Escolar Documentos

Profissional Documentos

Cultura Documentos

Anaerobic Co-Digestion of Algal Sludge and Waste Paper To Produce Methane

Enviado por

Ika SulistyaningtiyasDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Anaerobic Co-Digestion of Algal Sludge and Waste Paper To Produce Methane

Enviado por

Ika SulistyaningtiyasDireitos autorais:

Formatos disponíveis

Bioresource Technology 98 (2007) 130134

Anaerobic co-digestion of algal sludge and waste paper

to produce methane

Hong-Wei Yen

a

a,

, David E. Brune

Department of Chemical Engineering, Tunghai University, Taiwan, ROC

Department of Biosystems Engineering, Clemson University, SC, USA

Received 6 June 2005; received in revised form 11 November 2005; accepted 12 November 2005

Available online 4 January 2006

Abstract

The unbalanced nutrients of algal sludge (low C/N ratio) were regarded as an important limitation factor to anaerobic digestion process. Adding high carbon content of waste paper in algal sludge feedstock to have a balanced C/N ratio was undertaken in this study. The

results showed adding 50% (based on volatile solid) of waste paper in algal sludge feedstock increased the methane production rate to

1170 75 ml/l day, as compared to 573 28 ml/l day of algal sludge digestion alone, both operated at 4 g VS/l day, 35 C and 10 days

HRT. The maximum methane production rate of 1607 17 ml/l day was observed at a combined 5 g VS/l day loading rate with 60% (VS

based) of paper adding in algal sludge feedstock. Results suggested an optimum C/N ratio for co-digestion of algal sludge and waste

paper was in the range of 2025/1.

2005 Elsevier Ltd. All rights reserved.

Keywords: Anaerobic digestion; Co-digestion; C/N; Methane; Algal sludge

1. Introduction

The recently patented Partitioned Aquaculture System (PAS) has been proven to be able to increase aquaculture production capacity by improving pond waste nutrient

treatment (Brune et al., 2001). In the PAS, algae play a dual

role, as both an oxygen supplier to the Wsh and as a waste

nutrient cleaner. The capacity of Wsh production in the PAS

has been demonstrated to be four times greater than that of

conventional aquaculture and also at the same time the

wastewater discharges are signiWcantly decreased. However

concentrated algal sludge production from the PAS must

be continually removed from the ponds to control algal

density and water column respiration. The large amount of

algal sludge represents a potential source of fuel and recovered N and P fertilizer (Mulbry et al., 2005). Anaerobic

digestion of algal sludge produced from the PAS can not

*

Corresponding author. Tel.: +886 4 235 90 262x209; fax: +886 4 235 90

009.

E-mail address: hwyen@thu.edu.tw (H.-W. Yen).

0960-8524/$ - see front matter 2005 Elsevier Ltd. All rights reserved.

doi:10.1016/j.biortech.2005.11.010

only decrease the amount of waste to be handled, but also

yields methane to oVset the energy needs of the PAS achieving a sustainable aquaculture production system.

The solar energy stored in the algal biomass in results of

the photosynthesis reaction could be released as methane

through the anaerobic digestion. This concept was originally proposed over 40 years ago in a paper by Oswald and

Golueke (1960), describing integrated processes of largescale raceway pond cultivation of microalgae and wastewater treatment, followed by fermentation of algal biomass to

methane fuel. Due to the recalcitrant of algal sludge to biodegradation, Chen and Oswald (1998) found the heat pretreatment of algal sludge at 100 C for 8 h could improve

the eYciency of methane fermentation a maximum at 33%.

However, the improvement on the methane energy produced would not be economically competitive to the energy

lost on the heat pretreatment.

Except for the resistant to biodegradation, the low C/N

ratio of algal sludge is also a serious problem to the anaerobic digestion. Although, an optimum C/N range in feedstock for the anaerobic digestion is still debatable in the

H.-W. Yen, D.E. Brune / Bioresource Technology 98 (2007) 130134

literature, 20/130/1 is a most acceptable range (Parkin and

Owen, 1986). The C/N ratio in algal sludge is about 6/1,

which is too low for the digestion. Low C/N ratio feedstock

could result in high total ammonia nitrogen (TAN)

released and high volatile fatty acids (VFAs) accumulated

in the digester. The TAN and VFAs both are important

intermediates and potential inhibitors in the anaerobic

digestion process (Parkin and Owen, 1986). High concentration of TAN and VFAs in the digester would decrease

the methanogen activity and further accumulation could

fail the anaerobic digestion. One method to avoid excessive

ammonia accumulation is to adjust low feedstock C/N

ratios by adding high carbon content materials, thereby

improving the digestion performance. This practice has

been used for co-digestion of sewage sludge and municipal

solid waste (MSW) (Sosnowaki et al., 2003). Most MSW

consists of paper material (including oYce and newspaper),

which has a C/N ratio ranging from 173/1 to greater than

1000/1 while typical sewage sludge has a C/N ratio ranging

from 6/1 to 16/1 (Stroot et al., 2001). Co-digestion of cattle

manure slurry with fruit, vegetable wastes and chicken

manures is another example of successful blending of high

C/N and low C/N feedstocks to improve digester performance (Callaghan et al., 2002). Co-digestion of sisal pulp

and Wsh wastes had shown a 5994% increased in the methane production yield as compared to sisal pulp and Wsh

wastes digestion alone (Mshandete et al., 2004). The beneWts of co-digestion include: dilution of potentially toxic

ammonia, allowing for increased loading rate and

improved biogas yield (Sosnowaki et al., 2003).

The purpose of this work was to assess the possibility of

co-digestion of algal sludge and high carbon content of

waste paper at diVerent fraction to produce methane and

evaluate the waste paper adding eVects on the methane production.

2. Methods

2.1. Anaerobic digestion experiments

Bench-top anaerobic digesters with gas storage tanks

were fabricated from 25 mm Plexiglas sheet and contained

with a temperature-controlled water bath at 35 1 C.

