Escolar Documentos

Profissional Documentos

Cultura Documentos

Etileno Por Deshidrogenacion Oxidativa de Etano

Enviado por

Victor Artemio Espinoza GanozaDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Etileno Por Deshidrogenacion Oxidativa de Etano

Enviado por

Victor Artemio Espinoza GanozaDireitos autorais:

Formatos disponíveis

Ind. Eng. Chem. Res.

2009, 48, 75617566

7561

Oxidative Dehydrogenation of Ethane to Ethylene with CO2 over Fe-Cr/ZrO2

Catalysts

Shuang Deng,*,, Songgeng Li, Huiquan Li, and Yi Zhang

Downloaded by INSTITUTE OF PROC ENGINEERING on September 1, 2009 | http://pubs.acs.org

Publication Date (Web): July 2, 2009 | doi: 10.1021/ie9007387

Department of Chemical and Biomolecular Engineering, The Ohio State UniVersity, 140 West 19th AVenue,

Columbus, Ohio 43210, and Institute of Process Engineering, Chinese Academy of Sciences,

Beijing 10080, P. R. China

The catalytic performance of Fe-Cr/ZrO2 catalysts, prepared by two different methodsscoprecipitation and

coprecipitation-impregnation were examined in oxidative dehydrogenation of ethane to ethylene using CO2

as an oxidant. Thermogravimetric analysis and physicochemical characterization such as XPS, XRD, and

BET were performed to explore the correlation of catalytic performance with physicochemical properties of

the catalysts. Catalytic tests show that Fe-Cr/ZrO2 catalysts prepared by coprecipitation-impregnation have

higher catalytic stability, higher CO2 conversion, and lower ethylene selectivity in comparison to Fe-Cr/

ZrO2 prepared by coprecipitation. The characterization results indicate that the dehydrogenation of ethane is

activated by Cr3+ species and Fe3O4 is formed during the reaction, which can promote the reverse WGS

reaction. Coke deposition is the main reason of the deactivation of the catalysts. A possible reaction mechanism

was proposed on the basis of these results.

Introduction

Ethylene is a basic raw material in the petrol-chemical

industry. Thermal cracking of hydrocarbons (such as ethane)

in the presence of steam is currently the main source of

ethylene.1-3 However, steam cracking of ethane to ethylene is

a highly endothermic process that must be performed at high

temperatures, which consumes a great deal of energy. Moreover,

at high reaction temperatures, other unwanted reactions producing coke also occur, which can create serious problems with

reactor performance. For example, the large amount of coke

deposited on the inner walls of a tubular cracking reactor can

cause a reduction in the heat transfer rate from the walls, which

in turn requires a higher wall temperature to achieve the

desirable ethane conversion.2 Therefore, it is necessary to

develop a new technology devoted to the production of ethylene.

Oxidative dehydrogenation of ethane (ODE) by oxygen has

been proposed as an alternative route to the process of thermal

cracking of ethane because it is an exothermic process and can

be performed at lower temperatures.4-6 The low temperature

operation and exothermic reactions can significantly reduce the

external heat input to the process and lessen the coke formation.

However, the deep oxidation of ethylene could occur because

of the strong oxidation ability of oxygen, which will cause a

reduction in selectivity to ethylene. To suppress the deep

oxidation and enhance ethylene selectivity, carbon dioxide has

recently been employed as a mild oxidant for ODE instead of

oxygen.1,3,7-12

Thermodynamics analysis and experimental results10-12 have

indicated that ODE to ethylene by carbon dioxide (1) can be

described as the dehydrogenation reaction (2) coupled with

reverse water gas shift (WGS) reaction (3). The ethylene

production can be improved by the elimination of the hydrogen

produced from the dehydrogenation via the reverse WGS

reaction.

* To whom correspondence should be addressed. E-mail address:

shuang.deng@hotmail.com deng.55@osu.edu.

The Ohio State University.

Chinese Academy of Sciences.

C2H6 + CO2 T C2H4 + H2O + CO

(1)

C2H6 T C2H4 + H2

(2)

CO2 + H2 T CO + H2O

(3)

The key to promoting the reaction toward the desired reaction

pathway is the development of a catalyst with desirable

behaviors. A variety of catalysts have been examined in

ODE with carbon dioxide as an oxidant.1,3,4,7-13 Among these

catalysts, Cr-based catalysts have proven to be very effective

catalysts for this reaction.13,14 Various promoters have been used

to further improve catalytic performance. In our prior work,14-16

it has been demonstrated that Fe-promoted Cr2O3/ZrO2 catalysts

exhibit high catalytic activity.

It is known that the performance of a catalyst depends on its

physical-chemical properties, which are strongly affected by

the synthetic technique of the catalyst. In the research described

here, two different methodsscoprecipitation and coprecipitation-impregnation were adopted to prepare Fe-Cr/ZrO2

catalysts for the comparison. Various characterization techniques

including TEM, X-ray photoelectron spectroscopy (XPS), X-ray

diffraction (XRD), and thermogravimetric analysis were used

to examine the chemical and texture properties of the catalysts

before and after reaction aiming at understanding the activity

of Fe-Cr/ZrO2 catalysts in ODE to ethylene with CO2.

