Escolar Documentos

Profissional Documentos

Cultura Documentos

Dieselfacts 2014-3 Web

Enviado por

Tapas ChaudhuriDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Dieselfacts 2014-3 Web

Enviado por

Tapas ChaudhuriDireitos autorais:

Formatos disponíveis

A Technical Customer Magazine of MAN Diesel & Turbo

3/2014

The New MAN 175D

100% High-Speed

With the MAN 12V175D, MAN Diesel

& Turbo will be presenting the first

cylinder version of its new highspeed engine family at this years

maritime trade fair SMM in Hamburg.

The twelve-cylinder model, developed

especially for use in the shipping industry, is part of a product initiative

aimed at providing MAN customers

with a product portfolio that covers

every power requirement, from high

to low speed.

With the MAN 175D, we are supplementing and completing MAN

Diesel & Turbos and MAN Truck &

Buss product portfolio in the maritime sector, explains Dr. HansOtto Jeske, Chief Technology Officer and acting CEO for MAN Diesel

& Turbo. The new engine will be offered with an output spectrum from

1,500 to 2,200 Kilowatts and will be

available to the first pilot customers

from as early as 2015.

The 12-cylinder version of the

MAN 175D being presented in

Hamburg is designed to fit in precisely with the needs of commercial shipping and is optimized for

propelling ferries, offshore supply

vessels, tug boats and working vessels. Other central areas of application such as the markets for super-yachts and marine applications

are served by additional specialist

model versions.

The MAN 175D is compact, reliable and efficient - properties that

are of essential importance for use

on working vessels to allow safe

maneuverability in the most challenging and roughest weather

conditions, says the Project Lead

responsible for the MAN 175D,

Dr. Matthias Schlipf. The business

case behind it also has to be right

for the customer. And this is where

the engine sets standards in more

than just fuel consumption. Our aspiration is to make the MAN 175D

the overall most efficient engine

throughout its lifetime.

The MAN 175D also scores highly in terms of its eco-friendliness.

Its compact and modular exhaust

gas after-treatment system uses the

selective catalytic reduction (SCR)

method and is based on the MAN

Ad Blue technology that has undergone many thousands of hours

of testing. The engine will therefore satisfy the strict environmental

standards of the IMO Tier III from

the moment it hits the market.

The compact and robust engine is

designed for user-friendliness and...

Continued on page 2

ME-GI Adds Ethane

to Fuel Portfolio

as the Worlds First

Norwegian operator orders three

ethane-fuelled gas carriers

Ocean Yield ASA, the Oslo-based

shipowner, has placed orders for 3

36,000-m 3 capacity LEGCs (Liquefied Ethylene Gas Carriers), to

be built at Sinopacific Offshore &

Engineering, China. Each will be

powered by a single MAN B&W

ME-GI low-speed, dual-fuel engine that will run on ethane, which

ethylene carriers are also equipped

to transport, and represents the first

time ethane has been used as fuel to

propel an oceangoing vessel.

Hartmann Schiffahrt, part of Hartmann AG, the German shipowning and management group, has

acted as technical leader on the

TCT Turbochargers

Declared the best overall

package for two-stroke

engines

Propulsion Trends in

Bulk Carriers

New technical paper

released

First Gas-Powered

Car Carriers

Dual-fuel ME-GI engine

adds important reference

Hard at Work with

PrimeServ in the City that

Never Sleeps

News feature

> Page 3

> Pages 6-7

> Page 8

> Pages 10-11

LEGC project, while Gaschem Service, another Hartmann division, is

commercially responsible for the

employment of the vessel. The vessels are scheduled for delivery in

August, October and December

2016 respectively.

MAN Diesel & Turbo reports

that ethane was chosen as fuel, in

preference to HFO, due to its more

competitive pricing as well as the

significantly shorter bunkering time

it entails. As a fuel, its emissions

profile is also superior to HFO in

which respect it is similar to methane and compared to HFO...

Continued on page 2

PAGE 2

DIESELFACTS 3/2014

The New MAN 175D 100% High-Speed

Continued from front page

efficiency: Simple commissioning,

simple operation, simple maintenance, says Thomas Seidl, Head

of Product Line High-Speed at MAN

Diesel & Turbo, summing up the engines design concept. Its compact

dimensions and low weight make

the MAN 175D an efficient powerhouse.

Customer focus was also at the

forefront of the overall development

process:

Time and again, we were asked

to develop a high-speed engine

with a true MAN character, i.e. a

high-speed engine that works as

reliably as a medium-speed engine

and which has been tailor-made for

maritime use, explains Florian Keiler, responsible for the business development and market launch of the

MAN 175D. Throughout the development stage, we spoke to a num-

ber of customers across the whole

world to get a detailed picture of

their expectations and professional

requirements. This feedback has

been pumped directly into the development process.

MAN Diesel & Turbo is also creating a stir on the high-speed market with its service concept for the

MAN 175D, which follows MANs

trademark one-face-to-the-customer strategy. MAN 175D customers have full access to the worlds

MAN PrimeServ service network

with over 120 locations worldwide.

A service support point is available

in all major ports. Customers are

able to rely on the global and highquality service standards provided

by MAN PrimeServ everywhere.

Visit the new MAN 175D website

on www.175D.man.eu for additional information, picture and video

materials.

ME-GI Adds Ethane to Fuel Portfolio as the Worlds First

Continued from front page

contains negligible sulphur, 15-20%

lower CO2, and emits significantly

fewer particles. MAN Diesel & Turbo also states that the ME-GI engines will be set up such that they

can easily be converted to run on

methane as an alternative, as per

the owners wish.

Diesel vs. Otto

The ME-GI is a Diesel engine in contrast to the other dual- or triple-fuel

engines on the market, which are

Otto engines. Simply put, engines

that operate according to the Diesel principle have a higher efficiency and power concentration than

those following the Otto principle.

MAN Diesel & Turbo reports that

its ME-GI technology uses the Diesel cycle to maintain high efficiency and robust combustion with no

need for any derating. The compa-

ny also states that the engine by

virtue of its Diesel operating principle will have negligible methane/

fuel slip, one of many low-emission

characteristics, and dispenses with

the need for restrictive load ramps or

other knock-preventing measures.

The ME-GI engine

The ME-GI engine represents the

culmination of many years work

and gives shipowners and operators the option of utilising fuel or

gas depending on relative price and

availability, as well as environmental

considerations.

The ME-GI uses high-pressure

gas injection that allows it to maintain the numerous positive attributes

of MAN B&W low-speed engines

that have made them the default

choice of the maritime community.

MAN Diesel & Turbo sees significant opportunities arising for

gas-fuelled tonnage as fuel prices

rise and modern exhaust-emission

limits tighten. Indeed, research indicates that the ME-GI engine delivers significant reductions in CO2,

NO x and SO x emissions. Furthermore, the ME-GI engines negligible

fuel slip makes it the most environmentally friendly technology available. As such, the ME-GI engine

represents a highly efficient, flexible,

propulsion-plant solution.

An ME-LGI counterpart that uses

LPG, methanol and other liquid

gasses is also available, and has

already been ordered.

LEGCs

Ethylene carriers are generally considered the most sophisticated of

all gas tankers and are capable of

carrying most liquefied gas cargoes, but also ethylene at its atmospheric boiling point of 104C.

These vessels have insulated, 5%

nickel-steel cargo tanks and can

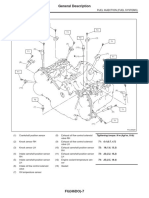

MAN Diesel & Turbos ME-GI engine, here a 9S90ME-GI version with cutaway section

accommodate most liquefied gas

cargoes up to a maximum specific

gravity of 1.8 at temperatures ranging from 104C to +80C at a maximum tank pressure of 4 bar.

Ethane

While ME-GI engines have been

designed for use by several, different fuel types to date, ethane is a

new departure. Ethane is one of the

natural-gas liquids (NGLs) that are

naturally occurring elements found

in natural gas (and frequently separated removed and sold as a separate product), and include propane

and butane, among others.

About Hartmann Schiffahrt

Hartmann Schiffahrt is a shipmanagement company based in

the northern German city of Leer.

