Escolar Documentos

Profissional Documentos

Cultura Documentos

A 810 - 01 Zinc Coated (Galvanized) Steel Pipe Winding Mesh

Enviado por

Victor Hugo Ortiz NajeraTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

A 810 - 01 Zinc Coated (Galvanized) Steel Pipe Winding Mesh

Enviado por

Victor Hugo Ortiz NajeraDireitos autorais:

Formatos disponíveis

(

AnT~l

dWJ..PT

_~~

Designation: A 810 - 01 (Reapproved 2009t 1

INTfillNAn0NAl:

Standard Specification for

Zinc-Coated (Galvanized) Steel Pipe Winding Mesh 1

This standard is issued under Ihe fixed designation A 810; Ihe number immediately following !he designation indicates the year of

original adoption or, in Ihe ease of revision, Ihe year of last revision. A number in parenlheses indieates Ihe year of last reapproval. A

superseript epsilon (e) indieates an editorial change since Ihe last revision or renpproval.

el Nam-Reapproved with edilorial changes in May 2009.

1. Scope

1.1 This specification covers various designs of welded wire

mesh or twisted (woven) hexagonal wire mesh. zinc coated

before fabrication. to be used as reinforcement for the concrete

applied in the manufacture of negative buoyancy pipe needed

for laying pipe in marshes or in water. The mesh is also used

as reinforcement for concrete applied to pipe as a bendable or

nonbendable mechanical protective coating when laying pipe

in a harsh environment.

1.2 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only

and are not considered standard.

1.3 The text of this standard references notes and footnotes

that provide explanatory material. These notes and footnotes

(exeluding those in tables and figures) shall not be considered

as requirements of the standard.

2. Referenced Documents

2.1 ASTM Staluiards: 2

A 90/A 90M Test Method for Weight [Mass] of Coaling on

Iron and Steel Artieles with Zinc or Zinc-Alloy Coatings

A :no Test Methods and Definitions for Mcchanical Testing

of Steel Products

I This specifieation is under Ihe jurisdielion of ASTM Committee A05 on

Metallie-Coated Iron and Steel Produels nnd is Ihe direct responsibilily of

Subcommittee A05.1.! on Wire Speeifieations .

Current edilion approved May 1, 2009. Published August 2009. Originally

approved in 1983. Last previous edition approved in 2008 as A 810 - 01!2oo8).

, For refereneed ASTM standards, visit Ihe ASTM websile, www.astm.org, or

contaet ASTM Customer Serviee at service@aslm.org. For Annllal Book o[ ASTM

Standards voJume inforrnation. refer 10 Ihe standard's Document Summary page on

Ihe ASTM website.

Copynght

A 64 l/A 641 ~1 Specification for Zinc-Coaled (Galvanized)

Carbon Steel Wire

A 902 Terminology Re1ating to Metallic Coated Stee1 Products

B 6 Specification for Zinc

3. Terminology

3.1 Defiflitiofls-For definitions of terms used in this specification, see Terminology A 902.

4. Classification

4.1 The steel pipe winding mesh is elassified by type. based

on method of manufacture, and by design number, related to

width, number of longitudinal wires, and wire sizes.

4.2 Types of Fabric:

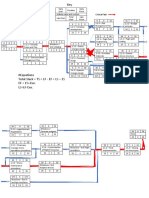

4.2.1 Type TW-Fabric manufactured by twisting wires to

form a mesh with a series of hexagonal openings, as shown in

Fig. l. One of the edges of the fabric ineludes a straight selvage

wire. Additional longitudinal reinforcing wires are ineluded

when specified.

4.2.2 Type WW-Fabric manufactured by welding a series

of longitudinal wires to transverse wires to form a mesh with

rectangular openings.

4.2.2.1 Type WW-C-Type WW fabric having uniform

spacing of longitudinal wires, with the longitudinal wires

crimped as indicated in Fig. 2.

4.2.2.2 Type WW-N-Type WW fabric having nonuniform

spacing of longitudinal wires, by having the space between the

edge wire and adjacent longitudinal wire double the spacing of

the intermediate longitudinal wires. AH longitudinal wires are

crimped as indicated in Fig. 3.

4.2,2.3 Type WW-S-Type WW fabric having straight longitudinal wires (without crimping), with uniform spacing as

indicated in Fig. 4.

e ASTM Intemational, 100 Barr Harbor Orive. PO Bo. C700, Wesl Conshohocken, PA 194282959, Unlted States.