Experimental Section

Catalyst Preparation. Fe-Cr/ZrO2 catalysts were synthesized by two different techniques: coprecipitation and

coprecipitation-impregnation. The coprecipitation method has

been described in a previous paper.14 For the coprecipitationimpregnation method, Fe was added to the support of zirconium

using the coprecipitation method. After vacuum drying at 80

C for 8 h, the obtained precipitate was further impregnated

with aqueous solutions of the appropriate amount of

Cr(NO3)3 9H2O and stirred for 6 h at 40 C. The carefully stirred

paste was then vacuum-dried at 60 C overnight. All the dried

samples were calcined at 600 C for 4 h, and then pressed,

10.1021/ie9007387 CCC: $40.75 2009 American Chemical Society

Published on Web 07/02/2009

Downloaded by INSTITUTE OF PROC ENGINEERING on September 1, 2009 | http://pubs.acs.org

Publication Date (Web): July 2, 2009 | doi: 10.1021/ie9007387

7562

Ind. Eng. Chem. Res., Vol. 48, No. 16, 2009

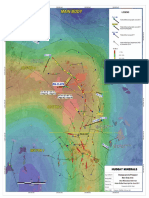

Figure 1. Catalytic activity and stability of Fe-Cr/ZrO2 catalysts.

crushed, and sieved into catalysts of 20-40 meshes. The

catalysts, which were prepared by the coprecipitation and

coprecipitation-impregnation methods, have the same loadings

of Fe and Cr (5 wt % of Fe and 10 wt % of Cr). Hereafter,

Fe-Cr/ZrO2(C) denotes the catalyst prepared by coprecipitation,

and Fe-Cr/ZrO2 (CI) stands for the catalyst prepared by

coprecipitation-impregnation.

Material Characterization Techniques. Specific surface

areas (SBET), pore sizes, and pore volumes of the catalysts were

measured by N2 adsorption-desorption isotherms at -196 C

on an Autosorb-1 physisorb analyzer. TEM images were taken

on a HITACHI H-8100 microscope. X-ray photoelectron

spectroscopy (XPS) was performed on a PHI 5300/ESCA

system (Perkin-Elmer) at 25 mA under the vacuum of 2.9

10-7 Pa. The X-ray source was AL Ka radiation. All binding

energies were referenced to C1s of 284.6 eV. X-ray diffraction

(XRD) patterns of the catalysts were obtained on a Rigaku

D/max-2400 X-ray diffractometer, operated at 40 kV and 120

mA with Ni filtered Cu Ka radiation. Thermogravimetric studies

of the catalysts were conducted on a Netzsch STA449C

thermobalance in a synthetic air oxidant atmosphere by elevating

the temperature from room temperature to 800 C at a heating

rate of 15 C /min.

Catalytic Tests. The catalytic tests were performed in a fixedbed flow type quartz reactor packed with 0.2 g of the catalyst

and 1 g of quartz sand at atmospheric pressure. The reactant

stream consisting of 20% ethane, 60% carbon dioxide, and 20%

Ar was introduced into the reactor at a flow rate of 15 mL/min.

The reaction temperature was controlled at 650 C. The products

were analyzed on line by a gas chromatograph (Shimadzu GC

14B) with a Porapak QS column and a 5A molecular sieve

column. After reaction, the reactor was cooled with pure Ar

until it cooled to room temperature. The used catalysts were

taken out from the reactor and placed in sealed sample bags,

which were stored in a desiccator before characterization.

Results and Discussion

Catalytic Performance. The blank test (the reactor contains only quartz particles) was performed first to verify that

the reactor material is inert in this reaction. The result shows

Table 1. Structural Properties of Fresh Fe-Cr/ZrO2 (C) and

Fe-Cr/ZrO2 (CI) Catalysts

catalysts

SBET (m2/g)

pore volume

(cm3/g)

average pore

size (nm)

Fe-Cr/ZrO2(C)

Fe-Cr/ZrO2 (CI)

172.1

181.7

0.51

0.61

11.79

13.44

that the ethane conversion is 1.10% at 650 C, which is

considered to be negligible in this reaction.