Founded in 1981, it manages the

technical and economical aspects

of its own and other fleets with a fo-

cus on the gas and container segments and is a world leader within

the gas-tanker segment. The company is part of Hartmann AG that

has diverse interests in the maritime transport and logistics sector

such as dry bulk, product tankers,

multi-purpose-vessels and OSVs.

About Ocean Yield

Ocean Yield is a Norwegian shipowner with investments within oilservice and industrial shipping. The

company focuses on modern assets with long-term charters to solid counterparties. The companys

asset base consists of six offshore

vessels, six Pure Car Truck Carriers

(PCTC) of which three newbuildings,

and three newbuilding Liquefied

Ethylene Gas carriers, all with long

term charters. Ocean Yield was established in March 2012 and was

listed on the Oslo Stock Exchange

in July 2013.

A graphical representation of the ME-GIs combustion process

DIESELFACTS 3/2014

PAGE 3

The New TCT Turbocharger Generation

MAN Diesel & Turbos TCT turbochargers specifically matched to

requirements for two-stroke engines and acclaimed as best overall package

The demands made on a modern turbocharger are manifold. It is crucial

that the technical requirements of the

engine manufacturer, as the direct

purchaser of the product, be met at

the lowest possible price. Shipyards

demand small overall dimensions to

facilitate installation in engine rooms

where space is at a premium. Finally,

shipowners, who operate the turbocharger, demand high operational reliability, low maintenance frequencies

and long life. The conflict of objectives is obvious. When developing the

TCT range, it was important to MAN

Diesel & Turbo to balance the individual demands of the different groups

of customers to achieve an optimum

overall result. The range of turbochargers which emerged is thought

to be the best overall package for twostroke engines.

Low fuel consumption and low

emissions (particularly NO x) are

the twin development objectives

of large new-generation two- and

four-stroke engines. They are

achieved by using the Miller process, which involves the introduction of a special timing system for

the inlet valve in a four-stroke en-

gine and the exhaust valve in a twostroke engine. However, the ways in

which this process is implemented

differ.

Fundamentally, the temperature

at the start of the combustion phase

is lowered by reducing the compression ratio in the cylinder during

the compression stroke, thus cutting the directly-related production

of NOx. In order to create similar circumstances under the conditions

of final compression pressure and

cylinder charging (the combustion

air ratio), part of the compression

must therefore be shifted to the turbocharging phase in order to obtain

similar conditions in relation to the

final compression pressure. Higher

turbocharger compressor pressure

ratios are thus necessary.

In four-stroke engines, the gas

exchange phase can also be used

to make a considerable positive

contribution to work, if the scavenging gradient between the inlet

and exhaust is sufficiently positive.

This is achieved by a higher degree

of turbocharging efficiency, as provided by two-stage turbocharging

with intercooling - as opposed to

single-stage turbocharging - in

parallel to potential for maximum

charging pressures. In the new TCX

range, MAN Diesel & Turbo has developed a turbocharger specifically

for two-stage turbocharging of fourstroke diesel and gas engines with

a total pressure ratio > 10.

Conversely, a positive scavenging gradient cannot be used for a

contribution to work in two-stroke

engines, but only for scavenging.

The scavenging gradient required

is moderate. Unlike four-stroke engines, a very high scavenging pressure (a very high pressure ratio) also

appears to obstruct optimal scavenging. This means that high degrees of turbocharging efficiency

at high compressor pressure ratios,

which can be achieved by singlestage turbocharging, are required

by two-stroke applications.

In the new TCT range, MAN

Diesel & Turbo has developed a

turbocharger which has been specifically matched to the requirements of two-stroke engines, without making any compromises. The

turbocharger efficiency has been

increased by 5% by using newlydeveloped compressor and turbine

wheel geometry, consequently in-

Not a jack in the box: MAN Diesel & Turbos new TCT Turbocharger for two-stroke engines promises the best overall package

creasing the waste heat recovery

potential by 30%, e.g. by means of

a Turbo Compound System (TCSPTG) from MAN Diesel & Turbo. At

the same time, the new TCT range

will deliver a 10% greater air flow

at a turbocharging pressure 25%

higher, while being 30% smaller

and 40% lighter than the existing

TCA range.

Individual TCT turbochargers

will cover a wider range of engine

ratings, depending upon their size.

Engine manufacturers will be able

to use just one size for turbocharging different numbers of cylinders.

Individual adaptation of the turbocharger to the engine is by the established method of using a variety of exchangeable parts within

the turbocharger. The TCT turbocharger can be manufactured costeffectively by dispensing with the

alternatives required for four-stroke

engines.

The new TCT range provides

shipowners and installation operators with significant advantages.

Customers who are already familiar

with the TCA ranges will find that

TCT turbochargers still provide

them with established, tried and

tested solutions. For example, the

patented Super-Bolt compressor

wheel mounting has been adopted

from the TCA range, making installation with ordinary tools a simple

matter. This saves maintenance

time. The life of expendable parts

has been extended by using highperformance components. This is

reflected in lower servicing frequencies.

In line with the well-established

MAN maintenance philosophy, servicing can be undertaken either by

the operator itself (MAN PrimeServ offers suitable training in this

respect) or by outlets on the global MAN PrimeServ network (where

our well-established engine and

turbocharger service is available

from a one-stop shop).

Too good to be true? The first customers will benefit from the TCT turbocharger - the best overall package for two-stroke engines - as

early as 2016. Between now and

then the TCT turbocharger will undergo an extensive validation programme in a thrust chamber and

several months of field tests.

PAGE 4

DIESELFACTS 3/2014

New Licence Agreement Signed at SMM

MAN Diesel & Turbo adds Chinese QMD to its two-stroke licensee family;

added engine-building capability extends reach of company to Northern China

On Tuesday September 9, 2014 at

Hamburgs SMM Marine trade fair,

MAN Diesel & Turbo signed a new licence agreement with QMD, a member of the CSIC Group together with

Dalian Marine Diesel Co., Ltd. and

Yichang Marine Diesel Engine Co.,

Ltd. In the process, QMD became

MAN Diesel & Turbos 12th Chinese

licensee. QMD (Qingdao Haixi Marine

Diesel Co., Ltd.) can boast of a modern

facility dedicated to the production

of large, two-stroke engines in North

East China.

Klaus Engberg, Senior Vice President and Head of MAN Diesel &

Turbo Two-Stroke Licensing said:

We have, today, signed an agreement that increases our presence

in the northerly part of China, such

that we now have a greater geographical reach in this important

market and are better able to reach

customers in this part of China.

For over 30 years, we have had

a successful licence agreement

with CSIC, which QMD belongs to,

and we look forward to an equally

fruitful cooperation with our new

licensee, Engberg added.

Pictured at the SMM signing ceremony (standing, from left): Sun Quan (MDT Shanghai), Zhang Tao (CSIC), Hu Xiang (CSIC, Xingang Shipyard), Xu Zhi Qiu (CSIC),

Goetz Kassing (MDT Shanghai), Ole Grne (MDT), Stephan Timmermann (MDT), Dong Qiang (CSIC); (seated, from left) Chen Yi Fang (CSIC YMD), Peng Gang Yi

(CSIC QMD), Thomas Knudsen (MDT), Klaus Engberg (MDT)

Daewoo Returns for Yet More Dual-Fuel Engines

Four two-stroke ME-GI engines ordered for two LNG carriers for BW Group

MAN Diesel & Turbo has received an

order for four MAN B&W 5G70ME-GI

engines in connection with Daewoo

Shipbuilding & Marine Engineering Co.,

Ltd. (DSME) agreeing a deal with the BW

Group to build two LNG carriers.

The technical engine specification

complies with IMO Tier II, with options to include remedies for Tier

III compliance at a later stage. The

173,400 m3 vessels are scheduled

for delivery in late 2017/early 2018

and will be built at DSMEs Okpo

shipyard in Geoje, Korea. The deal

represents the second LNG ME-GI

contract for DSME after a previous

order signed in 2012.

Tier III options

Compliance with IMO Tier III regulations basically requires an 80%

reduction in NOx emissions compared to Tier I within the designated emission control areas (ECAs)

over a defined test cycle.

MAN Diesel & Turbo has successfully developed two main approaches to comply with these

challenges: Selective Catalytic Reduction (SCR), which involves the

catalytically accelerated reaction

of nitrogen oxides with ammonia

to form water and nitrogen, and

Exhaust Gas Recirculation (EGR),

which works by recirculating a

portion of an engines exhaust gas

back to the engine cylinders.

