Escolar Documentos

Profissional Documentos

Cultura Documentos

Treating Sulfur in Wastewater

Enviado por

vaglohrdDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Treating Sulfur in Wastewater

Enviado por

vaglohrdDireitos autorais:

Formatos disponíveis

Something water related

Timothy Lebrecht, Air Products, USA, and Neil Hannay, Air Products,

UK, offer several ways to treat H2S in wastewater and discuss the benefits

and drawbacks of each.

ulfur species are typically treated within a process and

managed through reaction engineering. But what happens

when small concentrations of sulfur species make their way

into wastewater? For many substances, the result is the

creation of hydrogen sulfide (H2S), a dangerous, odorous substance.

This article looks at various ways to handle sulfur species,

particularly H2S, and offers specific treatment methods, along with

the benefits and drawbacks of each method. Although sulfur

treatment can be a significant challenge, a cost effective solution is

available through the creative use of oxygen based chemistry.

What is H2S?

H2S is a flammable, colourless gas that smells like rotten eggs. It

occurs both naturally and from manmade processes. H2S can be

released from volcanoes, sulfur springs, undersea vents, swamps,

stagnant bodies of water and, most commonly, in areas with crude

petroleum and natural gas production and refining. Other industries

that have to manage the creation and treatment of sulfur are water

treatment, landfill gas processing, manure handling, and pulp and

paper. In all of these areas, sulfur species continue to be difficult to

isolate and manage.

In wastewater treatment, sulfur and H2S concentrations tend to

be relatively low, yet high enough to cause issues with safety,

corrosion and odour complaints. This article will review some

techniques for treating sulfur species in wastewater and help

identify the most effective way to manage this odorous gas when it

occurs in the process.

HYDROCARBON

HYDROCARBON

ENGINEERING

ENGINEERING

Reprinted

Reprintedfrom

fromFebruary

February2015

2015

Table 1. Methods of sulfur control

Typical

requirement,

lb/lb H2S

Further

treatment

required

Process

application

area

Gas stream H2S

removal

Effluent flow

pH and stripping

control can

be difficult to

maintain at

equilibrium, plus

H2S is highly

soluble.

HS

Neutralisation

for discharge

In lagoon

pH too high for

biological activity.

Prevention,

removal and

control

SO

SO4

Maintenance

of high redox/

ORP

Effluent flow

and in lagoon

Must be

maintained to

prevent reduction

of S and SO4

H2O2

Permanganate

Chlorine

Chlorine

dioxide

Hypochlorite

Ozone

Removal and

control

S

SO

SO4

Removal of

solid and/or

prevention of

reconversion

to H2S

Effluent flow

and in lagoon

Expensive;

undesirable

organic reactions;

toxic chemical

handling

considerations.

Stripping

Air

CO2

Gas

stripping for

downstream

gas phase

treatment

H2S in carrier

gas

Gas collection

and scrubbing

Effluent flow

Low pH

maintenance

required for

effective full

sulfide removal;

CO2 carrier gas

is therefore

preferable to air.

Precipitation

Ferrous sulfate

Reaction

to solid

precipitate

Fe2S3 solid

Solids removal

and disposal

Effluent flow

Bactericidal

Acid/alkali

Chlorine

Permanganate

Kill all

bacteria

to remove

biological

reduction of

sulfur species

n/a

Ongoing

requirement

to ensure no

biological

activity

Effluent flow

Method of

control

Methods

Action

Main sulfur

compounds

produced

pH control

acid

Acid dose for

stripping pH<5

Removal

H2S dissolved

by pushing

equilibrium to

H2S (sol)

pH control

alkali

Base dosing for

maintaining in

solution pH>9

Control by

pushing

equilibrium

to HS

Redox/ORP

control

Oxygen (as

air or pure

oxygen)

Nitrate

Oxidation

Issues with H2S

H2S is a chemical that comes with severe dangers. It is a strong acid

when dissolved, extremely flammable and highly toxic. Since this

article focuses on wastewater, the flammability hazard is not part

of the discussion. However, the toxicity and odour of the

substance cause this material to be one of the most challenging to

handle. For example, elevated H2S levels can cause headaches and

nausea at just 5x the odour detection threshold, assuming a

detection threshold of 8 ppb (toxicity issue threshold would then

be 40 ppb). H2S has been lethal to humans at acute concentrations

generally exceeding 500 ppm.