Copyright ASTM IntematlonallASTM), 100 Sarr Harbor

Drive, West Conshohocken, PA, 1942&-2959 USA. All

rights reserved. Distrlbuted under ASTM lIcense by

Techstree~ Te]. 734-781).8(J00, www.techstreelcom.

A 810 - 01 (2009)"1

Longitudinal

Selvage Wire

l!

21! in. (63.5

If--l

in. (38mm)

mm)r'

LONGITUDINAL WIRE

11

('

TRANSVERSE WIRE

1

in.

(25. 4mm )

FIG. 4 Type WWS-Welded Mesh with Straight Longitudinal

Wires

nominal width of wire mesh fabric, in inches (millimetres),

B

number of straight reinforcing wires, not including the

straight selvage wire,

e nominal diameter of wire in hexagonal mesh and

straighl selvage wire, in in ches (millimetres), and

D

nominal diameter of straight reinforcing wires, not

ineluding straight selvage wire, in inches (millimetres).

(Example: 7.5 X l X 0.054 X 0.048.)

4.3.2 For Type WW fabric, where

FIG.1 Type TW-Twisted Hexagonal Mesh (Design Number 7.5 x

O x 0.054 x O)

LONGITUDINAL WIRE

1 in. (25.4 rrm)

nominal overall width of wire mesh fabric, in inches

(millimetres),

B = number ol' longitudinal wires,

e = nominal diameter of longitudinal wires, in inches

(millimetres), and

D = nominal diameter of transverse wires, in inches (millimetres). (Example: 7.5 X 8 X 0.063 X 0.063.)

1/2 in. (12.7 mm)

FIG. 2 Type WW-C-Crimped Welded Mesh with Uniform

Longitudinal Wire Spacing

2 511 in. (67 mm)

S. Ordering Information

5. l Orders for zinc-coated steel pipe winding mesh under

tbis specification shall inelude the following information, as

necessary to adequately describe the desired product:

5.1.1 Name of material (steel pipe winding mesh),

5.1.2 ASTM designation and year of issue,

5.1.3 Type of fabric (see 4.2),

5.1.4 Design number (see 4.3 and Tables l and 2),

5.1.4.1 Mesh dimensions for welded mesh (see 9.3 and

Table 3),

5.1.5 Zinc coating c1ass (see 8.1),

5.1 .6 Quantity (number of rolls),

5.1.7 Width of fabric and length of rolls, and

5.1.8 Packaging (see Section 14).

LONOmJDlNAL WIRE

TRANSVERSE WIRE

1 in. (25.4 mm)

2 in. (50.8 mm)

112 in. U2.7 mm)

6. Materials

6.1 The steel from which the wire is produced shall be made

by any commercially accepted steelmaking process.

6.1.1 The base metal shall be a steel having composition to

permit drawing to a finished size and also to ensure freedom

from zinc flaking during weaving or welding into mesh.

FIG. 3 Type WW-N-Crimped Welded Mesh with Non-Uniform

Longitudinal Wire Spacing

4.3 Design NlIInbers-The design number is in the form of

e x D.

4.3.1 For Type 1W fabric, where

A X B X

te '

A 810 .l (n (2009)"1

TABLE 1 Standard Sizes and Constructlons tor Type TW Woven Hexagonal Mesh

Previous Design

Numbers

Design Numbers

7.5 x

7.5 x

7.5 x

7.5 x

14.25

Ox

1 x

2 x

4 x

x 4

0.054 x

0.054 x

0.054 X

0.054 X

x 0.054

O

0.048 c

0.048

O.048 E

F

X O.048

107'12 x

207'12 x

307'12 x

507'12 x

514'1. X

1'12

1'12

1 1/2

1'12

1'1.

x

x

x

x

x

17

1718 C

1718

1718 E

1718 F

Nominal Width,

in. (mm)

71/2

7'12

7'12

7'12

14'1.