Both methods enable compliance with the most stringent of

regulations and give the customer

the flexibility to choose the solution

that suits their individual requirements best, for example, distances

travelled within ECA zones as a percentage of total ship usage, different ownership models or different

engine-operation profiles.

The ME-GI engine

The ME-GI engine represents the

culmination of many years work and

gives shipowners and operators the

option of utilising fuel or gas depending on relative price and availability, as

well as environmental considerations.

The ME-GI uses high-pressure

gas injection that allows it to maintain the numerous positive attributes

of MAN B&W low-speed engines

that have made them the default

choice of the maritime community.

MAN Diesel & Turbo sees significant opportunities arising for

gas-fuelled tonnage as fuel prices

rise and modern exhaust-emission

limits tighten. Indeed, research indicates that the ME-GI engine delivers significant reductions in CO2,

NO x and SO x emissions. Furthermore, the ME-GI engines negligible

fuel slip makes it the most environmentally friendly technology available. As such, the ME-GI engine

represents a highly efficient, flexible,

propulsion-plant solution.

An ME-LGI counterpart that uses

LPG, methanol and other liquid

gasses is also available, and has

already been ordered.

It is estimated that such new designs offer potential fuel-consumption savings of some 4-7%, and a

similar reduction in CO2 emissions.

In this respect, the fuel savings

and performance characteristics for

propellers featuring MAN Diesel &

Turbos unique Kappel blade design

have been well documented in recent years. Simultaneously, the engine itself can achieve a high thermal

efficiency using the latest engine process parameters and design features.

As such, the G-type series has

revolutionised the marine market.

Since its introduction, close to 900

engines bearing the G-prefix have

been ordered (including, now, 15

G95 units), representing a total

power output of some 15.9 GW. Of

these, over 100 G-type engines

have already entered service.

The G-type programme

MAN Diesel & Turbos G-type programme entered the market in October 2010 with the entry of the

G80ME-C9 model. The G-types

have designs that follow the principles of the large-bore, Mark 9 engine series that MAN Diesel & Turbo introduced in 2006. Their longer

stroke reduces engine speed, thereby paving the way for ship designs

with unprecedented high-efficiency.

Such vessels may be more compatible with propellers with larger diameters than current designs, and

facilitate higher efficiencies following adaptation of the aft-hull design

to accommodate a larger propeller.

Graphical rendering of an MAN B&W 5G70ME-GI engine

DIESELFACTS 3/2014

PAGE 5

MAN-Powered Cargo Vessel with

SCR Meets Strict Tier III Limits

MAN Diesel & Turbo has been awarded a Tier III-compatibility certificate

by the DNV-GL classification society

for an MAN 8L21/31 four-stroke engine aboard a DFDS Seaways ship

with a retrofitted SCR (Selective

Catalytic Reduction) system. While

the engine alone meets IMO Tier II

emission criteria, the SCR system

for NO x reduction raises the whole

system to the standard demanded

by IMO Tier III rules.

The vessel in question, the Petunia Seaways is a cargo ship that

sails a regular North Sea route

between Gothenburg and Immingham, respectively for DFDS

Seaways. Its SCR system greatly

reduces the level of nitrogen oxides (NO x) from the engines exhaust gas.

Since September 2012, when

one of Petunia Seaways 8L21/31

auxiliary engines was retrofitted

with a SCR system, it has played a

major role in the testing of this new

technology. As such, the system

has proven daily that freight ships

can now meet the strict emission

levels laid down by IMO Tier III

where NO x emissions have to be

reduced in certain areas by 75%

compared to current limits.

al control units and a surveillance

and control unit.

Proven technology

Technology of the future

already available

MAN Diesel & Turbo is the first

company to successfully make

four-stroke marine engines IMO

Tier III-compliant, based on a fully

modular SCR-kit that covers the

entire MAN Diesel & Turbo fourstroke engine portfolio. For the

last 8,800 hours, this particular

auxiliary engine of the Petunia

Seaways has consistently met Tier

III NO x limits under real life operating conditions and in full accordance with the rules laid down by

the IMO, said Dr. Daniel Struckmeier, Senior Project Manager

Emission 2016 at MAN Diesel &

Turbo.

The SCR method injects urea

into the exhaust gases and passes

them through a catalytic converter

at a temperature of 300 to 400C.

The subsequent, chemical reaction reduces the undesired nitrogen oxides (NOx) by over 80%. The

SCR system in its entirety consists

of a catalytic converter with sever-

Results on the test bed and at

open sea have been impressive

and shown that SCR technology

is reliable and ready for commercial production and operation. Accordingly, MAN Diesel & Turbo has

already made the basic version of

the SCR system available for all

four-stroke engines, from those

powering the largest cruise ships,

to ferries and specialised ships, to

small, coastal vessels.

It is important that we have proven to fulfil the same high standards

that will be demanded by Tier III in

the future, said Prof. Dr. Gunnar

Stiesch, Head of Advanced Engineering & Exhaust After-treatment

Four-Stroke Engines.

DFDS Seaways is also positive

and views the collaboration with

MAN Diesel & Turbo as having been

a success: I am happy that we have

helped develop a new, environmentally friendly technology. DFDS and

other operators are definitely going

Kasper Moos, Head of the Technical Organization at DFDS (right) congratulates

Arnd Lttgen, Member of the Executive Board, MAN Diesel & Turbo (left) at the

ceremony marking the awarding of the Tier III-compatibility certificate from DNV GL

to benefit from SCR meeting international standards, said Poul

Woodall, Director of Sustainability &

Public Affairs at DFDS Seaways.

Offshore Segment Orders Selective Catalytic Reduction

MAN Diesel & Turbo has won the contract to provide a Selective Catalytic

Reduction (SCR) system for each of

6 MAN 16V32/44CR engines. The

engines will power the Petrofac JDS

6000 deepwater derrick-lay vessel

ordered in January 2014 by Petrofac,

the international oil and gas services

provider. At the time, Yves Inbona,

Managing Director of Petrofacs Offshore Capital Projects business, said:

We are delighted to be working with

industry leaders on the design and

build of the key components of the

vessel.

The SCR systems and engines will

be constructed at MAN Diesel &

Turbos Augsburg, Germany facility,

while the vessel will be constructed

by the ZPMC yard in China using a

proprietary Petrofac design. MAN

Diesel & Turbo and Petrofac have

also entered a 12-year service contract for the management, maintenance and monitoring of the 6 engines. Vessel delivery is scheduled

for 2016 with the vessel expected

to be available for offshore construction and installation activities

from early 2017.

MAN Diesel & Turbo reports that

its advanced technology and after-sales experience, as well as the

lower running costs for the engines

and their higher power per cylinder,

were important factors in winning

the contract.

The deepwater vessel will provide

Petrofac with access to high-end,

turnkey opportunities in the highgrowth deepwater and SURF (Subsea Umbilicals, Risers and Flowlines) markets, while also expanding

access to shallow-water EPCI (Engineering, Procurement, Construction and Installation) projects.

The SCR technique

Selective Catalytic Reduction injects urea into exhaust gases and

passes them through a catalytic

converter at temperatures of 300

to 400 Celsius. The subsequent,

chemical reaction reduces undesired nitrogen oxides (NOx) by over

80%. The SCR system in its entirety consists of a catalytic converter

with several control units and a surveillance-and-control unit.

In September 2014, the DNV-GL

classification society awarded MAN

Diesel & Turbo a Tier III-compatibility certificate for its MAN 8L21/31

four-stroke engineaboard a DFDS

Seaways ship with a retrofitted SCR

system; the Petunia Seaways is a

cargo ship that sails a regular North

Sea route. While the engine alone

meets IMO Tier II emission criteria, the SCR system for NOx reduction raises the whole system to the

standard demanded by IMO Tier

III rules.

Proven technology

MAN Diesel & Turbo is the first

company to successfully make

four-stroke marine engines IMO Tier

III-compliant, based on a fully modular SCR-kit that covers the entire

MAN Diesel & Turbo four-stroke engine portfolio. For the last 8,800

hours, this particular engine aboard

the Petunia Seaways has consistently met Tier III NOx limits under

real-life operating conditions and

in full accordance with the rules,

said Dr. Daniel Struckmeier, Senior Project Manager Emission 2016,

MAN Diesel & Turbo when DNV-GL

presented the Tier III certificate in

September.