Figure 1 presents the catalytic activity and stability of Fe-Cr/

ZrO2 (C) and Fe-Cr/ZrO2 (CI) catalysts, respectively. The

ethylene yield on Fe-Cr/ZrO2 (C) dramatically drops from 50%

to 38% over the time on stream. However, the ethylene yield

on Fe-Cr/ZrO2 (CI) varies little. The ethylene selectivity over

Fe-Cr/ZrO2 (C) is higher than that over Fe-Cr/ZrO2 (CI) while

its CO2 conversion is lower. The selectivity toward ethylene

on both catalysts shows a slight increase at the initial reaction

stage and then gains level off. These results indicate that the

preparation methods significantly affect catalytic activity and

stability of Fe-Cr/ZrO2 catalysts. The Fe-Cr/ZrO2(CI) catalyst

exhibits high catalytic stability in comparison to the Fe-Cr/

ZrO2(C) catalyst. It is worth pointing out that the magnitude of

variation in the CO2 conversion is less than that in the

corresponding ethane conversion for the Fe-Cr/ZrO2(C). The

main reason is that the content of CO2 is higher than that of

the ethane in the feed gas where the mole ratio of CO2 to ethane

is 3:1.

Textural and Structural Properties. The BET surface area,

average pore size, and pore volume of the Fe-Cr/ZrO2 catalysts

are given in Table 1. The values of both catalysts are

comparable, which indicates that the structures of the Fe-Cr/

ZrO2 catalysts are not strongly affected by the preparation

methods. This similarity may be explained by the fact that the

Fe-Cr/ZrO2 (CI) catalyst is made from the impregnation of Cr

onto the surface of Fe/ZrO2, and thus, its structure is largely

determined by the Fe/ZrO2 structure, which is prepared with

the coprecipitation method as well.

Figure 2 shows the TEM images of the Fe-Cr/ZrO2(C) and

Fe-Cr/ZrO2 (CI) catalysts before and after reaction, which

provides visual examination for the catalysts. All of the fresh

catalysts investigated are regularly spherical in shape and exhibit

Ind. Eng. Chem. Res., Vol. 48, No. 16, 2009

7563

Downloaded by INSTITUTE OF PROC ENGINEERING on September 1, 2009 | http://pubs.acs.org

Publication Date (Web): July 2, 2009 | doi: 10.1021/ie9007387

Figure 2. TEM images of (a) fresh Fe-Cr/ZrO2 (C), (b) used Fe-Cr/ZrO2 (C), (c) fresh Fe-Cr/ZrO2 (CI), and (d) used Fe-Cr/ZrO2 (CI) catalysts.

Figure 3. XRD patterns of (a) fresh Fe-Cr/ZrO2 (CI), (b) used Fe-Cr/

ZrO2 (CI), (c) fresh Fe-Cr/ZrO2 (C), and (d) used Fe-Cr/ZrO2 (C) catalysts.

uniform particle size distribution. Coke can readily be observed

on the surface of the Fe-Cr/ZrO2 (C) catalyst after reaction,

and the boundaries between particles become blurry compared

with those before reaction. In contrast, much less coke was found

on surface of the Fe-Cr/ZrO2 (CI) catalyst after reaction. This

phenomenon has been confirmed by the TGA results, which

will be discussed in a later section.

XRD patterns of Fe-Cr/ZrO2(C) and Fe-Cr/ZrO2 (CI)

catalysts before and after reaction are presented in Figure 3.

Only tetragonal ZrO2 diffraction peaks can be observed on their

XRD spectra. No diffraction peaks corresponding to crystalline

Cr and Fe appear, suggesting that Cr and Fe active species were

highly dispersed in the catalysts and did not sinter after the high

temperature reaction. It should be noted that there is no obvious

change in the width and height of the diffraction peaks before

and after reaction for both catalysts. This means that there is

no appreciable growth of particles. The coke on the Fe-Cr/

ZrO2(C) and Fe-Cr/ZrO2 (CI) catalysts is considered amorphous

carbon since there are no diffraction peaks of crystal carbon on

their XRD patterns.

XPS Results. Surface Cr species on Fe-Cr/ZrO2(C) and

Fe-Cr/ZrO2 (CI) catalysts were examined with XPS before and

after reaction as shown in Figure 4. Two peaks appear on all

the fresh catalysts: one at 576 eV and the other at 579 eV,

which can be assigned to Cr3+ and Cr6+, respectively.1,17 After

reaction, the peak at 579 eV disappeared, suggesting that most

of Cr6+ species have been reduced to Cr3+ in the reaction.

There is a general consensus that the catalytic activity of Crbased dehydrogenation catalysts is strongly dependent on the

Cr species.3,17,18 However, there is a controversy on the

oxidation state of the active species of Cr. Wang et al.17

investigated the dehydrogenation of ethane with CO2 over

supported Cr-based catalysts and proposed that surface Cr3+

Figure 4. XPS spectra of Cr 2p on (a) fresh Fe-Cr/ZrO2 (CI), (b) used

Fe-Cr/ZrO2 (CI), (c) fresh Fe-Cr/ZrO2 (C), and (d) used Fe-Cr/ZrO2 (C)

catalysts.

