Escolar Documentos

Profissional Documentos

Cultura Documentos

Material Spec Sheets

Enviado por

AdityaDeshmukhDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Material Spec Sheets

Enviado por

AdityaDeshmukhDireitos autorais:

Formatos disponíveis

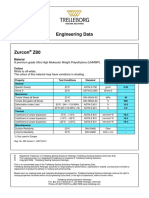

Material Specification Sheet

DISOGRIN 6865

Name:

Material:

Type:

Color:

DISOGRIN 6865

Premium polyurethane, TODI based

Injection molded

Natural

Property

Standard

Value

Units

Hardness

ASTM D-2240-68

92

Shore A

Tensile Strength

ASTM D-412 Die C

5,900

psi

Elongation Set

ASTM D-412 Die C

550

Elongation Set

ASTM D-412 Die C

15

300% Modulus

ASTM D-412 Die C

1,700

psi

100% Modulus

ASTM D-412 Die C

750

psi

Abrasion Loss

DIN 53/516

25

mm3

Tear Die C

ASTM D-624

660

pli

Tear Nicked

ASTM D-624

360

pli

Bayshore Resilence

ASTM D-2632-7

51

ASTM D-395-69, Method B

ASTM D-792, Method A1

1.15

Compression Set B

22 Hrs @ 70C

Specific Gravity

Important Notes:

Not to be used for specification purposes. These values serve only as a guide for engineering design. Values are

median values obtained from laboratory specimens.

Material Spec Sheet 6865 01.08.00

Material Specification Sheet

DISOGRIN 9250

Name:

Material:

Type:

Color:

DISOGRIN 9250

Premium polyurethane, TODI based

Cast

Natural

Property

Standard

Value

Units

Hardness

ASTM D-2240-68

92

Shore A

Tensile Strength

ASTM D-412 Die C

6,000

psi

Elongation Set

ASTM D-412 Die C

400

Elongation Set

ASTM D-412 Die C

18

300% Modulus

ASTM D-412 Die C

3,400

psi

100% Modulus

ASTM D-412 Die C

1,600

psi

Abrasion Loss

DIN 53/516

36

mm3

Tear Die C

ASTM D-624

700

pli

Tear Nicked

ASTM D-624

480

pli

Bayshore Resilence

ASTM D-2632-7

35

ASTM D-395-69 (Method B)

26

ASTM D-792, Method A1

1.17

Compression Set

22 Hrs @ 70C

Specific Gravity

Important Notes:

Not to be used for specification purposes. These values serve only as a guide for engineering design. Values are

median values obtained from laboratory specimens.

Material Spec Sheet 9250 01.08.00

Material Specification Sheet

DISOGRIN D92S

Name:

Material:

Type:

Color:

DISOGRIN D92S

Premium polyurethane, TODI based

Injection molded

Natural

Property

Standard

Hardness

ASTM D-2240

94 3

Shore A

Hardness

Tear Strength

ASTM D-2240

ASTM D-624

43 3

45

Shore D

N/mm, Min.

Tensile Strength

Modulus @ 300% Enlongation

ASTM D-412

ASTM D-412

25

15

MPa, Min.

MPa, Min.

Elongation

Compression Set

ASTM D-412

400

% Min.

ASTM D-395 (Method B)

30

% Max.

ASTM D-573

ASTM D-573

15

30

% Max.

ASTM D-573

-50

% Max.

ASTM D-471

10

% Max.

ASTM D-471

15

% Max.

22 Hours @ 70C

Heat Age (70 Hours @ 100C)

Change in Hardness

Change in Tensile Strength

Change in Elongation

Water Resistance (70 Hours @ 100C)

Change in Hardness,

Change in Valume

Fluid Resistance, ASTM #1 Oil (70 Hours @ 100C)

Change in Hardness

ASTM D-471

Value

Units

-5 to +15

% Max

Change in Tensile Strength

Change in Elongation

ASTM D-471

ASTM D-471

-25

-45

% Max

% Max.

Change in Volume

ASTM D-471

-10 to +5

% Max.

Fluid Resistance, ASTM #3 Oil (70 Hours @ 100C)

Change in Hardness

ASTM D-471

-10 to +5

% Max.

Change in Strength

Change in Elongation

ASTM D-471

ASTM D-471

-45

-45

% Max.

% Max.

Change in Volume

ASTM D-471

0 to +25

% Max.

Important Notes:

Not to be used for specification purposes. These values serve only as a guide for engineering design. Values are

median values obtained from laboratory specimens.

Material Spec Sheet D92S 01.08.00

Material Specification Sheet

DISOGRIN D80S

Name:

Material:

Type:

Color:

DISOGRIN D80S

Premium polyurethane, TODI based

Injection molded

Natural

Property

Standard

Value

Units

Hardness

ASTM D-2240

85 3

Shore A

Tear Strength

Tensile Strength

ASTM D-624

ASTM D-412

67

25

N/mm, Min.

MPa, Min.

Modulus @ 300% Enlongation

Elongation

ASTM D-412

ASTM D-412

9

400

MPa, Min.

%, Min.

Compression Set

22 Hours @ 70C

ASTM D-395 (Method B)

35

%, Max.

Change in Hardness

ASTM D-573

15

Shore A

Change in Tensile Strength

ASTM D-573

30

% Max.

Change in Elongation

ASTM D-573

-50

% Max.

Water Resistance (70 Hrs @ 100C)

Change in Hardness,

ASTM D-471

10

% Max.