Generally, MAN Diesel & Turbo

reports that results from the test

bed and open sea have been impressive and show that SCR technology is reliable and ready for commercial production and operation.

Accordingly, it has already made

the basic version of the SCR system available for every four-stroke

engine in its extensive portfolio.

About Petrofac

Petrofac is a leading international

service provider to the oil and gas

production and processing indus-

try, with a diverse customer portfolio including many of the worlds

leading integrated, independent

and national oil and gas companies. Petrofac is quoted on the London Stock Exchange (symbol: PFC).

Petrofac designs and builds oil

and gas facilities; operates, maintains and manages facilities and

trains personnel; enhances production; and, where it can leverage its service capability, develops

and co-invests in upstream and in-

frastructure projects. Petrofacs

range of services meets its customers needs across the full life

cycle of oil and gas assets.

With more than 18,000 employees, Petrofac operates out of seven strategically located operational

centres, in Aberdeen, Sharjah, Abu

Dhabi, Woking, Chennai, Mumbai

and Kuala Lumpur and has a further 24 offices worldwide.

www.petrofac.com

Graphical rendering of the Petrofac JDS 6000 deepwater derrick-lay vessel

(courtesy Petrofac)

Petrofac JDS 6000 Particular Data

Length (m)

215.9

Breadth (m)

49.0

Depth to main deck (moulded (m))

22.4

Ocean transit speed (kn)

12.0

Main generator sets/power (kW)

6 MAN 16V32/44CR / 9,600

PAGE 6

DIESELFACTS 3/2014

Propulsion Trends in Bulk Carriers

A new paper by Birger Jacobsen, Senior Researcher, MAN Diesel & Turbo, Copenhagen

Propulsion

SMCR power

kW

19,000

Average design ship speed, Vdes

Knots

19

18

17

18,000

G70ME-C9.5

16

0.95

15

0.75

100,000

150,000

200,000

250,000

VLBC

Large

Capesize

Capesize

Handymax

50,000

15,000

300,000

350,000

dwt

400,000

14,000

Deadweight of ship at scantling draught, dwtscant

Fig. 1: Average design ship speed of bulk carriers

0.60

0.65

Power and speed curve for

various propeller diameters (d)

with optimum p/d ratio

60

65

70

75

80

85

90

95

100

105 r/min

Engine/propeller speed at SMCR

Fig. 2: Influence of propeller diameter and pitch on SMCR for a 205,000 dwt large capesize bulk

carrier operating at 14.7 knots

SMCR

kW

30,000

SMCR power

kW

12,000

Average design

ship speed

Chinamax

Newcastlemax

25,000

14.7

Dunkirkmax

11,000

kn

14.7

SMCR power includes:

15% sea margin

10% engine margin

13.7

15,000

14.5

13.5

50,000

7,000

5S40ME-B9 (L1)

kn

5,000

6S30ME-B9 (L1)

4,000

5S30ME-B9 (L1)

3,000

The bulk carrier market, therefore,

is very attractive, which caused a

boost in newbuildings until the latest economy crisis in 2008. Since

then, bulk carrier orders in a short

period have been declining, but are

now picking up again.

The optimum propeller speed is

changing as well, steadily becoming lower, because the larger the

propeller diameter that can be used

for a ship, the actual propeller power and pertaining speed requirement will be correspondingly lower,

and the lower the propulsion power

demand per ton bulk transported.

These factors have an influence

on which main engine type should

be selected/installed as the prime

mover, and also on the size of the

bulk carrier to be built.

Recent development steps have

made it possible to offer solutions

which will enable significantly lower

transportation costs for bulk carriers as outlined in the following.

One of the goals in the marine

industry today is to reduce the impact of CO2 emissions from ships

13.5 kn

and, therefore, to reduce the fuel

consumption for the propulsion of

ships to the widest possible extent

at any load.

This also means that the inherent

design CO2 index of a new ship, the

so-called Energy Efficiency Design

Index (EEDI), will be reduced.

In the future, this drive may probably result in operation at lower

than normal service ship speeds

compared to earlier, resulting in

reduced propulsion power utilisation. However, it still seems to be

unchanged.

A more technically advanced development drive is to optimise the

aftbody and hull lines of the ship,

including bulbous bow, also considering operation in ballast condition. This makes it possible to

install propellers with a larger propeller diameter, thereby, obtaining

higher propeller efficiency, but at a

reduced optimum propeller speed,

i.e. using less power for the same

ship speed.

As the two-stroke main engine is

directly coupled with the propeller,

the introduction of the latest MAN

B&W ultra long stroke G engine

types meets this trend of installing

large propellers in the bulk carriers

which may reduce the ships fuel

consumption. Therefore, today bulk

carriers are often ordered with a G

engine type as prime mover.

Market development

Definition of a bulk carrier

A bulk cargo is defined as loose

5G40ME-C9 (L1)

12.5 kn

12.0 kn

11.5 kn

11.0 kn

1,000

0

100,000 150,000 200,000 250,000 300,000 350,000 400,000 dwt

Deadweight of ship at scantling draught, dwtscant

The demand for raw materials like

coal, steel, copper, etc., has increased

considerably since the turn of the millennium, especially in consequence of

globalisation and the great demand

for raw materials in China, owing to

the economic growth in this large

country. This means that the Chinese

industry, among others, is absorbing

large quantities of iron ore and other

bulk cargoes.

14.5 kn

14.0 kn

5S50ME-B9 (L1)

6G45ME-B9 (L1)

6S46ME-B8 (L1)

7S40ME-B9 (L1)

7G40ME-C9 (L1)

5G45ME-C9 (L1)

6G40ME-C9 (L1)

13.0 kn

2,000

Fig. 3: Propulsion SMCR power demand of an average bulk carrier

wer

ge po

Avera

6,000

6S35ME-B9 (L1)

kn

kn

13.5

kn

Handymax

Handysize

Small

13.5

14.5

8,000

VLBC

kn

15.0 kn

kn

kn

Large Capesize

.5

Panamax

14

13.7

kn

Capesize

10,000

kn

Handysize

9,000

1.0 kn

Alternative Handymax (St. Lawrence Canal)

20,000

SmalI

10,000

Kamsarmax

5,000

p/d

0.71

Power and speed curve for

the given propeller diameter

d = 8.8 m with different p/d ratios

G70ME-C9.5

Panamax

Handysize

Small

11

10

0.73

S70ME-C8.5

16,000

12

d

p/d

S70ME-C8.5

8.3 m

8.8 m

0.85

9.3 m

17,000

14

13

SMCR power and speed

are inclusive of:

15% sea margin

10% engine margin

5% propeller light running

4-bladed FP-propellers

d = Propeller diameter

p/d = Pitch/diameter ratio

Design Ship Speed = 14.7 kn

Design Draught = 16.1 m

5,000

10,000

15,000

20,000

25,000

30,000

35,000 dwt

Deadweight of ship at scantling draught, dwtscant

Fig. 4: Propulsion SMCR power demand of Small and Handysize bulk carriers

cargo that is loaded directly into a

ships hold, rather than in barrels,

bags, containers, etc., and is usually homogeneous and capable of

being loaded by gravity. This paper

describes the dry-bulk carrier type,

normally just known as bulk carrier

or bulker.

Bulk carriers were developed in

the 1950s and are one of the three

dominating merchant ship types together with tankers and container

vessels. Today, bulk carriers comprise about 43% of the world fleet

in tonnage terms.

Bulk carrier sizes and classes

Small < 10,000 dwt

Handysize 10,000-35,000 dwt

Handymax 35,000-55,000 dwt

Panamax 55,000-80,000 dwt

Capesize 80,000-200,000 dwt

Large Capesize 200,000300,000 dwt

VLBC >300,000 dwt (VLBC =

Very Large Bulk Carrier)

Average ship particulars as a

function of ship size

Average design ship speed, Vdes

In Fig. 1, the average ship speed

Vdes, used for design of the propulsion system and valid for the design

draught Ddes of the ship, is shown

as a function of the ship size.