(190)

(190)

(190)

(190)

(362)

Nominal Diameter 01

Zinc-Coated Wire,

in. (mm)

0.054

0.054

0.054

0.054

0.054 (1.37)

(1.37)/0.048

(1 .37)10.048

(1.37)/0.048

(1.37)/0.048

(1.22)

(1.22)

(1 .22)

(1.22)

Nominal Cross Sectional

Area Per Nominal Width,

In."(mm 2 )A

0.0252

0.0270

0.0287

0.0323

0.0529

Nominal Cross Sectional

Area Per Foot (Meter) 01

Widlh,

in."(mm 2 )AB

(16.26)

(17.42)

(18.52)

(20 .84)

(34.13)

0.0430

0.0489

0.0519

0.0580

0.0475

(91 .02)

(103.51)

(109.86)

(122.77)

(100.55)

ABased on nominal diameter.

"Includes minimum 'h-in. (12.70-rnm) lap 01 mesh as applied.

cPlus 0.048 in . (1.22 mm) line wire placad 4'12 In. (114.30 mm) lrom selvage.

Plus 0.048 in . (1.22 mm) IIne wires placed 3 in . (76.20 mm) and 6 in . (152.40 mm) Irom selvage.

Eplus 0.048 in. (1.22 mm) line wires placed 11/. In. (38.10 mm), 3 in. (76.20 mm) , 4'12 in. (114.30 mm), and 6 in . (152.40 mm) from selvage.

Fplus 0.048 in. (1.22 mm) line wires placed 3 in. (76.20 mm), 6 in. (152.40 mm), 9 in. (228.60 mm), and 12 in. (304.80 mm) from selvage.

TABLE 2 Standard Sizes and Constructlons For Type WW Welded Wire Mesh

Previous Design

Numbers

Design Numbers

7.5

7.5

7.5

7.5

7.5

7.5

x 8 x 0.059

x 8 x 0.063

x 8 x 0.079

x 8 x 0.079

x 8 x 0.098

x 8 x 0.118

x 0.059

x 0.063

x 0.063

x 0 .079

x 0.079

x 0.079

1.50 x 1.50

1.60 x 1.60

2.00 x 1.60

2.00 x 2.00

2.50 x 2.00

3.00 x 2.00

7.5 x 6 x 0.063 x 0.063

7.5 x 6 x 0.079 x 0.063

7.5 x 6 x 0.098 x 0.079

7.5 x 6 x 0.118 x 0.079

0.079

0.079

14

14

Nominal Diameter 01 Zinc-Coated

Wire, in. (mm)

Type

0.059

0.063

0.079

0 .079

0.098

0.118

Nominal Cross Sectional Area Per

Nominal Width, in."(mm 2 )A

Nominal Cross Sectional Area per

Feot (Metre) 01 Width, in. 2 (mm 2 )AB

WW-C-Unilorm Spaclng-Crimped

(1 .50)/0.059 (1 .50)

0.0219

(1 .60)/0.063 (1 .60)

0.0249

(2.00)/0.063 (1.60)

0.0392

(2.00)/0.079 (2.00)

0.0392

(2.50)/0.079 (2.00)

0.0603

(3.00)/0 .079 (2.00)

0.0875

(14.13)

(16.06)

(25.29)

(25.29)

(38.90)

(56.45)

0.0373 (78.96)

0.0426 (90.17)

0.0669 (141 .61)

0.0669 (141 .61)

0.1030 (218.03)

0.1493 (316.03)

Type WW-/V-Non-unilorm Spacing-Crimped

0.0187

0.063 (1.60)/0.063 (1 .60)

0.079 (2.00)/0.063 (1 .60)

0.0294

0.098 (2.50)/0.079 (2.00)

0.0453

0.0656

0.118 (3.00)/0.079 (2.00)

(12.06)

(18.97)

(29.23)

(42.32)

0.0374 (79.16)

0.0588 (124.46)

0.0905 (191.56)

0.1312 (277.71)

Type WW-5-Unnorm Spacing-Not Crimped

0.079 (2.00)/0.079 (2.00)

0.0446 (28.80)

0.0685 (145.06)

ABasad on nominal dlameter.

"Includes mlnimum V2-in. (12.70-mm) lap 01 mesh lor Types WW-C and WW-S, and 1-in. (25.4-mm) lap 01 mesh lor Type WW-N, as applied .

TABLE 3 Welded Mesh Sizes and Tolerances

7. Manufacture

7.l Hexagonal Woven Mesh-This fabric is manufactured

Norn 1-Mesh sizes are measured from center to center and always

indicated by two figures, L x S, where L = the distance between the

longitudinal wires_ in. (mm).