H2S removal versus control

In general, companies are very aware of processes that can

generate or accumulate sulfur and H2S. The dangers associated with

H2S, as well as the extreme odour, have companies doing what

they can to make sure they remove as much of the material as

possible within the process. Treating in process is the best way to

address H2S.

Reprinted from February 2015

HYDROCARBON

ENGINEERING

Comments

4 - 15

Applicable for

corrosion and

odour control in

pipelines.

An example from the refining industry is the Claus reaction,

which transforms H2S to elemental sulfur. Sour water can be

encountered and will need to be treated, but the vast majority of

H2S is handled outside of the wastewater process. Treatment

through specific reactions is most commonly done when volumes

are large and there can be another use for the sulfur. The challenges

become greater when H2S exists in small quantities. Developing a

way to cost effectively manage the substance is challenging, but

possible.

In general, sulfur is an element that is necessary to sustain life.

When sulfur is within an aerobic digestion wastewater system, it is

readily converted to an odourless sulfate. When sulfurs are present

in an anaerobic process, such as anaerobic digestion, however, H2S,

mercaptans or thiols can be formed. The odours associated with

sulfides can range from the smell of garlic to rotten eggs and worse.

The wastewater team at a given facility needs a strategy to

actively treat H2S in the wastewater stream, rather than wait for it

to become an issue that can create problems at the facility or in

the community. There are several good ways to treat H2S, each

with its own advantages and disadvantages. These strategies may

Table 2. Comparison of redox control methods

Method

of redox

control

Efficiency

losses w/

ea 1 mg/l

DO rise

above 0

Typical

energy

required

for

dissolution

(power)

Typical

method of

application

Typical

dose

rates

quantity

required

Mechanism

Side

reactions

Effect on

ecosystem

Benefits

Issues

Pure

oxygen

2%

0.0 - 0.3

kW/kg

Continuous

dissolved

oxygen;

automatically

controlled

injection

8 - 10 g

O2/m3

5 - 10 lb/

lb H2S

Maintains

high dissolved

oxygen

preventing

reduction of

sulfur species.

Local

oxidation of

sulfur species

by biological

and chemical

processes to

H2SO4, SO4

and S.

Biological

BOD removal.

Promotes

bacterial

activity.

Improves

biodiversity

and aerobic

treatment.

High

dissolved

oxygen

for final

discharge.

High

efficiency.

Low

agitation of

basin.

Small

footprint.

No

chemical

handling.

Fully

automated.

Low power.

Good

dissolution

required

to ensure

economics.

Air

10%

0.8 kW/kg

Continuous

surface

aeration

50 - 100g

O2/m3

(150 - 300g

air/m3)

Maintains

dissolved

oxygen levels

> 0.5 mg/l

preventing

reduction of

sulfur species.

Biological

BOD removal.

Stripping of

dissolved

H2S due to

nitrogen

waste gas.

Improves

biodiversity

and aerobic

treatment.

Low

technology

investment.

Dissolution

rates drop

in warm

weather,

when

biological

activity

increases.

Waste

nitrogen

gas can

cause over

mixing and

exacerbate

the release

of H2S from

the system.

Air will

strip H2S

at effluent

inlet due to

high volume

waste

nitrogen.

H2O2

N/A

N/A

Batch

delivery and

application

N/A

reaction

not DO

rise 1 - 5

lb/lb

@ 100%

H2O2

Local

chemical

reaction to S.

Stochiometric

1:1 but in

process nearer

5:1.

Chemical

oxidation

of organic

compounds

and biological

components.

Decomposes

to oxygen and

water.

Effectively

disinfects

local

injection

region

entirely

stopping

water

treatment.

Emergency

control of

H2S levels.

Biological

destruction

stimulates

increased

activity and

anaerobic

processes

once

oxidation

potential

lost.

Hazardous

chemical

handling.

Usually

very local

injection

required.

vary by treatment type and include equalisation ponds, anaerobic

ponds and deep storage industrial ponds.

In general, the goal for H2S control in an equalisation pond is

to keep organic material in solution and move it along quickly so

that anaerobic conditions do not develop. Anaerobic ponds are

the largest challenge, as sulfide gas bubbles (most commonly H2S)

can rise from the pond. Strategies to eliminate this include pH

control, stripping with scrubbing, and oxidation reduction

potential (ORP) control/oxidation. Deep industrial ponds can

encounter the same issues as anaerobic ponds, but on a more

seasonal basis. In general, the concepts of pH control, stripping

and scrubbing, and ORP control/oxidation are the best means to

control sulfur in wastewater.

