Escolar Documentos

Profissional Documentos

Cultura Documentos

Processes For Upgrading Metallurgical Grade Silicon To Solar Drade Silicon PDF

Enviado por

Willian Boneli de AlmeidaDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Processes For Upgrading Metallurgical Grade Silicon To Solar Drade Silicon PDF

Enviado por

Willian Boneli de AlmeidaDireitos autorais:

Formatos disponíveis

Available online at www.sciencedirect.

com

Energy Procedia 20 (2012) 88 97

Technoport RERC Research 2012

Processes for upgrading metallurgical grade silicon to solar

grade silicon

Jafar Safariana*, Gabriella Tranella, Merete Tangstada

Norwegian University of Science and Technology, Alfred Getz Vei 2, 7491, Trondheim, Norway

Abstract

The photovoltaic (PV) industry is in rapid growth and a large supply of PV feedstock materials must be

provided to maintain this growth. Since silicon is still the dominant material for the fabrication of solar

cells, low-cost solar-grade silicon (SoG-Si) feedstock is demanded. The most cost-effective and direct

approach for producing SoG-Si is to purify and upgrade metallurgical-grade silicon. Many impurities in

MG-Si can be effectively removed through directional solidification of molten silicon. However, the

removal of boron (B) and phosphorus (P) by this method is difficult and expensive due to the relatively

large distribution coefficients of these elements. Therefore, the elimination of B and P to the levels

required for SoG-Si feedstock requires the development of new processes. In the present study, the effect

of impurities on the solar cell efficiencies and the impurity contents in silicon materials are studied. The

chemical and metallurgical processes that can be applied to purify metallurgical grade silicon to solar

grade silicon are reviewed and evaluated. It is shown that under development silicon refining processes

are applicable to produce solar grade silicon. However, there are specific challenges for each process and

their benefits and risks must be considered for economic production.

2012Published

Publishedbyby

Elsevier

Selection

and

peer-review

under

responsibility

Technoport

and the

2012

Elsevier

Ltd.Ltd.

Selection

and/or

peer-review

under

responsibility

of the of

Centre

for

Renewable

OpenEnergy

access under CC BY-NC-ND license.

Centre for Energy.

Renewable

Keywords: Metallurgical grade silicon, solar grade silicon, cell efficiency, impurity, refining, directional solidification, slag,

leaching, plasma, solvent.

* Corresponding author. E-mail address: jafar.safarian@material.ntnu.no

1876-6102 2011 Published by Elsevier Ltd. Selection and/or peer-review under responsibility of the Centre for Renewable Energy.

Open access under CC BY-NC-ND license. doi:10.1016/j.egypro.2012.03.011

Jafar Safarian et al. / Energy Procedia 20 (2012) 88 97

1. Introduction

Metallurgical grade silicon (MG-Si) is the initial material to produce pure silicon for photovoltaic and

electronics applications. It is commercially produced through the reduction of silicon oxide (quartz) with

carbon in submerged arc furnaces [1]. An idealized form for the process can be written as:

SiO2 + 2C = Si+ 2CO (g)

(1)

The produced MG-Si is not pure, typically 99.0wt% Si, and it contains impurities such as Fe, Al, Ti, Mn,

C, Ca, Mg, B, P and so on. The minimum required purity of silicon for photovoltaic applications is 6N

and for silicon wafers used in the semiconductor industry is 9N. The impurities subject to limitations in

solar grade silicon (SoG-Si) are the same as in semiconductor silicon [2]. However, the acceptable

concentration levels in SoG-Si are substantially higher. The maximum acceptable concentrations of

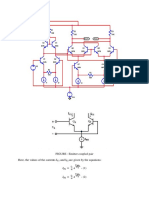

individual impurities in SoG-Si are defined by the conversion efficiency of solar cells. Figure 1 shows the

relationship between the cell efficiency and impurity concentration for different silicon grades.

Figure 1: Limits on impurity concentrations in p-type silicon for impurities determining degradation

threshold of solar cells [3]:1 Semiconductor-grade; 2 SoG-Si 3 Mg-Si.

The concurrent effect of the increase in the demand for solar silicon and of the costs associated with pure

silicon scrap from electronic industry, led the photovoltaic industry to focus the efforts on the

development of new production processes dedicated to solar silicon [4] . The development of several

alternative routes to the traditional Siemens chemical process of producing pure silicon, was accelerated

the produced polysilicon by this method is still the most used type of silicon

feedstock for solar cell manufacturing. In 2009, it had a market share of 97.5% of all the silicon feedstock

used for solar cell production, while the rest (2.5%) was represented by upgraded metallurgical grade

silicon materials and silicon scrap from the semiconductor industry [5]. The main advantage claimed by

manufacturers that developed dedicated metallurgical refining routes concerns the low energy

consumption rate. The status of some of the currently operating metallurgical routes of SoG-Si production

by producers in Norway, France and China has been recently reviewed by Tranell et al. [6]. According to

them, the produced SoG-Si through the combinations of metallurgical methods can provide the required

impurity levels for PV applications such as 0.3 ppmw B, 0.6 ppmw P and 1-10 ppmw metals.

89

90

Jafar Safarian et al. / Energy Procedia 20 (2012) 88 97

In the present study the chemical and metallurgical processes for SoG-Si feedstock production are studied

and the challenges in each method is presented and discussed.