Nurn 2---{:rimp depth V2 in. (12.7 mm), tolerance Vx in. (3.2 mm) .

Nominal Mesh Slze, L

S, in. (mm)

by twisting wires to form a series of openings, hexagonal in

shape, as specified in Table ) and Fig_ ) _ One of the edges of

the fabric shall be constructed to inelude a selvage wire. In

addition to those specified in Tabk ) and Fig_ 1. other designs

(width and other reinforcing wire configurations) are subject to

agreement between the purchaser and manufacturero

7_2 Welded Mesh-This fabric is manufactured by welding

a series of paraUel longitudinal wires to transverse wires lo

form rectangular openings. The longitudinal wires shall be

crimped or not crimped as indicated for the type specified_

Crimping shall be as indicated in Fig. 2. In addition to those

specified in Table 2, and Figs. 2-4, other designs (width and

longitudinal wire configurations) are subject to agreement

between the purchaser and manufacturer_

Tolerance, L x S, in. (mm)

the distance between Ihe transverse wires alter

Crimped mesh, where L

crlmplng; wilh L = 1 in. (25.4 mm) lor Type WW-C mesh, and 1 in. (25.4 mm) or 2

in. (50.8 mm) lor Type WW-N mesh (as indicated in Fig. 3).

L x 20/0 (67)

51.. (2) x ~ ':Y.. (5)

L x 30/0 (92)

~ 51.. (2) x ' :Y.. (5)

Noncrimped Style, where S = Ihe distanca between Ihe transversa wlres, in.

(mm)

1 (25.4) X 21/2 (63)

O/.. (2) x ~ 10/.. (5)

6_ 1.2 Wire for Welded Mesh-Before welding the galvanized wire shall have a mnimum tensile strength of 70 000 psi

(483 MPa),

6.1.3 Wire for Hexagonal Woven Mesh-Before weaving

the galvanized wire shall have a maximum tensile strength of

75000 psi (515 MPa),

6.2 Slab zinc used for the coating shall be any grade of zinc

conforming to Specification B 6_

8. Coating Requirements Coating Requirements

8_1 The zinc coating shall be Class 1 coating, or shall be

"regular coating", whichever is specified in the purchase order_

8_1_1 Class 1 zinc coating shall be as specified in Specification A 641/A 641.\1 .

8_1.2 Zinc-coated wire produced as "regular coating" shall

have the full surface covered with zinc, but there is no specified

mnimum weight of coating_

A 810 - 01 (2009)"1

10.2 Determine the weight of zinc coatings for wire specified to have a Class 1 coating, by the stripping test in

accordance with Test Method A 90/A 90M. Inspect wire specified to have a "regular coating" to verify that the wire is

completely coated (except for slight burning at welded intersections for wire inspected after fabrication).

10.2.1 For wire tested before fabrication, the minimum test

specimen length shall be 24 in. (600 mm).

10.2.2 For wire tested after fabrication, cut short lengths of

wire from between twists or welds, such that the total length

equals at least 24 in. (600 mm).

10.3 Tensile testing shall be as described in Test Methods

and Definitions A 370.

8.2 Slight buming of the zinc coating at we1ded intersections of welded mesh shalI not be cause for rejection.

9. Dimensions and Permissible Variations

9.1 Width of Fabric-Hexagonal mesh fabric is usualIy

available in 7 1/2-in. (l90-mm) width. Welded mesh fabric,

crimped, is usually available in 7-in. (I78-mm) width having a

maximum width of 7V2 in. (190 mm) including crimp. Noncrimped welded mesh fabric is usualIy available in 8-in.

(203-mm) width. Other widths of woven and we1ded fabrics

are available. Nominal width of fabric shalI be as agreed upon

between the purchaser and manufacturero

9.2 Length of Rol/-Nominal length of rolIs shaIl be as

agreed upon between the purchaser and manufacturero

9.3 Standard openings in Type TW mesh, between adjacent

wires parallel to the selvage wire, is shown in Fig. l. Standard

spacing for longitudinal wires in Type WW-C, Type WW-N,

and Type WW-S mesh is shown in Figs. 2-4, respectively.

Standard spacing for transverse wires in Type WW fabrics is

shown in Table 3. Al1 measurements are center to center of

wires. Spacing other than indicated are subject to agreement

between the purchaser and manufacturero

11. Retests and Rejection

11.1 If one or more of the samples fail to show compliance

with any of the requirements of this specification, the lot shall

be subjected to retest.

