitoring: Uncovering Your Transformers' Secrets ThroughDocumento12 páginasCondition Monitoring: Uncovering Your Transformers' Secrets ThroughTapasAinda não há avaliações

- UncoveringYourTransformersSecrets EbookDocumento12 páginasUncoveringYourTransformersSecrets Ebookchitra_bala31422Ainda não há avaliações

- Managing Mill Maintenance - Maintenance Options and ChallengesDocumento7 páginasManaging Mill Maintenance - Maintenance Options and ChallengesMilling and Grain magazineAinda não há avaliações

- Building A PM ProgDocumento4 páginasBuilding A PM ProgacaraliteiAinda não há avaliações

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneAinda não há avaliações

- Lecture 8 Run-to-Failure Management, PM EtcDocumento16 páginasLecture 8 Run-to-Failure Management, PM EtcMinhaj UllahAinda não há avaliações

- CBM of Rotating Equipments On OSI PI PlatformDocumento12 páginasCBM of Rotating Equipments On OSI PI PlatformduhaimAinda não há avaliações

- Mohd Khairul Azmi - PM - TUGASANDocumento6 páginasMohd Khairul Azmi - PM - TUGASANSyafiz NawawiAinda não há avaliações

- Maintenance MGMTDocumento21 páginasMaintenance MGMTSurbhi JainAinda não há avaliações

- 4considerations For Safe Hydraulic System Maintenance 1Documento9 páginas4considerations For Safe Hydraulic System Maintenance 1Josh WhiteAinda não há avaliações

- CH 4Documento63 páginasCH 4girma workuAinda não há avaliações

- Managing A Condition Monitoring Program: Get The Monitoring Right!Documento9 páginasManaging A Condition Monitoring Program: Get The Monitoring Right!Michaelben Michaelben100% (1)

- Maintenance of SubstationDocumento129 páginasMaintenance of Substationrama mohan100% (1)

- Aeration Control System Design: A Practical Guide to Energy and Process OptimizationNo EverandAeration Control System Design: A Practical Guide to Energy and Process OptimizationAinda não há avaliações

- 1Documento42 páginas1RAMKUMARAinda não há avaliações

- Burning Mechanism of Ammonium Perchlorate PropellantsDocumento42 páginasBurning Mechanism of Ammonium Perchlorate PropellantsRAMKUMARAinda não há avaliações

- IC Engine IES GATE IAS 20 Years Question and AnswersDocumento77 páginasIC Engine IES GATE IAS 20 Years Question and AnswersSaajal Sharma96% (26)

- Davis Besse Nuclear Background CheckDocumento6 páginasDavis Besse Nuclear Background CheckRAMKUMARAinda não há avaliações

- Correlating The Effects of Ap Particle Size and ConcentrationDocumento95 páginasCorrelating The Effects of Ap Particle Size and ConcentrationRAMKUMARAinda não há avaliações

- I Would Like To Begin by Talking With You - New Believer - About Your ConversionDocumento6 páginasI Would Like To Begin by Talking With You - New Believer - About Your ConversionRAMKUMARAinda não há avaliações

- Two-Dimensional Problem Solution: y X X yDocumento55 páginasTwo-Dimensional Problem Solution: y X X yRAMKUMARAinda não há avaliações

- Pressure Vessels: Lab BackgroundDocumento3 páginasPressure Vessels: Lab BackgroundRAMKUMARAinda não há avaliações

- AvogadroDocumento209 páginasAvogadrodraconnoxAinda não há avaliações

- Gaussian & Gaussview: Shubin Liu, Ph.D. Research Computing Center, Its University of North Carolina at Chapel HillDocumento86 páginasGaussian & Gaussview: Shubin Liu, Ph.D. Research Computing Center, Its University of North Carolina at Chapel HillRAMKUMARAinda não há avaliações

- Fast Packed SpheressDocumento9 páginasFast Packed SpheressRAMKUMARAinda não há avaliações

- ICME Workshop 140723Documento93 páginasICME Workshop 140723RAMKUMAR100% (1)

- Department Program Review and Strategic Plan 2017 - 2021 Division of Administration and FinanceDocumento1 páginaDepartment Program Review and Strategic Plan 2017 - 2021 Division of Administration and FinanceRAMKUMARAinda não há avaliações

- Ordinary Differential Equations - Solution ManualDocumento176 páginasOrdinary Differential Equations - Solution Manualrlewis120% (1)

- NOTICEDocumento14 páginasNOTICERAMKUMARAinda não há avaliações

- IntroDocumento32 páginasIntroRAMKUMARAinda não há avaliações

- Heart of JerusalemDocumento5 páginasHeart of JerusalemRAMKUMARAinda não há avaliações

- International Student Pre-Arrival Guide: University of Colorado Colorado SpringsDocumento25 páginasInternational Student Pre-Arrival Guide: University of Colorado Colorado SpringsRAMKUMARAinda não há avaliações

- LeSar UCSB Summer School PDFDocumento94 páginasLeSar UCSB Summer School PDFRAMKUMARAinda não há avaliações

- U2 08 04Documento11 páginasU2 08 04RAMKUMARAinda não há avaliações

- Introduction To The ExercisesDocumento2 páginasIntroduction To The ExercisesRAMKUMARAinda não há avaliações

- MATLAB LECTURE ON Rand PDFDocumento7 páginasMATLAB LECTURE ON Rand PDFshashank guptaAinda não há avaliações

- ISD Tariff Jan-16 VodafoneDocumento238 páginasISD Tariff Jan-16 VodafoneSantosh MhaskarAinda não há avaliações

- Buckling AnalysisDocumento4 páginasBuckling AnalysisanthraxpAinda não há avaliações