2. Chemical processes for silicon purification

In the chemical approach, the production of high purity polycrystalline silicon through reduction and

pyrolysis of volatile silicon compounds produced from MG-Si such as SiHCl3, SiH2Cl2, SiH4, SiCl4,

chloride

SiHBr3

hydride technology. Traditionally, high pure silicon has been produced through the established, well

known Siemens process, which was developed in the 1950s. The production of silicon goes through the

gasification of MG-Si, distillation and deposition of silicon [2, 3]. Trichlorosilan (SiHCl3), TCS, is first

produced through the interaction of MG-Si with HCl according to reaction (2) under high pressure and

temperatures, typically at 500C and 30MPa. The redistribution of chlorine and hydrogen atoms from

SiHCl3 to SiH2Cl2 and SiCl4 is then carried out (reaction (3)). The produced dichlorosilane gas is

redistributed and distilled to monochlorosilane gas, which again is transformed to silane gas according to

reactions (4) and (5). Through distillation, diboride and other impurities are removed. This is an important

step in the process as B is a harmful element disturbing the electrical properties of the final material.

5(MG-)Si + 16 HCl = 4 HSiCl3 + 6H2 + SiCl4

2 SiHCl3 = SiH2Cl2 + SiCl4

2 SiH2Cl2 = SiHCl3 + SiH3Cl

2 SiH3Cl = SiH2Cl2 + SiH4

(2)

(3)

(4)

(5)

The pure TCS gas is decomposed to pure Si on a U-shaped filament according to reaction (6), where the

produced HCl is re-used in the initial process step [3]. This chemical vapor deposition (CVD) reaction

takes place at 1000-1100C and the filament is heated with ohmic energy.

HSiCl3 + H2

Si(s) + 3HCl

(6)

Using silane (SiH4) instead of TCS (SiHCl3) during decomposition simplifies the process and in this

process SiH4 is decomposed according to the following reaction at 800-1000C [2]:

SiH4(g) = Si + H2(g)

(7)

Using silane instead of TCS during decomposition simplifies the process due to the lower boiling point of

silane compared to other liquids in the process, as hydrides, chlorides of boron, phosphorous and arsine.

A very pure gas is hence obtained, with less energy consumption. Moreover, the highly corrosive

chlorine-components are not present, which simplifies the material choices of the process equipment.

Using a Fluidized Bed Reactor (FBR), instead of a U-shaped filament during decomposition, increases

the decomposition surface and hence, the total production rate [7]. With FBR process, SoG-Si is produced

at a lower cost, and using much less energy than the traditional Siemens method for converting silane gas

to high purity silicon. Unlike the Siemens process which requires the breaking of polysilicon rods, FBR

granular is harvested in a ready to use form. In addition, the FBR process is continuous, which is an

advantage over the Siemens batch process [7]. It goes without saying that this can be a disadvantage with

regard to the more complicated process control of a fluidized bed reactor.

Jafar Safarian et al. / Energy Procedia 20 (2012) 88 97

The major problem of the chemical route is that it involves the production of chlorosilanes and reactions

with hydrochloric acid. In addition to being toxic, these compounds are corrosive, causing irritations of

the skin and mucous membranes. Moreover, their handling also requires the utmost care, since they are

explosive in the presence of water and hydrochloric acid. Chlorine emissions in polycrystalline silicon

production by the chemical route are estimated to amount to 0.002 kg of chlorine per square meter of cell.

Controlling this emission is important because chlorine is denser than air, which accelerates the poisoning

process [4]. These problems together with relatively high energy consumption of SoG-Si production

through the chemical route have been the driving force for the development of metallurgical processes for

SoG-Si feedstock production in the recent years.

3. Metallurgical processes for silicon purification

In SoG-Si production through metallurgical approach, MG-Si is purified by the combination of

metallurgical techniques. An overall sketch of the metallurgical route from quartz to SoG-Si is shown in

Fig. 2. As observed, directional solidification is a key process step for the metallurgical route. This is due

to the large segregation of the impurities between the liquid and solid silicon phases during solidification.

Boron and phosphorus, which are always present in the MG-Si (produced from ordinary raw materials)

has relatively large segregation coefficients in directional solidification, which are 0.8 and 0.35,

respectively [8, 9]. Therefore, the removal of these impurities by directional solidification is difficult and

cost ineffective. Hence, the application of other metallurgical techniques dedicated mainly to remove B

and P is necessary to produce a high-quality silicon (HQ-Si) devoid of B and P prior to directional

solidification.

Figure 2: Overall sketch of the SoG-Si production from quartz through metallurgical route.

Although many research works have been done on silicon purification with main focus on B and P

removal, a few full metallurgical processes have been developed. In Elkem Solar process in Norway,

MG-Si is refined through slag treatment followed by acid leaching and directional solidification [10]. In

French Photosil process, MG-Si is refined through two steps segregation refining, plasma purification,

post plasma segregation and directional solidification [ 11 ]. In China, a range of companies have

91

92

Jafar Safarian et al. / Energy Procedia 20 (2012) 88 97

developed and are currently operating industrial metallurgical processes for SoG-Si production. They

apply gas blowing, slag refining, acid leaching, vacuum refining and directional solidification to produce

SoG-Si [6]. In the NS Solar Material (NSSM) process in Japan, MG-Si is first refined by oxidation for B

removal, then it is vacuum treated for P removal, and directional solidification is applied to remove the

metal impurities [12]. Fesil Sunergy process in Norway is based on the use of pure raw materials (low in

B and P) application for SoG-Si production. In this process high purity silicon carbide is first produced

and then used for the carbothermic reduction of high purity quartz in electric arc furnace. The obtained

silicon is then refined through particle settlement, filtration, and oxygen purging and solidification [13].

Selected refining processes, which are currently used in the above mentioned processes, are studied as

follows.

3.1. Directional solidification

Directional solidification of silicon as mentioned before is a key process step in the SoG-Si production

through the metallurgical route. Significantly small segregation coefficient of many impurities (except B

and P) between the solid and molten silicon provides proper conditions for silicon refining by directional

solidification [8, 9]. Directional solidification of the melt takes place when the removal of both the heat

necessary for the melt to cool down to the solidification temperature and the latent heat generated at the

solidification front due, occurs along a single direction [ 14 ]. Directional solidification is usually

performed along the vertical direction, i.e. from the bottom to the top of the ingot. With regard to the

uniqueness of directional solidification on removal a wide range of impurities from silicon, it is expected

that this process will continue to be a part of the best developed process for SoG-Si production.

