Escolar Documentos

Profissional Documentos

Cultura Documentos

S.V.Tillu, R.S.Lokhande, J. Bacardit

Enviado por

inventionjournalsTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

S.V.Tillu, R.S.Lokhande, J. Bacardit

Enviado por

inventionjournalsDireitos autorais:

Formatos disponíveis

International Journal of Pharmaceutical Science Invention

ISSN (Online): 2319 6718, ISSN (Print): 2319 670X

www.ijpsi.org Volume 4 Issue 7 July 2015 PP.20-27

Effect of solvents on formation of disulphide bond in peptides: A

comparative study to produce the peptide using solvents used for

purification and therefore to reduce the introduction of chemicals

or metal ions in the manufacturing process.

S.V.Tillu1, R.S.Lokhande2, J. Bacardit3

1,2,3

Department of Chemistry, Jaipur National University, Jaipur-302017, India.

Abstract: A novel approach to the formation of disulphide bonds in peptides is developed by doing a series of

experiments to evaluate effect of solvents on the disulphide bond formation in peptides in terms of time required,

recovery, ease of processing during reaction working up and use of solvents. For evaluating the effect,

experiments were setup using Water:Acetonitrile, Water:Methanol and Water:Ethanol for disulphide bond

formation of Desmopressin and the results were compared with the aerial oxidation conducted in water. For

each solvent, a set of oxidation reactions was studied at 0.5 mg/ml, 1 mg/ml and 5 mg/ml concentration. The

acetonitrile water combination at concentration of either 0.5mg/ml or 1 mg/ml proved to deliver the best result

in terms of purity, yield and time required to complete reaction.

Keywords: Acetonitrile, Desmopressin Bis-SH, Ethanol, Methanol Peptide

I.

Introduction:

Disulfide bridges play a crucial role in the folding and structural stabilization of many important

extracellular peptides and proteins. In addition, the artificial introduction of extra disulfide bond into peptides

or proteins allows the creation of conformational constraints that can improve biological activity or thermo

stability. Due to that, disulfide bond containing peptides or proteins are very challenging to manufacture. Now

a-days biologically active molecules that are natural in sources or mimic of natural source are playing an

important role in curing/treating life threatening conditions. Scientists are working on peptide based

formulations which can lead to less aggressive treatment for those conditions, and as peptides are the naturally

occurring chemical entities in the body and therefore it is easier to control the diseases without too many side

effects.

Methods of disulphide bridge formation (1, 3 to12)

Lot of efforts have been put towards developing cyclisation strategies of Cysteine containing peptide. A review

of summarized work can be summarized as follows: (1, 3 to12)

1. Cyclisation of SH containing precursor by Aerial oxidation: In this method during the synthesis

protecting groups are removed by side chain deprotection reagent and the resulting Bis-SH peptide is

subjected to aerial oxidation in presence of molecular oxygen or oxygen bubbling. In this method the

peptide is oxidized typically at low concentration (0.1 mg/ml to 1 mg/ml).

That method is easy and straightforward to apply and also very mild for other amino acids in the molecule

(i.e fewer chances of side reaction happening) but being in diluted state it introduces for use of additional

concentration step such as reverse osmosis or adsorption on synthetic resins. Sometimes reactions take

days to complete.

2. Symmetrical Cyclisation from S-protected precursor:

Cyclisation of cysteine protected by Acm-group (i.e acetamidomethyl CH2-NH-CO-CH3) is done by using

iodine, thallium (III) Trifluoroacetate and a variety of alkyl trichlorosilanesulphoxide combinations. This

approach is used for intramolecular or intermolecular disulfide bond formation and it has the drawback that

side reaction are frequent specially on residues susceptible of entering redox reactions (e.g. Tryptophan).

Following are some protocols for oxidation of peptide containing cysteine:

1. Air oxidation

2. Oxidation by I2, Tl (III) Trifluoroacetate

3. Oxidation by potassium ferricyanide

4. Oxidation mediated by Charcoal

5. DMSO oxidation both in acidic and basic condition.

www.ijpsi.org

20 | P a g e

Effect of solvents on formation of disulphide

Every protocol has its advantages and disadvantages. Air oxidation is very clean and doesnt contain any harsh

chemical apart from the buffer, however some reaction take long time to complete (e.g. 40-72 days) even at

highly alkaline pH which might hydrolyse the peptide. In other protocols metal ions and high boiling solvents

are used as oxidizing agent are not easy to remove. So overall the cyclisation reaction of Cysteine containing

peptide is a key step in the manufacturing process, the quality and the quantity of peptide is dependent on the

outcome of this reaction. On industrial scale if we cannot get good yields with best quality then the resulting

product becomes difficult to process therefore in cyclic peptides oxidation is the key reaction and can affect the

quality and quantity of the product obtained.

II.

Materials and Methods:

Cyclisation of desmopressin Bis-SH was studied at 3 different concentration i.e 0.5mg/ml, 1mg/ml, 5 mg/ml

using Water, 50% ACN+50%WATER or 50% MEOH+50%WATER or 50% ETOH+50%WATER as follows:

Concentration: 0.5 mg/ml,

50 mg Desmopressin Bis-SH were weighed and dissolved separately in 100 ml of water, 50% ACN+WATER,

50% MEOH+WATER or 50% ETOH+WATER to perform reaction at 0.5 mg/ml concentration.

1. pH of the reaction was checked at the start and samples injected on HPLC as Before pH.

2. pH of the reaction was adjusted to 9.50.5 using ammonia solution.

3. Progress of reaction was checked by HPLC and pH was checked at regular interval.

4. After achieving a consume of the % of Desmopressin Bis-SH higher than 98.5% the reaction was

stopped by addition of acetic acid.