Table 2. Analysis of Cr Species on Fresh Fe-Cr/ZrO2 (C) and

Fe-Cr/ZrO2 (CI) Catalysts

catalyst

Cr3+BE (eV)

Cr6+BE (eV)

Cr6+/Cr3+

Fe-Cr/ZrO2 (C)

Fe-Cr/ZrO2 (CI)

576.2

576.3

578.9

579.0

2.70

1.73

species and Cr6+/Cr3+ couples are the active sites for the

dehydrogenation of ethane. Ge et al.19 used ESR and UV-DRS

to probe the active site for ODE with CO2 over silica-supported

chromium oxide catalysts. They found that species with a high

valence state (Cr5+ or Cr6+) are important for the reaction. In

our work, Cr3+ ions are considered the active species for

dehydrogenation, with the argument that only Cr3+ species has

been detected by XPS on the used catalysts and there is no

obvious deactivation of Fe-Cr/ZrO2 (CI) catalysts in the

stability test. (The degradation of Fe-Cr/ZrO2(C) catalysts is

caused by coke deposition, which is to be discussed in a later

section). The increase of ethylene selectivity in the beginning

of ODE can be attributed to the reduction of Cr6+ to Cr3+.

The Cr6+/Cr3+ ratio over the Fe-Cr/ZrO2(C) is higher than

the ratio over the Fe-Cr/ZrO2 (CI) as shown in Table 2, which

may indicate that Cr6+ ions have an effect on the dehydrogenation of ethane. Weckhuysen et al.18 research shows that Cr6+

ions are the precursors for the Cr3+ dehydrogenation centers.

Based on this finding, we speculate that there are more Cr6+

ions over the Fe-Cr/ZrO2 (C), which results in its high

selectivity toward ethylene (as indicated in Figure 1b), and its

high ethylene yield as well as ethane conversion in the beginning

of the reaction (shown in Figure 1a and Figure 1d, respectively).

7564

Ind. Eng. Chem. Res., Vol. 48, No. 16, 2009

Table 3. Analysis of O 1s on the Used Fe-Cr/ZrO2 (C) and

Fe-Cr/ZrO2 (CI) Catalysts

OI

OII

OIII

binding percent binding percent binding percent

catalysts energy (eV) (%) energy (eV) (%) energy (eV) (%)

Downloaded by INSTITUTE OF PROC ENGINEERING on September 1, 2009 | http://pubs.acs.org

Publication Date (Web): July 2, 2009 | doi: 10.1021/ie9007387

Fe-Cr/

ZrO2 (C)

Fe-Cr/

ZrO2(CI)

Figure 5. XPS spectra of Fe 2p on (a) fresh Fe-Cr/ZrO2 (CI), (b) used

Fe-Cr/ZrO2 (CI), (c) fresh Fe-Cr/ZrO2 (C), and (d) used Fe-Cr/ZrO2 (C)

catalysts.

Figure 6. XPS spectra of O 1s on (a) used Fe-Cr/ZrO2 (C) and (b) used

Fe-Cr/ZrO2 (CI) catalysts.

Figure 5 shows the XPS spectra of Fe 2p on the fresh and

used Fe-Cr/ZrO2(C) and Fe-Cr/ZrO2 (CI) catalysts. As shown

in Figure 5, the Fe 2p3/2 peaks for all the fresh catalysts are

located at 711.2 eV, which implies that the dominant phase on

the surface is Fe2O3.20,21 It is worth noting that the Fe 2p3/2

peaks on the examined used catalysts are shifted to the 710.7

eV, which is indicative of magnetite (Fe3O4) phase.20,21 It has

been reported that there exists a satellite peak for Fe 2p3/2 of

Fe2O3 located at 719 eV while there is no satellite peak for Fe

2p3/2 of Fe3O4.20 The absence of the satellite peak associated

with Fe 2p3/2 on the used catalysts further confirms the existence

of Fe3O4. Fe3O4 has an inverse spinal structure, which can

readily undergo rapid electron exchange between Fe3+ and Fe2+.

The electron hopping between Fe3+ and Fe2+ can facilitate the

proceeding of reaction 3.21,22

On the basis of the above analysis, it may be concluded that

for the ODE to ethylene using CO2 as an oxidant over Fe-Cr/

ZrO2 catalysts, Cr3+ species takes the role of the dehydrogenation of ethane and Fe promotes the CO2 hydrogenation

(reverse WGS reaction) through the redox cycle of Fe3+ and

Fe2+.