3.2. Slag refining

Slag refining technique is a process candidate for mainly B removal in which the boron impurity in

molten silicon is oxidized and removed by a molten silicate slag. The related chemical reaction can be

written as:

[B]Si + SiO2 = (B2O3) + Si

(8)

The thermodynamics of B removal by silicate slags has been studied through several works and the

distribution coefficient of B between slags and molten silicon ( LB

(% B) slag

[ B]Si

) has been measured. It has

been observed that LB decreases with increasing the basicity of CaO-SiO2 slags and a minimum of LB

is obtained for CaO/SiO2 = 0.85, while LB is increased with increasing the slag basicity [15]. Relatively

lower LB have been reported for the same slag system in the other studies [16, 17]. Reported measured LB

values in literature for different slag compositions show that the majority of them are in the range

between 0.5 and 3.5 [15, 16, 17, 18, 19]. The distribution coefficient of B is minimally affected by the

refining temperature and small increase of LB with increasing temperature has been reported [16]. Both

the research works and also the developed Elkem Solar process indicate that slag refining is efficient for

B removal. It is worth mentioning that slag treatment may also remove some other impurities. For

instance, there is no specific process step for phosphorus removal in the Elkem solar process; the P

elimination can take place likely to some extent through the slag refining.

93

Jafar Safarian et al. / Energy Procedia 20 (2012) 88 97

The application of slag refining for silicon purification has its own advantages and disadvantages. The

slag refining process is a kind of well known batch process in which solute and even solid impurities in a

molten metal are removed, and it is used in many metallurgical processes such as clean steel production.

The process operation may be not complicated and can be done in large scale in high capacity

metallurgical vessels. However, responding specific challenges is crucially important in this process such

as preparation of clean slag with ultimately low concentrations of B. Moreover, with regard to the

equilibrium thermodynamics (LB) in slag refining process, the removal of B from the usual concentrations

in MG-Si i.e. 20 ppmw to below 0.5 ppmw requires large volume of slag compared to the silicon, or slag

treatment in sequences. The kinetics issues in slag refining of silicon has not been studied extensively and

the parameters affecting the process rate are not well known.

3.3. Acid leaching

Many metallic elements such as Fe, Al, Ti, Ca, Mn, Mg, Sb, Sn, Zn, Cu, Au and Ni have high segregation

coefficients in silicon. Thus, during solidification of molten MG-Si, a major portion of these impurities

should precipitate at grain boundaries or at interstitial positions in polycrystalline silicon. Hence, acid

leaching of MG-Si dissolves the impurities located at the grain boundaries of silicon, while the silicon

matrix is not dissolved. Therefore, the silicon purity can be improved by leaching process. In practice, it

would be more beneficial to add Ca to the molten MG-Si and solidify the melt which causes the

precipitation of CaSi2 at the grain boundaries as the dominant present phase [20]. Other impurities are

concentrated as small grains in the calcium disilicide phase. The reaction of CaSi2 with HCl in acid

leaching gives:

3CaSi3 + 6HCl + 3 H2O = Si6H6O3 + 3 CaCl2 + 3H2

(9)

The lumps of calcium-containing silicon disintegrate during leaching into silicon grains less than about 2

mm and a fine-grained material that is easily separated from the silicon grains by washing. In the original

leaching alloy most of the impurities occur as very small grains in the calcium disilicide phase. Even if

they are not dissolved during the leaching, they are washed away with the fines. Some impurity particles

stick to the silicon crystals and are removed in a second leaching by hydrofluoric acid and some oxidizing

agent [20]. The removal efficiency of the impurities is in a range from 70 to around 90 %. However, the

treatment by leaching is not effective for B, C and O. Addition of Ca to the silicon alloy allows to remove

P by a factor of 5 down to relatively low concentrations less than 5 ppmw [21]. The effect of various

parameters such as leaching agent, temperature, particle size on leaching efficiency have been studied

[22, 23, 24] and all these parameters may affect the extents of impurities elimination.

3.4. Vacuum refining

Vacuum distillation technique for the purification of molten metals and alloys has been developed mainly

in the last century. Vacuum refining has also been applied in laboratory scale to remove particular

impurities from silicon such as phosphorus through several studies. As mentioned above, this method is

currently applied for SoG-Si in Chinese and Japanese companies. The difference in the vapour pressures

of the liquid silicon and the volatile impurities is the basic principle of vacuum refining. The relationship

between the saturated pressure and temperature for some pure elements is illustrated in Fig. 1. Based on

the Hertz-Langmuir-Knudsen equation for the evaporation of substances in vacuum, Olette [ 25 ]

developed a kinetic volatility criterion for vacuum refining. This criterion for the monatomic evaporation

of impurity i in dilute solution with silicon solvent can be written as:

94

Jafar Safarian et al. / Energy Procedia 20 (2012) 88 97

o

i

pio M Si

pSio

Mi

1/2

(10)

where pSi and pi are the vapour pressures of pure silicon and impurity at a given temperature, and i is

the Henrian activity coefficient of the impurity. MSi and Mi are the atomic weight of silicon and impurity,

respectively. The magnitude of from one solute to another indicates relative rates of refining when

monatomic evaporation controls rate of refining. If >1, the impurity can be removed almost completely

from silicon. If <1, the impurity cannot be removed and the silicon evaporation rate is greater than the

impurity. Obviously, =1 shows that both silicon and the impurity are evaporated with equal rates.

