Escolar Documentos

Profissional Documentos

Cultura Documentos

Delphi Variable Cam Faser

Enviado por

cano52140Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Delphi Variable Cam Faser

Enviado por

cano52140Direitos autorais:

Formatos disponíveis

POWERTRAIN SYSTEMS

Delphi Variable Cam Phaser

Delphi's Variable Cam Phaser (VCP) replaces the standard pulley,

sprocket or gear in an engine's valve train. It enables the cam lobe

(lift event) timing to crank shaft timing to be changed while the

engine is operating, based on the parameters of the engine.

The cam lobe angular position, or phase relationship, is controlled

by the internal vane mechanism of the VCP. Commands from the

engine control module adjust the position of the oil control valve

(See schematic.), which is mounted in the cylinder head and

regulates engine oil flow to either side of the vanes.

Delphi's variable cam phasing system includes an oil control valve,

which controls the flow of oil to advance, retard or hold the camshaft

position. Its high flow capacity provides fast phasing rates, and its

integral filtration keeps it debris-free avoiding the need for a

separate filter while providing increased packaging flexibility.

Variable cam phasing changes the timing of the valve lift event. It

can be used to shift the intake cam, the exhaust cam, or both on

dual overhead cam engines. This helps increase engine efficiency,

improving idle stability while delivering more torque and horsepower.

It also helps boost fuel economy and reduces hydrocarbon

emissions.

Delphi Variable Cam Phaser with Oil

Control Valve

Benefits

Optimized size versus torque for dynamic stability

Packaging flexibility on the engine is enabled by a standard rotor/stator pack in the VCP and a remote mounted oil

control valve

Mechanical lock pin maintains default positions when parked at low pressure conditions

Low-restriction four-way control valve provides low pressure operation and continuously variable position operation

High precision manufacturing processes enable low leakage and low lash for improved performance and noise free

operation

System integration capability to assist customers with base engines and engine management system development

and implementation

Typical Applications

A Delphi Variable Cam Phaser can be applied to virtually any engine to help broaden the torque curve,

increase peak power at high rpm, reduce hydrocarbon and NOx emissions and help increase fuel

economy. VCP benefits are application-specific and are derived by increasing volumetric efficiency,

reducing pumping losses and in-cylinder internal dilution control associated with varying the cam timing.

www.delphi.com | Delphi. All rights reserved. |

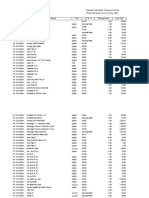

Delphi Variable Cam Phaser

Phaser Position

Control Valve

Off

50%

100%

Intake

Exhaust

Valve Overlap

Retard

Advance

Minimum

Intermediate: Flow is restricted to "hold" position.

Advance

Retard

Maxi

This chart indicates the control logic between the variable cam phaser and the oil control valve.

Hydraulic System Schematic

This diagram shows the system-level mechanization of the variable cam phaser,

oil control valve, control module, crank sensor and cam sensor to the engine.

www.delphi.com | Delphi. All rights reserved. |

Delphi Variable Cam Phaser

Performance Advantages

Delphi's variable cam phasing technology achieves a balance

of response times, torque capacity and optimal packaging.

Further optimization can be achieved to meet applicationspecific goals. The construction of the cam phaser and the oil

control valve permits either two-position or continuously

variable operation. Advantages of Delphi's variable cam

phasing technology include:

Intermediate lock pin feature enables improved fuel economy

and performance in dual independent cam phasing applications

Flexible packaging and compact size for pulley, sprocket or gear

drive

Optimized design and process to provide low cost components

System-level support with integration of software, capability to

supply engine hydraulics designs and control algorithms,

including diagnostics

Delphi produces a wide variety of variable cam

Delphi is a leading manufacturer of cam phasers and has

phasers and oil control valves to meet

received numerous patents for these technologies. Delphi can

individual customer requirements.

tailor cam phasing systems to help achieve the optimal

balance of efficiency and power. Implementation is simplified

because of the vane configuration, which reduces mass and contributes to packaging flexibility.

Delphi manufactures cam phasing systems in North America, Europe and Asia, with additional product

development and customer support facilities worldwide to enable exceptional on-time delivery.

The Delphi Advantage

Delphi offers the benefits of more than 75 years' experience in valve train systems and its high-quality

conventional valve train products have earned industry-wide respect. Our deep understanding of the

combustion process, vast research and development capabilities have enabled continuing innovation.

Delphi offers one of the industry's most comprehensive lines of valve train products and we support our

customers at many levels, from components to valve train design and optimization.