ASTM D-471

15

% Max.

Heat Age (70 Hrs @ 100C)

Change in Valume

Fluid Resistance, ASTM #1 Oil (70 Hrs @ 100C)

Change in Hardness

ASTM D-471

-5 to +15

% Max

Change in Tensile Strength

Change in Elongation

ASTM D-471

ASTM D-471

-25

-45

% Max

% Max

Change in Volume

ASTM D-471

-10 to +5

% Max

Fluid Resistance, ASTM #3 Oil (70 Hrs @ 100C)

Change in Hardness

ASTM D-471

Change in Strength

Change in Elongation

ASTM D-471

ASTM D-471

-10 to +5

% Max.

-45

-45

% Max.

% Max.

Important Notes:

Not to be used for specification purposes. These values serve only as a guide for engineering design. Values are

median values obtained from laboratory specimens.

Material Spec Sheet D80S 01.08.00

Material Specification Sheet

DISOGRIN 928

Name:

DISOGRIN 928

Material: Premium polyurethane, TODI based

Color:

Natural

Property

Standard

Value

Units

Hardness

DIN 53505

98 2

Shore A

Hardness

DIN 53505

60 5

Shore D

Specific Gravity

DIN 53479

1.20 0.02

Resilience

DIN 53512

25

Tensile Strength

DIN 53455

30

N/mm2

Elongation at Break

DIN 53455

300

300% Modulus

DIN 53455

28

N/mm2

Tear Strength

DIN 53507

90

N/mm2

Wear

DIN 53516

50

mm3

Glass Transition

-17

Low Temperature Brittleness

-50

Compression Set

24 Hrs @ 20C

DIN 53517

20

22 Hrs @ 70C

DIN 53517

35

70 Hrs @ 100C

DIN 53517

65

Important Notes:

Not to be used for specification purposes. These values serve only as a guide for engineering design. Values are

median values obtained from laboratory specimens.

Material Spec Sheet D928 01.08.00

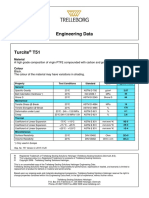

Material Specification Sheet

SIMRITAN 94 AU 925

Name:

SIMRITAN 94 AU 925

Material: Premium polyurethane, TODI based

Color:

Blue

Property

Standard

Value

Units

Specific gravity

DIN 53479

1.18

g/cm3

Hardness

DIN 53505

94

Shore A

Rebound resilience

DIN 53512

35

Modulus at 100%

DIN 53504

11.9

N/mm2

Tensile strength

DIN 53504

61.0

N/mm2

Ultimate elongation

DIN 53504

428

DIN 53517

40

Compression Set

22h @ 70C

Important Notes:

Not to be used for specification purposes. These values serve only as a guide for engineering design. Values are

median values obtained from laboratory specimens. The given values are based on a limited number of tests on

standard test pieces (2mm sheets) produced in the laboratory. The data of finished parts can deviate from above

values depending on the manufacturing process and the component geometry.

Material Spec Sheet 94AU925 01.08.00

Material Specification Sheet

SIMRITAN 98 AU 928

Name:

SIMRITAN 98 AU 928

Material: Premium polyurethane (TODI based)

Color:

Blue

Property

Standard

Value

Units

Specific gravity

DIN 53479

1.20

g/cm3

Hardness

DIN 53505

97

Shore A

Modulus at 100 %

DIN 53504

21.1

N/mm2

Tensile strength

DIN 53504

41.4

N/mm2

Ultimate elongation

DIN 53504

389

Important Notes:

Not to be used for specification purposes. These values serve only as a guide for engineering design. Values are

median values obtained from laboratory specimens. The given values are based on a limited number of tests on

standard test pieces (2mm sheets) produced in the laboratory. The data of finished parts can deviate from above

values depending on the manufacturing process and the component geometry.

Material Spec Sheet Simritan 98 AU 928 01.08.00

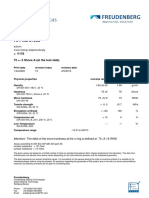

Material Specification Sheet

NOVATHAN 95 AU V142

Name:

NOVATHAN 95 AU V142

Material: Premium polyurethane, MDI based

Color:

Blue

Property

Standard

Value

Units

Durometer hardness

ASTM D-2240

95 2

Shore A

Durometer hardness

ASTM D-2240

48 3

Shore D

Density

ASTM D-792

1.20 0.01 g/cm3

Tensile strength

ASTM D-412

40

N/mm2

Elongation at break

ASTM D-412

500

Tear strength

ASTM D-624

120

N/mm

Rebound resilience

DIN 53512

42

Abrasion

DIN 53516

18

mm3

ASTM D-395 (Method B)

27

ASTM D-395 (Method B)

24

ASTM D-395 (Method B)

26

Compression set

70h/70C, 25% compression

Compression set

24h/100C, 25% compression

Compression Set

70h/70C, 25% compression

Important Notes:

Not to be used for specification purposes. These values serve only as a guide for engineering design. Values are

median values obtained from laboratory specimens. The given values are based on a limited number of tests on

standard test pieces (2mm sheets) produced in the laboratory. The data of finished parts can deviate from above

values depending on the manufacturing process and the component geometry.