The level of acidity in the treatment basin can be a key way

to make sure H2S does not leave the basin. When wastewater has

a pH level of >9, nearly all H2S will stay in solution as HS and

HYDROCARBON

ENGINEERING

Reprinted from February 2015

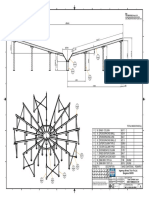

Figure 1. Air Products' Halia mixer aeration

system, consisting of oxygen supply, either as

liquid oxygen or onsite generation, combined with

OxyMix technology jointly developed by

Aqua-Aerobic Systems, Inc. and Air Products.

Figure 2. OxyMix technology installed in a

wastewater treatment tank.

will not exit the treatment area. This may sound like a simple

approach, however, in biological wastewater, the micro

organisms are the key to treatment. These organisms cannot

live in such a high pH environment. The challenge is that for

these organisms to be healthy, pH must be much closer to

neutral. Doing so keeps the bacteria healthy, but it does not

keep the H2S in solution.

Another means of controlling H2S is stripping it from the

stream with air or CO2 and then scrubbing the H2S. This tends to

be a costly approach due to the large volume of water that

would need to be stripped of H2S, as well as the operating cost

of a scrubber. In most instances, this is not the chosen path of

treatment.

The most common approach in water treatment is ORP

control/oxidation. Oxidation involves the reaction of H2S with

oxygen (O2) to form sulfur (S), sulfate (SO4), sulfuric acid (H2SO4)

or other soluble sulfur compounds. In this way, the challenge of

H2S is changed to an alternate chemical that is more simply

treated or controlled. The issue with oxidation is that it requires

the oxygen molecule in the wastewater at a concentration high

enough to react with the H2S without slipping into anaerobic

conditions. Ponds or treatment basins try to maintain dissolved

oxygen (DO) content at an acceptable level, but due to process

variation and seasonality, DO levels will vary.

A summary of the different types of control for sulfur species

odour is shown in Table 1. As described above, there are multiple

Reprinted from February 2015

HYDROCARBON

ENGINEERING

paths to consider, but the most common path, especially when

anaerobic issues are the root cause, is oxidation.

When employing oxidation or ORP control techniques,

process demand variance or seasonality require a dynamic way to

control the input of oxygen. These variations can be controlled

proactively or reactively. A proactive approach is to install the

necessary wastewater equipment to make sure that the dissolved

oxygen level is relatively consistent. A reactive approach is to

wait for the pond or treatment basin to be overcome with an

impurity and then treat on an as needed basis. The reactive

approach can be lower cost if H2S does not start to leave the

treatment system. However, if the levels of the gas leave the

water and create a toxic or odorous environment, the price can

be quite high both in cost and company image.

Oxidation and ORP control

The most common way of controlling sulfur species in a

lagoon or treatment pond is through oxidation or redox/ORP

control. Achieving the necessary level of dissolved oxygen in

the pond or treatment basin requires air, pure oxygen or

hydrogen peroxide. Each of these substances has pros and

cons, which are compared in Table 2.

Air typically has the lowest operating cost; however, due

to the way oxygen is added to the treatment pond, air can

actually cause more H2S to leave the pond than it stops

through reaction with the oxygen. Typically, air is not a

reliable means for control due to the possibility of stripping

and the seasonal variability of O2 retention with temperature.

Although oxygen in air is readily available, the challenge

is getting it into the water solution. Large air based mixers

and aerators can require large horsepower motors and

significant capital to get enough oxygen into the water

solution. One issue this may create is an increase in overall

VOCs into the atmosphere by stripping the treatment pond

of impurities and pushing them into the air. Additionally, over

mixing the pond can exacerbate the release of H2S because

of the high volume of waste nitrogen coupled with increased

sediment disturbance in lagoon type basins. Also, dissolution

efficiency rates tend to drop in warm weather when

biological activity increases, requiring even more energy. For

H2S, the air based approach needs to be handled carefully, as

the solution may cause more issues than the initial problem

or vary by season.

Pure oxygen requires unique equipment to ensure

appropriate mixing and distribution in the treatment ponds.

Good dissolution is required to ensure the economics make

sense for oxygen. The safety of oxygen also needs to be

carefully understood, and special consideration of the

handling and care for the equipment is necessary. Oxygen

based equipment can add the product without stripping the

VOCs. Several methods involve adding the O2 under water in

ways that increase its ability to mix with the wastewater

based on a sensors measurement of dissolved oxygen.