As a global leader in engine management systems technology, Delphi can help manufacturers around the

world meet emissions requirements, improve fuel economy and enhance performance. Delphi is a source

for high value solutions and our systems approach is built into every product. Delphi's flexible engineering

approach encourages collaboration. And, Delphi has a thorough understanding of automotive markets

around the world and a global network of resources.

www.delphi.com | Delphi. All rights reserved. |

Você também pode gostar

- Mercedes E Class Petrol Workshop Manual W210 & W211 SeriesNo EverandMercedes E Class Petrol Workshop Manual W210 & W211 SeriesNota: 4.5 de 5 estrelas4.5/5 (9)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideNo EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideNota: 4.5 de 5 estrelas4.5/5 (8)

- Diesel HFT Fuel PumpDocumento2 páginasDiesel HFT Fuel PumpBishwajeet Pratap SinghAinda não há avaliações

- Delphi DPGE Medium Duty Diesel Rotary Fuel Injection Pump: Powertrain SystemsDocumento2 páginasDelphi DPGE Medium Duty Diesel Rotary Fuel Injection Pump: Powertrain SystemsAsif ShahAinda não há avaliações

- Bomba Inyeccion - PDF IvecoDocumento2 páginasBomba Inyeccion - PDF IvecoJhonald Lanz LossadaAinda não há avaliações

- Delphi Common Rail Diesel System PDFDocumento3 páginasDelphi Common Rail Diesel System PDFjamesmarin007100% (1)

- PDFDocumento2 páginasPDFandis_aAinda não há avaliações

- Delphi DP310 Rotary Mechanical Diesel Fuel Injection Pump: Powertrain SystemsDocumento2 páginasDelphi DP310 Rotary Mechanical Diesel Fuel Injection Pump: Powertrain SystemsAmerican Bosch Diesel Olzam Sas33% (3)

- ProductBrochure EC220D en 21 20030375-BDocumento28 páginasProductBrochure EC220D en 21 20030375-BFernando Pauli PradoAinda não há avaliações

- Ice Engine PresentationDocumento20 páginasIce Engine PresentationAj SiddAinda não há avaliações

- Brochure EC250D EC300D T3 EN 30 20035491 CDocumento28 páginasBrochure EC250D EC300D T3 EN 30 20035491 CLU YO100% (1)

- Variable Valve Timing TechnologyDocumento4 páginasVariable Valve Timing TechnologyVignesh Samban100% (1)

- Electronic Diesel Exhaust Gas Recirculation Valves PDFDocumento2 páginasElectronic Diesel Exhaust Gas Recirculation Valves PDFdeeparunAinda não há avaliações

- 077 Torque ConvertersDocumento2 páginas077 Torque Convertersphilospanashe01Ainda não há avaliações

- Brochure Ec220d t3 en 30 20035507 b-1Documento24 páginasBrochure Ec220d t3 en 30 20035507 b-1iban iboAinda não há avaliações

- Delphi Diesel EGR 1 PDFDocumento3 páginasDelphi Diesel EGR 1 PDFjamesmarin007Ainda não há avaliações

- ProductBrochure L250G EU English 2011 - 11Documento24 páginasProductBrochure L250G EU English 2011 - 11AlexandreAinda não há avaliações

- Delphi DDU CRSDocumento2 páginasDelphi DDU CRSFaraz HaiderAinda não há avaliações

- Volvo ExcavatorsDocumento28 páginasVolvo ExcavatorsCristian Ecos AlaAinda não há avaliações

- Delphi Direct Acting Light Duty Diesel Common Rail System: Powertrain SystemsDocumento3 páginasDelphi Direct Acting Light Duty Diesel Common Rail System: Powertrain SystemsAsif ShahAinda não há avaliações

- ProductBrochure L150G L180G L220G EN 21 20023724-C 2012.04Documento32 páginasProductBrochure L150G L180G L220G EN 21 20023724-C 2012.04Daniel Marx ChillitupaAinda não há avaliações

- Gas Multec EfiDocumento7 páginasGas Multec EfiSwapnil SolaskarAinda não há avaliações

- EC140D - EC160D - EC220D Excavator Product BrochureDocumento24 páginasEC140D - EC160D - EC220D Excavator Product Brochuremilan_popovic_2100% (1)

- Cat 745Documento28 páginasCat 745Imam TL100% (1)

- WSG - Westfalia Separator Ecoforce enDocumento16 páginasWSG - Westfalia Separator Ecoforce enbanerjeeamlanAinda não há avaliações

- Ficha Tecnica Cargador CatDocumento20 páginasFicha Tecnica Cargador Catcristian1955Ainda não há avaliações

- Bearing CapacityDocumento36 páginasBearing CapacityAjay SinghAinda não há avaliações