Material Spec Sheet NOVATHAN 01.08.00

Material Specification Sheet

Merkel 70 NBR B209

Name:

Merkel 70 NBR B209

Material: NBR (Acrylonitrile Bunadiene Rubber)

Color:

Black

Property

Standard

Value

Units

Density

1.20 0.02 g/cm3

Hardness

70 5

SHORE A

Hardness

70 5

IRHD

Tensile Strength

11

N/MM

Ultimate Elongation

250

Modulus 100% Elongation*

4.4

N/mm 2

Tear Strength*

11

N/mm

ASTM Oil I (168 hr/100C)

-5.4

ASTM Oil III (168 hr/100C)

13

ASTM Oil I (168 hr/100C)

Point

ASTM Oil III (168 hr/100C)

-8

Point

Change In Volume*

Change In Hardness*

Compression Set

24 hr/70C

DIN 53517

11

70 hr/100C

DIN 53517

23

24 hr/70C

ASTMD 395 B

10

70 hr/100C

ASTM-D 395 B

15

*Typical Properties

Important Notes:

Not to be used for specification purposes. These values serve only as a guide for engineering design. Values are

median values obtained from laboratory specimens. The given values are based on a limited number of tests on

standard test pieces (2mm sheets) produced in the laboratory. The data of finished parts can deviate from above

values depending on the manufacturing process and the component geometry.

Material Spec Sheet 70 NBR B209 01.08.00

Material Specification Sheet

Merkel 70 NBR B276

Name:

Merkel 70 NBR B276

Material: NBR (Acrylonitrile Bunadiene Rubber)

Color:

Black

Property

Standard

Value

Units

Density

DIN 53479

1.23 0.02 g/cm3

Hardness

DIN 53505

70 5

Shore A

Hardness

DIN 53519

73 5

IRHD

Tensile Strength

DIN 53504

14

N/mm2

Ultimate Elongation

DIN 53504

280

Modulus 100% Elongation

DIN 53504

N/mm2

Resistance To Tear Propagation

DIN 53515

18

N/mm2

Low Temperature Reference Value TR

DIN 53520

-22

Brittle Point TS

DIN 53546

-50

ASTM Oil I (168 hr/100C)

-5

ASTM Oil III (168 hr/100C)

11

ASTM Oil I (168 hr/100C)

Points

ASTM Oil III (168 hr/100C)

-6

Points

Change In Volume

Change In Hardness

Compression Set

24 hr /70C

DIN 53517

17

70 hr /100C

DIN 53517

32

24 hr /70C

ASTM-D 395 B

12

70 hr /100C

ASTM-D 395 B

20

Important Notes:

Not to be used for specification purposes. These values serve only as a guide for engineering design. Values are

median values obtained from laboratory specimens. The given values are based on a limited number of tests on

standard test pieces (2mm sheets) produced in the laboratory. The data of finished parts can deviate from above

values depending on the manufacturing process and the component geometry.

Material Spec Sheet 85 NBR 70 B276 01.08.00

Material Specification Sheet

Merkel 72 NBR 872

Name:

Merkel 72 NBR 872

Material: NBR (Acrylonitrile Bunadiene Rubber)

Color:

Black

Property

Standard

Value

Units

Specific gravity

DIN 53479

1.21

g/cm2

Hardness

DIN 53505

72

Shore A

Rebound resilience

DIN 53512

34

Modulus at 100 %

DIN 53504

6.5

N/mm2

Tensile strength

DIN 53504

16.5

N/mm2

Ultimate elongation

DIN 53504

270

Compression set (22 hr/100C)

DIN 53517

20

Important Notes:

Not to be used for specification purposes. These values serve only as a guide for engineering design. Values are

median values obtained from laboratory specimens. The given values are based on a limited number of tests on

standard test pieces (2mm sheets) produced in the laboratory. The data of finished parts can deviate from above

values depending on the manufacturing process and the component geometry.

Material Spec Sheet Simrit 72 NBR 872 01.08.00

Material Specification Sheet

Merkel 79 NBR B246

Name:

Merkel 79 NBR B246

Material: NBR (Acrylonitrile Bunadiene Rubber)

Color:

Black

Property

Standard

Value

Units

Density

DIN 53479

1.22 0.02 g/cm3

Hardness

DIN 53505

78 5

Shore A

Hardness

DIN 53519

78 5

IRHD

Tensile Strength

DIN 53504

10.5

N/mm2

Ultimate Elongation

DIN 53504

250

Modulus 100% Elongation*

DIN 53504

6.5

N/mm2

Tear Strength*

DIN 53515

16

N/mm

ASTM Oil I (168 hr/100C)

-1.7

ASTM Oil III (168 hr/100C)

16

ASTM Oil I (168 hr/100C)

Points

ASTM Oil III (168 hr/100C)

-12

Points

Change In Volume*

Change In Hardness*

Compression Set

24 hr/70C

DIN 53517

15

70 hr/100C

DIN 53517

40

24hr/70C

ASTM-D 395 B

14

70 hr/100C

ASTM-D 395 B

26

*Typical Properties

Important Notes:

Not to be used for specification purposes. These values serve only as a guide for engineering design. Values are

median values obtained from laboratory specimens. The given values are based on a limited number of tests on

standard test pieces (2mm sheets) produced in the laboratory. The data of finished parts can deviate from above

values depending on the manufacturing process and the component geometry.