Concentration: 1 mg/ml,

100 mg Desmopressin Bis-SH weighed and dissolved separately in 100 ml of water, 50% ACN+WATER, 50%

MEOH+WATER or 50% ETOH+WATER to perform oxidation at 1 mg/ml concentration.

1. pH of the reaction was checked at the start and samples injected on HPLC as Before pH.

2. pH of the reaction was adjusted to 9.50.5 using ammonia solution.

3. Progress of reaction was checked by HPLC and pH was checked at regular interval.

4. After achieving a consume of the % of Desmopressin Bis-SH higher than 98.5% the reaction was

stopped by addition of acetic acid.

Concentration: 5 mg/ml,

500 mg Desmopressin Bis-SH weighed and dissolved separately in 100 ml of water, 50% ACN+WATER, 50%

MEOH+WATER or 50% ETOH+WATER to perform reaction at 5 mg/ml concentration.

1. pH of the reaction was checked at the start and samples injected on HPLC as Before pH.

2. pH of the reaction was adjusted to 9.50.5 using ammonia solution.

3. Progress of reaction was checked by HPLC and pH was checked at regular interval.

4. After achieving a consume of the % of Desmopressin Bis-SH higher than 98.5% the reaction was

stopped by addition of acetic acid.

Progress of reactions as follows:

50%ACN+50%Water, 1 mg/ml concentration

uV

2500000

2250000

2000000

1750000

1500000

1250000

1000000

750000

500000

250000

0

12.5

15.0

17.5

20.0

www.ijpsi.org

22.5

25.0

27.5

min

21 | P a g e

Effect of solvents on formation of disulphide

50%ACN+50%Water,

0.5 mg/ml concentration

uV

2000000

1750000

1500000

1250000

1000000

750000

500000

250000

0

18.0

19.0

20.0

21.0

22.0

min

50%ACN+50%Water,

5 mg/ml concentration

uV

2250000

2000000

1750000

1500000

1250000

1000000

750000

500000

250000

16.0

17.0

18.0

19.0

20.0

21.0

22.0

23.0

24.0 min

50%Ethanol+50%Water,

1 mg/ml concentration

uV

2250000

2000000

1750000

1500000

1250000

1000000

750000

500000

250000

0

18.0

18.5

19.0

19.5

20.0

20.5

21.0

21.5

22.0min

50% Ethanol +50%Water, 0.5 mg/ml concentration

uV

2000000

1750000

1500000

1250000

1000000

750000

500000

250000

0

18.0

19.0

20.0

21.0

22.0 min

50% Ethanol +50%Water, 5 mg/ml concentration

uV

2000000

1750000

1500000

1250000

1000000

750000

500000

250000

0

17.5

18.0

18.5

19.0

19.5

www.ijpsi.org

20.0

20.5

21.0

21.5

min

22 | P a g e

Effect of solvents on formation of disulphide

50% Methanol +50%Water, 1 mg/ml concentration

uV

2000000

1750000

1500000

1250000

1000000

750000

500000

250000

0

18.0

19.0

20.0

21.0

22.0

23.0

min

50% Methanol +50%Water, 0.5 mg/ml concentration

2250000

uV

2000000

1750000

1500000

1250000

1000000

750000

500000

250000

0

18.0

19.0

20.0

21.0

22.0

min

50% Methanol +50%Water, 5 mg/ml concentration

uV

2250000

2000000

1750000

1500000

1250000

1000000

750000

500000

250000

0

18.0

19.0

20.0

21.0

22.0

min

Water, 1 mg/ml concentration

2500000

uV

2250000

2000000

1750000

1500000

1250000

1000000

750000

500000

250000

0

17.5

20.0

22.5

min

Water, 0.5 mg/ml concentration

uV

2250000

2000000

1750000

1500000

1250000

1000000

750000

500000

250000

0

15. 0

17. 5

www.ijpsi.org

20. 0

22. 5

min

23 | P a g e

Effect of solvents on formation of disulphide

Water, 5 mg/ml concentration

uV

1000000

750000

500000

250000

18.0

19.0

20.0

21.0

22.0

min

The overlapped chromatograms above are showing the progress of the oxidation in each reaction condition. The

overlap is followed in the sequence from top to bottom as desmopressin std, desmopressin Bis-SH standard,

reaction at 0 hours to completion of reaction. The first graph in each is overlap is of desmopressin std, second is

of desmopressin bis-SH std, third is of 0 hours and then subsequent hours, the last graph is after acetic acid

addition.

Details of Analytical Method used for Monitoring the Reaction:

1. Buffer A: Dissolve 9.08 gm of Potasium dihydrogen phosphate in 1 L water and add 5 ml of

Trifluoroacetic acid and 5 ml Triethyl amine mix well and adjust pH to 5.01 with 10N NaOH.

2. Buffer B: 500 ml Buffer A+425 ml Acetonitrile+75ml Tetrahydrofuran.

3. Preparation of Desmopressin Standard Solution: Desmopressin Working Standard Vial dissolved in 25

ml of Milli-Q water.

4. Preparation of Desmopressin Bis-SH Standard Solution: 12.5 mg of desmopressin Bis-SH were

dissolved in 25 ml of water.