Digesters were connected to gas storage tanks and gas sampling ports using silicone tube. The digester and gas storage

tank measured 12.5 14 30 cm and 16.5 15.2 30 cm,

respectively (working volume, 4l). Semi-continuously feeding type was adopted and digesters were fed once per day

following the removal of the same volume of eZuent. Hand

mixing of the digester was performed with a permanently

installed mixing rod prior to eZuent removal and immediately after loading. The digestion was operated at 10 days

HRT. The pH was 6.5 and was controlled (based on the

samples pH) by adding 5 N sodium hydroxide solution, if

necessary. The daily biogas production was recorded by

measurement of water displacement. Daily samples were

stored at 4 C for analysis. The digesters were operated for

131

20 days and then assumed to be in steady-state (variation in

daily biogas production was within 10% of average production). Furthermore, a NR ratio ( D TKNin/TKNout)

between 0.95 and 1.05 was used as a measure of steady-state

conditions (Cobbs and Hill, 1990).

2.2. Characteristics of substrates

Algal sludge and waste paper were used as feeding substrates in this investigation. Algal sludge was harvested

from Partition Aquaculture System, Clemson University.

The species of algae in the sludge would change by seasons,

but most of the species would be Scenedesmus spp. and

Chlorella spp. Waste paper was collected from recycle bins

at the Clemson Computing and Information Technology

labs (DCIT). This paper was used in laser printer with one

side printed mostly and was cut by shredder or scissor

into 0.5 1 cm pieces before mixing with algal sludge for

feeding.

2.3. Analytical methods

Biogas was collected from the digester gas sampling

ports with gas sampler tube. The tubes were allowed to

sample for 1015 s before shutting the outlet valve to insure

that the sample was representative of digester gas. The biogas composition was determined using a gas chromatograph (SRI-8610C, SRI instruments) with a thermal

conductivity detector (TCD). A 0.5 ml of gas sample was

injected into the chromatograph with a column temperature of 45 C, using helium as the carrier gas. The sample

gas concentration was compared to a standard gas mixture

consisting of 40% methane and 60% carbon dioxide, and

60% methane and 40% carbon dioxide. Glucose-release rate

from conversion of carbomethycellulose (CMC) by cellulase during a predetermined time period was used as measurement method of cellulase activity. Cellulase activity is

expressed as mg of glucose-released per ml of sample per

minute at 38 C. Soluble total ammonia nitrogen (TAN)

was measured using an ammonia sensor (ORION-720A).

Volatile fatty acids (VFAs) and total kjeldahl nitrogen

(TKN) were determined following standard methods

(APHA, 1995).

3. Results and discussion

Total carbon and kjeldahl nitrogen was 10,500 mg/l and

2000 mg/l, and 406 mg/g and 182 mg/kg in algal sludge and

waste paper, respectively. The C/N ratios were about 5.3/1

in algal sludge and 2000/1 in waste paper.

3.1. Algal sludge digestion

Digesters fed with algal sludge alone at 2, 4 and 6 g VS/

l day loading rate were undertaken to investigate the digestibility of algal sludge and following methane production

rate. As seen in Table 1, methane production rates

132

H.-W. Yen, D.E. Brune / Bioresource Technology 98 (2007) 130134

Table 1

Methane production rates, VFAs, and TAN (SD) in algal sludge digestion operated at diVerent loading rates and 10 days HRT

Loading rate (g VS/l day)

CH4 (ml/l day)

CO2 (ml/l day)

VFAs (mg/l)

TAN (mg/l)

2

4

6

180 8

573 28

818 96

72 5

258 15

384 44

1305 148

4978 635

5862 1769

589 86

837 65

998 29

increased in proportion to increases in loading rate. The

methane production rate was 180 8 ml/l day at 2 g VS/

l day loading rate, and increased to a maximum methane

production rate of 818 96 ml/l day at 6 g VS/l day loading

rate. Both VFAs and TAN concentrations increased with

increasing loading rate to 5682 1769 mg/l and 998

29 mg/l at 6 g VS/l day loading rate. It was expected that the

VFAs and TAN concentration eventually would achieve

the toxicity concentration, if the loading rate kept increasing. Methane production yields were 90, 143 and 136

CH4 ml/g VS introduced at loading rates of 2, 4 and 6 g VS/

l day, respectively. Methane production yields of 100140

CH4 ml/g VS introduced at 10 days HRT acquired in this

investigation were lower than the yield of 260 ml methane/g

VS introduced at 30 days HRT acquired by Oswald and

Golueke (1960). Apparently, a longer HRT would be detrimental to have a higher methane production yield. However, HRT increase would decrease the loading rate, and

the lower loading rate would have the less methane production rate, as seen in Table 1. The reactor capital cost was

considered as the major investment in the anaerobic digestion (Rivard, 1993). Therefore, introducing shorter HRT

and higher loading rate to minimize the reactor volume

required could be a good choice for having a economical

competitive digestion process.

3.2. Co-digestion of algal sludge and waste paper

at a loading rate of 4 g VS/l day

The results of co-digestion of algal sludge and waste

paper at diVerent blending fractions at 4 g VS/l day loading rate were shown in Table 2. Five ml of trace elements

per day and 350 mg-N as ammonium chloride were added

each day in the digester of waste paper to prevent from

the nutrients limitation. The waste paper fractions in the

co-digestion with algal sludge were on the volatile solid

basis. Co-digestion of algal sludge and paper blended at

4 g VS/l day loading rate, with paper addition at 50% of

VS, led to signiWcant increases in the methane production

rate to 1170 75 ml/l day; or two-fold higher than that

observed in algal sludge digestion alone. According to the

observed methane production rates in Table 2, neither

algal sludge alone nor waste paper alone was an optimum

substrate for anaerobic digestion. Digester TAN levels

decreased with the increased feedstock C/N ratio to the

minimum of 65 10 mg/l at 75% of waste paper fraction.

Digesters fed with 50% algal sludge and 50% paper

yielded relatively low VFA levels of 3912 1290 mg/l

compared to 4978 635 mg/l during algal sludge digestion

alone. With the increase of C/N ratio to 36.4/1 at a 75%

paper and 25% algal sludge, the digester performance

turned to be unstable. Possible reasons for this observed

instability could be (1) toxicity of high VFAs at

10,848 713 mg/l, and (2) low TAN concentrations of

65 10 mg/l.

A balanced C/N ratio in feedstock was likely to be beneWcial to the methanogen activity and resulted in VFAs concentration decreased by more VFAs converted to methane.

However, at 75% paper fraction in feedstock, the C/N ratio

of 36.4/1 was possibly too high for the anaerobic digestion,

which led to low TAN levels of 65 10 mg/l observed.