Material Spec Sheet 79 NBR B246 01.08.00

Material Specification Sheet

Merkel 80 NBR 709

Name:

Merkel 80 NBR 709

Material: NBR (Acrylonitrile Bunadiene Rubber)

Color:

Black

Property

Standard

Value

Units

Specific gravity

DIN 53479

1.27

g/cm2

Hardness

DIN 53505

82

Shore A

Rebound resilience

DIN 53512

29

Modulus at 100 %

DIN 53504

10.2

N/mm2

Tensile strength

DIN 53504

16.9

N/mm2

Ultimate elongation

DIN 53504

290

Compression set (22 hr/100C)

DIN 53517

25

Important Notes:

Not to be used for specification purposes. These values serve only as a guide for engineering design. Values are

median values obtained from laboratory specimens. The given values are based on a limited number of tests on

standard test pieces (2mm sheets) produced in the laboratory. The data of finished parts can deviate from above

values depending on the manufacturing process and the component geometry.

Material Spec Sheet Simrit 80 NBR 709 01.08.00

Material Specification Sheet

Merkel 80 NBR 878

Name:

Merkel 80 NBR 878

Material: NBR (Acrylonitrile Bunadiene Rubber)

Color:

Black

Property

Standard

Value

Units

Specific gravity

DIN 53479

1.30

g/cm2

Hardness

DIN 53505

83

Shore A

Rebound resilience

DIN 53512

26

Modulus at 100 %

DIN 53504

10.5

N/mm2

Tensile strength

DIN 53504

15.5

N/mm2

Ultimate elongation

DIN 53504

170

Compression set (22 hr/100C)

DIN 53517

20

Important Notes:

Not to be used for specification purposes. These values serve only as a guide for engineering design. Values are

median values obtained from laboratory specimens. The given values are based on a limited number of tests on

standard test pieces (2mm sheets) produced in the laboratory. The data of finished parts can deviate from above

values depending on the manufacturing process and the component geometry.

Material Spec Sheet Simrit 80 NBR 878 01.08.00

Material Specification Sheet

Merkel 85 NBR B248

Name:

Merkel 85 NBR B248

Material: NBR (Acrylonitrile Bunadiene Rubber)

Color:

Black

Property

Standard

Value

Units

Density

DIN 53479

1.37 0.02

g/cm3

Hardness

DIN 53505

84 5

Shore A

Hardness

DIN 53519

86 5

IRHD

Tensile Strength

DIN 53504

14

N/mm2

Ultimate Elongation

DIN 53504

200

Modulus 100 % Elongation*

DIN 53504

5.8

N/mm2

Tear Strength*

DIN 53515

30

N/mm

ASTM Oil I

168hr/100C

-3.5

ASTM Oil III

168hr/100C

11

ASTM Oil I

168hr/100C

Points

ASTM Oil III

168hr/100C

-7

Points

24 hr/70C

DIN 53517

35

70 hr/100C

DIN 53517

55

24 hr/70C

ASTM-D 395 B

30

70 hr/100C

ASTM-D 395 B

55

Change In Volume*

Change In Hardness*

Compression Set

*Typical Properties

Important Notes:

Not to be used for specification purposes. These values serve only as a guide for engineering design. Values are

median values obtained from laboratory specimens. The given values are based on a limited number of tests on

standard test pieces (2mm sheets) produced in the laboratory. The data of finished parts can deviate from above

values depending on the manufacturing process and the component geometry.

Material Spec Sheet 85 NBR BI B248 01.08.00

Material Specification Sheet

Merkel 87 NBR B247

Name:

Merkel 87 NBR B247

Material: NBR (Acrylonitrile Bunadiene Rubber)

Color:

Black

Property

Standard

Value

Units

Density

DIN 53479

1.25 0.02 g/cm3

Hardness

DIN 53505

86 5

Shore A

Hardness

DIN 53519

87 5

IRHD

Tensile Strength

DIN 53504

17.5

N/mm2

Ultimate Elongation

DIN 53504

200

Modulus (100% Elongation*)

DIN 53504

8.8

N/mm2

Tear Strength*

DIN 53515

21

N/mm

ASTM Oil I (168 hr/100C)

-2.5

ASTM Oil III (168 hr/100C)

12.6

168hr/100C

Point

168hr/100C

-10

Point

Change In Volume*

Change In Hardness*

Compression Set

24 hr/70C

DIN 53517

20

70 hr/100C

DIN 53517

35

24 hr/70C

ASTM-D 395 B

20

70 hr/100C

ASTM-D 395 B

33

*Typical Properties

Important Notes:

Not to be used for specification purposes. These values serve only as a guide for engineering design. Values are

median values obtained from laboratory specimens. The given values are based on a limited number of tests on

standard test pieces (2mm sheets) produced in the laboratory. The data of finished parts can deviate from above

values depending on the manufacturing process and the component geometry.

Material Spec Sheet 87 NBR B247 01.08.00

Material Specification Sheet

Merkel 88 NBR 101

Name:

Merkel 88 NBR 101

Material: NBR (Acrylonitrile Bunadiene Rubber)

Color:

Black

Property

Standard

Value

Units

Specific gravity

DIN 53479

1.41

g/cm2

Hardness

DIN 53505

90

Shore A

Rebound resilience

DIN 53512

18

Modulus at 100 %

DIN 53504

8.0

N/mm2

Tensile strength

DIN 53504

13.5

N/mm2

Ultimate elongation

DIN 53504

230

Compression set (22 hr/100C)

DIN 53517

43

Important Notes:

Not to be used for specification purposes. These values serve only as a guide for engineering design. Values are

median values obtained from laboratory specimens. The given values are based on a limited number of tests on

standard test pieces (2mm sheets) produced in the laboratory. The data of finished parts can deviate from above

values depending on the manufacturing process and the component geometry.