The O 1s XPS spectra of the used Fe-Cr/ZrO2(C) and

Fe-Cr/ZrO2 (CI) catalysts are depicted in Figure 6. The O 1s

XPS spectra are wide and unsymmetrical, which can be

deconvoluted into three components with different banding

energy values of 529.5, 531, and 532 eV. The peak at the

lower binding energy is assigned to surface lattice oxygen O2(hereafter denoted as O1).23,24 The peak at the higher binding

energy (531 eV) can be attributed to carbonates or adsorbed

CO2 (hereafter denoted as OII).24 The peak at the highest binding

529.74

68.38

531.38

6.48

532.37

24.78

529.51

82.64

531.35

11.10

532.19

6.25

energy (532 eV) is defined to be adsorbed oxygen species

(O-, O2) and/or surface hydroxyls (OH) (hereafter denoted as

OIII).23,24

Table 3 gives the proportions of these oxygen species on the

catalysts obtained by the fitting program. The Fe-Cr/ZrO2 (CI)

catalyst has a higher proportion of oxygen species in adsorbed

CO2 (OII) than the Fe-Cr/ZrO2 (C) catalyst, which means that

there are more active sites for CO2 on its surface. Therefore,

the Fe-Cr/ZrO2 (CI) catalyst exhibits higher CO2 conversion

as indicated in the catalytic performance experiment. Previous

research14,25,26 show that CO2 can be activated by basic sites.

For this reason, the number of adsorbed CO2 (OII) could be

related to the number of basic sites. It is conceivable that OIII

is highly relevant to oxygen vacancies present in the samples.24

The higher proportion of OIII sites on Fe-Cr/ZrO2 (C) catalyst

imply that a larger amount of oxygen vacancies were created

by the coprecipitation method. Research has indicated that

oxygen vacancies benefit WGS reaction.21,27 For example,

Zhang et al.21 compared three different preparation methods for

catalysts in WGS reaction, which shows that sol-gel provides

the highest catalytic performance because there are more oxygen

vacancies created during sol-gel process. From this perspective,

it is reasonable that the Fe-Cr/ZrO2(C) catalyst has higher

ethylene selectivity than Fe-Cr/ZrO2 (CI).

Reaction Mechanism. In consideration of the roles of Cr,

Fe, and O species in the ODE to ethylene over the Fe-Cr/

ZrO2 catalysts in the presence of CO2, the following reaction

mechanism was proposed (shown in Figure 7). Ethane is

activated by Cr3+ species to generate ethylene and H atom. Some

of the H atoms recombine to form H2. Other atoms combine

with lattice oxygen to produce H2O, simultaneously reducing

Fe3+ to Fe2+. CO2 dissociates on the active site (denoted as [ ])

to produce CO and active oxygen species (O*). The active

oxygen species (O*) are absorbed by oxygen vacancies (denoted

as 0) to form adsorbed oxygen species (Oad). Then, these

adsorbed oxygen species (Oad) diffuse into the crystal to create

lattice oxygen, which supplements the reduced lattice oxygen

that is used to produce H2O. At the same time, the active oxygen

species (O*) reoxidize Fe2+ to Fe3+, which forms the reductionoxidation cycle.

Catalyst Deactivation. In general, coke deposition, thermal

degradation, and the transformation of an active phase are key

Figure 7. Possible reaction mechanism of the oxidative dehydrogenation

of ethane by CO2 over Fe-Cr/ZrO2 catalysts.

Ind. Eng. Chem. Res., Vol. 48, No. 16, 2009

7565

Acknowledgment

This research was supported by the National Science Foundation of China (Gant No. 20436050), and National 863 Program

Youth Foundation (Grant No. 2004AA649230).

Literature Cited

Downloaded by INSTITUTE OF PROC ENGINEERING on September 1, 2009 | http://pubs.acs.org

Publication Date (Web): July 2, 2009 | doi: 10.1021/ie9007387

Figure 8. TG-DTG profiles of used Fe-Cr/ZrO2 (C) and Fe-Cr/ZrO2 (CI)

catalysts.

factors that lead to the deactivation of catalysts in dehydrogenation reactions.18 The thermal degradation and transformation

of an active phase can be excluded from the causes of catalyst

deactivation in our work since there was no substantial evidence

found.

TEM results indicate there is coke on surface of the

catalysts, particular on Fe-Cr/ZrO2(C) catalyst. To evaluate

the content of the carbon deposition, thermogravimetric

analyses were performed for the used catalysts in oxidant

atmosphere (shown in Figure 8). The peak at 360 C on

the derived thermogravimetric profile (DTG) is related to the

burning of coke.28 It was found that there was obvious weight

loss of the Fe-Cr/ZrO2 (C) catalyst compared with that of

the Fe-Cr/ZrO2 (CI) due to the burning of the coke. The

percentage of coke per weight of catalysts is 9.64% for the

used Fe-Cr/ZrO2 (C) and 1.13% for the used Fe-Cr/ZrO2

(CI). The relatively high coke deposition on Fe-Cr/ZrO2 (C)

catalyst gives an explanation for its dramatic decrease in the

production of ethylene over the time on stream. It is

speculated that more CO2 was involved in the decoking

reaction 4 over the Fe-Cr/ZrO2 (CI) catalyst

C + CO2 f 2CO

(4)

after considering its higher CO2 conversion and higher

stability in comparison to these catalytic properties over the

Fe-Cr/ZrO2(C) catalyst. Further investigation should be

conducted to confirm this speculation.