The application of vacuum induction melting for the purification of metallurgical grade silicon (MG-Si)

has been investigated through several experimental works and they were reviewed recently by authors

[26]. Phosphorus is the main element removed through vacuum distillation due to its much higher vapour

pressure which gives large -value. However, the removal of other volatile impurities such as Al, Ca, Mg,

the silicon melt affects the P removal rate and it is faster from cleaner melts [27].

Figure 3: The changes of the standard vapour pressure of pure substances with temperature calculated

from the reported thermodynamic data [27].

Vacuum refining is a process with particular advantages which make this technique as a successful

process candidate for SoG-Si production in combination with other processes for the removal of nonvolatile elements such as B. The process is not complicated and its control is not difficult. In vacuum

refining, no other material except the holding crucible is in contact with the silicon melt which prevents

the introduction of impurities during the refining. Since silicon is not conductive, the application of

vacuum induction technique can be the best solution with using high purity graphite crucible, which is

available in the market. The process can be done combined with directional solidification in a single

furnace, which is more energy efficient.

Jafar Safarian et al. / Energy Procedia 20 (2012) 88 97

3.5. Plasma refining

Plasma refining is a technique that has been used for the removal of B from silicon. The removal of boron

from metallurgical-grade silicon was investigated by Suzuki et al. [28] with applying an Ar/H2O plasma

treatment. They reported concentration changes of boron in MG-Si from 35.7 to 0.4 ppmw within 25

minutes of refining time. Within the framework of the NEDO program, Japanese groups studied boron

removal and developed a purification process combining arc plasma, electron beam, and directional

solidifications. Plasma treatment used water as the reactive gas to remove boron, an electron beam was

used to remove phosphorus under vacuum, and two directional solidification steps allowed metallic

impurities to be removed. The amount of silicon treated during these studies reached 300 kg per batch

[29]. The French Photosil process is the other process with progresses toward industrial production [30]

which makes use of plasma refining as a key step for B removal. In this process the dissolved B in liquid

silicon is converted to boron oxides such as BO, B2O, BO2, B2O2, B2O3 or boron hydrates such as BHO,

BH2, BHO2, BH2O2, BH3O3, B2H4O4, B3H3O3, B3H3O6, which are volatile compounds [31] compared to

liquid silicon.

Although silicon refining has shown good results in B removal, there are particular cases to be

considered. The process seems to be complicated from technology and process control points of view.

The limitation in boron volatilization is due to the formation, at high oxygen flow rate, of a silica layer at

the surface of the molten silicon, which results in a dramatic drop of the volatilization rate [32]. The

silicon yield in plasma refining is not clear and it might be high due to the high temperature on the silicon

melt surface.

3.6. Solvent refining

Solvent refining is a purification process in which MG-Si is dissolved in a melt and then it is

recrystallized in more pure form a supersaturated melt. The refining efficiency depends on the segregation

behavior of different elements in solid silicon and the liquid phase. Solvent refining of silicon through

using Si-Al melts has been studied in the recent years in Japan [33, 34, 35] and it has been indicated that

the segregation coefficient of the impurities between solid silicon and liquid Si-Al melts is considerably

smaller than that between solid and liquid silicon. For instance, the segregation coefficient of B in Si is

0.8 at the silicon melting point (1414C), whereas it is around 0.2 when silicon is solidified from Si-Al

melt at 1000C. For phosphorus the segregation coefficient is 0.06 when silicon is solidified from Si-Al

melt at 700C, which is much less than 0.35 for recrystallization from liquid silicon [Feil! Bokmerke er

ikke definert.]. Solvent refining of silicon through silicon recrystallization from Si-Ni melts has also

been studied recently and it has been shown that impurities can be effectively removed from silicon

through solvent refining by Si-Ni melts [36].

Solvent refining using Si-Al and Si-Ni melts as the impurity trappers has shown high impurities removal

efficiencies mostly above 90%. This may indicate that solvent refining is a promising method. However,

there are particular challenges to utilize this method in industrial scale. Preparation of high purity alloying

metals (such as Al and Ni) with reasonable price is a case. The application of the produced impure

metal/alloy through solvent refining which carries the impurities of the MG-Si is also another issue. If it

is recycled in plant, it requires extra refining processes which are cost effective to the final purified

silicon product. The separation of recrystallized silicon from the refiner melt, or from the solidified melt

containing Si crystals is also a challenge. The separation may be not perfect with high silicon yield. It can

also introduce impurities to the refined silicon, in particular if crushing is needed.

95

96

Jafar Safarian et al. / Energy Procedia 20 (2012) 88 97

4. Concluding remarks

Although the produced SoG-Si through chemical routes is still the dominant feedstock material

for PV industry, metallurgical processes for SoG-Si feedstock production have had significant

progress in the recent years.

Production of SoG-Si through metallurgical approach combines a number of refining steps in

addition to refining directional solidification.

All the pyro- and hydrometallurgical refining methods have specific advantages and

disadvantages and they face particular challenges.

Operation and process control, energy consumption, impurity removal efficiency, silicon yield,

pure refiner material preparation, recycling or selling of polluted refiner material, and separation

of purified silicon from refiner material are the challenges in the metallurgical techniques for

silicon refining.

Acknowledgements

The authors acknowledge the fund provided through the BASIC project (191285/V30) by the

Norwegian Research Council.

References

[1] Schei A., Tuset J Kr, Tveit H. Production of high silicon alloys. Trondheim, Tapir Forlag; 1998.

[2] Gribov BG, Zinov,ev KV. Preparation of high-purity silicon for solar cells. Inorganic Materials 2003; 39: 653-662.

[3] Bathey BR, Cretella MC, Solar-grade silicon. J. Mat. Sci. 1982; 17: 3077-3096.

[4] Braga AFB, Zampieri PR, Bacchin JM, Mei PR. New processes for the production of solar-grade polycrystalline silicon: A

review. Solar Energy Materials & Solar Cells 2008; 92: 418-424.