Material Spec Sheet Simrit 88 NBR 101 01.08.00

Material Specification Sheet

Merkel 90 NBR B283

Name:

Merkel 90 NBR B283

Material: NBR (Acrylonitrile Bunadiene Rubber)

Color:

Black

Property

Standard

Value

Units

Density

DIN 53479

1.30 0.02 g/cm3

Hardness

DIN 53505

93 5

Shore A

Hardness

DIN 53519

93 5

IRHD

Tensile Strength

DIN 53504

14

N/mm2

Ultimate Elongation

DIN 53504

100

Tear Strength*

DIN 53515

19

N/mm

ASTM Oil I

168hr / 100 C

-3.5

ASTM Oil III

168hr / 100 C

ASTM Oil I

168hr / 100 C

Points

ASTM Oil III

168hr / 100 C

-5

Points

24 hr / 70 C

DIN 53517

18

70 hr / 100 C

DIN 53517

32

24 hr / 70 C

ASTM-D 395 B

16

70 hr / 100 C

ASTM-D 395 B

26

Change in Volume

Change in Hardness*

Compression Set

*Typical Properties

Important Notes:

Not to be used for specification purposes. These values serve only as a guide for engineering design. Values are

median values obtained from laboratory specimens. The given values are based on a limited number of tests on

standard test pieces (2mm sheets) produced in the laboratory. The data of finished parts can deviate from above

values depending on the manufacturing process and the component geometry.

Material Spec Sheet 90 NBR B283 01.08.00

Material Specification Sheet

Merkel 70 FPM K682

Name: Merkel 70 FPM K682

Material: FPM (Fluoroelastomer)

Property

Standard

Value

Units

Density

DIN 53479

1.85 0.02 g/cm3

Hardness

DIN 53505

70 5

Shore A

Hardness

DIN 53519

69 5

IRHD

Tensile Strength

DIN 53504

10

N/mm2

Ultimate Elongation

DIN 53504

150

Modulus 100% Elongation

DIN 53504

5.7

N/mm2

Resistance To Tear Propagation

DIN 53515

10

N/mm2

ASTM Oil III (70 hr/150C)

1.8

Service Fluid No. (101 70hr/200C)

10

ASTM Oil III (70 hr/150C)

Points

Service Fluid No.101

-6

Points

Change In Volume

Change In Hardness

Compression Set

70 hr/100C

DIN 53517

14

70 hr/200C

DIN 53517

28

Important Notes:

Not to be used for specification purposes. These values serve only as a guide for engineering design. Values are

median values obtained from laboratory specimens. The given values are based on a limited number of tests on

standard test pieces (2mm sheets) produced in the laboratory. The data of finished parts can deviate from above

values depending on the manufacturing process and the component geometry.

Material Spec Sheet 70 FPM K682 01.08.00

Material Specification Sheet

Merkel 70 FPM K655

Name:

Merkel 70 FPM K655

Material: FPM (Fluoroelastomer)

Color:

Black

Property

Standard

Value

Units

Density

DIN 53479

1.90 0.02 g/cm3

Hardness

DIN 53505

76 5

Shore A

Hardness

DIN 53519

76 5

IRHD

Tensile Strength

DIN 53504

12

N/mm 2

Ultimate Elongation

DIN 53504

140

Modulus %100 Elongation

DIN 53504

M/mm2

Resistance To Tear Propagation

DIN 53515

13.5

N/mm2

ASTM III (70 hr/150C)

Service Fluid No. 101

9.5

ASTM Oil III (70 hr/150C)

-2

Points

Service Fluid No. 101

-7

Points

Change In Volume

Change In Hardness

Compression Set

70 hr/100C

DIN 53517

13

70 hr/200C

DIN 53517

25

70 hr/100C

ASTM-D 395 B

10

70 hr/200C

ASTM-D 395 B

20

Important Notes:

Not to be used for specification purposes. These values serve only as a guide for engineering design. Values are

median values obtained from laboratory specimens. The given values are based on a limited number of tests on

standard test pieces (2mm sheets) produced in the laboratory. The data of finished parts can deviate from above

values depending on the manufacturing process and the component geometry.

Material Spec Sheet 70 FPM K655 01.08.00

Material Specification Sheet

Merkel HGW HG600

Name:

HGW HG600

Material: Fabric Reinforced Resin

Color:

Blue

Property

Standard

Value

Units

Compression Strength

DIN 53454

340

N/mm2

Flexural Strength

DIN 53452

100

N/mm2

Ball impression hardness at 23C

DIN 53456

110

N/mm2

Specific gravity

DIN 53479

1.25-1.48

g/cm3

Water absorption after 24h at 23C

DIN 53495

<1

Water absorption (to saturation point)

DIN 53495

<4

Coefficient of thermal expansion

VDE 0304

60-70 x 10

Temperature limit

DIN 53479

120

%

-6

1/K

C

Important Notes:

Not to be used for specification purposes. These values serve only as a guide for engineering design. Values are

median values obtained from laboratory specimens. The given values are based on a limited number of tests on

standard test pieces (2mm sheets) produced in the laboratory. The data of finished parts can deviate from above

values depending on the manufacturing process and the component geometry.