5. Resolution Solution: Oxytocin Desmopressin validation mixture dissolved in water to obtain a

concentration of 0.25mg/ml

6. Test Solution: 1 ml of sample diluted to 10 ml Milli-Q water.

Chromatographic condition:

C18, 250X4.6mm, 5

Column

1.5ml/min

Flow rate

50 L for Blank, Std solution ( Desmopressin and Desmopressin Bis-SH)

Injection volume

50 L for Test solution

50 min

Run time

System Suitability: Details of Analysis

Sample Solution

Retention Time of Principal Peak

Desmopressin Std Solution

Around 19 min

Desmopressin Bis-SH Std Solution

Around 20 min

Resolution between main peak due to Desmopressin

and main peak due to Oxytocin

NLT 1.5

www.ijpsi.org

24 | P a g e

Effect of solvents on formation of disulphide

III.

Result and Discussion:

Cyclisation reaction in water:

In terms of purity: The cyclized desmopressin obtained by aerial oxidation at three different concentration of

0.5mg/ml, 1 mg/ml, 5 mg/ml showed purities of 62.71%, 56.06% and 61.51% respectively which is lower as

compared to other experiments done with other solvents.

In terms of Time: The cyclisation reaction of desmopressin by aerial oxidation, at three different

concentration of 0.5mg/ml, 1 mg/ml, 5 mg/ml took 17 hours, 33 hours and 35 hours respectively. The time at 1

mg/ml and 5 mg/ml is the longest time taken by reaction for completion as compared to other reaction

conditions.

In terms of Yield: Yield of the cyclisation reaction of desmopressin by aerial oxidation, at three different

concentrations of 0.5mg/ml, 1 mg/ml, 5 mg/ml was 107.68%, 113.30% and 18.42% respectively.

From the above observation it is clear that even though water is the cleanest way to do the cyclisation of

peptides, due to solubility issues of peptides in water there are chance of low reaction yield. As the reaction

takes longer time for completion therefore there are more chances of disulphide scrambling and thus more

unwanted dimers or polymers can form during cyclisation reaction, which leads to low yields and poor purity

levels, purity. Therefore it is clear that the water alone is not a suitable medium for cyclisation reaction of

peptides.

Cyclisation reaction in Water: Acetonitrile:

In terms of purity: The cyclized desmopressin obtained by Water:Acetonitrile oxidation and at three different

concentrations of 0.5mg/ml, 1 mg/ml and 5 mg/ml showed purity by HPLC of 76.61%, 74.76% and 72.92%

respectively which is comparably higher when as compared to other experiments done with other solvents.

In terms of Time: The cyclisation reaction of desmopressin by Water: Acetonitrile oxidation, at three different

concentrations (0.5mg/ml, 1 mg/ml, 5 mg/ml) took 8 hours, 11 hours and 18 hours respectively. Even though

the reaction took comparably similar time with respect to reaction in Water: Methanol, Water: Ethanol in terms

of purity and yield it was higher in acetonitrile: water mixtures than in any of the other experimental conditions.

In terms of Yield: Yield of the cyclisation reaction of desmopressin by Water: Acetonitrile oxidation, at three

different concentrations (0.5mg/ml, 1 mg/ml, 5 mg/ml) was 133.81%, 106.07% and 133.81% respectively.

Considering overall Yield, time taken for completion of reaction and purity then the Water:Acetonitrile

reaction condition is comparatively cleaner and therefore preferred over Water:Methanol and Water:Ethanol

solvent conditions

Cyclisation reaction in Water: Methanol:

In terms of purity: The cyclized desmopressin obtained by Water:Methanol oxidation and at three different

concentrations (0.5mg/ml, 1 mg/ml, 5 mg/ml) was having purity of 76.82%, 77.68% and 76.25% respectively

which is comparably high at all three concentration conditions when compared with results for other solvents

In terms of Time: The cyclisation reaction of desmopressin by Water: Methanol oxidation, at three different

concentrations (0.5mg/ml, 1 mg/ml, 5 mg/ml) took 18 hours, 10 hours and 22 hours respectively. Even though

the purity of desmopressin using this condition is better than the previous, The time required for reaction is

higher as compared to other conditions and that can lead to lower yield.

In terms of Yield: Yield of the cyclisation reaction of desmopressin by Water: Methanol oxidation, at three

different concentrations (0.5mg/ml, 1 mg/ml, 5 mg/ml) was 136.89%, 114.74% and 102.29% respectively.

www.ijpsi.org

25 | P a g e

Effect of solvents on formation of disulphide

Even though Reaction at 0.5mg/ml was having comparable yield and purity with cyclisation reaction using

Water: Acetonitrile at 0.5 mg/ml and 1mg/ml, Still time taken to complete the reaction in Water: Methanol

media at 0.5mg/ml was 18 hours which longer than the Water: Acetonitrile (8 hours). Reaction at 1 mg/ml took

only 10 hours to complete. The yield was only 114.74% which is 18.07 % lower than Water: Acetonitrile

reaction at 0.5mg/ml. Reaction at 5 mg/ml took 22 hours to complete and had lower yields due to longer

reaction times.

Cyclisation reaction in Water: Ethanol:

In terms of purity: The cyclized desmopressin obtained by Water:Ethanol aerial oxidation and at three

different concentrations (0.5mg/ml, 1 mg/ml, 5 mg/ml) was having purity of 72.82%, 73.23% and 76.25%

respectively which was comparably lower as compared to experiments done in Water:Acetonitrile and

Water:Methanol.

In terms of Time: The cyclisation reaction of desmopressin by Water:Ethanol aerial oxidation, at three

different concentrations (0.5mg/ml, 1 mg/ml, 5 mg/ml) took 7 hours, 17 hours and 7 hours respectively. The

reaction time in Water: Ethanol is comparable to that of Water: Acetonitrile mixtures. Yields are also

comparable but purities are slightly lower (76.61% in Water: Acetonitrile and 72.82% in Water: Ethanol).