McCarty (1964) reported that 50200 mg/l of TAN was

required for growth of anaerobic microorganism. Therefore, low TAN levels of 65 10 mg/l resulting from high C/N

ratio feedstock was likely limiting growth of the microbial

population in these digesters.

Vinzant et al. (1990) reported that paper digestion

under aerobic environment was more eYcient than the

digestion under anaerobic environment. Also, 12 days of

HRT in anaerobic digestion of paper was the minimum

required for a stable digester operation (Vinzant et al.,

1990). Therefore, it was believed 10 days HRT used in this

study was too short for the paper digestion alone. In the

batch of paper digestion alone, even if the C/N was

Table 2

Methane production rates, VFAs and TAN concentrations (SD) in co-digestion of algal sludge and waste paper at loading rate 4 g VS/l day (with diVerent waste paper fractions) and 10 days HRT

Feedstock

C/N

CH4 (ml/l day)

CO2 (ml/l day)

VFAs (mg/l)

TAN (mg/l)

Algal sludge

(25%) of waste paper + algal sludge

(50%) of waste paper + algal sludge

(75%) of waste paper + algal sludgea

(100%) of waste paperb

6.7

11.8

18.0

36.4

21.5

573 28

968 73

1170 75

317 114

452 36

258 15

556 37

769 49

277 82

278 22

4978 635

3480 679

3912 1290

10,848 713

7350 1259

837 65

697 51

524 24

65 10

629 51

a

b

Digestion performance is not at stable situation.

Adding trace element and NH4Cl 87.5 mg-N/l day as the nitrogen source.

H.-W. Yen, D.E. Brune / Bioresource Technology 98 (2007) 130134

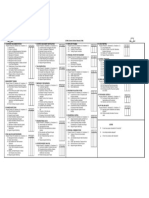

3.3. Cellulase activity in the co-digestion of algal sludge

and waste paper at 4 g VS/l day

Co-digestion of waste paper and algal sludge could

eYciently balance feedstock carbon and nitrogen and a

balanced C/N ratio of feedstock was likely to beneWt the

methane production rate. The increase of cellulase activity

resulting from paper addition was another possible reason

for explaining increased methane production rate. Cellulase are inducible enzymes which are synthesized and

mostly secreted into the environment by microorganisms

during their growth on cellulosic materials, oligo and dimmer sugars, including some of their derivates (Busto et al.,

1996). Cellulose hydrolysis is considered the rate-limiting

step in digesters fed with a high cellulosic content feedstock. It was suggested that paper addition to the digester

might induce cellulase excretion by bacteria such as Clostridium themocellum (Suto and Tomita, 2001). In fact, in

the digesters fed paper and algal sludge blends at 4 g VS/

l day loading rate, cellulase activity increased, resulting in a

positive impact on the methane production rate (Fig. 1). At

75% paper fraction, elevated VFA concentrations suppressed cellulase activity to 1.26 0.14 mg/l min. The highest level of cellulase activity (3.02 0.09 mg/l min) was

during paper digestion alone. However, the methane production rate was only 452 36 ml/l day as compared to

573 28 ml/l day for algal sludge digestion alone. These

results suggested that breakdown of algal biomass contributed some key components to the improvement of methanogenic activity. Therefore, a low methane production rate

was observed in the digester fed paper alone, even if there

were no nutrients limitation and had high cellulase activity

in the digester (see Table 3).

3.5

Cellulase activity

3

Glu. released mg/l m

adjusted to 21.5/1 by adding ammonic chloride, it still had

a low methane production rate of 452 36 ml/l day. One

possible explanation for this was that algal biomass was

not only playing a nitrogen source supplier in this codigestion process, but also supplied nutrients to the

digester microXora after the degradation of algal biomass.

This might be able to explain why the co-digestion of algal

sludge and waste paper had a higher methane production

rate than the paper digestion alone, even if the C/N ratio of

digester fed paper alone was adjusted to 21.5/1 by adding

ammonium chloride.

133

2.5

2

1.5

1

0.5

0

25%

50%

75%

100%

Paper fraction in feedstock

Fig. 1. Cellulase activity in digesters fed algal sludge and waste paper at a

combined loading rate of 4 g VS/l day and 10 days HRT.

3.4. Co-digestion of waste paper and a Wxed amount

of algal sludge

The eVects of varying waste paper loading (0, 1, 2, 3 and

4 g VS/l day) blended with a Wxed amount of algal sludge

loading at 2 g VS/l day on co-digestion performance were

investigated. Digesters fed at a Wxed algal sludge loading

rate of 2 g VS/l day and paper loading rates of 0, 1, 2, 3 and

4 g VS/l day yielded a maximum methane production rate

1607 17 ml/l day at a combined loading rate of 5 g VS/

l day (C/N D 22.6/1). This decreased to 856 40 ml/l day at

a combined loading of 6 g VS/l day (C/N D 27.2/1). With

the increase of loading rate, the VFAs increased and TAN

levels decreased. Since nitrogen source in this co-digestion

was came from the breakdown of algal sludge, at a Wxed

algal sludge loading (2 g VS/l day), TAN levels decreased

with the increased paper loading. That meant the waste

paper in the combined feedstock turned to be the main carbon source instead of algal sludge. Results suggested that

at a loading rate of 6 g VS/l day, the paper fraction in feedstock achieved 67% (C/N D 27.2) was too high for the

anaerobic digestion process, which led to lower methane

production rate than 5 g VS/l day loading rate. C/N ratio

between 20 and 25/1 was optimum (Fig. 2) for the anaerobic co-digestion of algal sludge and waste paper at 10 days

HRT and 35 C.

Table 3

Methane and carbon dioxide production rates, VFAs and TAN concentrations (SD) in digesters at 2 g VS/l day of algal sludge loading and varying loadings of waste paper (0, 1, 2, 3, 4 g VS/l day) and 10 days HRT

Combined loading (g VS/l day)

C/N

CH4 (ml/l day)

CO2 (ml/l day)

VFAs (mg/l)

TAN (mg/l)

2

3

4

5

6

6.7

13.3

18.0

22.6

27.2

180 34

823 16

1170 75

1607 17

856 40

72 5

397 14

769 49

1080 21

561 23

1305 147

3780 458

3912 1290

5220 855

6228 685

589 86

541 2

524 24

396 8

175 7

134

H.-W. Yen, D.E. Brune / Bioresource Technology 98 (2007) 130134

350

algal sludge + paper

Methane yield, CH4 ml/g VS in

300

250

200

150

100

paper + NH4

50

0

0

10

15

20

25

30

35

40

C/N

Fig. 2. Methane yield vs. C/N ratio in digesters with algal sludge and paper

loading at combined loading rates of 2, 3, 4, 5 and 6 g VS/l day and 10 days

HRT.