Fig. 1 also shows that today the

average design ship speed except for Small and Handysize bulk

carriers is generally higher than

or equal to 14.5 knots. The trend

shown for large Capesize and

VLBC shows an even higher selected design ship speed.

In general, the selected design

ship speed today seems not to be

lower than before the economy

crisis in 2008-2009. The reason is

probably that shipowners still wish

to operate the ships at a high ship

speed, if needed, but in normal service on reduced ship speeds. Thus,

many ships are today installed with

main engines prepared for efficient

low load operation at reduced ship

speeds.

Major design parameters and

propulsion power demand of

average bulk carriers

Major propeller and engine

parameters

In general, the highest possible

propulsive efficiency required to

provide a given ship speed is obtained with the largest possible propeller diameter d, in combination

with the corresponding, optimum

pitch/diameter ratio p/d.

As an example, this is illustrated for a 205,000 dwt large capesize bulk carrier with a service ship

speed of 14.7 knots, see the black

curve in Fig. 2. The needed propulsion SMCR (Specified Maximum Continuous Rating) power

and speed is shown for a given

optimum propeller diameter d and

p/d ratio.

According to the black curve, the

existing propeller diameter of 8.3

m may have the optimum pitch/diameter ratio of 0.71, and the low-

est possible SMCR shaft power of

about 17,700 kW at about 88 r/min.

The black curve shows that if a

bigger propeller diameter of for example 9.3 m is possible, the necessary SMCR shaft power will be

reduced to about 16,700 kW at

about 70 r/min, i.e. the bigger the

propeller, the lower the optimum

propeller speed.

If the pitch for example for the

diameter of 8.8 m is changed, the

propulsive efficiency will be reduced, i.e. the necessary SMCR

shaft power will increase, see

the red curve. The red curve also

shows that propulsion-wise it will

always be an advantage to choose

the largest possible propeller diameter, even though the optimum

pitch/diameter ratio would involve a

too low propeller speed (in relation

to the required main engine speed).

Thus, when using a somewhat lower pitch/diameter ratio, compared

with the optimum ratio, the propeller/engine speed may be increased

and will only cause a minor extra

power increase.

The efficiency of a two-stroke main

engine particularly depends on the

ratio of the maximum (firing) pressure

and the mean effective pressure. The

higher the ratio, the higher the engine

efficiency, i.e. the lower the Specific

Fuel Oil Consumption (SFOC). Therefore, today the main engine may often

be derated.

Furthermore, the higher the

stroke/bore ratio of a two-stroke

engine, the higher the engine ef-

DIESELFACTS 3/2014

ficiency. This means, for example,

that an ultra long stroke engine

type, as the G70ME-C9, may have

a higher efficiency compared with

a shorter stroke engine type, like a

super long stroke S70ME-C8.

The application of new propeller

design technologies may also motivate use of main engines with lower rpm. Thus, for the same propeller diameter, these propeller types

can demonstrate an up to 4% improved overall efficiency gain at the

same or a slightly lower propeller

speed. This is valid for propellers

with Kappel technology available

at MAN Diesel & Turbo, Frederikshavn, Denmark.

Furthermore, due to lower emitted pressure impulses, the Kappel

propeller requires less tip clearance

that can be utilised for installing an

even larger propeller diameter, resulting in a further increase of the

propeller efficiency.

Hence, with such a propeller

type, the advantage of the new lowspeed G engine types can also be

utilised even though a larger propeller cannot be accommodated.

PAGE 7

If for a required ship speed, the

needed nominal MCR power for a

given main engine is too high, it is

possible to derate the engine, i.e.

using an SMCR power lower than

the nominal MCR power, which

involves a lower specific fuel consumption of the engine.

Considering the high fuel price

and the EEDI demands, it is today

normal practice to select a derated main engine in order to get an

SFOC as low as possible.

Small and Handysize bulk carriers

For Small and Handysize bulk

carriers, see Fig. 4, the selection

of main engines is not so distinct

as for the large bulk carrier classes.

Some owners and yards might prefer four-stroke engines, while others prefer and specify two-stroke

engines. For the larger bulk carrier

classes, the selection of main engine is, as mentioned, more uniform.

SMCR power

kW

14,000

13,000

Handymax

5G60ME-C9 (L1)

Panamax

7S50ME-B9 (L1)

7G50ME-C9 (L1)

12,000

15.0 kn

11,000

10,000

6S50ME-C8 (L1)

9,000

5G50ME-C9 (L1)

6G45ME-C9 (L1)

6S46ME-B8 (L1)

8,000

ge power

Avera

Average propulsion power demand

Based on the already described

average ship particulars and ship

speeds for bulk carriers built or

contracted during the period of

20002013 with due consideration of the latest ones contracted,

we have made a power prediction

calculation (Holtrop & Mennens

Method) for such bulk carriers in

various sizes from 5,000 dwt up to

400,000 dwt.

For all cases, we have assumed

a sea margin of 15% and an engine

margin of 10%, i.e. a service rating

of 90% SMCR, including 15% sea

margin.

Capesize, Large Capesize and

The average ship particulars used VLBC bulk carriers and examples

are, basically, referring to standard of EEDI

single side bulk carriers, but the

Today, in particular the 6S60MESMCR power demand found may, C8, 6G60ME-C9 and 5/6S70MEas a good guidance, also be used C8 and 5/6G70ME-C9 engines are

for double side bulk carriers, by used for propulsion of the Capesize

referring to a slightly higher dead- bulk carriers, see Fig. 6.

weight tonnage than valid for the

For large Capesize, it is particusingle side hull design. For exam- larly the 6G70ME-C9 which is of

ple, a 54,000 dwt double side hull interest.

design could be corresponding to

For VLBCs, the 7S80ME-C9 and

an about 55,000 dwt single side 7G80ME-C9 engine types are alhull design.

most exclusively used as the main

The graph in Fig. 3 shows the engine today, see Fig. 6.

above-mentioned table figures of

As an example, the influence

the specified engine MCR (SMCR) of the ship speed on the EEDI is

power needed for propulsion of an shown in Figs. 7 and 8, valid for

average bulk carrier. The SMCR 205,000 dwt Large Capesize bulk

power curves valid for the future carrier with the design ship speed

-1.0 knot lower compared to the av- of 14.7 kn and 14.0 kn, respectively.

erage design ship speed are also The influence of the propeller diamshown.

eter and the corresponding main

engine types are also shown.

Propulsion power demand of

Fig. 7 shows that for the design

average bulk carriers as a func- ship speed of 14.7 knots, the two

tion of ship speed

6G70ME-C9 cases are the only

When the required ship speed is ones to meet the 2015 reference

changed, the required SMCR pow- EEDI.

er will change too, as mentioned

For the reduced design ship

above, and other main engine op- speed of 14.0 knots, see Fig. 8.

tions could be selected. This trend With the G70ME-C9 engines, it

with the average ship particulars will now be possible to meet the

and average ship speed as the ba- 2020 reference EEDI figure withsis is shown in detail in Figs. 4-6. out further optimisation of hull and/

See also the description below giv- or propeller.

ing the results of the main engine

This article is an extract from a full

selection for the different classes paper, which is available from MAN

of bulk carriers.

Diesel & Turbo upon request.

14.0 kn

5G50ME-C9 (L1)

13.0 kn

6G40ME-C9 (L1)

6,000

5,000

4,000

3,000

2,000

Kamsarmax

1,000

0

10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000 dwt

Deadweight of ship at scantling draught, dwtscant

Fig. 5: Propulsion SMCR power demand of Handymax and Panamax bulk carriers

SMCR power

kW

35,000

Capesize

Large Capesize

VLBC

7G80ME-C9 (L1)

7S80ME-C9 (L1)

30,000

Handymax and Panamax

bulk carriers

The main engines most often selected for Handymax bulk carriers,

see Fig. 5, are the 5 and 6S50MEC8/ME-B9, with the 6/7S50MEB9 and 6/7G50ME-C9 types being the optimum choice for meeting

the power demand of all Handymax bulk carriers sailing up to 15.0

knots in service.

The main engines used for

Panamax bulk carriers, see Fig.

5, are mainly the 5/6G60ME-C9,

6/7G50ME-C9 and the 7S50MEB9 and 7G50ME-C9 types being

the optimum choice for meeting the

power demand for nearly all Panamax bulk carriers sailing up to 15

knots in service.