In terms of Yield: Yield of the cyclisation reaction of desmopressin by Water: Ethanol oxidation, at three

different concentrations (0.5mg/ml, 1 mg/ml, 5 mg/ml) was 134.94%, 124.26% and 88.93% respectively.

Conclusion:

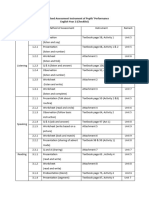

The results of the above experiments are tabulated in following table in order of decreasing yield.

Time

% yield as compared to

concentration required

area of desmopressin BisPurity of

Medium of reaction

of reaction in for

SH at start and

desmopressin

mg/ml

completion Desmopressin at end of

in Hours

reaction

50%MEOH +50% Water

0.5

18

136.89%

76.82%

50%ETOH + 50%Water

0.5

7

134.94%

72.82%

50%Acetonitrile+50%Water

0.5

8

133.81%

76.61%

50%Acetonitrile+50%Water

5

18

132.01%

72.92%

50%ETOH + 50%Water

1

17

124.26%

73.23%

50%MEOH +50% Water

1

10

114.74%

77.68%

Water

1

33

113.30%

56.06%

Water

0.5

17

107.68%

62.71%

50%Acetonitrile+50%Water

1

11

106.07%

74.76%

50%MEOH +50% Water

5

22

102.29%

76.25%

50%ETOH + 50%Water

5

7

88.93%

66.25%

Water

5

35

18.42%

61.51%

From above observation it is clear that reaction in acetonitrile and water as a medium is one of the best

combination for disulphide bond formation in peptides. Higher yields of the reaction are indicating towards an

improved solubility of peptides in the Water: solvent mixtures. The time required for reactions is comparably

less as compared to reactions in water. Due to lower reaction times and higher yields the concentration

condition of 0.5 mg/ml and 1 mg/ml in Water: Acetonitrile are selected as suitable for cyclisation of

desmopressin at industrial scale. Similarly this can be applied to other peptides to improve the yields and

lowering the time of processing by using organic solvents for oxidation compatible with those used during the

purification step.

Acknowledgement:

We are thankful to Hemmo Pharmaceuticals Pvt. Ltd. for the support provided for research.

www.ijpsi.org

26 | P a g e

Effect of solvents on formation of disulphide

Reference:

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

[18]

[19]

[20]

[21]

David Andreu, Fernando Albercio, Nuria A. Sole, Mark C Munson, Ferrer, George Barany, Formation of disulfide bonds in

peptides and proteins In Peptide Synthesis Protocols, (91-169 Pennington, M.W.Bunn, B.M.ED, Humana Press: New Jersey,

1994)

Jacek Leluk, , Why Cysteine is Special?, Institute of Biochemistry and Molecular Biology, University of Wroclaw, Poland.

Jean E.F. Rivier, La Jolla, Robert F. Galyean, San Marcos, Calif, Method for cyclisation of peptides, US patent 4216141, 1980.

Grzegorz Bulaj, Biotechnology Advances, Formation of disulfide bonds in proteins and peptides 23, 2005, 87-92.

James P Tam, Disulfide Bond Formation in Peptides by Dimethyl Sulphoxide. Scope and Application, Journal of American

Chemical Society, 113, 1991, 6657-6662.

Lin Chen, Ioana Annis and George Barany, Current protocols in protein sciences, Disulfide Bond formation in Peptides, (John

Wiley and Sons, Inc., 2001)18.6.1 18.6.19.

Xio-Yan Wang et. al., Synthesis of small cyclic peptides containing the disulfide bond, ARKIVOC 2006 (xi), 2006, 1-7.

Ruth Hogue Angelettil, Lisa Bibbs, Lynda F. Bonewald, Gregg B Fields, John S Mcmurray, William T Moore and John T.

Stulrs, Formation of a disulfide bond in an Octreotide-Like Peptide: A Multicenter Study, Techniques in Protein Chemistry VII,

1996, 261-273.

Christian B. Anfinsen and Edgar Haber, Studies on the reduction and re-formation of protein disulfide bonds, The journal of

biological chemistry, 236(5), 1961, 1361-1363.

Christian Birr, Leimen/St. Ilgen Fed. Rep. of Germany, Process for the selective formation of disulfide bridges in polypeptides

and therapeutic compositions, US Patent 4351764, 1982.

David Stevenson, Scarsdale, N.Y; Mohammad A Islam, Edison N.Y, Process for the preparation and purification of peptides,

US patent 4623716, 1986.

Dallas L. Rabenstein, Tiesheng Shi, Chemical reagents for formation of disulfide bonds in peptides, US patent 6686443 B1,

2004.

A.P.Ryle, F. Sanger, F. Smith, Ruth Kitai, The disulfide Bonds of Insulin, Bioch.,1954, 541-556.

Jiang Wu and J Throck Watson, Edited by: C. Kannicht, Method Molecular Biology, Posttranslational Modifications of Proteins:

Tools for Functional Proteomics, Assignment of Disulfide Bonds in Proteins by chemical Cleavage and Peptide Mapping by

Mass Spectroscopy. ( Humana Press Inc., Totowa, NJ), 2002) 194:1-22

Freedman, R. B., Hirst, T. R., and Tuite, M. F. Protein disulfide isomerase: building bridges in protein folding. Trends Biochem.

Sci. 19, 1994, 331336.

Creighton, T. E. Disulfide bond formation in proteins, in Methods in Enzymology, vol. 107 (Wold, F. and Moldave, K.,eds,

1984), Academic, San Diego, CA, pp. 305329.