4. Conclusions

Co-digestion of algal sludge and waste paper was useful

and oVered two beneWts: (1) a balance of C/N ratio. The

optimized C/N range for the co-digestion was 2025/1; (2)

increase in cellulase activity. The increase in cellulase activity might be helpful in the biodegradation of algal sludge,

which could provide nutrients in the digester, which Wnally

would improve methane production rate.

References

APHA, 1995. Standard methods for the examination of water and wastewater. In: Eaton, A.D., Clesceri, L.S., Greenberg, A.E., (Eds.), Washington, DC.

Brune, D.E., Collier, J.A., Schwedler, T.E., 2001. Partitioned aquaculture

system. US patent 6192833.

Busto, M.D., Ortega, N., Perez-Mateos, M., 1996. Location, kinetics and

stability of cellulases induced in Trichoderma reesei cultures. Bioresource Technology 57, 187192.

Callaghan, F.J., Wase, D.A.J., Thayanithy, K., Forster, C.F., 2002. Continuous-co-digestion of cattle slurry with fruit and vegetable wastes and

chicken manure. Biomass and Bioenergy 27, 7177.

Chen, P.H., Oswald, W.J., 1998. Thermochemical treatment for algal fermentation. Environment International 24, 889897.

Cobbs, S.A., Hill, D.T., 1990. Using nitrogen ratio as an indicator of biomass retention and steady-state in anaerobic fermentation. Transactions of the ASAE 33, 223227.

McCarty, P.L., 1964. Anaerobic waste treatment fundamentals. III. Toxic

materials and their control. Public Works 95, 9194.

Mshandete, A., Kivaisi, A., Rubindamayugi, M., Mattiasson, B., 2004.

Anaerobic batch co-digestion of sisal pulp and Wsh wastes. Bioresource

Technology 95, 1924.

Mulbry, W., Westhead, E.K., Pizarro, C., Sikora, L., 2005. Recycling of

manure nutrients: use of algal biomass from dairy manure treatment as

a slow release fertilizer. Bioresource Technology 96, 451458.

Oswald, J.W., Golueke, C.G., 1960. Biological transformation of solar

energy. Advance Applied Microbiology 2, 223261.

Parkin, G.F., Owen, W.F., 1986. Fundamental of anaerobic-digestion of

wastewater sludge. Journal of Environmental Engineering 112, 867

920.

Rivard, C.J., 1993. Anaerobic bioconversion of municipal solid waste

using a novel high-solids reactor design. Applied Biochemistry and

Biotechnology 39/40, 7182.

Sosnowaki, P., Wieczorek, A., Ledakowicz, S., 2003. Anaerobic co-digestion of sewage sludge and organic fraction of municipal solid wastes.

Advances in Environmental Research 7, 609616.

Stroot, P.G., McMahon, K.D., Mackie, R.I., Raskin, L., 2001. Anaerobic

codigestion of municipal solid waste and biosolids under various

mixing condition. I. Digester performance. Water Research 35, 1804

1816.

Suto, M., Tomita, F., 2001. Induction and catabolite repression mechanisms of cellulase in fungi. Journal of Bioscience and Bioengineering 9,

305311.

Vinzant, T.B., Adney, W.S., Grohmann, K., Rivard, C.J., 1990. Aerobic and

anaerobic digestion of processed municipal solid waste: eVects of retention time on cellulose degradation. Applied Biochemistry and Biotechnology 24/25, 765771.

Você também pode gostar

- PET TroubleshootingDocumento37 páginasPET TroubleshootingRoland_II96% (24)

- TNT Trinitrotoluenes and Mono and Dinitrotoluenes PDFDocumento136 páginasTNT Trinitrotoluenes and Mono and Dinitrotoluenes PDFmahdiarAinda não há avaliações

- KS4 Reversible ReactionsDocumento25 páginasKS4 Reversible ReactionsAisha KhanAinda não há avaliações

- 2020 Orica Sustainability ReportDocumento39 páginas2020 Orica Sustainability ReportIka SulistyaningtiyasAinda não há avaliações

- Industrial _ Engineering Chemistry Process Design and Development Volume 19 issue 4 1980 [doi 10.1021_i260076a001] Garside, John; Shah, Mukund B. -- Crystallization Kinetics from MSMPR Crystallizers.pdfDocumento6 páginasIndustrial _ Engineering Chemistry Process Design and Development Volume 19 issue 4 1980 [doi 10.1021_i260076a001] Garside, John; Shah, Mukund B. -- Crystallization Kinetics from MSMPR Crystallizers.pdfIka SulistyaningtiyasAinda não há avaliações

- Industrial _ Engineering Chemistry Process Design and Development Volume 19 issue 4 1980 [doi 10.1021_i260076a001] Garside, John; Shah, Mukund B. -- Crystallization Kinetics from MSMPR Crystallizers.pdfDocumento6 páginasIndustrial _ Engineering Chemistry Process Design and Development Volume 19 issue 4 1980 [doi 10.1021_i260076a001] Garside, John; Shah, Mukund B. -- Crystallization Kinetics from MSMPR Crystallizers.pdfIka SulistyaningtiyasAinda não há avaliações

- Gypsum in CementDocumento2 páginasGypsum in CementManish Kumar100% (1)

- Biogas Productionfrom Algae Biomass Harvestedat Wastewater TreaDocumento5 páginasBiogas Productionfrom Algae Biomass Harvestedat Wastewater TreaNitin PatilAinda não há avaliações

- Biogas 11 PDFDocumento9 páginasBiogas 11 PDFUkhtie JulieAinda não há avaliações

- Eiroa Et Al 2012 - Potencial de Biometano Residuo Solido de PescadoDocumento6 páginasEiroa Et Al 2012 - Potencial de Biometano Residuo Solido de PescadoJulio ReyesAinda não há avaliações