6S50ME-B9 (L1)

6G50ME-C9 (L1)

6S50ME-C8 (L1)

13.5 kn

7G40ME-C9 (L1)

7,000

14.5 kn

e

rag

Ave

25,000

er

pow

6G70ME-C9 (L1)

20,000

10,000

14.0

13.5

kn

kn

n

3.0 k

6S70ME-C8 (L1)

7G60ME-C9 (L1)

5G70ME-C9 (L1)

6S65ME-C8 (L1)

6G60ME-C9 (L1)

6S60ME-C8 (L1)

8G50ME-C9 (L1)

7G50ME-C9 (L1)

5S60ME-C8 (L1)

6G50ME-C9 (L1)

15,000

kn

15.0

kn

14.7

kn

14.5

7G70ME-C9 (L1)

6G70ME-C9 (L1)

6S70ME-C8 (L1)

er

ow

ep

ag

er

Av

6G80ME-C9 (L1)

6S80ME-C9 (L1)

Chinamax

Newcastlemax

5,000

Dunkirkmax

0

0

50,000

100,000

150,000

200,000

250,000

300,000

350,000 400,000 dwt

Deadweight of ship at scantling draught, dwtscant

Fig. 6: Propulsion SMCR power demand of Capesize, Large Capesize and VLBC bulk carriers

Reference and actual EEDI

CO2 emissions

gram per dwt/n mile

75% SMCR: 14.5 kn without sea margin

3.0

EEDI reference (2.81/100%)

2.5

2.63

94%

Actual/Reference

EEDI %

Year

100 2013

EEDI actual

2.59

2.48

92%

88%

2.42

90 2015

86%

80 2020 before 1 January

2.0

Contract date

70 2025

60

1.5

50

40

1.0

30

20

0.5

10

0

Dprop:

6S70ME-C8.5

N1

8.2 m 4

6S70ME-C8.5

N2

8.7 m 4

6G70ME-C9.5

N3

8.7 m 4

6G70ME-C9.5

N4

9.3 m 4

Fig. 7: Reference and actual Energy Efficiency Design Index (EEDI) for a 205,000 dwt Large Capesize Bulk Carrier with the

design ship speed of 14.7 knots

Reference and actual EEDI

CO2 emissions

gram per dwt/n mile

75% SMCR: 13.8 kn without sea margin

3.5

EEDI reference (2.81/100%)

3.0

2.5

2.34

83%

2.0

2.26

80%

Actual/Reference

EEDI %

120

EEDI actual

110

Year

100 2013

90 2015 Contract date

2.22

79%

2.16

80 2020 before 1 January

77%

70 2025

60

1.5

50

40

1.0

30

20

0.5

10

0

Dprop:

6S70ME-C8.5

N1

8.3 m 4

5G70ME-C9.5

N2

8.8 m 4

5G70ME-C9.5

N3

9.3 m 4

6G70ME-C9.5

N4

9.3 m 4

Fig. 8: Reference and actual Energy Efficiency Design Index (EEDI) for a 205,000 dwt Large Capesize Bulk Carrier with the

design ship speed of 14.0 knots

PAGE 8

DIESELFACTS 3/2014

New Order Placed for the Very

First Gas-Powered Car Carriers

Dual-fuel ME-GI engine adds important reference to growing list of marine segments

United European Car Carriers (UECC)

has signed a contract for the construction of two LNG-powered Pure

Car/Truck Carriers (PCTCs). A single

MAN B&W 8S50ME-GI dual-fuel engine will power each newbuilding.

The PCTCs will be capable of operating on LNG fuel, heavy fuel oil

or marine gas oil, providing greater

flexibility and efficiency. They represent the first such vessels globally to be fitted with an LNG propulsion system. When in service,

they will be capable of completing a

fourteen-day round trip in the Baltic

operating solely on LNG, including

main engine and auxiliary power

generation.

UECC ordered the newbuildings

in conjunction with a long-term fleet

evaluation process concerning its

Baltic fleet. Among the key requirements for new tonnage was an ability to meet all expected environmental legislation (SECA).

In this respect, LNG is recognised as the cleanest and most environmentally friendly choice of fuel

suitable for marine transport. LNG

fuel significantly reduces CO2 and

NOx emissions, as well as almost

entirely eliminating oxides of sulphur

(SOx) and particulate emissions. To

this end, UECC has signed an exclusive contract for the supply of

LNG fuels to the vessels in the port

of Zeebrugge using a dedicated

LNG ship-to-ship bunker vessel.

The vessels will be constructed

at the NACKS shipyard in Nantong,

China, which is a joint venture between Kawasaki Heavy Industries

(KHI) and China Ocean Shipping

(Group) Company. Delivery for both

vessels is scheduled for the second

half of 2016.

Exciting step

Glenn Edvardsen, CEO of UECC,

has previously stated: The LNG

installation is a pioneering design

and will be one of the largest employed on a commercial vessel and

the largest yet of its kind on a pure

car and truck carrier. We are proud

of the exciting step UECC is taking

towards greener and more environmentally friendly shipping.

Edvardsen also said: UECC will be

able to provide our customers with

transportation in the Baltic area

with unparalleled efficiency, reliability and superior environmental

performance.

About UECC

jointly owned by Nippon Yusen Kabushiki Kaisha (NYK) and Wallenius

Lines was founded in 1990 and

is Europes leading short-sea RoRo

operator. Today, the company

transports around 1.5 million units

a year, comprising cars, commercial vehicles, high & heavy equipment and trailers. UECC operates

a vessel fleet of 23 Pure Car and

Truck Carriers, all of which have

been designed or adapted to meet

the necessary flexibility and efficiency requirements of the short

sea market.

United European Car Carriers

UECC Pure Car/Truck Carriers main particulars

Length overall (m)

181

Beam (m)

30

Design draught (m)

8.40

Gross tonnage (t)

43,200

Deadweight at design draught (t)

Main engine

12,182

1 8S50ME-GI Mark 8.2

maximum continuous output (kW)

11,000 @ 113 rpm

normal output - 80% MCO (kW)

8,800 @ 105 rpm

speed: optimised/design (kn)

Turbochargers

16.5/18.6

2 TCA66

Finnish/Swedish ice class

Cargo and approx. capacity

1A Super1

3,800 standard-sized cars (and/or

trucks), spread over 10 decks (31,900 m2)

Designed to operate in difficult ice conditions, mainly without icebreaker assistance, facilitating year-round trading in the Baltic region

Graphical rendering of the new ME-GI-powered PCTCs showing engine and fuel-tank placement (courtesy UECC)

China Orders More Dual-Fuel Units

MAN Diesel & Turbo has announced

a further order for its MAN 51/60DF

engine. After a longer period of evaluation, an international consortium,

including Teekay LNG Partners, has

selected a Dual-Fuel Diesel Electric

(DFDE) propulsion solution featuring

212V51/60DF + 28L51/60DF engines for each of four Liquid Natural

Gas Carriers (LNGCs).

The new order follows that which

MAN Diesel & Turbo announced

in July 2013 when it won the contract to supply 30 MAN 51/60DF

dual-fuel engines for six LNGCs. In

both instances, the DFDE solution

provides the customer with the optimum redundancy.

The engines from both orders

will be produced at MAN Diesel &

Turbos Augsburg, Germany facil-

ity with delivery scheduled during

2015. They are specified as IMO

Tier II-compliant in diesel mode

with lower exhaust-gas emissions

in gas mode than IMO Tier III stipulates.

The new LNG carriers will be

constructed at Hudong-Zhonghua

Shipyard in Shanghai, Chinas only

builder of large LNG carriers, as

will those from the July 2013 order.

Following delivery between September 2017 and January 2019,

the ships will support the shipment

of LNG cargoes from BG Groups

Queensland Curtis Island LNG project.

The project, developed off the

eastern coast of Australia, will be

the worlds first project to turn gas

from coal seams into LNG.