- VoronoiDocumento77 páginasVoronoiRAMKUMARAinda não há avaliações

- PADT Webinar Post26 2012 - 04 - 12 PDFDocumento54 páginasPADT Webinar Post26 2012 - 04 - 12 PDFRAMKUMARAinda não há avaliações

- 11-Tips-Tricksfor Non LinearbucklingDocumento3 páginas11-Tips-Tricksfor Non Linearbucklingabhijet29Ainda não há avaliações

- Report Tim ChenDocumento163 páginasReport Tim ChenRAMKUMARAinda não há avaliações

- Static and Dynamic Analysis of Marine RisersDocumento8 páginasStatic and Dynamic Analysis of Marine RiserstobysavioAinda não há avaliações

- Uhde Brochure Ammonia SCR PDFDocumento28 páginasUhde Brochure Ammonia SCR PDFBaher ElsheikhAinda não há avaliações

- PSSR SafetyDocumento10 páginasPSSR SafetyHedi Ben Mohamed100% (1)

- Glossário de MáquinasDocumento297 páginasGlossário de MáquinasTiago ContinoAinda não há avaliações

- 30rap 8pd PDFDocumento76 páginas30rap 8pd PDFmaquinagmcAinda não há avaliações

- 1.3.5 PreHeat TrainDocumento20 páginas1.3.5 PreHeat TrainflowealthAinda não há avaliações

- J.L. Smith. - Textile Processing-Abhishek Publications (2009.)Documento165 páginasJ.L. Smith. - Textile Processing-Abhishek Publications (2009.)Purnesh JagadAinda não há avaliações

- Hvac AssignmentDocumento27 páginasHvac AssignmentChethan. M.D.100% (1)

- Pro/Ii Casebook Methyl Tertiary Butyl Ether (MTBE) PlantDocumento0 páginaPro/Ii Casebook Methyl Tertiary Butyl Ether (MTBE) PlantridhajamelAinda não há avaliações

- Elements of Food ProcessingDocumento75 páginasElements of Food ProcessingEd Casas0% (1)

- P-H Diagrams: Refrigeration CoolingDocumento7 páginasP-H Diagrams: Refrigeration CoolingVamsi Krishna SarmaAinda não há avaliações

- Proximus 807B-04-07C Eng PM PDFDocumento32 páginasProximus 807B-04-07C Eng PM PDFIvanAinda não há avaliações

- Treated Fresh Air Guidelines by BryairDocumento13 páginasTreated Fresh Air Guidelines by BryairRajanAinda não há avaliações

- CFD Analysis of Heat Transfer Enhancement in Shell and Tube Type Heat Exchanger Creating Triangular Fin On The TubesDocumento10 páginasCFD Analysis of Heat Transfer Enhancement in Shell and Tube Type Heat Exchanger Creating Triangular Fin On The TubesEditor IJTSRDAinda não há avaliações

- 120 Libros para Dimensionamiento de Equipos y Diseño de Plantas en Ingeniería QuímicaDocumento3 páginas120 Libros para Dimensionamiento de Equipos y Diseño de Plantas en Ingeniería Químicapedro encinasAinda não há avaliações

- McQuay Chilled Water SolutionDocumento260 páginasMcQuay Chilled Water SolutionJeffy ShannonAinda não há avaliações

- PRODUCTIONOFMALEICANHYDRIDEFROMOXIDATIONOFn BUTANE PDFDocumento457 páginasPRODUCTIONOFMALEICANHYDRIDEFROMOXIDATIONOFn BUTANE PDFJayshree Mohan100% (1)

- Set Free Brochure May 08Documento25 páginasSet Free Brochure May 08Elena Mihaela PetrilaAinda não há avaliações

- Chapter - 4 (Livro Com Exercícios Termodinâmica)Documento56 páginasChapter - 4 (Livro Com Exercícios Termodinâmica)Eder SoaresAinda não há avaliações

- P 651 14 HPC 3 08 DSD DSDX SeriesDocumento7 páginasP 651 14 HPC 3 08 DSD DSDX SeriesMuzz HalirapAinda não há avaliações

- Design and Performance Evaluation of An Ice Block Making MachineDocumento9 páginasDesign and Performance Evaluation of An Ice Block Making Machinebasel abduAinda não há avaliações

- Belzona 1321 (Ceramic S-Metal) : Key BenefitsDocumento22 páginasBelzona 1321 (Ceramic S-Metal) : Key BenefitsIrvansyah RazadinAinda não há avaliações

- Hammelmann 2016Documento68 páginasHammelmann 2016Cleaner MagazineAinda não há avaliações

- Ekwdsg1206 AbDocumento24 páginasEkwdsg1206 AbGaruda GarudaAinda não há avaliações

- ACMVDocumento110 páginasACMVx3350Ainda não há avaliações

- TechnicalspecificationsofheatexchangeralongwithSOI 20200314062818.362 XDocumento78 páginasTechnicalspecificationsofheatexchangeralongwithSOI 20200314062818.362 XAvinash ShuklaAinda não há avaliações

- Week8 Shell&TubeHEPart2Documento56 páginasWeek8 Shell&TubeHEPart2Mochammad ReshaAinda não há avaliações

- Astm D 3370 PDFDocumento11 páginasAstm D 3370 PDFmilidarksAinda não há avaliações

- Installation Manual: Alfa Laval Copenhagen A/SDocumento144 páginasInstallation Manual: Alfa Laval Copenhagen A/SaAinda não há avaliações

- Technical Report PDFDocumento57 páginasTechnical Report PDFKaushik ArnavAinda não há avaliações

- Heat Exchangers DesignDocumento58 páginasHeat Exchangers DesignShubhamAinda não há avaliações