Material Spec Sheet HGW HG600 01.08.00

Você também pode gostar

- Material Spec Sheets PolyurethaneDocumento21 páginasMaterial Spec Sheets PolyurethaneVũ GiangAinda não há avaliações

- Zurcon Z80 PDFDocumento1 páginaZurcon Z80 PDFLuz SmithAinda não há avaliações

- Datasheets E FDMDocumento5 páginasDatasheets E FDMAlireza YaghoubiAinda não há avaliações

- Rubber Elements PropertiesDocumento1 páginaRubber Elements PropertiesMa ProvoloneAinda não há avaliações

- Glass Fiber Reinforced PBT Material Injection Molding Grade Pellets / GranulesDocumento2 páginasGlass Fiber Reinforced PBT Material Injection Molding Grade Pellets / GranulesmuthuAinda não há avaliações

- FFKM Material SheetDocumento1 páginaFFKM Material Sheetmarco SimonelliAinda não há avaliações

- Material NBR NB807101: Technical Data Sheet in Accordance With ASTMDocumento2 páginasMaterial NBR NB807101: Technical Data Sheet in Accordance With ASTMDacetIronForceAinda não há avaliações

- TPU technical data sheetDocumento2 páginasTPU technical data sheetElőd JobbAinda não há avaliações

- 3M™ Adhesive Transfer Tape 966_20231209Documento10 páginas3M™ Adhesive Transfer Tape 966_20231209Son NguyenAinda não há avaliações

- 3M™ Adhesive Transfer Tape 9471 - 20231201Documento8 páginas3M™ Adhesive Transfer Tape 9471 - 20231201dsfasdfafsAinda não há avaliações

- 3M™ Adhesive Transfer Tape 950 - 20240112Documento8 páginas3M™ Adhesive Transfer Tape 950 - 20240112qualityAinda não há avaliações

- Material FKM FP801801: Technical Data Sheet in Accordance With ASTMDocumento3 páginasMaterial FKM FP801801: Technical Data Sheet in Accordance With ASTMElőd JobbAinda não há avaliações

- 94 AU 925-EnDocumento2 páginas94 AU 925-EnDaniel CringusAinda não há avaliações

- TDS Co-3-X 27 03 2018 (003) - 1687274055Documento2 páginasTDS Co-3-X 27 03 2018 (003) - 1687274055KSXAinda não há avaliações

- Rhodia - Tds - Technylstar S 218 v30 Black 31 N - enDocumento5 páginasRhodia - Tds - Technylstar S 218 v30 Black 31 N - ennimonhAinda não há avaliações

- TDBL - Polystone P Grey Homopolymer - GBDocumento1 páginaTDBL - Polystone P Grey Homopolymer - GBreinpolyAinda não há avaliações

- ALUBOND SpecificationsDocumento2 páginasALUBOND SpecificationssoosanantonyAinda não há avaliações

- Gazguard 026: Units Typical Value Initial PropertyDocumento2 páginasGazguard 026: Units Typical Value Initial PropertyTeguh SetionoAinda não há avaliações

- 80 NBR 878Documento2 páginas80 NBR 878adhityaAinda não há avaliações

- Typical Physical Properties - AsiaPolyDocumento1 páginaTypical Physical Properties - AsiaPolyasiapolyAinda não há avaliações

- Turcite T51 Engineering DataDocumento1 páginaTurcite T51 Engineering DataAntonio Rivera VillavicencioAinda não há avaliações

- Marco Material Datasheet V1005Documento2 páginasMarco Material Datasheet V1005Bib GmzAinda não há avaliações

- DIN 7060 Curcular Sight Glass PDFDocumento14 páginasDIN 7060 Curcular Sight Glass PDFalathekoala100% (2)

- Charla Ing. Andreas Hunger - Nuevas Tendencias en El ProcesoDocumento39 páginasCharla Ing. Andreas Hunger - Nuevas Tendencias en El ProcesoWalter-uniAinda não há avaliações

- FKM 37508 Material PropertiesDocumento2 páginasFKM 37508 Material PropertiesXavierAinda não há avaliações

- Thermoplastic Elastomers - Tension'.: ASTM D412Documento2 páginasThermoplastic Elastomers - Tension'.: ASTM D412techzonesAinda não há avaliações

- NBR 70.10-02Documento3 páginasNBR 70.10-02titi suryaniAinda não há avaliações

- 23 M-AstDocumento4 páginas23 M-AstLegi YangAinda não há avaliações

- 4376 Industrial Gear Oil CLP 320Documento1 página4376 Industrial Gear Oil CLP 320ralish12Ainda não há avaliações

- 31barg CalculationDocumento10 páginas31barg Calculationshani5573Ainda não há avaliações

- ELITE 5401G: Blown Film ResinDocumento2 páginasELITE 5401G: Blown Film ResinEndayenew MollaAinda não há avaliações

- 95 AU V 142-EnDocumento2 páginas95 AU V 142-EnDaniel CringusAinda não há avaliações

- Technical Data SheetDocumento2 páginasTechnical Data SheetLeductoan LeAinda não há avaliações

- Elastomeric Bearing Pads SpecificationsDocumento5 páginasElastomeric Bearing Pads SpecificationsMad WonderAinda não há avaliações

- Chemonit 181Documento4 páginasChemonit 181Zack OsAinda não há avaliações

- Raise3d Premium PETG TDS V3Documento3 páginasRaise3d Premium PETG TDS V3Faris AlmarshadAinda não há avaliações

- KOPA® KN333G40SIBL: Properties Measurement Condition Test Method Unit Typical ValueDocumento2 páginasKOPA® KN333G40SIBL: Properties Measurement Condition Test Method Unit Typical Valuehugo santiago chavez godoyAinda não há avaliações