- Brochure l150h l180h l220h t3 en 30 20047153 DDocumento28 páginasBrochure l150h l180h l220h t3 en 30 20047153 Dgosiamail100% (1)

- l110g, l120g: Volvo Wheel LoadersDocumento32 páginasl110g, l120g: Volvo Wheel LoadersRalle RadioAinda não há avaliações

- Veriable Valve Timing Mechanism: A Seminar Report ONDocumento19 páginasVeriable Valve Timing Mechanism: A Seminar Report ONAshish Kumar PandeyAinda não há avaliações

- V A25d-A40d D10, D12 PDFDocumento28 páginasV A25d-A40d D10, D12 PDFBEEMK_01Ainda não há avaliações

- Power For Electrical GenerationDocumento4 páginasPower For Electrical Generationagil9551Ainda não há avaliações

- Delphi HpcrsDocumento2 páginasDelphi HpcrsSrikanth SridharanAinda não há avaliações

- V ACTenginebrochureConexpo2005Documento12 páginasV ACTenginebrochureConexpo2005Halil KaraAinda não há avaliações

- Porsche Engine Power PlusDocumento4 páginasPorsche Engine Power PluswattafillingAinda não há avaliações

- Optimized Service Intervals For Caterpillar EquipmentDocumento34 páginasOptimized Service Intervals For Caterpillar EquipmentGracia SediAinda não há avaliações

- Brochure l45h l50h t4f en 21 20048824 BDocumento28 páginasBrochure l45h l50h t4f en 21 20048824 BHidrokop PuteviAinda não há avaliações

- Multec Gasoline Multi Port Fuel Injectors PDFDocumento3 páginasMultec Gasoline Multi Port Fuel Injectors PDFAlejandro SabaAinda não há avaliações

- Brochure l150h l180h l220h t4f en 21 20039761 GDocumento28 páginasBrochure l150h l180h l220h t4f en 21 20039761 GMustafa YilmazAinda não há avaliações

- A35d A40dDocumento28 páginasA35d A40dcankurtaran50% (2)

- Specalog 745Documento28 páginasSpecalog 745Aulia Farhan100% (1)

- CAT 950H Wheel LoaderDocumento28 páginasCAT 950H Wheel Loaderojhawk1380% (5)

- PDF Partees PrincipalesDocumento13 páginasPDF Partees Principalesguapo86Ainda não há avaliações

- BP Hydraulik Pum Mot EnGB 144026Documento44 páginasBP Hydraulik Pum Mot EnGB 144026Jasmin Kahrimanovic100% (3)

- EC140D EC160D and EC220D BrochureDocumento24 páginasEC140D EC160D and EC220D BrochureRomuald PogorzelczykAinda não há avaliações

- Engine TuningDocumento7 páginasEngine TuningJOSE100% (1)

- Mech Valvetronic Engine Technology ReportDocumento20 páginasMech Valvetronic Engine Technology Reportsubhankar dash0% (1)

- Brochure l150g l180g l220g T4i en 21 20023724 C PDFDocumento32 páginasBrochure l150g l180g l220g T4i en 21 20023724 C PDFram_thriveniAinda não há avaliações

- Spesifikasi Wheel Loader Volvo E-Handbook PDFDocumento32 páginasSpesifikasi Wheel Loader Volvo E-Handbook PDFMuhammad Ilham Al-Fayyaadl IAinda não há avaliações

- Delphi Medium Duty Diesel Electronic Unit Pump: BenefitsDocumento2 páginasDelphi Medium Duty Diesel Electronic Unit Pump: BenefitsAmerican Bosch Diesel Olzam SasAinda não há avaliações

- Preface: Practical Knowledge Leads A Man To Perfection'Documento17 páginasPreface: Practical Knowledge Leads A Man To Perfection'Shrigopal PrajapatAinda não há avaliações

- V A25d-A40d 211 2507 (0210Documento15 páginasV A25d-A40d 211 2507 (0210Asenat Sarai Velazquez100% (1)

- Ti FCMDocumento28 páginasTi FCMpapaki2100% (1)

- L110 120FDocumento32 páginasL110 120Fdalibor_bogdan100% (1)

- Delphi MT05 Engine Control Module Series: BenefitsDocumento2 páginasDelphi MT05 Engine Control Module Series: BenefitsAdrian IvanissevichAinda não há avaliações

- Brochure l150h l180h l220h t4f en 22 20039762 HDocumento28 páginasBrochure l150h l180h l220h t4f en 22 20039762 HAdnan MujkicAinda não há avaliações

- GM 6.2 & 6.5 Liter Diesel Engines: How to Rebuild & ModifyNo EverandGM 6.2 & 6.5 Liter Diesel Engines: How to Rebuild & ModifyAinda não há avaliações