The MAN 8L51/60DF engine

DIESELFACTS 3/2014

PAGE 9

MAN Turbochargers Power Worlds

First ME-GI and 28/32 Dual-Fuel Engines

TOTE container ship receives all-MAN package including MAN B&W main engine,

MAN auxiliary engines and TCA66 and TCR18 turbochargers

The recent delivery of the worlds first Unit MAN Diesel & Turbo, said:

dual-fuel, low-speed ME-GI engine Playing a crucial role for a leading

from Doosan Engine to the American developer and builder of two- and

National Steel and Shipbuilding Com- four-stroke, low- and mediumpany (NASSCO) set a new, historical speed engines as it does, the Turmilestone in engine technology. The bocharger Business Unit has a deep

8L70ME-C8.2-GI main engine is as- understanding of all the core techpirated by 2 TCA66 turbochargers nologies of large engines and the

and will power a 3,100-teu container way they interact with turbochargship ordered by TOTE, the American ers. The result is world- and marmarine transportation company. Fur- ket-leading turbocharger technolthermore, the ship will receive 3 ogy that easily keeps pace with all

9L28/32DF auxiliary engines, each innovations and new developments

featuring a single TCR18 turbocharger. within large diesel technology.

MANs engines and turbochargA second, identical vessel is currently

ers will allow TOTE to maintain its

under construction.

commitment resourcefulness, reWith this set-up, TOTE has not only liability, and responsiveness while

chosen the most environmentally reducing our impact on the envifriendly engine technology availa- ronment noted Anthony Chiarello,

ble but also the most flexible pow- President and CEO of TOTE. We

er solution in that both the ME-GI are excited to be the worlds first Publicity shot of the TCA66 turbocharger, one of two that will power the worlds first ME-GI engine (MAN Diesel & Turbo)

and 28/32DF engines can run on LNG-powered containership and

HFO or gas. Gas operation means the first to use MANs ME-GI engine.

With the TCA66 and TCR18 tur- in fact, had totally omitted the previ- including main engine, auxiliary en- TOTE Maritime, TOTE Logistics,

a significant reduction in CO2, NOx,

particulate matter and SO x emis- bochargers, TOTE has chosen ously necessary bearing inspection gines and turbochargers, TOTE can TOTE Services, and TOTE Shipholdnow enjoy the additional benefit of ings, TOTE is a wholly-owned subsions both engines are charac- proven products that integrate between major overhauls.

The company also stated that MAN PrimeServs one-stop service sidiary of Saltchuk, a Seattle-based

terised by having no methane slip. well with the latest engine technolTOTEs containership is slated to be ogy and match operators require- maintenance on its turbochargers for engines and turbochargers, Dirk family business comprised of

freight transportation and petrolethe first gas-powered containership ments for long service intervals can be carried out by the operators Balthasar concluded.

um distribution companies located

in the world and will lead the way and straightforward maintenance. own crew after appropriate training

nationwide. For more information,

for additional investments in infra- To this end, MAN Diesel & Turbo or by MAN PrimeServ, MAN Diesel About TOTE

recently announced that not only & Turbos global service organisation. TOTE is one of the United States visit www.toteinc.com and www.

structure for liquefied natural gas.

Dirk Balthasar, Head of Sales and had it extended the inspection in- Its one of our unique selling points: leading marine transportation com- saltchuk.com.

Promotion Turbocharger Business tervals of its TCA turbochargers but, having chosen an all-MAN package, panies. TOTEs subsidiaries include

PrimeServ Clinches Significant Service

Deal with Major Offshore Operator

At a signing ceremony at SMM, the

international marine trade fair in

Hamburg, MAN PrimeServ, MAN Diesel & Turbos service division, signed

a service framework agreement with

DOF ASA, the Norwegian off-shore

services company.

Wayne Jones Head of MAN

PrimeServ Diesel signed the contract on behalf of MAN PrimeServ,

with Lars Heine Njstad CPO of

DOF, signing for DOF.

Jones said: This is one of the

pillars of our strategy: to enter into

long-term contracts with professional clients who value the support of an OEM. Our global network,

technical expertise and a strong

commitment from all involved parties were the key factors in this success. When our organisation works

together on such projects, we are

a formidable team.

Pictured at the signing ceremony: (standing, from left) Mikael Adler Managing Director, MAN Diesel & Turbo, Norway; Serghei Nastas MAN PrimeServ

O&M Sales Manager; Dr. Stephan Timmermann Member of Executive Board,

MAN Diesel & Turbo; Stefan Eefting Vice President, Head of MAN PrimeServ;

(seated, from left) Lars-Heine Njstad Chief Procurement Officer, DOF; and

Wayne Jones Senior Vice President, Head of MAN PrimeServ Diesel

Lars Heine Njstad said: With

this agreement we get advice on

long-term planning for the MAN

equipment in our fleet. This increas-

es predictability and we strongly

believe that such a strong cooperation will contribute to ensure maximum uptime for our vessels.

MAN Diesel & Turbo reports that

the successful conclusion of the

service agreement came about

in great part as a result of intensive work carried out by PrimeServ

teams in Norway, Holeby (Denmark), Brazil and Augsburg. Mikael

Adler, Managing Director of MAN

Diesel & Turbo, Norway said: We

are confident that the new framework agreement with DOF will be a

great success and that it will form

the basis for future agreements

with other customers.

Agreement details

The service agreement covers the

servicing of 15 vessels and 68 MAN

engines (44 32/40 + 24 other engines of 21/31, 28/32 and 27/38

MAN types) covering a total of 518

cylinders. The scope of the agreement includes:

maintenance-planning support

the delivery of planned, unplanned

and emergency spare-parts

the provision of technical support for scheduled and unscheduled service

the provision of engine-related

training

online service access.

About DOF

DOF ASA is a Norwegian group of

international companies operating

within the offshore oil-and-gas industry. The Group operates 13 offshore vessels (platform-supply vessels, anchor-handling tug supply

vessels and construction-support

vessels) equipped with MAN Diesel

& Turbo-designed engines. Two additional vessels are currently under

construction in Brazil and scheduled to enter operation during 2014,

with activity primarily in offshore

Brazil and the North Sea.

PAGE 10

DIESELFACTS 3/2014

Hard at Work with MAN PrimeServ

in the City that Never Sleeps

DieselFacts recently went out on a slide-fuel-valve retrofit with PrimeServ New York

Newark Bay and areas of the New York/New Jersey Port with Manhattan in the background, and

Elizabeth Channel and Port Elizabeth in foreground ( Maureen from Buffalo, USA)

Its 10 in the evening when DieselFacts pulls up at PrimeServ New

Yorks premises in suburban New Jersey. Weve been promised the opportunity to observe a PrimeServ team at

work and have made the drive over to

the service centre in Woodbridge to

meet up with some of the local crew.

In the gloom, DieselFacts greets

two of them Jon Norman and

Mario Wongshue. The men are

loading tools onboard the PrimeServ pickup and wondering aloud

where Steiner Gulbrandsen, the

third man, is.

Gulbrandsen

Gulbrandsen is noted for his punctuality but, this night, turns up 10

minutes late, stymied by the closing

of the Outerbridge Crossing between Staten Island and New Jersey for maintenance and which

forced him on an unexpected detour through the backstreets of

Jersey. Leading the job tonight, he

checks with the two other men that

the requisite tools are loaded and

then we hit the road.

Gulbrandsen is a veteran with 40 Due in port around 11pm for just

years experience in the field with 10 hours or so, the PrimeServ team

MAN engines. Originally from the has been tasked with modifying the

Norwegian province of Telemark, ships MAN B&W 8S70MC-C enhe emigrated to the US as a young gine cylinder covers for the retrofitman and worked closely with Mae- ting of slide fuel-valves.

Steiner navigates our way

rsk for much of his career where

he learned fluent Danish to go with through a myriad of minor roads

his Norwegian, English and the and different toll booths before we

Spanish he picked up doing main- emerge onto the New Jersey Turntenance jobs in Puerto Rico over pike. The Bayway Refinery violently

lights up the night sky and signals

two decades.

our passing into the extended Port

On the road

of New York and New Jersey facilEn route, DieselFacts gets some ity. The landscape becomes promore details about the job. Were gressively more industrial as we

heading for Port Elizabeth, part of drive along miles and miles of road

the Port Newark-Elizabeth Marine fringed with jersey barriers, pass

Terminal and itself a major compo- under innumerable flyovers, and

nent of the Port of New York and past stacks of shipping containers

New Jersey. This latter entity is and acres of container x-ray mathe principal container-ship facility chines that resemble an outdoor

for goods entering and leaving the cinema. All the while, a multitude

New York metropolitan area and of tractor-trailers wait silently on the

the northeastern US, a key reason roadside, ready to cart any vetted

for PrimeServ New Yorks location. containers off in an instant.