Smith, D. L. and Zhou, Z., Strategies for locating disulfi de bonds in proteins, in Methods in Enzymology, vol. 193 (McCloskey,

J. A., ed., 1990), Academic, NewYork, pp. 374389.

Miriam Gongora-Benitez, Fernando Albericio et.all, Optimised Fmoc-Solid-Phase Synthesis of Cysteine-Rich Peptide

Linaclotide, Peptide Science, Vol.96, 2010, 69-80.

K.M. Bhaskara Reddy et.all, Large Scale Solid Phase Synthesis of Peptide Drugs: Use of Commercial Anion Exchange Resin as

Quenching Agent for Removal of Iodine during Disulphide Bond Formation, International Journal of Peptides, volume 2012.

John S. Davies, The Cyclization of Peptides and Depsipeptides, Journal of Peptide Science,9, 2003, 471-501.

Hirokazu Tamamura, et.all, Disulfide Bond Formation in S-Acetamidomethyl Cysteine-Conataining peptides by the Combination

of Silver Trifluoromethanesulfonate and Dimethylsolfoxide/Aqueous HCl, Tetrahydron Letters, Vol. 34 No.31, 1993, 49314934.

www.ijpsi.org

27 | P a g e

Você também pode gostar

- The Year's Best Horror Stories - Karl Edward Wagner PDFDocumento298 páginasThe Year's Best Horror Stories - Karl Edward Wagner PDFAmbaejo96100% (1)

- Acupuncture Desk ReferenceDocumento418 páginasAcupuncture Desk Referencegigicarvajal96% (27)

- Tracing Practice Preschool Workbook PDFDocumento20 páginasTracing Practice Preschool Workbook PDFO ga100% (3)

- Simple Stress & StrainDocumento34 páginasSimple Stress & StrainfaisalasgharAinda não há avaliações

- Disha Computer KnowledgeDocumento247 páginasDisha Computer KnowledgeBalachandarMahadevanAinda não há avaliações

- Bio Lab 8 (Submit)Documento6 páginasBio Lab 8 (Submit)Nor Ashikin IsmailAinda não há avaliações

- Student Engagement: A Comparative Analysis of Traditional and Nontradional Students Attending Historically Black Colleges and UniversitiesDocumento12 páginasStudent Engagement: A Comparative Analysis of Traditional and Nontradional Students Attending Historically Black Colleges and Universitiesinventionjournals100% (1)

- Enzyme Lab Report FinalDocumento6 páginasEnzyme Lab Report Finalrsenser2100% (2)

- Williamson Synthesis Lab ReportDocumento5 páginasWilliamson Synthesis Lab ReportNicholas Johnson100% (2)

- EnzymeDocumento5 páginasEnzymeBinnie KaurAinda não há avaliações

- Practical BiochemistryDocumento35 páginasPractical BiochemistryMockinjay100% (1)

- Strut & Tie ModelDocumento67 páginasStrut & Tie Modelahmed adel100% (9)

- Effect of Organic Solvents Antigen Antibody InteractionsDocumento7 páginasEffect of Organic Solvents Antigen Antibody InteractionsMohammad RehanAinda não há avaliações

- Enzyme Catalytic Promiscuity The Papain-Catalyzed Knoevenagel Reaction (Paper 2)Documento6 páginasEnzyme Catalytic Promiscuity The Papain-Catalyzed Knoevenagel Reaction (Paper 2)thamtusieuquayAinda não há avaliações

- Biology Coursework Hydrogen PeroxideDocumento6 páginasBiology Coursework Hydrogen Peroxidekezevifohoh3100% (1)

- New Colorimetric Methodfor Lipases Activity Assayin Microbial MediaDocumento4 páginasNew Colorimetric Methodfor Lipases Activity Assayin Microbial MediaFina Mustika SimanjuntakAinda não há avaliações

- Analysis of SalivaDocumento14 páginasAnalysis of Salivajgbalanay8492antAinda não há avaliações

- Esterification Process To Synthesize Isopropyl Chloroacetate Catalyzed by Lanthanum Dodecyl SulfateDocumento6 páginasEsterification Process To Synthesize Isopropyl Chloroacetate Catalyzed by Lanthanum Dodecyl SulfateVinay JainAinda não há avaliações

- Bio Lab ReportDocumento10 páginasBio Lab ReportMariamAinda não há avaliações

- Total Oxidant Status (TOS) : Fully AutomatedDocumento2 páginasTotal Oxidant Status (TOS) : Fully AutomatedvyasakandarpAinda não há avaliações

- A Validated Stability Indicating Uplc Method For Montelukast Impurities in Montelukast Sodium Oral GranulesDocumento12 páginasA Validated Stability Indicating Uplc Method For Montelukast Impurities in Montelukast Sodium Oral GranulesHanimi ReddyAinda não há avaliações

- Journal of Biodiversity and Environmental Sciences (JBES)Documento9 páginasJournal of Biodiversity and Environmental Sciences (JBES)International Network For Natural SciencesAinda não há avaliações

- Enzymatic Hydrolysis of Gluten From Wheat FlourDocumento4 páginasEnzymatic Hydrolysis of Gluten From Wheat FlourLynzee Reyes100% (1)

- Lab BiochemDocumento14 páginasLab BiochemHyacinth Damolo88% (8)

- Enzyme Liver Catalase Hydrogen PeroxideDocumento9 páginasEnzyme Liver Catalase Hydrogen PeroxideCarmen Muir100% (2)

- Mahyar Rahmani IA Biology Final DraftDocumento13 páginasMahyar Rahmani IA Biology Final Draftvaldisspam.0Ainda não há avaliações

- TMP 83 F3Documento8 páginasTMP 83 F3FrontiersAinda não há avaliações

- Extraction: Miranda, Marilyn, de Guzman, Anne KDocumento4 páginasExtraction: Miranda, Marilyn, de Guzman, Anne KAegeeAinda não há avaliações