11.2 Retesting of the 10t shall be on the basis of a sampling

frequency of one sample for each 50 roUs. If any sample fails

to show compliance with the requirements of this specification,

the entire lot shall be rejected.

9.4 Tolerances:

9.4.1 Width:

9.4.1.1 Hexagonal Mesh-Actual width between outer

12. Inspection

12.1 The manufacturer shall afford the inspector representing the purchaser al1 reasonable facilities to satisfy the inspector that the material is being furnished in accordance with this

specification. AH tests and inspections shall be made at the

place of manufacture before sbipment, unless otherwise specified, and be conducted so as not to interfere unnecessarily with

the operation of the works.

wires shaIl not be more than 1h in. (13 mm) under the specified

width.

9.4.1.2 Welded Mesh-Actual width between outer wires

shall not be more than 13/6 4 in. (5 mm) under the specified

width.

9.4.2 Length-Actual length shall be ordered length -O,

+3%.

9.4.3 Mesh Size:

13. Certification

9.4.3.1 For hexagonal mesh, the tolerance shal1 be Vs in.

(3.2 mm).

9.4.3.2 Welded mesh size tolerances shall be in accordance

with Table 3.

9.4.4.1 Permissible variation of the nominal diameter of

wire shaIl be as folIows:

13.1 When specified in the purchase order or contract, the

purchaser shaIl be furnished certification that the samples

representing each lot have been either tested or inspected as

directed in tbis specification and that the requirements have

been met. When specified in the purchase order or contract, a

report of the test results shalI be furnished.

0.035 in. (0.89 mm) lo under 0.076 in. (1 .93 mm) :!: 0.002 in. (0.05 mm)

0.076 In. (1.93 mm) and over :!: 0.003 in. (0.08 mm)

14. Packaging, Marking, and Loading

9.4.4 Wire Size:

14.1 Packaging will be based on negotiations between the

purchaser and the manufacturero Banding or strapping with or

without pallets represents a common form of package.

14.2 A tag shall be securely attached to each bundle and

shall be marked with the type, design number, wire sizes,

ASTM designation, and name or mark of the manufacturero

10. Sampling and Testing

, .,

10.1 For test purposes, one sample shall be taken from one

roll selected at random from each 200 rolls or fraction thereof.

10.1.1 Development of cross-sectional area data shall come

from these samples.

10.1.2 Because of the distortion inherent in the manufacturing of the mesh, it is normal to test for coating weight and

tensile compliance on samples of wire before fabrication. The

number of test specimens will vary with the quality control

procedures and facilities of each manufacturero

15. Keywords

15.1 concrete reinforcement; mesh (for steel pipe/tube);

steel wire; zinc-coated steel wire

(

4

'o

A 810 - 01 (2009)E1

ASTM Intemational takes no position respecting the validity of any patent rigllts asserted in connection with any item mentioned

in this standard, Users of this standard are expressly advised that determination of tIle vaJidity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or witlldrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM Intemational Headquarters. Your comments will receive careful consideration at a meeting of tIle

responsible technical committee, which you may attend. If yoo feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM Intemational, 100 8arr Harbor Drive, PO 80J( C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple cop/es) of tIlis stendard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or seNice@astm.org (e-mail); or through the ASTM website

(www.astm.org).

"

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- CPM Method Wilmont's Drone Case PDFDocumento2 páginasCPM Method Wilmont's Drone Case PDFRwa Gihuta100% (3)

- Astm D4541 PDFDocumento16 páginasAstm D4541 PDFVictor Hugo Ortiz Najera100% (1)

- Astm C1176-13 PDFDocumento5 páginasAstm C1176-13 PDFVictor Hugo Ortiz NajeraAinda não há avaliações

- Aws A 5-1Documento57 páginasAws A 5-1mech_nedian9714Ainda não há avaliações

- Portland Cement ASTM C 150 PDFDocumento8 páginasPortland Cement ASTM C 150 PDFLuis AngelAinda não há avaliações

- Aqwa Tether Manual PDFDocumento178 páginasAqwa Tether Manual PDFHari SreenivasanAinda não há avaliações

- Article - LNF Q230 Particle CountDocumento2 páginasArticle - LNF Q230 Particle CountSyaiful FuadAinda não há avaliações