Planes from Newark Liberty InWere rendezvousing with the

Manet, a 2,220-teu container ternational Airport are thundering

ship owned by Global Ship Lease by overhead as we turn onto Mo(GSL), the containership lessor. hawk St and port security begins,

some 40 minutes after we set out.

We wait for an official escort to the

ship shes currently manoeuvring

into port. 10 minutes later, an official port car shows up to escort

us to the Manet, a necessity in this

monster of a port. Newark Port

ranks as the 22nd-busiest in the

world today, but was number one

as recently as 1985. It remains the

largest container port in the eastern

United States.

A little patience

The Manet has berthed and theres

already a hive of activity onboard

as we park the pickup and get the

tools out. As we approach the ship,

an alarm signals the approach of a

gigantic gantry crane that slowly

rolls along a dedicated track, which

allows it to move alongside the full

length of the vessel. Once in position, its giant arms reach over the

Manet to pluck individual containers, which it then places on the

quay where a small army of straddle carriers fetches them and disappears into an ocean of containers to deposit them.

Working for PrimeServ, patience

is probably one of the better virtues

to have. Its 11pm and were waiting for US Customs officials who,

by law, must come aboard before

anyone else in order to process the

ship, its cargo and crew. The one

notable exception to this cast-iron

rule is that the lashers are allowed

aboard to loosen the straps on the

containers so the cranes can immediately get to work. In the US,

commerce always comes first.

Wongshue

While were waiting, DieselFacts

talks to Mario Wongshue. Originally from Kingston, Jamaica, Mario

came to America as a child and

was raised in Queens. Hes been

with PrimeServ New York since

its Grand Opening in 2007 where

he primarily takes care of welding

jobs. He says working with PrimeServ has been full of variety and

seen him sent on jobs along the

east coast, the Bahamas, Mexico and Puerto Rico, among other places. He got up for work as

usual this morning at 4.30 am, but

DIESELFACTS 3/2014

slipped home for some extra sleep

in the afternoon before returning to

Woodbridge in preparation for the

Manet job.

A question of time

Time is getting to be an issue. Its

midnight and theres still no sign

of customs as, apparently, theyre

busy with other ships. Gulbrandsen

says PrimeServ might have to follow Manet down the coast to start

the job if they dont turn up soon.

This would mess up his schedule as

he has a main-bearing inspection

job coming up on Monday aboard a

ship in Wilmington, Delaware.

Lupus in fabula, the customs officials show up shortly afterwards.

Steiner approaches them and

PrimeServ receives permission to

come aboard as long as we dont

interfere with their passport/papers

inspection. At the top of the gangway, we show ID to a Manet crew

member and receive our ships

passes. PrimeServ holds a brief

pow-wow with the Manets chief

engineer who asks them to begin

work on cylinder #8.

The PrimeServ crew gets into its

work clothes and descends into

the bowels of the ship to the engine room where its hot, humid and

noisy. Wongshue and Norman immediately start unscrewing the fuel

lines on #8 so they can get at the

injectors and slide-fuel valves. At

the same time, Gulbrandsen heads

over to the spare cylinder cover

where he uses callipers to measure how much the cylinder heads

will need to be reamed to accommodate the new fuel valves.

With the fuel lines off, Wongshue

and Norman remove the two existing fuel valves using a special

jack to remove the valves as they

sit at an angle and cant be pulled

straight out. Norman then sets

about cleaning out the first of the

two fuel-valve seats so it can be

reamed to the correct tolerances,

while Wongshue starts disassembling the fuel lines on cylinder #7.

Norman

Jon Norman has experience from

the automotive industry. The Pennsylvania native says: The different

car manufacturers all have their

own, different set-ups and idiosyncrasies, and transferring my skills to

PrimeServ and working with diesel

engines hasnt been as difficult as

you might imagine. It was more a

question of learning MANs way of

building engines and adapting my

skill set to that.

He has been with MAN for one

year, during which time he has been

on a job where he sailed down the

US east coast and from Savannah,

Georgia across the Atlantic while

overhauling an auxiliary engine.

Four-stroke engines make for longer jobs while two-stroke sometimes

mean more unsociable hours, he

says. But tonight should be relatively straightforward and Ive performed a similar job recently so

know what to expect here.

A time to work

The ships chief engineer drops by

every now and then to see how the

PAGE 11

job is going but for now excuses

himself as he is monitoring bunkering from the control room whose

insulated walls provide respite from

the noise and humidity of the engine room. Theres no doubt but

that its a tough working environment. When its this hard to communicate verbally, the PrimeServ

crew frequently uses exaggerated

expressions and hand signals to

get a point across.

The Manet doesnt have time to

dock for the job to be completed so PrimeServ will do as much

work as time here allows, and will

follow the vessel down the coast

to complete the job. Gulbrandsen

thinks well manage two cylinders

and the spare piston cover tonight

before we are ordered off. At 2.30,

he confirms that theyre not going to open up any more cylinders

and says: They hate it when the

ship has to wait. But as well as

the two covers were working on,

if we finish preparing the spare cylinder cover, then thats time saved

in the future.

With the reaming complete on

#8, Mario and Jon start to reassemble its fuel-injection assemblage. The clock reaches 3 am and

the PrimeServ crew is clambering about the engine and working

up a good sweat. Its hard, physical work at an hour when the vast

majority of the 20 or so million inhabitants from the New York City

metropolitan area are sleeping.

Regarding the late hour, Mario

Wongshue is happy with the progress PrimeServ has made and

says that while the tiredness is

tough, that as long as you keep

moving, its not too bad. Standing

still taking notes, DieselFacts is already desperate for bed.

Later, while Jon Norman finishes re-assembling #8, Mario moves

over to #7 where he has to use a

hydraulic jack, a powerful tool that

employs an impressive 20 bar of

pressure, to remove a recalcitrant

nut on a pipe attached to the fuel

valve. Shortly after 4 am, Steiner

says the Manet is sailing at 7 so we

need to be off by 6. The cylinder

cover is then reamed out and the

slide fuel valves inserted, having

first been inspected, cleaned and

lubricated in an adjacent tool room.

Mario and Jon then clean up, wiping oil and lubricants off the engine

and the fuel-injection assembly.

Counting sheep

Job done, the Manets Chief Engineer is roused from his bunk to

sign the job off and PrimeServ is

free to go. We hand our ID back

to ship security and climb down

the gangway.

Dawn is breaking as we depart

Port Elizabeth. Leaving proves to

be tricky without an escort to show

the way out but, soon, the V85L engine of the PrimeServ pickup roars

as we hit the New Jersey Turnpike heading south. Around 7 am,

PrimeServ reaches Woodbridge

where the workshop is already

open, ready for a new day.

In an earlier interview, Ruben

Caparros, Regional General Manager at PrimeServ New York and

himself a former PrimeServ engineer in his native Spain, said: You

get addicted to the life of a superintendent travelling to a job and

the pressure youre under, going

aboard a ship. And the great feeling of freedom when youve solved

a problem and walk down the

gangway. Sometimes, you even

find yourself getting bored after

three days at home again! But,

right now, thats a moot point. All

anybody from the Manet job wants

to do is count sheep while falling

asleep.

Slide fuel-valves

Especially popular within the marine two-stroke segment, the slide

fuel-valves strong market performance is testimony to the fuel savings and increased environmental profile it brings to working vessels. Slide fuel-valves improve the low-load operating capability of

engines and reduce/eliminate the need to run at high revolutions in

order to clean exhaust channels.

The slide fuel-valve eliminates the so-called sac volume, which reduces fuel-oil consumption and eliminates dripping from the fuelvalve nozzle. This contributes to an improved combustion process,

resulting in fewer deposits throughout the gas ways and a reduction

in overall emissions, such as HC, NOx and particulate matter. Today,

slide fuel-valves come as standard on all new MAN B&W engines.

First introduced at the turn of the millennium, MAN PrimeServ retrofitted its 20,000th slide fuel-valve during 2013.