Lastly, hydrogen peroxide (H2O2) can offer a solution.

Typically, H2O2 is used as a reactive approach to water

treatment. Ongoing supply can be challenging to distribute

appropriately, which lends itself to be more of a reactive

means of control. Since distribution and control are

challenges, the cost in terms of product, labour and yield are

significant issues. Due to the substances high degree of

Table 3. Choosing the right oxygen supply mode

reactivity, H2O2 can react with

impurities other than H2S,

Supply features

Liquid oxygen

Onsite generation

Pipeline*

thereby reducing its ability to

Flow range (tpd)

0 - 50

50 - 150+

100+

effectively treat H2S. One of

Commitment

Low

High

Medium

these side reactions is biological

Time

to

implement

(months)

1

2

10

18

6-8

destruction of organisms in the

Location limitations

Yes

No

Yes

basin, which can stimulate a

second activity in anaerobic

Application best fit

processes once oxidation

Flow

Low

Medium/high

High

potential is lost. The safety of

Use pattern

Variable

Steady

Variable/steady

using H2O2, which requires

*Gas piped in from remote air seperation plant

hazardous chemical handling,

also increases the cost of this

flexible source of oxygen. Evaluating the optimal mode of supply

option.

requires the review of a host of factors, including:

As illustrated in Table 2, oxidation through the use of pure

nn Size of the oxygen requirement (average and peak demand).

oxygen creates the safest and lowest cost option.

nn Expected use pattern (continuous, seasonal, erratic).

nn Presence of other nearby oxygen consuming applications, such

Oxygen injection

as ozone.

Pure oxygen can be injected into wastewater in a number of

nn Power availability and cost.

ways. For years, this approach has been used in activated sludge

nn Proximity of delivered oxygen source.

systems to boost the dissolved oxygen content when other

means have been exhausted. Oxygen tends to be a way to boost

Table 3 provides rough guidance about the best mode of

a treatment ponds performance without increasing its size.

supply in the context of these parameters. From the early stages of

These same methods are also good for the treatment of H2S. In

the project, an industrial gas company like Air Products will work

the treatment of H2S, oxygen tends to be better because it does

closely with a wastewater treatment plant to jointly determine the

not lift impurities in the air through stripping, and most of the

best mode of oxygen supply.

O2 is injected into the water without significant agitation of the

pond.

Some typical ways of adding oxygen are: diffusion into a

Conclusion

pipeline, diffusion into a grid in the treatment pond, a floating mixer

Sulfur species are problematic for many industries. However, there

aerator unit or a floating diffuser based system. Each of these

is hope for a way to control this substance even when treatment

systems varies in yield and complexity. The simplest way to add the

conditions are variable. Equipment designed to use pure oxygen

pure O2 is through basic diffusion. This can be done by adding O2

with an accompanying DO probe and a programmable logic

controller can maintain the necessary dissolved oxygen content

through a lance into a line of water that feeds the treatment basin.

required to transition H2S and other sulfur species into treatable

Another simple way is to have a static diffusion grid in the treatment

pond bubbling oxygen through the depth of the pond. Each way has

sulfates. Other types of treatment can prove to be more costly or

definite limits on efficiency. Typically, only 10 - 15% of the oxygen

create more problems than they solve. For example, temporary

put into the pipe or diffusion grid is captured by the water, and the

fixes, such as hydrogen peroxide, do not solve the issue. Use of

rest escapes into the atmosphere.

H2O2 is costly, creates safety challenges, and is not a permanent

There are several other approaches that use a more complex

solution. The more practical solution is pure oxygen, which

method for adding oxygen. Diffusion based forced water/oxygen

provides a continuous supply to a treatment pond without

systems can be operated. Industrial gas companies like Air Products

exposure to a hazardous chemical for workers and without danger

offer this type of equipment. Oxygen efficiency can reach up to 90%

of hurting or causing an issue with the planned biological treatment

under specific operating parameters. Air Products offers such items

of the wastewater.

as the Halia Mixer Aerator and the Halia Venturi Aerator units for

both deep and shallow treatment pond conditions. These units,

References

1. Hydrogen Sulfide; MSDS No. 300000000081; Air Products: Allentown,

pictured below, can add up to 10 000 lb/d of oxygen per unit to a

Pa., February 8, 2014.

treatment zone.