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsNo EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsNota: 5 de 5 estrelas5/5 (5)

- VW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)No EverandVW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Nota: 1 de 5 estrelas1/5 (3)

- Fisher Fieldvue DVC6200 SIS Digital Valve Controller: Instruction ManualDocumento116 páginasFisher Fieldvue DVC6200 SIS Digital Valve Controller: Instruction Manualanon_179203922Ainda não há avaliações

- BVA J Series Manual Toe JackDocumento12 páginasBVA J Series Manual Toe JackTitanplyAinda não há avaliações

- Alfa Laval Thinktop v50 and v70 Instruction ManualDocumento32 páginasAlfa Laval Thinktop v50 and v70 Instruction ManualEsteban BaezaAinda não há avaliações

- Syngas Valve Train Techno-Commercial Quote & Schematic: Mash MakesDocumento9 páginasSyngas Valve Train Techno-Commercial Quote & Schematic: Mash MakesShamshuddin TanekhanAinda não há avaliações

- Control Valve SizingDocumento4 páginasControl Valve SizingMehfuz AnsariAinda não há avaliações

- Hyster S40CPDocumento247 páginasHyster S40CPAlessandro de Oliveira100% (1)

- Mechanical Completation and PrecommissioningDocumento11 páginasMechanical Completation and Precommissioninggiovanni perozzi100% (1)

- Compresor QSB-25 Libro de PartesDocumento82 páginasCompresor QSB-25 Libro de PartesGustavo Gamarra100% (1)

- DeHav Dash 8 AMM CH06Documento72 páginasDeHav Dash 8 AMM CH06jmcaero100% (1)

- E-101-25 KitZ ValveDocumento52 páginasE-101-25 KitZ ValveHoang Cong DungAinda não há avaliações

- TT US Circuit-Saver PDFDocumento7 páginasTT US Circuit-Saver PDFxxshAinda não há avaliações

- Ba 921Documento36 páginasBa 921Jason Cecile100% (1)

- SX 1D Users Manual - EngDocumento1 páginaSX 1D Users Manual - EngZepo DepoAinda não há avaliações

- Private Fire HydrantDocumento4 páginasPrivate Fire HydrantAkilaJosephAinda não há avaliações

- 17561Documento30 páginas17561Amit GhadeAinda não há avaliações

- MEPF-Testing and Commissioning ChecklistDocumento90 páginasMEPF-Testing and Commissioning ChecklistADEN LIUAinda não há avaliações

- Master Store Items With LPP 12-09-2022Documento44 páginasMaster Store Items With LPP 12-09-2022m.braumAinda não há avaliações

- Spitwater 10120Documento11 páginasSpitwater 10120Brendon Stanley100% (1)

- 3TNV88 NHBDocumento29 páginas3TNV88 NHBPablo Burgos100% (1)

- Grundfos Submersible Deep Well - Motor - Acc - SP a-SPDocumento104 páginasGrundfos Submersible Deep Well - Motor - Acc - SP a-SPIlyas Kurniawan100% (2)

- Sona GroupDocumento56 páginasSona GroupbrindatammaAinda não há avaliações

- SafetyValveCorp E110-12 v3Documento4 páginasSafetyValveCorp E110-12 v3K Mohana PraneshAinda não há avaliações

- Renewal Parts YK (Stype F)Documento56 páginasRenewal Parts YK (Stype F)Thang TV100% (2)

- AVID CR Position MonitorsDocumento5 páginasAVID CR Position MonitorsNanDo Wandi SaputraAinda não há avaliações

- How To Do Mechanical WalkthroughDocumento6 páginasHow To Do Mechanical WalkthroughPulung Dwi AnggoroAinda não há avaliações

- 2 WaydistributorDocumento53 páginas2 WaydistributormbhaditAinda não há avaliações

- What Went Wrong Issue 55Documento4 páginasWhat Went Wrong Issue 55kirandevi1981Ainda não há avaliações

- Electro HydraulicsDocumento202 páginasElectro HydraulicsRavikumar GangadharanAinda não há avaliações

- Code: Btpp/Turbine/007/Vacuum Raising Guidelines For Condenser Vacuum Raising PreconditionDocumento5 páginasCode: Btpp/Turbine/007/Vacuum Raising Guidelines For Condenser Vacuum Raising PreconditionPrakash ChoudharyAinda não há avaliações

- Fuel Delivery Pipe Removal: Engineer's Handbook Cylinder HeadDocumento25 páginasFuel Delivery Pipe Removal: Engineer's Handbook Cylinder HeadJavierAinda não há avaliações