Conclusions

Fe-Cr/ZrO2 catalysts prepared by different methods have

been examined in ODE to ethylene in the presence of

CO2.The catalyst prepared by the coprecipitation-impregnation method exhibits stable catalytic performance during the

time on stream. In contrast, there is obvious deactivation

(ethylene yield and ethane conversion) for the catalyst

prepared by the coprecipitation method, which can be

attributed to coke deposition during the reaction. The catalyst

prepared by the coprecipiation method gives higher ethylene

selectivity and lower CO2 conversion. The high ethylene

selectivity could be explained by its larger amount of oxygen

vacancies (OIII). Less adsorbed CO2 (OII) on the catalyst may

cause its low CO2 conversion. The characterization results

indicate that Cr3+ species are the active sites for the

dehydrogenation of ethane and Fe2O3 is reduced to Fe3O4

during the reaction, which may enhance the reverse WGS

reaction.

(1) Wang, S.; Murata, K.; Hayakawa, T.; Hamakawa, S.; Suzkuki, K.

Effect of promoters on catalytic performance of Cr/SiO2 catalysts in

oxidative dehydrogenation of ethane with carbon dioxide. Catal. Lett. 2001,

73, 107.

(2) Choudary, V. R.; Mulla, S. A. R. Coupling of thermal cracking with

noncatalytic oxidative conversion of ethane to ethylene. AIChE J. 1997,

43, 1545.

(3) Mimura, N.; Okamoto, M.; Yamashita, H.; Oyama, S.; Murata, K.

Oxidative dehydrogenation of ethane over Cr/ZSM-5 catalysts using CO2

as an oxidant. J. Phys. Chem. B 2006, 110, 21764.

(4) Wang, S.; Murata, K.; Hayakawa, T.; Hamakawa, S.; Suzkuki, K.

Excellent performance of lithium doped sulfated zirconia in oxidative

dehydrogenation of ethane. Chem. Commun. 1999, 1999, 103.

(5) Mamedov, E. A.; Cortes-Corberan, V. Oxidative dehydrogenation

of lower alkanes on vanadium oxide-based catalysts. The present state of

the art and outlooks. Appl. Catal., A 1995, 127, 1.

(6) Huff, M.; Schmidt, L. D. Ethylene formation by oxidative dehydrogenation of ethane over monoliths at very short contact times. J. Phys. Chem.

1993, 97, 11815.

(7) Shi, X.; Ji, S.; Wang, K.; Li, C. Oxidative dehydrogenation of ethane

with CO2 over novel Cr/SBA-15/Al2O3/FeCrAl monolithic catalysts. Energy

Fuels. 2008, 22, 3631.

(8) Heracleous, E.; Vakros, J.; Lemonidou, A.; Kordulis, C. Role of

preparation parameters on the structure-selectivity properties of MoO3/

Al2O3 catalysts for the oxidative dehydrogenation of ethane. Catal. Today.

2004, 91, 28992.

(9) Zhang, X.; Liu, J.; Jing, Y.; Xie, Y. Support effects on the catalytic

behavior of NiO/Al2O3 for oxidative dehydrogenation of ethane to ethylene.

Appl. Catal., A 2004, 240, 143.

(10) Xu, L.; Lin, L.; Wang, Q.; Li, Y.; Wang, D.; Liu, W. A new route

for C2H4 production by reacting C2H6 with CO2 over a catalyst of chromium

oxide supported on silicalite-2 type zeolite. Stud. Surf. Sci. Catal. 1998,

119, 605.

(11) Xu, L.; Liu, J.; Yang, H.; Xu, Y.; Wang, D.; Lin, W. Regeneration

behaviors of Fe/Si-2 and Fe-Mn/Si-2 catalysts for C2H6 dehydrogenation

with CO2 to C2H4. Catal. Lett. 1999, 62, 185.

(12) Dale, B.; Emerson, H.; Min-Hon, R. Carbon dioxide as hydrogen

acceptor in dehydrogenation of alkanes. Ind. Eng. Chem. Prod. Res. DeV.

1972, 11, 444.

(13) Wang, S.; Zhu, Z. Catalytic conversion of alkanes to olfines by

carbon dioxide oxidative dehydrogenationsA review. Energy Fuels. 2004,

18, 1126.

(14) Deng, S.; Li, H.; Li, S.; Zhang, Y. Activity and characterization of

modified Cr2O3/ZrO2 nanocomposite catalysts for oxidatave dehydrogenation

of ethane to ethylene with CO2. J. Mol. Catal A: Chem. 2007, 268, 169.

(15) Deng, S.; Li, H.; Zhang, Y. Oxidative dehydrogenation of ethane

with carbon dioxide to ethylene over nanosized Cr2O3 catalysts. Chin. J.

Catal. 2003, 24, 744.

(16) Deng, S.; Li, H.; Zhang, Y. Dehydrogenation of ethane with CO2

over nano-Cr2O3 and composite catalysts. Chin. J. Chem. Eng. 2003, 54,

875.