- OptimizationofExtractionofBioactiveAlkaloidsandAntioxidantsfromRhizomeCoptidisCoptischinensisFranchbyusingResponseSurfaceMethodology. 012 0103 4Documento9 páginasOptimizationofExtractionofBioactiveAlkaloidsandAntioxidantsfromRhizomeCoptidisCoptischinensisFranchbyusingResponseSurfaceMethodology. 012 0103 4MANUEL ALEJANDRO CHACON FUENTESAinda não há avaliações

- Lipid Peroxidation Inhibition and Antiradical Activities of Some Leaf Fractions of Mangifera IndicaDocumento7 páginasLipid Peroxidation Inhibition and Antiradical Activities of Some Leaf Fractions of Mangifera IndicaRoy WilsonAinda não há avaliações

- Research Article: Silica Sol-Gel Entrapment of The Enzyme ChloroperoxidaseDocumento11 páginasResearch Article: Silica Sol-Gel Entrapment of The Enzyme ChloroperoxidaseShalwa 29Ainda não há avaliações

- Solubility and Dissolution Improvement of Ketoprofen by Emulsification Ionic GelationDocumento7 páginasSolubility and Dissolution Improvement of Ketoprofen by Emulsification Ionic GelationAfifah Dwi CahyaniAinda não há avaliações

- Interaction of Carbohydrates With Alcohol Dehydrogenase: Effect On Enzyme ActivityDocumento5 páginasInteraction of Carbohydrates With Alcohol Dehydrogenase: Effect On Enzyme ActivityindahAinda não há avaliações

- Journal Periodica Polytechnica 2018Documento6 páginasJournal Periodica Polytechnica 2018Martin Raynaldi SimanjuntakAinda não há avaliações

- Acs74 - 46 56758gfhydnsmDocumento6 páginasAcs74 - 46 56758gfhydnsmAnn Nitha ChanAinda não há avaliações

- FlavocillinspecificationDocumento12 páginasFlavocillinspecificationjeyiy92174Ainda não há avaliações

- Isolation of Invertase PHDocumento4 páginasIsolation of Invertase PHJohn Mark Flores VillenaAinda não há avaliações

- Activity 20 25Documento8 páginasActivity 20 25wangshannahAinda não há avaliações

- Lab Report 3Documento7 páginasLab Report 3Shelby StottsAinda não há avaliações

- BET Newsletter July2010Documento5 páginasBET Newsletter July2010vpnarashimmanAinda não há avaliações

- Enzymes Formal ReportDocumento5 páginasEnzymes Formal ReportLian Phillip DonatoAinda não há avaliações

- Test Instructions For Measuring The Microbial Metabolic Activity in Water Samples - ObstDocumento3 páginasTest Instructions For Measuring The Microbial Metabolic Activity in Water Samples - ObstgotcanAinda não há avaliações

- Giotrif: MiljöpåverkanDocumento4 páginasGiotrif: Miljöpåverkanrx bafnaAinda não há avaliações

- Sagar, 2011, Genesis and Development of DPPH Method PDFDocumento11 páginasSagar, 2011, Genesis and Development of DPPH Method PDFkmiloAinda não há avaliações

- Final Report Amit NayakDocumento48 páginasFinal Report Amit NayakAmit NayakAinda não há avaliações

- Effect of Bioenzyme On Deinking Mill Effluent Treatment by Dissolved Air FlotationDocumento12 páginasEffect of Bioenzyme On Deinking Mill Effluent Treatment by Dissolved Air FlotationarjunanpnAinda não há avaliações

- Formulation and Evaluation of Prednisolone Sodium Phosphate InjectionDocumento8 páginasFormulation and Evaluation of Prednisolone Sodium Phosphate InjectionMiranda MileAinda não há avaliações

- Activity of Guaiacol Peroxidase of Solanum Lycopersicum in Presence of Detergents and Chaotropic AgentsDocumento5 páginasActivity of Guaiacol Peroxidase of Solanum Lycopersicum in Presence of Detergents and Chaotropic AgentsIOSR Journal of PharmacyAinda não há avaliações

- 2 - Denaturation of ProteinDocumento3 páginas2 - Denaturation of ProteinnotshiroAinda não há avaliações

- Food Chemistry: I. Stoilova, A. Krastanov, A. Stoyanova, P. Denev, S. GargovaDocumento7 páginasFood Chemistry: I. Stoilova, A. Krastanov, A. Stoyanova, P. Denev, S. GargovaAbhishekShuklaAinda não há avaliações

- Pintilie o 2 16Documento3 páginasPintilie o 2 16Anonymous p52JDZOdAinda não há avaliações

- Diao Et Al.. 2019. Optimized Extraction Process and Compositional Analysis of Bioflocculant Produced by Klebsiella M1Documento22 páginasDiao Et Al.. 2019. Optimized Extraction Process and Compositional Analysis of Bioflocculant Produced by Klebsiella M1Azb 711Ainda não há avaliações

- Tetrahedron Letters 52 (2011) 3339-3341Documento3 páginasTetrahedron Letters 52 (2011) 3339-3341Arthur Girardi CarpanezAinda não há avaliações

- Study On Preparation and Application in Flocculants of Modified LigninDocumento4 páginasStudy On Preparation and Application in Flocculants of Modified LigninTechnologist ChemicalAinda não há avaliações

- Degradation of Methylene Blue Dye Using A Photochemical ReactorDocumento5 páginasDegradation of Methylene Blue Dye Using A Photochemical ReactorIJSTEAinda não há avaliações