- Comparison of Biogas Production From Cow Dung and Pig Dung Under Mesophilic ConditionDocumento6 páginasComparison of Biogas Production From Cow Dung and Pig Dung Under Mesophilic Conditionwww.irjes.comAinda não há avaliações

- Novel Bioreactor Configuration for Organic Waste DigestionDocumento270 páginasNovel Bioreactor Configuration for Organic Waste Digestionclaudio06111983Ainda não há avaliações

- Evaluation of The Biomethane Potential of Solid Fish Waste - 2012Documento6 páginasEvaluation of The Biomethane Potential of Solid Fish Waste - 2012Ivan Lobos PanguilefAinda não há avaliações

- Kim 2003Documento13 páginasKim 2003naranjo-01Ainda não há avaliações

- Park Et Al. 2011a Estanques de Al Algas para Tratamiento para Produccion de BiodiselDocumento8 páginasPark Et Al. 2011a Estanques de Al Algas para Tratamiento para Produccion de BiodiselAlexis Hugo Hernández PérezAinda não há avaliações

- Anaerobic Co-Digestion of Chicken Manure PDFDocumento6 páginasAnaerobic Co-Digestion of Chicken Manure PDFAgos RiosAinda não há avaliações

- Art 7Documento6 páginasArt 7Rodny NavarroAinda não há avaliações

- Inorganic Nitrogen Dynamics in Sequencing Batch Reactors Using Biofloc Technology To Treat Aquaculture SludgeDocumento7 páginasInorganic Nitrogen Dynamics in Sequencing Batch Reactors Using Biofloc Technology To Treat Aquaculture SludgeSyamala KAinda não há avaliações

- Accepted Manuscript: Bioresource TechnologyDocumento38 páginasAccepted Manuscript: Bioresource Technologymaria camila muñoz obregonAinda não há avaliações

- Comparison Between Wet and Dry Anaerobic Digestions of Cow Dung Under Mesophilic and Thermophilic ConditionsDocumento11 páginasComparison Between Wet and Dry Anaerobic Digestions of Cow Dung Under Mesophilic and Thermophilic ConditionsFábio Macêdo NunesAinda não há avaliações

- Use of Jatropha Curcas Hull Biomass For Bioactive Compost ProductionDocumento4 páginasUse of Jatropha Curcas Hull Biomass For Bioactive Compost ProductionAnil DhariwalAinda não há avaliações

- 2010 - Gregor D - Anerobic Digester TanneryDocumento8 páginas2010 - Gregor D - Anerobic Digester TanneryJulio ReyesAinda não há avaliações

- Anaerobic Treatment of Cattle Manure For Biogas ProductionDocumento10 páginasAnaerobic Treatment of Cattle Manure For Biogas ProductionMohamed MahmoudAinda não há avaliações

- Process performance evaluation of intermittent–continuous stirred tank reactor for anaerobic hydrogen fermentation with kitchen wasteDocumento10 páginasProcess performance evaluation of intermittent–continuous stirred tank reactor for anaerobic hydrogen fermentation with kitchen wastenabilAinda não há avaliações

- Comparative Study of Mesophilic Biogas Production Potentials of Selected Agro-WastesDocumento6 páginasComparative Study of Mesophilic Biogas Production Potentials of Selected Agro-WastestheijesAinda não há avaliações

- Microbial EEA Affects Performance in A Full-Scale Modified ASPDocumento8 páginasMicrobial EEA Affects Performance in A Full-Scale Modified ASPCelina SanchezAinda não há avaliações

- Picot Et Al 2001 Odor Control With Peat Bed PlantsDocumento8 páginasPicot Et Al 2001 Odor Control With Peat Bed PlantsMiguel Angel Sunagua ChAinda não há avaliações

- Estimation of Viable Biomass in Wastewater A N D Activated Sludge by Determination of Atp, Oxygen Utilization Rate A N D Fda HydrolysisDocumento7 páginasEstimation of Viable Biomass in Wastewater A N D Activated Sludge by Determination of Atp, Oxygen Utilization Rate A N D Fda HydrolysismpakzadehAinda não há avaliações

- 2015-Zayneb Article MorphologicalPhysiologicalAndBDocumento7 páginas2015-Zayneb Article MorphologicalPhysiologicalAndBNathália Felix BomfimAinda não há avaliações

- 2006 - Effects of Temperature and Hydraulic Retention TimeDocumento5 páginas2006 - Effects of Temperature and Hydraulic Retention TimeAgung Ariefat LubisAinda não há avaliações

- Biogas Production From Thermophilic Codigestion of Air-Dried Rice Straw and Animal ManureDocumento10 páginasBiogas Production From Thermophilic Codigestion of Air-Dried Rice Straw and Animal Manurecallisto69Ainda não há avaliações

- Performance of A Sisal Fibre Fixed-Bed Anaerobic Digester For Biogas Production From Sisal Pulp WasteDocumento11 páginasPerformance of A Sisal Fibre Fixed-Bed Anaerobic Digester For Biogas Production From Sisal Pulp WasteAnugrah Perdana RahmantaAinda não há avaliações

- 13 Kabouris Etal WER 2009Documento10 páginas13 Kabouris Etal WER 2009ibrahim3318Ainda não há avaliações

- Petroleum Groundwater Remediation Using Activated CarbonDocumento7 páginasPetroleum Groundwater Remediation Using Activated CarbonIbrahim NurrachmanAinda não há avaliações

- Pelendridou_et_al._2013Documento9 páginasPelendridou_et_al._2013demclassychiczAinda não há avaliações

- Anaerobic Treatment of Brackishwater Aquaculture Sludge PDFDocumento11 páginasAnaerobic Treatment of Brackishwater Aquaculture Sludge PDFkarpanaiAinda não há avaliações

- 8 Final Stydy On Ferric Chloride CoagulationDocumento10 páginas8 Final Stydy On Ferric Chloride CoagulationMervatAinda não há avaliações

- Bioresource Technology: Sami Luste, Sari LuostarinenDocumento8 páginasBioresource Technology: Sami Luste, Sari LuostarinenJim TsikasAinda não há avaliações

- Biogas Production in The Anaerobic Treatment of Cattle ManureDocumento8 páginasBiogas Production in The Anaerobic Treatment of Cattle Manuretera novaAinda não há avaliações