- Quality Control Program For An Apparel Manufacturing Unit: Assignment 2Documento12 páginasQuality Control Program For An Apparel Manufacturing Unit: Assignment 2Amrita MitraAinda não há avaliações

- Tail RotorsDocumento4 páginasTail Rotorsvenmeen14Ainda não há avaliações

- HttpsDocumento17 páginasHttpsFjri NdaAinda não há avaliações

- HOW To DO Capsmill Cycle Time Reduction CadcamDocumento23 páginasHOW To DO Capsmill Cycle Time Reduction CadcamrajualagAinda não há avaliações

- Din 8743 (En) 0505 1Documento35 páginasDin 8743 (En) 0505 1ensentisAinda não há avaliações

- Test Report: EN 397: 2012 + A1:2012 Industrial Safety HelmetsDocumento19 páginasTest Report: EN 397: 2012 + A1:2012 Industrial Safety Helmetsangelica corredorAinda não há avaliações

- Digi Schmidt 2000 ManualDocumento22 páginasDigi Schmidt 2000 ManualBerkah SuprayogiAinda não há avaliações

- Machinist - 1 Semester - Module: 1 - Safety: Questions: Level 1 1 A B CDocumento42 páginasMachinist - 1 Semester - Module: 1 - Safety: Questions: Level 1 1 A B CÀñkëshpawar creationAinda não há avaliações

- Submission of 7-Days Concrete Mix Design Test ResultsDocumento2 páginasSubmission of 7-Days Concrete Mix Design Test ResultsAdyam YonasAinda não há avaliações

- Project Management: Michel Tollenaere (INPG)Documento56 páginasProject Management: Michel Tollenaere (INPG)Smitha K BAinda não há avaliações

- Apps - Forms Personalization in Oracle HRMSDocumento7 páginasApps - Forms Personalization in Oracle HRMSHacene LamraouiAinda não há avaliações

- Us Products Industrial Air BrochureDocumento24 páginasUs Products Industrial Air BrochureAnonymous vRyv4wMAinda não há avaliações

- BS 5656-1Documento32 páginasBS 5656-1Atif NaveedAinda não há avaliações

- Sat SahebDocumento7 páginasSat SahebAMIT JHAAinda não há avaliações

- S-Mart Seal Material and Profile OverviewDocumento8 páginasS-Mart Seal Material and Profile OverviewTimon2005Ainda não há avaliações

- Catalogo Locinox 2012Documento72 páginasCatalogo Locinox 2012RUI MIGUEL SILVAAinda não há avaliações

- Supply Chain Management - Test 1 MemoDocumento5 páginasSupply Chain Management - Test 1 MemoNaomiAinda não há avaliações

- Tronox LP Eng GesichertDocumento3 páginasTronox LP Eng GesichertForeverAinda não há avaliações

- J Fluids Engineering 2009 Vol 131 N8Documento110 páginasJ Fluids Engineering 2009 Vol 131 N8Нильва Александр100% (1)

- Electromagnetic Environment - EG 07 - Final Report PDFDocumento22 páginasElectromagnetic Environment - EG 07 - Final Report PDFTyra RogersAinda não há avaliações

- Error Proofing TechniquesDocumento140 páginasError Proofing TechniquesThe Informative Corner हिंदीAinda não há avaliações

- IBM Tivoli Provisioning Manager V7.1.1 Deployment and IBM Service Management Integration Guide Sg247773Documento762 páginasIBM Tivoli Provisioning Manager V7.1.1 Deployment and IBM Service Management Integration Guide Sg247773bupbechanhAinda não há avaliações

- BS en 10228-2-2016Documento20 páginasBS en 10228-2-2016Sorin Mirt100% (1)

- 2017aptransco RT 263Documento10 páginas2017aptransco RT 263Arogya Raju PudhotaAinda não há avaliações

- System Dynamic Archetypes in Capacity Planning (Final)Documento12 páginasSystem Dynamic Archetypes in Capacity Planning (Final)Muhammad Rizki KresnawanAinda não há avaliações

- BAR-US SimGrip Product Brochure EnglishDocumento19 páginasBAR-US SimGrip Product Brochure EnglishBarusRebarCouplersAinda não há avaliações

- Bell Crank White PaperDocumento9 páginasBell Crank White PaperagniflameAinda não há avaliações