- Enzyme Stability - SBiranPhD - ThesisDocumento154 páginasEnzyme Stability - SBiranPhD - ThesisChar YosAinda não há avaliações

- Study of Process Optimization On Aerobic System Treating Tofu Waste WaterDocumento8 páginasStudy of Process Optimization On Aerobic System Treating Tofu Waste WaterDevySetyanaAinda não há avaliações

- Monsal Enzymic Hydrolysis New Developments and Lessons LearntDocumento23 páginasMonsal Enzymic Hydrolysis New Developments and Lessons LearntAnonymous MVHQ97KEoPAinda não há avaliações

- Chemistry 211 Experiment 10Documento9 páginasChemistry 211 Experiment 10zFe 6Ainda não há avaliações

- The Allelopathy and Allelopathic Mechanism of Phenolic Acids On Toxic Microcystis AeruginosaDocumento7 páginasThe Allelopathy and Allelopathic Mechanism of Phenolic Acids On Toxic Microcystis AeruginosaArmando Chiclla SalazarAinda não há avaliações

- The Study of Enzyme Hydrolysis Saccharification Process of Stems and Leaves of BananaDocumento6 páginasThe Study of Enzyme Hydrolysis Saccharification Process of Stems and Leaves of BananaBarnabas Rifqi AbdulrahimAinda não há avaliações

- 1 s2.0 S0304389407005407 MainDocumento6 páginas1 s2.0 S0304389407005407 MainFarah TalibAinda não há avaliações

- Peterson 1983Documento25 páginasPeterson 1983Ryan PratamaAinda não há avaliações

- Ref (Ellman - 1961)Documento9 páginasRef (Ellman - 1961)Tasso SalesAinda não há avaliações

- Accepted Manuscript: International Journal of Biological MacromoleculesDocumento16 páginasAccepted Manuscript: International Journal of Biological MacromoleculesMuhammad LuthfiAinda não há avaliações

- E3sconf Wrem2019 01014Documento9 páginasE3sconf Wrem2019 01014Desmonius Lab GroupAinda não há avaliações

- Quality Control OF Bulk Drug FormulationsNo EverandQuality Control OF Bulk Drug FormulationsAinda não há avaliações

- The Effect of Transformational Leadership, Organizational Commitment and Empowerment On Managerial Performance Through Organizational Citizenship Behavior at PT. Cobra Direct Sale IndonesiaDocumento9 páginasThe Effect of Transformational Leadership, Organizational Commitment and Empowerment On Managerial Performance Through Organizational Citizenship Behavior at PT. Cobra Direct Sale Indonesiainventionjournals100% (1)

- Negotiated Masculinities in Contemporary American FictionDocumento5 páginasNegotiated Masculinities in Contemporary American FictioninventionjournalsAinda não há avaliações

- Effects of Online Marketing On The Behaviour of Consumers in Selected Online Companies in Owerri, Imo State - NigeriaDocumento12 páginasEffects of Online Marketing On The Behaviour of Consumers in Selected Online Companies in Owerri, Imo State - Nigeriainventionjournals100% (1)

- Effects of Online Marketing On The Behaviour of Consumers in Selected Online Companies in Owerri, Imo State - Nigeria.Documento12 páginasEffects of Online Marketing On The Behaviour of Consumers in Selected Online Companies in Owerri, Imo State - Nigeria.inventionjournalsAinda não há avaliações

- A Discourse On Modern Civilization: The Cinema of Hayao Miyazaki and GandhiDocumento6 páginasA Discourse On Modern Civilization: The Cinema of Hayao Miyazaki and GandhiinventionjournalsAinda não há avaliações

- Inter-Caste or Inter-Religious Marriages and Honour Related Violence in IndiaDocumento5 páginasInter-Caste or Inter-Religious Marriages and Honour Related Violence in IndiainventionjournalsAinda não há avaliações

- Islamic Insurance in The Global EconomyDocumento3 páginasIslamic Insurance in The Global EconomyinventionjournalsAinda não há avaliações

- The Network Governance in Kasongan Industrial ClusterDocumento7 páginasThe Network Governance in Kasongan Industrial ClusterinventionjournalsAinda não há avaliações

- The Social Composition of Megaliths in Telangana and Andhra: An Artefactual AnalysisDocumento7 páginasThe Social Composition of Megaliths in Telangana and Andhra: An Artefactual AnalysisinventionjournalsAinda não há avaliações

- The Impact of Leadership On Creativity and InnovationDocumento8 páginasThe Impact of Leadership On Creativity and InnovationinventionjournalsAinda não há avaliações

- An Appraisal of The Current State of Affairs in Nigerian Party PoliticsDocumento7 páginasAn Appraisal of The Current State of Affairs in Nigerian Party PoliticsinventionjournalsAinda não há avaliações

- Muslims On The Margin: A Study of Muslims OBCs in West BengalDocumento6 páginasMuslims On The Margin: A Study of Muslims OBCs in West BengalinventionjournalsAinda não há avaliações

- The Usage and Understanding of Information and Communication Technology On Housewife in Family Welfare Empowerment Organization in Manado CityDocumento10 páginasThe Usage and Understanding of Information and Communication Technology On Housewife in Family Welfare Empowerment Organization in Manado CityinventionjournalsAinda não há avaliações

- Effect of P-Delta Due To Different Eccentricities in Tall StructuresDocumento8 páginasEffect of P-Delta Due To Different Eccentricities in Tall StructuresinventionjournalsAinda não há avaliações

- F0606015153 PDFDocumento3 páginasF0606015153 PDFinventionjournalsAinda não há avaliações

- E0606012850 PDFDocumento23 páginasE0606012850 PDFinventionjournalsAinda não há avaliações