(17) Wang, S.; Murata, K.; Hayakawa, T.; Hamakawa, S.; Suzuki, K.

Dehydrogenation of ethane with carbon dioxide over supported chromium

oxide catalysts. Appl. Catal., A 2000, 196, 1.

(18) Weckhuysen, B. M.; Schoonheydt, R. A. Alkane dehydrogenation

over supported chromium oxide catalysts. Catal. Today. 1999, 51, 223.

(19) Ge, X.; Zhu, M.; Shen, J. Catalytic performance of silica supported

chromium oxide catalysts in ethane dehydrogenation with carbon dioxide.

React. Kinet. Catal. Lett. 2002, 77, 103.

(20) Yamashita, T.; Hayes, P. Analysis of XPS spectra of Fe2+ and Fe3+

ions in oxide materials. Appl. Surf. Sci. 2008, 254, 2441.

(21) Zhang, L.; Wang, X.; Millet, J.; Matter, P.; Ozkan, U. Investigation

of highly active Fe-Al-Cu catalysts for water-gas shift reaction. Appl.

Catal., A 2008, 351, 1.

(22) Lund, C. R. F.; Kubsh, J. E.; Dumesic, J. A. Water Gas Shift oVer

Magnetite-Based Catalysts: Nature of ActiVe Sites for Adsorption and

Catalysis; American Chemical Society: Washington, DC, 1985.

(23) Tabata, K.; Hirano, Y.; Suzuki, E. XPS studies on the oxygen

species of LaMn1-xCuxO3+. Appl. Catal., A 1998, 170, 245.

7566

Ind. Eng. Chem. Res., Vol. 48, No. 16, 2009

Downloaded by INSTITUTE OF PROC ENGINEERING on September 1, 2009 | http://pubs.acs.org

Publication Date (Web): July 2, 2009 | doi: 10.1021/ie9007387

(24) Hueso, J. L.; Caballero, A.; Ocana, M.; Gonzalez-Elipe, A. R.

Reactivity of lanthanum-substituted cobaltites toward carbon particles. J.

Catal. 2008, 257, 334.

(25) Chen, Y.; Liaw, B.; Lai, W. ZrO2/SiO2- and La2O3/Al2O3- supported

platinum catalysts for CH4/CO2 reforming. Appl. Catal., A 2002, 230, 73.

(26) Matsui, N.; Anzai, K.; Akamatsu, N.; Nakagawa, K.; Ikenaga, N.;

Suzuki, T. Reaction mechanisms of carbon dioxide reforming of methane

with Ru-loaded lanthanum oxide catalyst. Appl. Catal., A 1999, 179, 247.

(27) Chen, C.; Cheng, W.; Lin, S. Enhanced activity and stability of a

Cu/SiO2 catalyst for the reverse water gas shift reaction by an iron promoter.

Chem. Commun. 2001, 18, 1770.

(28) Ordonez, S.; Diez, F.; Sastre, H. Characterization of the deactivation

of platinum and palladium supported on activated carbon used as hydrodechlorination catalysts. Appl. Catal., B 2001, 31, 113.

ReceiVed for reView May 6, 2009

ReVised manuscript receiVed June 7, 2009

Accepted June 19, 2009

IE9007387

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- 2.-Resol. Rec. Jass PilloniDocumento3 páginas2.-Resol. Rec. Jass PilloniVictor Artemio Espinoza GanozaAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- 4 Learning Experience 5Documento1 página4 Learning Experience 5Victor Artemio Espinoza GanozaAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- June Plan Map Hole 72 PDFDocumento1 páginaJune Plan Map Hole 72 PDFVictor Artemio Espinoza GanozaAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Pampa BMI July2011 v001 z4qkz4 PDFDocumento1 páginaPampa BMI July2011 v001 z4qkz4 PDFPedro Luis Trujillo HermitañoAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- WST 09 518Documento15 páginasWST 09 518Victor Artemio Espinoza GanozaAinda não há avaliações

- Ope Ii ExDocumento2 páginasOpe Ii ExVictor Artemio Espinoza GanozaAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- QIDocumento38 páginasQIVictor Artemio Espinoza GanozaAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Conversion of Reaction Rate Coefficient K or PreDocumento2 páginasConversion of Reaction Rate Coefficient K or PreVictor Artemio Espinoza GanozaAinda não há avaliações

- Ultimo Opsi 2015 IDocumento37 páginasUltimo Opsi 2015 IVictor Artemio Espinoza GanozaAinda não há avaliações

- Opsi TarDocumento6 páginasOpsi TarVictor Artemio Espinoza GanozaAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Conversion of Reaction Rate Coefficient K or PreDocumento2 páginasConversion of Reaction Rate Coefficient K or PreVictor Artemio Espinoza GanozaAinda não há avaliações