[5] Bernreuter J, Haugwitz F. Global perspectives through 2010, April 2010.

[6] Tranell G, di Sabatino M, Tronstad R, Kvande R, Krystad E, Degoulange J, Chen C, Zheng S. Silicon feedstock for solar cellsavaialbility, quality criteria and future production routes, Int. Workshop on Science and Technology of Crystalline Silicon Solar

Cells (CSSC-4),, Taipei, Taiwan, 27-29 October 2010.

[7] www.recgroup.com (Novenber 2011)

[8] Davis JR, Rohatgi A, Hopkins RH, Blais PD, Rai-Choudhury P, Mccormick JR, Mollenkopf HC. Impurities in silicon solar

cells. IEEE Trans. Elect. Dev. 1980; ED-27: 677-687.

[9] Hopkins RH, Rohatgi A. Impurity effects in silicon for high efficiency solar cells. J. Cryst. Growth 1986; 75: 67-79.

[10] www.elkem.com (November 2011)

[11] Einhaus R, Kraiem J, Cocco F, Caratini Y, Bernou D, Sarti D, Rey G, Monna R, Trassy C, Degoulange J, Delannoy Y,

Martinuzzi S, Pe richaud I, Record MC, Rivat P. PHOTOSIL simplified production of solar silicon from metallurgical silicon, in:

Proceedings of the 23th European Photovoltaic Solar Energy Conference, Dresden, 4 8 September 2006: 580 583.

[12] Kishida Y, Okajima M, Kondo J, Okazawa K, Tokumaru S, Dohnomae H, Hiyoshi M. Compensation free SoG silicon

feedstock by metallurgical refinement. 26th European Photovoltaic Solar Energy Conference and Exhibition, Hamburg, Germany

2011: 925-928.

[13] Geerling LJ, Wyers GP, Jensen R, Raaness O, Wrnes AN, Santen S, Reinink A, Wiersma B, Solar-grade silicon by a direct

route based on carbothermic reduction of silica:requirements and production technology. Energy research Centre of the Netherlands

ECN 2002; 2-5.

[14] Kvande R. Incorporation of impurities during directional solidification of multicrystalline silicon for solar cells. PhD Thesis,

NTNU, Trondheim 2008.

[15] Teixeira LAV, Tokuda Y, Yoko T, Morita K. Behaviour and state of boron in CaO-SiO2 slags during refining of solar grade

silicon. ISIJ Int. 2009; 49: 777-782.

[16] Suzuki K, Sugiyama T, Takano K, Sano N. Thermodynamics for removal of boron from metallurgical silicon by flux treatment.

J. Jpn. Inst. Met. 1990; 54: 168 172.

[17] Weiss T, Schwerdtfeger K. Chemical Equilibria between Silicon and Slag Melts. Met. Mat. Trans. B 1994; 25b: 497-504.

Jafar Safarian et al. / Energy Procedia 20 (2012) 88 97

[18] Tanahashi M, Shinpo Y, Fujisawa T, Yamauchi C. Distribution behaviour of boron between SiO 2-saturated NaO0.5-CaO-SiO2

flux and molten silicon. J. Min. Mat. Proc. Inst. Japan 2002; 118: 497-505.

[19] Johnston MD, Barati M. Distribution of impurity elements in slag-silicon equilibria for oxidative refining of metallurgical

silicon for solar cell applications. Solar Energy Materials & Solar Cells 2010; 94: 2085-2090.

[20] Schei A. High purity silicon production, International seminar on refining and alloying of liquid aluminium and ferro-alloys

1985, Trondheim, Norway.

[21] Juneja J.M., Mukherjee TK. A study of the purification of metallurgical grade silicon. Hydrometallurgy 1986; 16: 69-75.

[22] Santos IC, Goncales AP, Silva Santos C, Almeida M, Afonso MH, Joaquina Cruz M. Purification of metallurgical grade silicon

by acid leaching. Hydrometallurgy 1990; 23: 237-246.

[23] Dietle J. Refining of metallurgical-grade silicon. Silicon for Photovoltaics 1987; 2: 285 352.

[24] Lian SS, Kammel R, Kheiri MJ. Preliminary study of hydrometallurgical refining of MG-silicon with attrition grinding. Solar

Energy Materials & Soalr Cells 1992; 26: 269-276.

[25] Olette M, Physical chemistry of process metallurgy, Part 2, G.R. St-Pierre, ed. Interscience, New York, NY, 1961: 1065-1087.

[26] Safarian J, Tangstad M. Vacuum behaviour of the dissolved elements in molten silicon. Silicon for the Chemical and Solar

Industry X, lesund-Geiranger, June 28-July 02, Norway 2010: 41-50.

[27] Safarian J, Xakalashe B, Tangstad M. Vacuum removal of the impurities from different silicon melts. 26th European

Photovoltaic Solar Energy Conference and Exhibition, Hamburg, Germany 2011: 1810-1813.

[28] Suzuki K, Kumagai T, Sano N. Removal of boron from metallurgical grade silicon by applying the plasma treatment. ISIJ int.

1992; 32: 630-634.

[29] Yuge N, Abe M, Hanazawa K, Baba H, Nakamura N, Kato Y, Sakaguchi Y, Hiwasa, Aratani F. Purification of metallurgical

grade silicon up to solar grade. Prog. Photovolt.: Res. Appl. 2001; 9: 203-209.

[30] Margaria1 T, Cocco F, Neulat L, Kraiem J, Einhaus R, Degoulange J, Pelletier D, Dubois S, Delannoy Y, Chichignoud G,

Delsol R, Bruni MD. UMG Silicon from the PHOTOSIL project a status overview in 2011 on the way towards industrial

production, 26th European Photovoltaic Solar Energy Conference and Exhibition, Hamburg, Germany 2011: 1806-1809.