2. MOUSSAVI et al., The Removal of H2S from Process Air by Diffusion

Oxygen supply

The supply of oxygen is also an area where great expertise is needed.

Oxygen can be provided from a liquid oxygen tank or an onsite

generator.

The most common mode of supply for delivered oxygen is via on

road liquid oxygen tankers from a central manufacturing facility. The

oxygen is stored as a liquid at the site in an insulated tank and

vaporised at the time of use. This is the most flexible mode of supply.

Oxygen can also be generated onsite using cryogenic or

adsorption technologies. At locations in the vicinity of an oxygen

pipeline, supply via pipeline could be the most cost effective and

into Activated Sludge, Env Tech, Vol 28, pp. 987 - 993, 2007.

3. HJORTH et al., Redox Potential as a Means to Control the Treatment of

Slurry to Lower H2S Emissions, Sensors 2012, 12,

pp. 5349 - 5362.

4. Septicity in Sewers: Causes, Consequences and Containment, Boon

1995, Water Sci tech, Vol 31, No 7, pp. 237 - 253.

5. Metcalf and Eddy Wastewater Engineering 2003 Fourth Edition.

6. EPA: Process Design Manual for Sulfide Control in Sanitary Sewerage

Systems 1974.

7. Economical, Efficient and Effective Mixing: Three Approaches to

Controlling Odor in Wastewater Treatment Ponds White Paper

Medora Corp.

8. NIELSEN at al., Aerobic and Anaerobic Transformations of Sulphide in

a Sewer, WEFTEC 2006.

HYDROCARBON

ENGINEERING

Reprinted from February 2015

Você também pode gostar

- Hydrogen Sulfide Odors BulletinDocumento4 páginasHydrogen Sulfide Odors Bulletinagagne9503Ainda não há avaliações

- Contolling Reduced Suphur Species H2O2 SolvayDocumento9 páginasContolling Reduced Suphur Species H2O2 SolvayjppmjAinda não há avaliações

- 12pg142 146 Dehydration and Sweetening of Natural Gas 160214194840Documento16 páginas12pg142 146 Dehydration and Sweetening of Natural Gas 160214194840Muhammad sherazAinda não há avaliações

- GasSweetening WorkshopDocumento34 páginasGasSweetening Workshophrijucse100% (3)

- The Purification of BiogasDocumento23 páginasThe Purification of BiogasHamed HpAinda não há avaliações

- What Is DesulfurizationDocumento20 páginasWhat Is DesulfurizationYash NandurkarAinda não há avaliações

- Acid Rain in Distilleries in Pakistan: AbstractDocumento3 páginasAcid Rain in Distilleries in Pakistan: AbstractQasim ShahzadAinda não há avaliações

- The Purification of BiogasDocumento29 páginasThe Purification of Biogasaldipdg100% (1)

- Rule of Thumb - Oxygen Scavenging 8-19-2021Documento4 páginasRule of Thumb - Oxygen Scavenging 8-19-2021Jignesh DodiyaAinda não há avaliações

- GTZ Purification of Biogas 1985Documento25 páginasGTZ Purification of Biogas 1985ghffhgjhjkhAinda não há avaliações

- Leachate ControlDocumento5 páginasLeachate ControlAndrew Cahyo AdhiAinda não há avaliações

- Medida Del Hidrogeno SulfuradoDocumento12 páginasMedida Del Hidrogeno SulfuradodagingoAinda não há avaliações

- Unit 3Documento14 páginasUnit 3Parth TripahiAinda não há avaliações

- Advanced Oxidation Processes PresentationDocumento6 páginasAdvanced Oxidation Processes PresentationNarendra PrajapatiAinda não há avaliações

- Lecture 16Documento15 páginasLecture 16Fabiha Shafi MimAinda não há avaliações

- CV3015 - Assignment 2 - Yandi Layadi Lay (U1120277F)Documento4 páginasCV3015 - Assignment 2 - Yandi Layadi Lay (U1120277F)Yandi LayadiAinda não há avaliações

- WEF Denver Apr07Documento12 páginasWEF Denver Apr07James EldridgeAinda não há avaliações

- Paper presentedtoWEFConferenceDec2005Documento15 páginasPaper presentedtoWEFConferenceDec2005Nikhil MalhotraAinda não há avaliações

- Textile Waste Water Management: Course: Introduction To General Chemistry Course Code: CHE 101Documento7 páginasTextile Waste Water Management: Course: Introduction To General Chemistry Course Code: CHE 101Ishtiaq Ahmed MugdhaAinda não há avaliações