- Improved Anaerobic Digestion by The Addition of Paper Tube Residuals: Pretreatment, Stabilizing, and Synergetic E FfectsDocumento8 páginasImproved Anaerobic Digestion by The Addition of Paper Tube Residuals: Pretreatment, Stabilizing, and Synergetic E Ffectsnavri_nalhadAinda não há avaliações

- Anaerobic Batch Co Digestion of Sisal PuDocumento6 páginasAnaerobic Batch Co Digestion of Sisal PuIman EbrahimzadeAinda não há avaliações

- Pretreatment of Laminaria Japonica For Bioethanol Production With Extreme Low Acid ConcenterationDocumento5 páginasPretreatment of Laminaria Japonica For Bioethanol Production With Extreme Low Acid ConcenterationFajar SyahrezaAinda não há avaliações

- Provided For Non-Commercial Research and Educational Use Only. Not For Reproduction or Distribution or Commercial UseDocumento7 páginasProvided For Non-Commercial Research and Educational Use Only. Not For Reproduction or Distribution or Commercial UseCristiano RégisAinda não há avaliações

- Pilot Scale Resource Recovery From Cattle Paunch Waste: C M Mehta, P D Jensen, and D J BatstoneDocumento8 páginasPilot Scale Resource Recovery From Cattle Paunch Waste: C M Mehta, P D Jensen, and D J BatstoneSuselohandokoAinda não há avaliações

- Anaerobic Digestion of The Vinasses From The Fermentation of Agave Tequilana Weber To Tequila - The Effect of PH, Temperature and Hydraulic Retention Time On The Production of Hydrogen and MethaneDocumento7 páginasAnaerobic Digestion of The Vinasses From The Fermentation of Agave Tequilana Weber To Tequila - The Effect of PH, Temperature and Hydraulic Retention Time On The Production of Hydrogen and MethaneprofjohnalencarAinda não há avaliações

- Anaerobic Ponds Treatment of Starch Wastewater Case Study in ThailandDocumento9 páginasAnaerobic Ponds Treatment of Starch Wastewater Case Study in ThailandPurnama Muhlis KaimunAinda não há avaliações

- Biomass and Bioenergy: Research PaperDocumento9 páginasBiomass and Bioenergy: Research PaperajitsssAinda não há avaliações

- Yan 2009Documento6 páginasYan 2009theressa julietaAinda não há avaliações

- Artikel 1Documento9 páginasArtikel 1Agung PrabowoAinda não há avaliações

- ANTONOPOULOU - 2015 - Modeling of Anaerobic Digestion of Food Industry WastesDocumento7 páginasANTONOPOULOU - 2015 - Modeling of Anaerobic Digestion of Food Industry WastesThobiasAinda não há avaliações

- Algae/Bacteria Ratio in High-Rate Ponds Used For Waste TreatmentDocumento8 páginasAlgae/Bacteria Ratio in High-Rate Ponds Used For Waste Treatment'Hady' HadiyantoAinda não há avaliações

- Effect of leachate recirculation on anaerobic food waste digestionDocumento4 páginasEffect of leachate recirculation on anaerobic food waste digestionRianAwanggaAinda não há avaliações

- Anaerobic Digestion of Fruit Wastes For Biogas Production Ijariie10528Documento5 páginasAnaerobic Digestion of Fruit Wastes For Biogas Production Ijariie10528SESHADHIRI KIS-GROUPAinda não há avaliações

- Anaerobic Digestion of Sewage Sludge in An Anaerobic Fixed Bed DigesterDocumento3 páginasAnaerobic Digestion of Sewage Sludge in An Anaerobic Fixed Bed DigesterNurul RazakAinda não há avaliações

- Research Inventy: International Journal of Engineering and ScienceDocumento9 páginasResearch Inventy: International Journal of Engineering and ScienceinventyAinda não há avaliações

- Sunwoo 2018Documento13 páginasSunwoo 2018indahyanuarAinda não há avaliações

- Modified UCT Chemo SphereDocumento7 páginasModified UCT Chemo SpherevaiopoulouAinda não há avaliações

- Logan - 2002 - Biological Hydrogen Production Measured in Bath Anaerobic RespirometersDocumento6 páginasLogan - 2002 - Biological Hydrogen Production Measured in Bath Anaerobic RespirometersMaythee SaisriyootAinda não há avaliações

- Bioresource Technology: Jianguo Jiang, Xuejuan Du, Siio NG, Chang ZhangDocumento7 páginasBioresource Technology: Jianguo Jiang, Xuejuan Du, Siio NG, Chang Zhang233701Ainda não há avaliações

- Impact of Seed Bioaugmentation on Thermophilic Anaerobic DigestersDocumento10 páginasImpact of Seed Bioaugmentation on Thermophilic Anaerobic DigestersMario WhoeverAinda não há avaliações

- Biomethanation of Banana Peel and Pineapple WasteDocumento4 páginasBiomethanation of Banana Peel and Pineapple WasteolieAinda não há avaliações

- Application of Enzyme-Hydrolyzed Cassava Dregs As Carbon Source in BFT Shrimp Aquaculture-Science of The Total Environment Volume 615 Issue 2018 PDFDocumento10 páginasApplication of Enzyme-Hydrolyzed Cassava Dregs As Carbon Source in BFT Shrimp Aquaculture-Science of The Total Environment Volume 615 Issue 2018 PDFLe Dinh DucAinda não há avaliações

- Biogas Production by Co-Digestion of Cassava Peels With UreaDocumento3 páginasBiogas Production by Co-Digestion of Cassava Peels With UreaInnovative Research PublicationsAinda não há avaliações

- Effect of Inoculum-to-Substrate Ratio on Sheep Paunch Manure BiogasDocumento7 páginasEffect of Inoculum-to-Substrate Ratio on Sheep Paunch Manure BiogasendeshawAinda não há avaliações

- tmpBB6B TMPDocumento9 páginastmpBB6B TMPFrontiersAinda não há avaliações

- Anaerobic Digestion of Microalgae Residues Resulting From The Biodiesel Production ProcessDocumento10 páginasAnaerobic Digestion of Microalgae Residues Resulting From The Biodiesel Production ProcesskayeAinda não há avaliações

- Climate Change and Cotton Production in Modern Farming SystemsNo EverandClimate Change and Cotton Production in Modern Farming SystemsAinda não há avaliações