[31] Ji-Jun W, Wen-hui M, Bin Y, Yong-nian D, Morita K. Boron removal from metallurgical grade silicon by oxidizing refining.

Trans. Nonferrous Met. China 2009; 19: 463.467.

[32] Alemany C, Trassy C, Pateyron B, Li KI, Delannoy Y. Refining of metallurgical-grade silicon by inductive plasma. Solar

Energy Materials & Solar Cells 2002; 72: 21-48.

[33] Yushikawa T, Morita K. Removal of phosphorus by the solidification refining with Si-Al melts. Sci. Tech. Adv. Mat. 2003; 4:

531-537.

[34] Yushikawa T, Arimura K, Morita K. Boron removal by titanium addition in solidification refining of silicon with Si-Al melt.

Met. Mat. Trans. B 2005; 36B: 837-842.

[35] Morita K, Yoshikawa T, Thermodynamic evaluation of new metallurgical refining processes for SoG-silicon production. Trans.

Nonferrous Met. Soc. China 2011; 21: 685-690.

[36] Yin Z, Oliazadeh A, Esfahani S, Johnston M, Barati M. Solvent refining of silicon using nickel as impurity getter. Canadian

Metallurgical Quarterly 2011; 50: 166-172.

97

Você também pode gostar

- Oxidation of Organic Compounds: Medium Effects in Radical ReactionsNo EverandOxidation of Organic Compounds: Medium Effects in Radical ReactionsNota: 4 de 5 estrelas4/5 (1)

- Replacing Materials in Aging Aircraft to Improve Corrosion Resistance and Fatigue PerformanceDocumento22 páginasReplacing Materials in Aging Aircraft to Improve Corrosion Resistance and Fatigue Performancemarin.petre2815100% (1)

- The Biodeterioration of Synthetic Resins Used in ConservationDocumento8 páginasThe Biodeterioration of Synthetic Resins Used in ConservationJorge Rafael Mayorga Sandoval100% (1)

- A designer's guide to engineering polymer technologyDocumento11 páginasA designer's guide to engineering polymer technologyNataly Calderon100% (1)

- New Metallic Materials-Al-Li AlloysDocumento23 páginasNew Metallic Materials-Al-Li AlloyszorazhrAinda não há avaliações

- Second law of thermodynamics entropy increasesDocumento3 páginasSecond law of thermodynamics entropy increasesthienAinda não há avaliações

- Structure and Properties of Mullite PDFDocumento16 páginasStructure and Properties of Mullite PDFFelipe Kellyta SouzaAinda não há avaliações

- A History of SherrittDocumento15 páginasA History of SherrittLud Pas100% (1)

- Hydrophobic Glass Coated With Surface Modified Silica Film Prepared From Sodium Silicate PDFDocumento5 páginasHydrophobic Glass Coated With Surface Modified Silica Film Prepared From Sodium Silicate PDFIrna I. SyafitriAinda não há avaliações

- Geologic CO2 Storage Report OKDocumento40 páginasGeologic CO2 Storage Report OKWINSTON VILLANUEVAAinda não há avaliações

- ProfileofScientists1 Against Climate ChngeDocumento8 páginasProfileofScientists1 Against Climate ChngeAtish KissoonAinda não há avaliações

- SiC-SiC Composites, A State of The Art ReviewDocumento12 páginasSiC-SiC Composites, A State of The Art ReviewMaría Camila Belduque CorreaAinda não há avaliações

- Epoxy - Chemical ResistanceDocumento13 páginasEpoxy - Chemical ResistanceLaxmesh Hegde100% (1)

- Silica ExtractionDocumento5 páginasSilica ExtractionRV RVAinda não há avaliações

- The Evolution of Al-Li Base Products For AerospaceDocumento14 páginasThe Evolution of Al-Li Base Products For AerospaceRichard HilsonAinda não há avaliações

- Graphene-doped Silicon Nano Powder ProductionDocumento15 páginasGraphene-doped Silicon Nano Powder ProductionKholidFadullahAinda não há avaliações

- Tarascon 2001-Issues and Challenges Facing Rechargeable Lithium Batteries PDFDocumento9 páginasTarascon 2001-Issues and Challenges Facing Rechargeable Lithium Batteries PDFZeynep ErdölAinda não há avaliações

- Bioconversion of Natural Gas To Liquid Fuel: Opportunities and ChallengesDocumento19 páginasBioconversion of Natural Gas To Liquid Fuel: Opportunities and ChallengesMauhibahYumnaAinda não há avaliações

- Failure PDFDocumento101 páginasFailure PDFManuel GasparAinda não há avaliações

- Colour Anodizing of Aluminum Alloys Outdated)Documento3 páginasColour Anodizing of Aluminum Alloys Outdated)tootalldeanAinda não há avaliações

- Comparing tribological behaviors of new organomolybdenum additiveDocumento9 páginasComparing tribological behaviors of new organomolybdenum additivehusinwidjajaAinda não há avaliações

- Economics of Polysilicon Process - A View From JapanDocumento22 páginasEconomics of Polysilicon Process - A View From JapanccokapAinda não há avaliações

- Nasa O2clean 2001Documento49 páginasNasa O2clean 2001benAinda não há avaliações

- Fayaz Report On Challenges Associated With Sepn of Hcl-Water Azeotrope 04.08Documento27 páginasFayaz Report On Challenges Associated With Sepn of Hcl-Water Azeotrope 04.08fayaz5uin1234Ainda não há avaliações

- Catalyst To EthanolDocumento26 páginasCatalyst To EthanolFatih FıratAinda não há avaliações

- Recommendations For Welding Aluminum Castings - Modern CastingDocumento6 páginasRecommendations For Welding Aluminum Castings - Modern CastingOnnuri WonAinda não há avaliações