- Hypochlorite Breakdown and Reaction Products Relevant For The BPR Fina...Documento8 páginasHypochlorite Breakdown and Reaction Products Relevant For The BPR Fina...Dorina CotoarăAinda não há avaliações

- H2S and Other Hazardous GasesDocumento4 páginasH2S and Other Hazardous GasescafegrAinda não há avaliações

- Seminar ReportDocumento35 páginasSeminar ReportAkhilesh DamaniaAinda não há avaliações

- Green Solvents For Petroleum and Hydrocarbon IndustriesDocumento6 páginasGreen Solvents For Petroleum and Hydrocarbon IndustriesMădălina GrigorescuAinda não há avaliações

- Chapter 1 ClausDocumento13 páginasChapter 1 ClausWoMeiYouAinda não há avaliações

- 18 Ijarset Masjidhassan 1.... Caustic TreatmentDocumento9 páginas18 Ijarset Masjidhassan 1.... Caustic TreatmentFarah Talib Al-sudaniAinda não há avaliações

- BOD and COD RemovalDocumento13 páginasBOD and COD Removaldesireeh200950% (2)

- Removal of Hydrogen Sulfide (H S) From Wastewater Using Chemical Oxidation and Red Mud-A Comparative StudyDocumento4 páginasRemoval of Hydrogen Sulfide (H S) From Wastewater Using Chemical Oxidation and Red Mud-A Comparative StudyVenkatesh VenkyAinda não há avaliações

- EPA DechlorinationDocumento7 páginasEPA Dechlorinationant29539432Ainda não há avaliações

- Performances of An Activated Sludge Proc20160202 15516 14586m1 With Cover Page 1.2Documento9 páginasPerformances of An Activated Sludge Proc20160202 15516 14586m1 With Cover Page 1.2Abdul rahmanAinda não há avaliações

- Plant Design For Microbial Treatment of Waste Water With Advanced Oxidation ProcessDocumento30 páginasPlant Design For Microbial Treatment of Waste Water With Advanced Oxidation ProcesslazamAinda não há avaliações

- Chemical Pretreatment For Ro - HydraunauticDocumento16 páginasChemical Pretreatment For Ro - HydraunauticBerliana Cahya NingtiasAinda não há avaliações

- h202 Handling and Storage EnglishDocumento26 páginash202 Handling and Storage EnglishSo MayeAinda não há avaliações

- Reaction Kinetics of Waste Sulfuric Acid Using H2O2 Catalytic OxidationDocumento9 páginasReaction Kinetics of Waste Sulfuric Acid Using H2O2 Catalytic OxidationMisum AliAinda não há avaliações

- Theural Zeolite Ratio and AdsorbeDocumento9 páginasTheural Zeolite Ratio and AdsorbeNick RonaldAinda não há avaliações

- Advanced Oxidation Process - WikipediaDocumento4 páginasAdvanced Oxidation Process - WikipediaSauptik DattaAinda não há avaliações

- O Physical Processes o Chemical Processes o Biological ProcessesDocumento7 páginasO Physical Processes o Chemical Processes o Biological ProcessesGloria Garcia RodriguezAinda não há avaliações

- Hidroxido de Magnesio Una Altenativa para Disminuir h2sDocumento6 páginasHidroxido de Magnesio Una Altenativa para Disminuir h2sBetzabe MPAinda não há avaliações

- Summary Treatment by CTC For Penetrant Waste Rinses Using AOP ProcessDocumento3 páginasSummary Treatment by CTC For Penetrant Waste Rinses Using AOP ProcessWONG TSAinda não há avaliações

- CHARACTERISTICS OF SEWAGE: Analysis RequiredDocumento7 páginasCHARACTERISTICS OF SEWAGE: Analysis RequiredJade Paul D. BesanaAinda não há avaliações

- Ijct 13 (3) 203-217Documento15 páginasIjct 13 (3) 203-217د. سامي أبو جهادAinda não há avaliações

- Water Research X: Karine Kiragosyan, Johannes B.M. Klok, Karel J. Keesman, Pawel Roman, Albert J.H. JanssenDocumento10 páginasWater Research X: Karine Kiragosyan, Johannes B.M. Klok, Karel J. Keesman, Pawel Roman, Albert J.H. JanssenJoel de la BarreraAinda não há avaliações