- Nano-Scale ZSM-5 Zeolite Effectively Cracks HydrocarbonsDocumento9 páginasNano-Scale ZSM-5 Zeolite Effectively Cracks HydrocarbonsIka SulistyaningtiyasAinda não há avaliações

- Cetak Pisah A2-SCAT p2Documento1 páginaCetak Pisah A2-SCAT p2Ika SulistyaningtiyasAinda não há avaliações

- Pca Guidelines Vol1Documento26 páginasPca Guidelines Vol1Ika SulistyaningtiyasAinda não há avaliações

- Amonium HidroksidaDocumento5 páginasAmonium HidroksidaYonandaRayiAyuningtyas100% (1)

- Poster - Help Fight Global WarmingDocumento1 páginaPoster - Help Fight Global WarmingIka SulistyaningtiyasAinda não há avaliações

- AR Pertamina 2016Documento710 páginasAR Pertamina 2016Yudha SitorusAinda não há avaliações

- 2020 Sustainability Data CentreDocumento4 páginas2020 Sustainability Data CentreIka SulistyaningtiyasAinda não há avaliações

- Assessment of Explosion Hazards in Refuse Shredders: June 2, 1976Documento191 páginasAssessment of Explosion Hazards in Refuse Shredders: June 2, 1976Ika SulistyaningtiyasAinda não há avaliações

- Poster - Team Work & SafetyDocumento1 páginaPoster - Team Work & SafetyIka SulistyaningtiyasAinda não há avaliações

- Poster - Team Work & SafetyDocumento1 páginaPoster - Team Work & SafetyIka SulistyaningtiyasAinda não há avaliações

- Journal of Physical Chemistry A Volume 108 issue 52 2004 [doi 10.1021_jp0462862] Parsons, Matthew T.; Knopf, Daniel A.; Bertram, Allan K. -- Deliquescence and Crystallization of Ammonium Sulfate Par.pdfDocumento9 páginasJournal of Physical Chemistry A Volume 108 issue 52 2004 [doi 10.1021_jp0462862] Parsons, Matthew T.; Knopf, Daniel A.; Bertram, Allan K. -- Deliquescence and Crystallization of Ammonium Sulfate Par.pdfIka SulistyaningtiyasAinda não há avaliações

- ITM Annual Report 2015Documento450 páginasITM Annual Report 2015Ika SulistyaningtiyasAinda não há avaliações

- Poster - Help Fight Global WarmingDocumento1 páginaPoster - Help Fight Global WarmingIka SulistyaningtiyasAinda não há avaliações

- Aceh International Journal of Science and Technology: ISSN: 2088-9860Documento10 páginasAceh International Journal of Science and Technology: ISSN: 2088-9860Ika SulistyaningtiyasAinda não há avaliações

- TS Mmis Incin Guide PDFDocumento58 páginasTS Mmis Incin Guide PDFAshok KumarAinda não há avaliações

- Journal of Physical Chemistry A Volume 108 issue 52 2004 [doi 10.1021_jp0462862] Parsons, Matthew T.; Knopf, Daniel A.; Bertram, Allan K. -- Deliquescence and Crystallization of Ammonium Sulfate Par.pdfDocumento9 páginasJournal of Physical Chemistry A Volume 108 issue 52 2004 [doi 10.1021_jp0462862] Parsons, Matthew T.; Knopf, Daniel A.; Bertram, Allan K. -- Deliquescence and Crystallization of Ammonium Sulfate Par.pdfIka SulistyaningtiyasAinda não há avaliações

- Energy For Sustainable Development Volume 23 Issue 2014 (Doi 10.1016 - J.esd.2014.08.005) Sarantopoulos, Ioannis Chatzisymeon, Efthalia Foteinis, Spyros - Optimization of Biodiesel Production FromDocumento5 páginasEnergy For Sustainable Development Volume 23 Issue 2014 (Doi 10.1016 - J.esd.2014.08.005) Sarantopoulos, Ioannis Chatzisymeon, Efthalia Foteinis, Spyros - Optimization of Biodiesel Production FromIka SulistyaningtiyasAinda não há avaliações

- Renewable Energy: Pedro J. García-Moreno, Mohriam Khanum, Antonio Guadix, Emilia M. GuadixDocumento7 páginasRenewable Energy: Pedro J. García-Moreno, Mohriam Khanum, Antonio Guadix, Emilia M. GuadixIka SulistyaningtiyasAinda não há avaliações

- Journal of Crystal Growth Volume 20 Issue 3 1973 (Doi 10.1016 - 0022-0248 (73) 90002-x) Maurice A. Larson John W. Mullin - Crystallization Kinetics of Ammonium SulphateDocumento9 páginasJournal of Crystal Growth Volume 20 Issue 3 1973 (Doi 10.1016 - 0022-0248 (73) 90002-x) Maurice A. Larson John W. Mullin - Crystallization Kinetics of Ammonium SulphateIka SulistyaningtiyasAinda não há avaliações

- C Compiler Optimization TechniquesDocumento72 páginasC Compiler Optimization TechniquesIka SulistyaningtiyasAinda não há avaliações

- Chemical Engineering Journal Volume 134 Issue 1-3 2007 (Doi 10.1016 - J.cej.2007.03.077) Abderrahim Bouaid Mercedes Martinez Jose Aracil - A Comparative Study of The Production of Ethyl Esters FromDocumento7 páginasChemical Engineering Journal Volume 134 Issue 1-3 2007 (Doi 10.1016 - J.cej.2007.03.077) Abderrahim Bouaid Mercedes Martinez Jose Aracil - A Comparative Study of The Production of Ethyl Esters FromIka SulistyaningtiyasAinda não há avaliações

- Energy Procedia Volume 52 Issue 2014 (Doi 10.1016 - J.egypro.2014.07.089) Li, Yu-Ru Shue, Meei-Fang Hsu, Yi-Chyun Lai, Wen-Liang Chen, - Application of Factorial Design Methodology For OptimizatiDocumento6 páginasEnergy Procedia Volume 52 Issue 2014 (Doi 10.1016 - J.egypro.2014.07.089) Li, Yu-Ru Shue, Meei-Fang Hsu, Yi-Chyun Lai, Wen-Liang Chen, - Application of Factorial Design Methodology For OptimizatiIka SulistyaningtiyasAinda não há avaliações