- Pool Operator HandbookDocumento87 páginasPool Operator Handbooktonyeld100% (2)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- 08 - Enriquecedor de Oxigeno AS-DDocumento61 páginas08 - Enriquecedor de Oxigeno AS-DCRISTIAN ALEXANDER SALDANA GARZONAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Calorific Value of A Fuel Is TheDocumento4 páginasThe Calorific Value of A Fuel Is TheRana PrathapAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Lecture 1 Ideal Gases and Their MixtureDocumento24 páginasLecture 1 Ideal Gases and Their MixtureMuez GhideyAinda não há avaliações

- Lamb Meat NutritionDocumento3 páginasLamb Meat NutritionMuhammad MuhsininAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Water Quality in El Malecón: Colegio Bilingue New Horizons Global Expo 2018 High SchoolDocumento11 páginasWater Quality in El Malecón: Colegio Bilingue New Horizons Global Expo 2018 High SchoolLeonard PolancoAinda não há avaliações

- Nutrients Deficiency SymptomsDocumento4 páginasNutrients Deficiency SymptomsJodie Mer DayamaAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Steelstrong: Always Strong in Valve WorldDocumento32 páginasSteelstrong: Always Strong in Valve WorldBharat Bhushan SharmaAinda não há avaliações

- Resilon 4301 Polyurethane Specs ResourcesDocumento2 páginasResilon 4301 Polyurethane Specs ResourcesAdolfo CarellaAinda não há avaliações

- Republic Act No. 6969 An Act To Control Toxic Substances and Hazardous and Nuclear Wastes, Providing Penalties For Violations Thereof, and For Other PurposesDocumento3 páginasRepublic Act No. 6969 An Act To Control Toxic Substances and Hazardous and Nuclear Wastes, Providing Penalties For Violations Thereof, and For Other PurposesLizzy WayAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Report BeetrootDocumento11 páginasReport BeetrootSya Subi100% (3)

- Welding Procedure Specification (WPS) : JointsDocumento2 páginasWelding Procedure Specification (WPS) : JointsNavanitheeshwaran SivasubramaniyamAinda não há avaliações

- Emerging Solar Cell PDFDocumento23 páginasEmerging Solar Cell PDFJaffar LoneAinda não há avaliações

- I. Reading Development A. Before You ReadDocumento11 páginasI. Reading Development A. Before You Readhilda wirandaAinda não há avaliações

- Eazistrip Reinforcement Continuity SystemsDocumento12 páginasEazistrip Reinforcement Continuity SystemscormolioAinda não há avaliações

- Molykote Lubrication BrochureDocumento12 páginasMolykote Lubrication BrochureLiam MoylanAinda não há avaliações

- Tufail ResumeDocumento3 páginasTufail ResumeAsif Fareed QaisraniAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- As-MS Binding AssayDocumento9 páginasAs-MS Binding AssayAnonymous IGfaYDAinda não há avaliações

- Arthrex Starfish ™ Scope Rotation Attachment Insert Manual: 950-0036-01 Revision 0 08/2020Documento36 páginasArthrex Starfish ™ Scope Rotation Attachment Insert Manual: 950-0036-01 Revision 0 08/2020eliaAinda não há avaliações

- Jasmuheen - Telepathic CommunicationDocumento6 páginasJasmuheen - Telepathic Communicationmelrakki100% (3)

- Solution Manual For Chemistry 10th Edition by Kenneth W Whitten Larry Peck Raymond e Davis and George G StanleyDocumento14 páginasSolution Manual For Chemistry 10th Edition by Kenneth W Whitten Larry Peck Raymond e Davis and George G Stanleycuonganh51wAinda não há avaliações

- Service Manual CSCU-RE12GKE PDFDocumento16 páginasService Manual CSCU-RE12GKE PDFJose Vicente Ausina100% (1)

- Por Si Te Puede ServirDocumento7 páginasPor Si Te Puede ServirJordi ClaudioAinda não há avaliações

- Sizing Up The Valve Guide: by Dave MonyhanDocumento4 páginasSizing Up The Valve Guide: by Dave MonyhanRidwanUsmanAinda não há avaliações

- Pure Substances MixturesDocumento2 páginasPure Substances MixturesShannen Abegail FernandezAinda não há avaliações

- Specific HeatDocumento2 páginasSpecific HeatVanessa Christonette SistosoAinda não há avaliações

- Analisis Fitokimia Daun Pepaya (Carica Papaya L.) A'yun Et Al.Documento7 páginasAnalisis Fitokimia Daun Pepaya (Carica Papaya L.) A'yun Et Al.Cahaya Medika1Ainda não há avaliações

- Geas FinalDocumento489 páginasGeas FinalroselleAinda não há avaliações

- NTK O2 Sensor HistoryDocumento9 páginasNTK O2 Sensor Historyonukvedat7219Ainda não há avaliações

- Thermocouples and SensorsDocumento40 páginasThermocouples and SensorsEliasAinda não há avaliações