- Advanced Oxidation Processes: Advanced Oxidation Processes (Aops), in A Broad Sense, Are A Set ofDocumento42 páginasAdvanced Oxidation Processes: Advanced Oxidation Processes (Aops), in A Broad Sense, Are A Set ofRishu RajAinda não há avaliações

- Hydrogen Sulphide Gas in Sewers - The Challenges of Odour and CorrosionDocumento7 páginasHydrogen Sulphide Gas in Sewers - The Challenges of Odour and CorrosionPaola P. VillegasAinda não há avaliações

- Biogas UpgradingDocumento31 páginasBiogas UpgradingMohamad FarhanAinda não há avaliações

- Hydrogen Sulfide (h2s) Training CourseDocumento78 páginasHydrogen Sulfide (h2s) Training CourseMichael Angelo RamirezAinda não há avaliações

- Enviro Chem SlidesDocumento35 páginasEnviro Chem SlidesJane PollyAinda não há avaliações

- Aerobic Digestion-Deo KnjigeDocumento16 páginasAerobic Digestion-Deo Knjigemilenaknezevic.mikanaAinda não há avaliações

- Inorganic PeroxyDocumento5 páginasInorganic PeroxyKrizel Ashley GuzmanAinda não há avaliações

- Common Methods of ETP ProcessDocumento3 páginasCommon Methods of ETP Processvishal kashyapAinda não há avaliações

- O /uv Coupled With Membranes: Oil Industry Wastewater Treatment For ReuseDocumento8 páginasO /uv Coupled With Membranes: Oil Industry Wastewater Treatment For ReuseMarcelo Varejão CasarinAinda não há avaliações

- Safety Manual Hydrogen Sulfide ProgramDocumento8 páginasSafety Manual Hydrogen Sulfide ProgramPPO Field OperationAinda não há avaliações

- Multiples UsosDocumento9 páginasMultiples UsosDiego LopezAinda não há avaliações

- Reducing Hydrocarbons in Sws Acid GasDocumento15 páginasReducing Hydrocarbons in Sws Acid GasHanan AmarkiAinda não há avaliações

- #Biogas ScrubbingDocumento13 páginas#Biogas ScrubbingLai Mei EeAinda não há avaliações

- The Chemistry of Agricultural Fungicides and InsecticidesNo EverandThe Chemistry of Agricultural Fungicides and InsecticidesAinda não há avaliações

- Low Cost Wastewater Bioremediation Technology: Innovative Treatment of Sulfate and Metal-Rich WastewaterNo EverandLow Cost Wastewater Bioremediation Technology: Innovative Treatment of Sulfate and Metal-Rich WastewaterAinda não há avaliações

- Ion Exchange Resins and Adsorbents in Chemical Processing: Second EditionNo EverandIon Exchange Resins and Adsorbents in Chemical Processing: Second EditionNota: 5 de 5 estrelas5/5 (1)

- Environmental Control in Petroleum EngineeringNo EverandEnvironmental Control in Petroleum EngineeringNota: 4.5 de 5 estrelas4.5/5 (3)

- Enterprise Social Listening Platforms, Q1 2016Documento16 páginasEnterprise Social Listening Platforms, Q1 2016DuDu Smile100% (1)

- W 50-1376 PDFDocumento2 páginasW 50-1376 PDFvaglohrdAinda não há avaliações

- 50 9693Documento2 páginas50 9693vaglohrdAinda não há avaliações

- WQ PurewaterDocumento92 páginasWQ PurewatervaglohrdAinda não há avaliações

- 68 0312Documento140 páginas68 0312vaglohrdAinda não há avaliações

- 69 2012Documento20 páginas69 2012vaglohrdAinda não há avaliações

- System Installation GuideDocumento48 páginasSystem Installation GuidevaglohrdAinda não há avaliações

- POE City Owners Manual SXT 2011Documento16 páginasPOE City Owners Manual SXT 2011vaglohrdAinda não há avaliações

- Filtration in Bottled Water ProcessingDocumento2 páginasFiltration in Bottled Water ProcessingvaglohrdAinda não há avaliações

- Aeration Water Treatment Systems: Tip SheetDocumento2 páginasAeration Water Treatment Systems: Tip SheetvaglohrdAinda não há avaliações

- Novatek 01 Introduction To Water Softeners How To SizeDocumento10 páginasNovatek 01 Introduction To Water Softeners How To SizevaglohrdAinda não há avaliações

- MSDS - Minium (Red Lead)Documento9 páginasMSDS - Minium (Red Lead)billfrindall7261Ainda não há avaliações