- Biodiesel Factorial DesignDocumento7 páginasBiodiesel Factorial DesignRoe HauAinda não há avaliações

- Fuel Volume 89 Issue 1 2010 (Doi 10.1016 - J.fuel.2009.01.025) F. Ferella G. Mazziotti Di Celso I. de Michelis V. Stanisci - Optimization of The Transesterification Reaction in Biodiesel ProductiDocumento7 páginasFuel Volume 89 Issue 1 2010 (Doi 10.1016 - J.fuel.2009.01.025) F. Ferella G. Mazziotti Di Celso I. de Michelis V. Stanisci - Optimization of The Transesterification Reaction in Biodiesel ProductiIka SulistyaningtiyasAinda não há avaliações

- Journal of Physical Chemistry A Volume 108 issue 52 2004 [doi 10.1021_jp0462862] Parsons, Matthew T.; Knopf, Daniel A.; Bertram, Allan K. -- Deliquescence and Crystallization of Ammonium Sulfate Par.pdfDocumento9 páginasJournal of Physical Chemistry A Volume 108 issue 52 2004 [doi 10.1021_jp0462862] Parsons, Matthew T.; Knopf, Daniel A.; Bertram, Allan K. -- Deliquescence and Crystallization of Ammonium Sulfate Par.pdfIka SulistyaningtiyasAinda não há avaliações

- Kode-HS-2012 PDFDocumento190 páginasKode-HS-2012 PDFPungkyRamadhaniPamungkasAminotoAinda não há avaliações

- ASTM D 2330 - 02 - RDIZMZA - (Methylene Blue Active Substances)Documento8 páginasASTM D 2330 - 02 - RDIZMZA - (Methylene Blue Active Substances)Osmel García Morfi100% (1)

- Fixation and Types of Fixative AgentsDocumento14 páginasFixation and Types of Fixative AgentsHARIS KHANAinda não há avaliações

- Chemistry Diagnostic TestDocumento3 páginasChemistry Diagnostic TestJohn John RoacheAinda não há avaliações

- Student Experiments for Quantitative Chemical Analysis ExperimentsDocumento55 páginasStudent Experiments for Quantitative Chemical Analysis ExperimentsCINTHIAAinda não há avaliações

- Sulphuric Acid - Specification: Indian StandardDocumento20 páginasSulphuric Acid - Specification: Indian Standard8085roAinda não há avaliações

- Sedifilt Oil & Gas Brochure PDFDocumento8 páginasSedifilt Oil & Gas Brochure PDFAalap DerasaryAinda não há avaliações

- Ijftr 29 (2) 239-259Documento21 páginasIjftr 29 (2) 239-259aymanAinda não há avaliações

- KSR Publication 30Documento12 páginasKSR Publication 30K S RAJESHAinda não há avaliações

- THG Hooks Forged Hooks Catalogue SheetDocumento5 páginasTHG Hooks Forged Hooks Catalogue SheetjhonAinda não há avaliações

- Western Region-Ordinary Members PDFDocumento21 páginasWestern Region-Ordinary Members PDFjaydeep daveAinda não há avaliações

- Extend Shelf Life of Bread with Propionic AcidDocumento5 páginasExtend Shelf Life of Bread with Propionic AcidnajwaAinda não há avaliações

- AOMT 123602 PEER-M VP15TF Mitsubishi CarbideDocumento2 páginasAOMT 123602 PEER-M VP15TF Mitsubishi CarbideTungstenCarbideAinda não há avaliações

- Chapter 6 Thermochemistry: StudentDocumento28 páginasChapter 6 Thermochemistry: StudentKing Ray TabalbaAinda não há avaliações

- Cabbage Chemistry: LaboratoryDocumento2 páginasCabbage Chemistry: LaboratoryTrixieCamposanoAinda não há avaliações

- Astm G21 13Documento5 páginasAstm G21 13AbinashBeheraAinda não há avaliações

- Hydrocarbons MarathonDocumento353 páginasHydrocarbons MarathonGully GamingAinda não há avaliações

- PREOSDocumento18 páginasPREOSLija BinuAinda não há avaliações

- GCFGCGCFGFDGDocumento15 páginasGCFGCGCFGFDGZabrinaRuizAinda não há avaliações

- BIOFILLERSDocumento37 páginasBIOFILLERSMOHAMMED K HISHAMAinda não há avaliações

- Chapter 16 LQDocumento4 páginasChapter 16 LQ叶子临Ainda não há avaliações

- Measurement of Conductance and Kohlrauch's LawDocumento23 páginasMeasurement of Conductance and Kohlrauch's Lawknowledge of sciencesAinda não há avaliações

- Seite 14-15 Marsoflex Universal Chemical Hose Type 45HW PDFDocumento1 páginaSeite 14-15 Marsoflex Universal Chemical Hose Type 45HW PDFVăn Đại - BKHNAinda não há avaliações

- EnnnDocumento9 páginasEnnnSajid AliAinda não há avaliações

- 2018-07-01 Chemistry Times PDFDocumento68 páginas2018-07-01 Chemistry Times PDFMilena KafkaAinda não há avaliações

- Glycolic AcidDocumento8 páginasGlycolic AcidrajkamleshAinda não há avaliações

- IFARS generic drugsDocumento5 páginasIFARS generic drugsOky Spinola IdroosAinda não há avaliações

- Electronic ISSN: 2656-3088 Homepage:: Yenni Sri Wahyuni, Erjon Reza AftaridaDocumento7 páginasElectronic ISSN: 2656-3088 Homepage:: Yenni Sri Wahyuni, Erjon Reza AftaridaPutri YuliaAinda não há avaliações

![Industrial _ Engineering Chemistry Process Design and Development Volume 19 issue 4 1980 [doi 10.1021_i260076a001] Garside, John; Shah, Mukund B. -- Crystallization Kinetics from MSMPR Crystallizers.pdf](https://imgv2-1-f.scribdassets.com/img/document/284126833/149x198/abec42366b/1444359067?v=1)

![Journal of Physical Chemistry A Volume 108 issue 52 2004 [doi 10.1021_jp0462862] Parsons, Matthew T.; Knopf, Daniel A.; Bertram, Allan K. -- Deliquescence and Crystallization of Ammonium Sulfate Par.pdf](https://imgv2-2-f.scribdassets.com/img/document/284126828/149x198/f1492acec8/1444359060?v=1)