- Literary Conviviality and Aesthetic Appreciation of Qasa'id Ashriyyah (Decaodes)Documento5 páginasLiterary Conviviality and Aesthetic Appreciation of Qasa'id Ashriyyah (Decaodes)inventionjournalsAinda não há avaliações

- A Critical Survey of The MahabhartaDocumento2 páginasA Critical Survey of The MahabhartainventionjournalsAinda não há avaliações

- Non-Linear Analysis of Steel Frames Subjected To Seismic ForceDocumento12 páginasNon-Linear Analysis of Steel Frames Subjected To Seismic ForceinventionjournalsAinda não há avaliações

- E0606012850 PDFDocumento23 páginasE0606012850 PDFinventionjournalsAinda não há avaliações

- H0606016570 PDFDocumento6 páginasH0606016570 PDFinventionjournalsAinda não há avaliações

- C0606011419 PDFDocumento6 páginasC0606011419 PDFinventionjournalsAinda não há avaliações

- Non-Linear Analysis of Steel Frames Subjected To Seismic ForceDocumento12 páginasNon-Linear Analysis of Steel Frames Subjected To Seismic ForceinventionjournalsAinda não há avaliações

- C0606011419 PDFDocumento6 páginasC0606011419 PDFinventionjournalsAinda não há avaliações

- D0606012027 PDFDocumento8 páginasD0606012027 PDFinventionjournalsAinda não há avaliações

- F0606015153 PDFDocumento3 páginasF0606015153 PDFinventionjournalsAinda não há avaliações

- H0606016570 PDFDocumento6 páginasH0606016570 PDFinventionjournalsAinda não há avaliações

- D0606012027 PDFDocumento8 páginasD0606012027 PDFinventionjournalsAinda não há avaliações

- Development of Nighttime Visibility Assessment System For Road Using A Low Light CameraDocumento5 páginasDevelopment of Nighttime Visibility Assessment System For Road Using A Low Light CamerainventionjournalsAinda não há avaliações

- Multicast Live Video Broadcasting Using Real Time TransmissionDocumento2 páginasMulticast Live Video Broadcasting Using Real Time Transmissionaruna2707Ainda não há avaliações

- Port of Spain Case StudyDocumento18 páginasPort of Spain Case StudyThe Cropper Foundation83% (6)

- Group 1 Secb MDCMDocumento7 páginasGroup 1 Secb MDCMPOOJA GUPTAAinda não há avaliações

- Enterprise Exam Style QuestionsDocumento2 páginasEnterprise Exam Style Questionsapi-301785352Ainda não há avaliações

- Hot Dip Galvanized SheetDocumento2 páginasHot Dip Galvanized SheetgorakdiasAinda não há avaliações

- Microsoft Word - Performance AppraisalDocumento7 páginasMicrosoft Word - Performance Appraisalapi-3809437100% (1)

- Concept Screening-PostedDocumento16 páginasConcept Screening-PostedCintia NurliyanaAinda não há avaliações

- GFDGFDGDocumento32 páginasGFDGFDGKelli Moura Kimarrison SouzaAinda não há avaliações

- Ceramic Engineer Materials in Houston TX Resume Mariano VelezDocumento2 páginasCeramic Engineer Materials in Houston TX Resume Mariano VelezMarianoVelezAinda não há avaliações

- Edible Cell WorksheetDocumento3 páginasEdible Cell Worksheetm_frajman100% (4)

- Sample Summary of TA ConductedDocumento1 páginaSample Summary of TA ConductedJAN MICHAEL RIPARIPAinda não há avaliações

- Vision Board MasteryDocumento10 páginasVision Board MasteryElena Costa PalacínAinda não há avaliações

- Program Checklist PDFDocumento4 páginasProgram Checklist PDFlornaAinda não há avaliações

- Linguistic VariablesDocumento2 páginasLinguistic VariablesShankhyaneel SarkarAinda não há avaliações

- Esp QuestionnaireDocumento9 páginasEsp QuestionnaireMarivic SolijonAinda não há avaliações

- South Coast LIDAR Project, 2008 - Delivery 1 QC AnalysisDocumento15 páginasSouth Coast LIDAR Project, 2008 - Delivery 1 QC AnalysisariesugmAinda não há avaliações

- Penyelarasan Instrumen Pentaksiran PBD Tahun 2 2024Documento2 páginasPenyelarasan Instrumen Pentaksiran PBD Tahun 2 2024Hui YingAinda não há avaliações

- A Study On Green Supply Chain Management Practices Among Large Global CorporationsDocumento13 páginasA Study On Green Supply Chain Management Practices Among Large Global Corporationstarda76Ainda não há avaliações

- Github & SourceTree Manual - 15831Documento6 páginasGithub & SourceTree Manual - 15831Jose Cristian Cañaveras VelezAinda não há avaliações

- Analisis Penerapan Prinsip Prinsip Koperasi Dalam UUDDocumento10 páginasAnalisis Penerapan Prinsip Prinsip Koperasi Dalam UUDSaikhudinAinda não há avaliações

- Customer Relationship Management: Summer Internship ProjectDocumento16 páginasCustomer Relationship Management: Summer Internship ProjectSoniNitinAinda não há avaliações

- 1920 Course Pre Information FINALDocumento16 páginas1920 Course Pre Information FINALIamSajid JatoiAinda não há avaliações

- Manual To KivyDocumento2 páginasManual To KivyvalkmaxAinda não há avaliações

- Master of Business Administration - MBA Semester 3 ProjectDocumento2 páginasMaster of Business Administration - MBA Semester 3 ProjectAnkur SharmaAinda não há avaliações