- PPT 14 Air, Water, Weather (22.6.20) PDFDocumento17 páginasPPT 14 Air, Water, Weather (22.6.20) PDFAyushi Gupta100% (1)

- Upper Midim Final ReportDocumento147 páginasUpper Midim Final ReportHydropower NepalAinda não há avaliações

- DR JovesDocumento3 páginasDR JovesCzara DyAinda não há avaliações

- North Goa District, Goa State: Ground Water Information BookletDocumento27 páginasNorth Goa District, Goa State: Ground Water Information Bookletshubham100% (1)

- Fossils (Science Matters)Documento23 páginasFossils (Science Matters)Harsh Bharti100% (1)

- Assignment 1 Individual IMPC IklimaDocumento15 páginasAssignment 1 Individual IMPC IklimaIklima MariamAinda não há avaliações

- BY Anjala Nasreen Z. B160765CE A BatchDocumento18 páginasBY Anjala Nasreen Z. B160765CE A BatchDasari NavyaAinda não há avaliações

- Winterization Notice To OccupyDocumento2 páginasWinterization Notice To OccupywhistleblowermnAinda não há avaliações

- Dura FRAC®-JH310113-03 (Eng) (Rev03)Documento1 páginaDura FRAC®-JH310113-03 (Eng) (Rev03)Peter LeanoAinda não há avaliações

- FloKing IndiaDocumento12 páginasFloKing IndiaweidashareAinda não há avaliações

- About The Rocky Shoals Spider LilyDocumento4 páginasAbout The Rocky Shoals Spider LilyThe State NewspaperAinda não há avaliações

- Geography - MCQ WWW - Qmaths.inDocumento40 páginasGeography - MCQ WWW - Qmaths.inSam Selin100% (1)

- Aashto T 259 02Documento3 páginasAashto T 259 02alicarlos1367% (3)

- Grade VII PA2 Revision Work Sheet 2023-24.docx EditedDocumento10 páginasGrade VII PA2 Revision Work Sheet 2023-24.docx Editedrishaankala1234Ainda não há avaliações

- Oi Atro Hydrodynamic Screws en PDFDocumento6 páginasOi Atro Hydrodynamic Screws en PDFmat lehAinda não há avaliações

- III I Civ CT Unit ViDocumento18 páginasIII I Civ CT Unit ViShriAinda não há avaliações

- C. Water Meter: Plumbing CodeDocumento8 páginasC. Water Meter: Plumbing CodeLil'lhiz ArazasAinda não há avaliações

- DrawingDocumento16 páginasDrawingAashish sahuAinda não há avaliações

- A Case Study of Slope Failure in Central Trinidad Due To Water Pipe LeakageDocumento6 páginasA Case Study of Slope Failure in Central Trinidad Due To Water Pipe Leakageneil beeraspatAinda não há avaliações

- Amphibian ColombiaDocumento19 páginasAmphibian ColombiaOmar Andrés Cifuentes GaitánAinda não há avaliações

- OLFNSA Guidelines For Safe Anchor Handling and TowingDocumento25 páginasOLFNSA Guidelines For Safe Anchor Handling and TowingAjay Singh100% (1)

- Mitigation of Internal Corrosion in Carbon Steel Gas Pipeline SystemsDocumento24 páginasMitigation of Internal Corrosion in Carbon Steel Gas Pipeline Systemsakshat agrawalAinda não há avaliações

- Land Spread CompressedDocumento11 páginasLand Spread CompressedSimon ThuoAinda não há avaliações

- Sathiamurthy, Rahman - 2017 - Late Quaternary Paleo Fluvial System Research of Sunda Shelf A ReviewDocumento12 páginasSathiamurthy, Rahman - 2017 - Late Quaternary Paleo Fluvial System Research of Sunda Shelf A Reviewsutanto0612Ainda não há avaliações

- Carpark Drainage DesignDocumento64 páginasCarpark Drainage DesigndrAinda não há avaliações

- Water PPT PresentaionDocumento17 páginasWater PPT PresentaionAnkush ManchandaAinda não há avaliações

- Nuclear Power in India FINALDocumento28 páginasNuclear Power in India FINALsureshAinda não há avaliações

- Commercial Book ListDocumento6 páginasCommercial Book Listoto saviourAinda não há avaliações

- Ensign 7Documento6 páginasEnsign 7Demetrios GkikasAinda não há avaliações