- Arcam EBM Ti6Al4V ELI Titanium AlloyDocumento3 páginasArcam EBM Ti6Al4V ELI Titanium AlloyABHUSGAinda não há avaliações

- RECENT DEVELOPMENTS IN ELASTOMER CROSSLINKINGDocumento31 páginasRECENT DEVELOPMENTS IN ELASTOMER CROSSLINKINGAzizol WahabAinda não há avaliações

- Nasa Cr-132332 Analysis of Fatigue DataDocumento188 páginasNasa Cr-132332 Analysis of Fatigue DataarabeauAinda não há avaliações

- Alcoa Aerospace Briefing June92011Documento20 páginasAlcoa Aerospace Briefing June92011Mark Evan SalutinAinda não há avaliações

- Energy Recovery - TspaceDocumento26 páginasEnergy Recovery - TspaceAlfonso Blanco100% (1)

- Report on zeolite synthesis and characterizationDocumento12 páginasReport on zeolite synthesis and characterizationAditya PAinda não há avaliações

- G. Kachaniwsky and C. Newman Eds. Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy. Co-Sponsored by the Non-Ferrous Pyrometallurgy and Hydrometallurgy Sections OfDocumento279 páginasG. Kachaniwsky and C. Newman Eds. Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy. Co-Sponsored by the Non-Ferrous Pyrometallurgy and Hydrometallurgy Sections Ofsgaluf5Ainda não há avaliações

- Khan (2019) Deoxygenation of Triglycerides For Jet Fuel Range HydrocarbonsDocumento24 páginasKhan (2019) Deoxygenation of Triglycerides For Jet Fuel Range HydrocarbonsAisyah ZafiraAinda não há avaliações

- The Mechanical Properties of Poly (Ether-Ether-Ketone) (PEEK) With Emphasis On The Large Compressive Strain ResponseDocumento18 páginasThe Mechanical Properties of Poly (Ether-Ether-Ketone) (PEEK) With Emphasis On The Large Compressive Strain ResponseUriel PeñaAinda não há avaliações

- OandG StatementDocumento1 páginaOandG Statementjfenster7540Ainda não há avaliações

- Evaluation and Selection of Heat Exchangers: ControlDocumento11 páginasEvaluation and Selection of Heat Exchangers: Controlkinjalpatel12345Ainda não há avaliações

- 2008 Abstract Booklet 9-12-08.FINALDocumento63 páginas2008 Abstract Booklet 9-12-08.FINALgladiolus86Ainda não há avaliações

- The Windscale Reactor Accident-50 Years OnDocumento6 páginasThe Windscale Reactor Accident-50 Years OnTroy LivingstonAinda não há avaliações

- Advances in Carbon CaptureDocumento3 páginasAdvances in Carbon Capturetassili17Ainda não há avaliações

- Role of Catalysis in Sustainable Development4thDocumento59 páginasRole of Catalysis in Sustainable Development4thSwamiAinda não há avaliações

- Iron Making in Mini Blast Furnace MBFDocumento4 páginasIron Making in Mini Blast Furnace MBFMaheswar SethiAinda não há avaliações

- Accelerated CoolingDocumento7 páginasAccelerated CoolingHarikrishnan N SivaprasadAinda não há avaliações

- State of the Art in Steel Mill Dust RecyclingDocumento6 páginasState of the Art in Steel Mill Dust RecyclingCeyhun TatarAinda não há avaliações

- Finnish Li Pegmatites PDFDocumento88 páginasFinnish Li Pegmatites PDFcrazybearAinda não há avaliações

- Pankow Cherry Dnapl Book 1996Documento538 páginasPankow Cherry Dnapl Book 1996rodrigonapalmy50% (2)

- Copper Wire ArchingDocumento14 páginasCopper Wire ArchingKaarthicNatarajanAinda não há avaliações

- Hazardous Materials Section 4.8 Hydrogen Safety: Environment, Safety and Health Manual - ANL-EDocumento11 páginasHazardous Materials Section 4.8 Hydrogen Safety: Environment, Safety and Health Manual - ANL-Ehk168Ainda não há avaliações

- Properties of Lactic Acid Based Polymers and Their Correlation With CompositionDocumento41 páginasProperties of Lactic Acid Based Polymers and Their Correlation With CompositionAero Fortia Natura100% (2)

- Synthesis of Zeolite A A ReviewDocumento6 páginasSynthesis of Zeolite A A ReviewSohel SurtiAinda não há avaliações

- Economic Measurements of Polysilicon For The Photovoltaics IndustryDocumento10 páginasEconomic Measurements of Polysilicon For The Photovoltaics IndustryRishi SoniAinda não há avaliações

- Hydrothermal Synthesis of ZeoliteDocumento40 páginasHydrothermal Synthesis of ZeoliteMuhammadNoumanHashmatAinda não há avaliações

- Jjmie: Salt Fog Corrosion Behavior of Nanostructured Tialn and Alcrn Hard Coatings On Astm-Sa213-T-22 Boiler SteelDocumento7 páginasJjmie: Salt Fog Corrosion Behavior of Nanostructured Tialn and Alcrn Hard Coatings On Astm-Sa213-T-22 Boiler SteelAgustine SetiawanAinda não há avaliações

- Hatch and Northern Graphite PaperDocumento6 páginasHatch and Northern Graphite PaperNarayana Murthy GadiAinda não há avaliações

- Pyrometallurgical Extraction of PGM AssignmentDocumento10 páginasPyrometallurgical Extraction of PGM Assignmentprincekamutikanjore100% (1)

- Industry Disaster ListDocumento6 páginasIndustry Disaster Listaliakbar51214Ainda não há avaliações

- Polymers in Aerospace ApplicationDocumento26 páginasPolymers in Aerospace ApplicationSoufajit BiswalAinda não há avaliações