- (AdvanSix) (TDS) Aegis H135ZPDocumento3 páginas(AdvanSix) (TDS) Aegis H135ZPMarcos KodairaAinda não há avaliações

- LG PVC Ls100H: Straight PVC: Extrusion GradeDocumento1 páginaLG PVC Ls100H: Straight PVC: Extrusion GradeJhon Angel Molina LeonAinda não há avaliações

- Global's New High Performance PE4710 MaterialDocumento5 páginasGlobal's New High Performance PE4710 MaterialIván López PavezAinda não há avaliações

- NBR 60.10-01Documento1 páginaNBR 60.10-01UcokAinda não há avaliações

- SuperS InhibitedTransformerOil SpecDocumento2 páginasSuperS InhibitedTransformerOil Spechhahn01Ainda não há avaliações

- GP100ORXP enUS ASTMDocumento1 páginaGP100ORXP enUS ASTMRaul ArmendarizAinda não há avaliações

- Filament Specifications Unit ValueDocumento4 páginasFilament Specifications Unit ValueRoberto Gonzalo PelazAinda não há avaliações

- Blown Film Resin - ELITE 5400G Enhanced PolyethyleneDocumento2 páginasBlown Film Resin - ELITE 5400G Enhanced PolyethyleneEndayenew MollaAinda não há avaliações

- Selective Laser SinteringDocumento12 páginasSelective Laser SinteringMihai CitcauanAinda não há avaliações

- Silicone Rubber Sheet (General Purpose, Solid)Documento2 páginasSilicone Rubber Sheet (General Purpose, Solid)MohamedAinda não há avaliações

- LG PVC Ls100H: Straight PVC: Extrusion GradeDocumento1 páginaLG PVC Ls100H: Straight PVC: Extrusion GradeKishan PatelAinda não há avaliações

- Technical Data SheetDocumento3 páginasTechnical Data SheetAbdul BasithAinda não há avaliações

- Technical datasheet rubber fenders propertiesDocumento1 páginaTechnical datasheet rubber fenders propertiesFandy SipataAinda não há avaliações

- Green Cast Setacryl UKDocumento4 páginasGreen Cast Setacryl UKgillestalbotAinda não há avaliações

- Material PTFE PT000702: Technical Data Sheet in Accordance With ASTMDocumento2 páginasMaterial PTFE PT000702: Technical Data Sheet in Accordance With ASTMpitrer123Ainda não há avaliações

- Braskem Braskem PP PCD 0140BR Polypropylene Impact CopolymerDocumento2 páginasBraskem Braskem PP PCD 0140BR Polypropylene Impact CopolymerBFCAinda não há avaliações

- Af-200 Universal AngDocumento4 páginasAf-200 Universal AngGeorgi KalchevAinda não há avaliações

- Filament Specifications Unit ValueDocumento4 páginasFilament Specifications Unit ValueRoberto Gonzalo PelazAinda não há avaliações

- Technical Data SheetDocumento2 páginasTechnical Data SheetIVANCHUAinda não há avaliações

- Jotaguard RBDocumento2 páginasJotaguard RBSatish VishnubhotlaAinda não há avaliações

- P004525 Megol Motorenoel Future LL 12 FE SAE 0W 30 20 en - GBDocumento1 páginaP004525 Megol Motorenoel Future LL 12 FE SAE 0W 30 20 en - GBJavier AneirosAinda não há avaliações

- 04 Casting HandoutsDocumento23 páginas04 Casting HandoutsAnand KumarAinda não há avaliações

- Much - ManyDocumento1 páginaMuch - ManyAdityaDeshmukhAinda não há avaliações

- Sherlock Hlomes StoriesDocumento221 páginasSherlock Hlomes StoriesAdityaDeshmukhAinda não há avaliações

- Centrifugal CastingDocumento8 páginasCentrifugal Castingassignment2012Ainda não há avaliações

- Chapter 8. Conjugations With The Auxiliary WouldDocumento6 páginasChapter 8. Conjugations With The Auxiliary Wouldbáh_leeAinda não há avaliações

- 6081HF001 I S0 R0Documento2 páginas6081HF001 I S0 R0AdityaDeshmukh100% (1)

- History of The Camless EngineDocumento19 páginasHistory of The Camless EngineAdityaDeshmukh100% (1)

- Robust Design and Taguchi MethodsDocumento6 páginasRobust Design and Taguchi MethodsAdityaDeshmukhAinda não há avaliações

- Chapter 8. Conjugations With The Auxiliary WouldDocumento6 páginasChapter 8. Conjugations With The Auxiliary Wouldbáh_leeAinda não há avaliações

- Making Windows XP Start 60% Faster Code: Whenever You StartDocumento7 páginasMaking Windows XP Start 60% Faster Code: Whenever You StartToronto_ScorpionsAinda não há avaliações

- Modal Form BasicsDocumento2 páginasModal Form BasicsAdityaDeshmukhAinda não há avaliações

- Who, Whom, Whose - What, WhichDocumento2 páginasWho, Whom, Whose - What, WhichAdityaDeshmukhAinda não há avaliações

- Diesel EngineDocumento2.033 páginasDiesel EngineAdityaDeshmukhAinda não há avaliações

- Four Stroke Diesel EngineDocumento185 páginasFour Stroke Diesel EngineAdityaDeshmukh0% (1)

- Forming Comparative and Superlative AdjectivesDocumento4 páginasForming Comparative and Superlative Adjectivesoe2sayoeAinda não há avaliações

- A Little A FewDocumento1 páginaA Little A FewJoseph Eric NardoAinda não há avaliações

- WealthDocumento28 páginasWealthAdityaDeshmukhAinda não há avaliações

- Do or MakeDocumento2 páginasDo or MakeAdityaDeshmukhAinda não há avaliações

- BS EN 1992-1-1:2004 Slenderness criteria for isolated compression membersDocumento2 páginasBS EN 1992-1-1:2004 Slenderness criteria for isolated compression membersLại Tiến PhongAinda não há avaliações

- 3 Tier Grillage Design CalculationDocumento5 páginas3 Tier Grillage Design CalculationDebesh KuanrAinda não há avaliações

- Rankine-Froude Model: Blade Element Momentum Theory Is A Theory That Combines BothDocumento111 páginasRankine-Froude Model: Blade Element Momentum Theory Is A Theory That Combines BothphysicsAinda não há avaliações

- Introduction To ThermodynamicsDocumento12 páginasIntroduction To ThermodynamicsEstanislao Amadeo AvogadroAinda não há avaliações

- Physics Chapter 5 Test A - Work, Energy, PowerDocumento4 páginasPhysics Chapter 5 Test A - Work, Energy, PowerCamdrn WrightAinda não há avaliações

- AISC Basic Steel Design Session 6 - Stability Analysis and Design I 10-29-2013Documento28 páginasAISC Basic Steel Design Session 6 - Stability Analysis and Design I 10-29-2013Eric RicoAinda não há avaliações

- ASNT Level II Study Guide-Ultrasonic Testing Method (UT) - Third EditionDocumento93 páginasASNT Level II Study Guide-Ultrasonic Testing Method (UT) - Third EditionMOHAMMAD RAMZAN100% (1)

- BEAM SampleDocumento70 páginasBEAM SampleAira Joyce Salazar100% (1)

- Admin Instructions - MA3003 - S2 AY 2014-15Documento3 páginasAdmin Instructions - MA3003 - S2 AY 2014-15johnconnorAinda não há avaliações

- In A Sliding Pair Minimum Number of Degree of FreedomDocumento15 páginasIn A Sliding Pair Minimum Number of Degree of FreedomanuanwarAinda não há avaliações

- Ancient Greek Astronomers Measure Solar SystemDocumento4 páginasAncient Greek Astronomers Measure Solar Systemhoangnghia_hcmupAinda não há avaliações

- Week10 11Documento49 páginasWeek10 11LilyAinda não há avaliações

- LR Bachelor 2018 ENDocumento63 páginasLR Bachelor 2018 ENdaniel dusAinda não há avaliações

- Me 2202Documento2 páginasMe 2202pandikalaiAinda não há avaliações

- Theory of MachinesDocumento3 páginasTheory of Machinesjaspreet singh100% (1)

- Mechanical Energy Balance Intro and OverviewDocumento33 páginasMechanical Energy Balance Intro and OverviewGarcia RaphAinda não há avaliações

- Unit 3 One Marks QuestionsDocumento6 páginasUnit 3 One Marks QuestionsRahulAinda não há avaliações

- MD ProbsetDocumento27 páginasMD ProbsetRicky AlamoAinda não há avaliações

- Ductility by ChinnarajuDocumento76 páginasDuctility by ChinnarajuRamen KishoreAinda não há avaliações

- Advanced Thermodynamics-3Documento59 páginasAdvanced Thermodynamics-3Onggy Aries SekaAinda não há avaliações

- Linear Failure Criteria With Three Principal StressesDocumento74 páginasLinear Failure Criteria With Three Principal StressesAgroEmpresario ExportadorAinda não há avaliações

- Characteristics of Wear Result Tested by Pin On Disc at Moderate To High SpeedsDocumento9 páginasCharacteristics of Wear Result Tested by Pin On Disc at Moderate To High SpeedsDavid Rafael RamírezAinda não há avaliações

- 2 - FLDS 385 Chapter 2 Principles of HydraulicsDocumento47 páginas2 - FLDS 385 Chapter 2 Principles of HydraulicsAvneet MultaniAinda não há avaliações

- Dynamics Model of A Four-Wheeled Mobile Robot For Control Applications - A Three-Case StudyDocumento18 páginasDynamics Model of A Four-Wheeled Mobile Robot For Control Applications - A Three-Case StudyirhoAinda não há avaliações

- HeatTransferModuleUsersGuide PDFDocumento580 páginasHeatTransferModuleUsersGuide PDFjmiscAinda não há avaliações

- Anchor Bolt and Circular Base Plate Design As Per BS 5950Documento16 páginasAnchor Bolt and Circular Base Plate Design As Per BS 5950Shamim Ahsan ZuberyAinda não há avaliações

- Numerical Analysis of Composite Steel-Concrete Columns of Arbitrary Cross SectionDocumento10 páginasNumerical Analysis of Composite Steel-Concrete Columns of Arbitrary Cross SectionNasar KhanAinda não há avaliações

- Chapter-04-Applications-Thermodynamics-Earth 4744 0 PDFDocumento43 páginasChapter-04-Applications-Thermodynamics-Earth 4744 0 PDFJou IndrajatiAinda não há avaliações

- Column New EC2 LastDocumento81 páginasColumn New EC2 LastsuniljayaAinda não há avaliações

- Simple Harmonic Motion Multiple Choice 2013 07 11 PDFDocumento4 páginasSimple Harmonic Motion Multiple Choice 2013 07 11 PDFYuusuf AhmedAinda não há avaliações