- When Nameplate Is Not EnoughDocumento9 páginasWhen Nameplate Is Not Enoughgreenisin100% (1)

- 10 11648 J Am 20150402 13Documento7 páginas10 11648 J Am 20150402 13Willian Boneli de AlmeidaAinda não há avaliações

- EES ManualDocumento191 páginasEES ManualGustavo FaggionAinda não há avaliações

- Solving Equations With ExcelDocumento6 páginasSolving Equations With Excelengineer_khaula7035Ainda não há avaliações

- 0811 1432Documento33 páginas0811 1432Willian Boneli de AlmeidaAinda não há avaliações

- Cooling Tower FundamentalsDocumento117 páginasCooling Tower FundamentalspadzicAinda não há avaliações

- Sccharomyces CervisiaeDocumento9 páginasSccharomyces CervisiaeWillian Boneli de AlmeidaAinda não há avaliações

- U.S. Silicon Production and Use in 2014Documento2 páginasU.S. Silicon Production and Use in 2014Willian Boneli de AlmeidaAinda não há avaliações

- Mcs 2014Documento199 páginasMcs 2014Camila Contreras CarrascoAinda não há avaliações

- Chapter 13: Analog To Digital Conversion, Data Acquisition and ControlDocumento11 páginasChapter 13: Analog To Digital Conversion, Data Acquisition and ControlAnonymous GQjHHSX9yAinda não há avaliações

- Tda 7269Documento8 páginasTda 7269JCMAinda não há avaliações

- Service Manual: Indoor UnitDocumento28 páginasService Manual: Indoor UnitEmanuel MarquesAinda não há avaliações

- Ics 61800 4Documento9 páginasIcs 61800 4Bharat Kumar0% (2)

- MSP 430 G 2955Documento71 páginasMSP 430 G 2955ezekielmuddAinda não há avaliações

- BoardSet v160522Documento2 páginasBoardSet v160522Pepe CastilloAinda não há avaliações

- Littelfuse Varistor DC Application Varistor Design Guiderev02272014finalDocumento25 páginasLittelfuse Varistor DC Application Varistor Design Guiderev02272014finalRizAinda não há avaliações

- MOSFET - TutorialspointDocumento3 páginasMOSFET - Tutorialspointgunasekaran k100% (1)

- CS11002Documento1 páginaCS11002Rinaldy67% (3)

- VBG08H-E: Ignition Coil Driver Power I.CDocumento34 páginasVBG08H-E: Ignition Coil Driver Power I.CAngel VelasquezAinda não há avaliações

- A Ferroelectric FET Based In-Memory Architecture For Multi-Precision Neural NetworksDocumento6 páginasA Ferroelectric FET Based In-Memory Architecture For Multi-Precision Neural NetworksnandakishoryadavAinda não há avaliações

- BJT Gibert MultiplierDocumento5 páginasBJT Gibert MultiplierJyoti GoyalAinda não há avaliações

- Details PDF: Image Part Number Description Manufacturer QtyDocumento1 páginaDetails PDF: Image Part Number Description Manufacturer QtySamsung J2Ainda não há avaliações

- MOS and CMOS Process OverviewDocumento36 páginasMOS and CMOS Process OverviewashishAinda não há avaliações

- 100 RFME 2 MarksDocumento11 páginas100 RFME 2 MarksdhanarajAinda não há avaliações

- Behavior of The EBehavior of The Electronic Dielectric Constant in Covalent and Ionic Materialslectronic Dielectric Constant in Covalent and Ionic MaterialsDocumento14 páginasBehavior of The EBehavior of The Electronic Dielectric Constant in Covalent and Ionic Materialslectronic Dielectric Constant in Covalent and Ionic MaterialsHoang Van DungAinda não há avaliações

- En Acs800-607 HW CDocumento82 páginasEn Acs800-607 HW CjakkyjeryAinda não há avaliações

- Thermistor A1Documento4 páginasThermistor A1Ahmed Abu SharbainAinda não há avaliações

- Ohmic Heating of FoodsDocumento18 páginasOhmic Heating of FoodsHarish SrinivasanAinda não há avaliações

- Impulse Testing of TransformersDocumento20 páginasImpulse Testing of TransformersSantosh VardhanAinda não há avaliações

- X Ray Flat Panel Detector - MEDICALDocumento14 páginasX Ray Flat Panel Detector - MEDICALatnafu takeleAinda não há avaliações

- Avago Application Note 1335 - Main Applications and Selection of Gate Driver Optocouplers PDFDocumento8 páginasAvago Application Note 1335 - Main Applications and Selection of Gate Driver Optocouplers PDFFabiano TonnAinda não há avaliações

- Semiconductor Module Users GuideDocumento318 páginasSemiconductor Module Users GuideR YAinda não há avaliações

- Quick Charge Device List PDFDocumento20 páginasQuick Charge Device List PDFEnoAinda não há avaliações

- Westinghouse Ds and DSL Low Voltage Power Circuit Breakers and Cell PartsDocumento28 páginasWestinghouse Ds and DSL Low Voltage Power Circuit Breakers and Cell PartsRodney PimentaAinda não há avaliações

- Standards List For ElectricalDocumento46 páginasStandards List For ElectricalSunil PurohitAinda não há avaliações

- Characterizing PV Array Output Using Few Measured ParametersDocumento5 páginasCharacterizing PV Array Output Using Few Measured ParametersAbdelkaderGourbiAinda não há avaliações

- MC33030 DC Servo Motor Controller/Driver: Marking DiagramsDocumento17 páginasMC33030 DC Servo Motor Controller/Driver: Marking DiagramsAndrés ThompsonAinda não há avaliações

- Programme Des Cours STANFORD UNIVDocumento4 páginasProgramme Des Cours STANFORD UNIVAbu FayedAinda não há avaliações