Escolar Documentos

Profissional Documentos

Cultura Documentos

TI-700 - Eng-R1 - Inook

Enviado por

Anonymous DJrec2Descrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

TI-700 - Eng-R1 - Inook

Enviado por

Anonymous DJrec2Direitos autorais:

Formatos disponíveis

no.

: TI-700_eng

rev.

: 1

date

: 14.10.10

TECHNICAL INFORMATION

page

: 1 von 6

SCHNEIDER-High Pressure Steam Generator

for closed circuits - Series iNook

1. Functionality

The iNook is a High Pressure Steam generator of vertical

design especially developed for closed circuits. He is

installed directly below the steam consumer (the

condenser) connected to it and not capable of being shut

off.

The generated high pressure steam transports the heat

into the condenser where the heat energy is transferred

in a thermal process by condensing. High Pressure

Steam Generator iNook and Condenser are operated in

an absolute closed circuit driven by natural circulation.

Figure 1 - iNook

Since the natural circulation works by gravity only one

has to heed during design and installation that the

condensate returns to the iNook without any obstruction.

In other words sufficient difference in altitude must be

provided secured by locating the condenser directly

above the iNook not to mention that the difference in

altitude has to be calculated for each project. Furthermore the steam and condensate connections

between the iNook and the condenser must be sufficient

designed in means of dimensions, installed with sufficient

incline, no strictures, no bends, no components such as

valves etc.

The iNook installed in a closed circuit allows an operation without the regular boiler equipment

such as water level control and feed water pumps. To avoid water leakages all connections of supply and return lines, connections with equipments are welded or for safety valves monitored by

automatic leakage control.

Doc.: TI-700_eng-R1 - iNook.doc

SCHNEIDER Engineering GmbH

Email / Internet

Hildburghauser Strae 79

12249 Berlin

Tel.: +49-30-75 44 93 99-0

Fax: +49-30-75 44 93 99-21

info@schneider-kessel.com

www.schneider-kessel.com

no.

: TI-700_eng

rev.

: 1

date

: 14.10.10

TECHNICAL INFORMATION

page

: 2 von 6

SCHNEIDER-High Pressure Steam Generator

for closed circuits - Series iNook

2. Design Features

The iNook is a vertical designed boiler High

Pressure Steam Generator without a steam

drum. In means of flue gas system the iNook

is a Three Pass Boiler where the furnace is

the 1st pass and the 2nd and 3rd pass are

formed by the concentrically arranged tube

coils of the convection part.

The burner is installed as roof burner on top

of the boiler. The iNook consists of two (2)

concentrically arranged tube coils in Membrane Wall design with the latter as the most

superior advantage in compare with other

boiler brands designed without steam drum for

closed circuits.

The superior advantage of the Membrane

Wall design secures that the vertical evaporator tubes can be welded into the bottom and

top ring collectors without reduction. This design feature is the ultimate precondition to ensure unobstructed water flow and hence thermal overheating even during peak loads

and/or sudden load fluctuation which very often result in tube cracks. The gap between the

vertical tubes is flue gas tight closed by membranes a reliable design feature which is tried

and tested and used for water tube boilers

world wide.

Figure 2 - Boiler Sections

Burner/Flame/Vessel (1st, 2nd and 3rd pass)

Doc.: TI-700_eng-R1 - iNook.doc

SCHNEIDER Engineering GmbH

Email / Internet

Hildburghauser Strae 79

12249 Berlin

Tel.: +49-30-75 44 93 99-0

Fax: +49-30-75 44 93 99-21

info@schneider-kessel.com

www.schneider-kessel.com

no.

: TI-700_eng

rev.

: 1

date

: 14.10.10

TECHNICAL INFORMATION

page

: 3 von 6

SCHNEIDER-High Pressure Steam Generator

for closed circuits - Series iNook

iNook Design

Other Design

(Membrane Wall)

(Tube-to-Tube Wall)

Figure 3 - Membrane Wall Design versus Tubeto-Tube Design

Figure 4 Manufacturing of membrane wall tube cage

Doc.: TI-700_eng-R1 - iNook.doc

SCHNEIDER Engineering GmbH

Email / Internet

Hildburghauser Strae 79

12249 Berlin

Tel.: +49-30-75 44 93 99-0

Fax: +49-30-75 44 93 99-21

info@schneider-kessel.com

www.schneider-kessel.com

no.

: TI-700_eng

rev.

: 1

date

: 14.10.10

TECHNICAL INFORMATION

page

: 4 von 6

SCHNEIDER-High Pressure Steam Generator

for closed circuits - Series iNook

3. Main Characteristics of iNook

Safe and reliable operation due to Membrane Wall design, no risk of surface overheating by obstruction of circulation.

Minimized furnace volume load and heating surface load by thoroughly adjusted boiler

design.

Ideally adjustably to limited spaces by compact design.

Self supporting design and unobstructed vertical expansion.

High flexibility of fuel range.

72 hrs supervision free operation by state-of-the-art electronic boiler control system.

No hazardous substances such as thermal oils used for heat transfer.

No risk of corrosion in the steam and condensate system due to welded connections

instead of flanged.

High plant efficiency by optimized and efficient heat transfer avoiding flue gas leakages

by using the Membrane Wall design.

Possibility of further increasing the plant efficiency by utilizing the flue gas heat i.e. with

waste recovery systems such as combustion air pre-heater.

Pre-assembled boiler system including control box, electrical wiring etc. minimizing the

installation time on site.

4. Application

The iNook supplies high pressure steam for process engineering plants where special safety regulations are enforced especially in productions where leakages shall not contaminate the product.

This requirement can only be met with water of treated quality but not when using thermal oil for

heat transfer.

Hence the main application of the iNook is the entire food industry especially focussed on

-

deodorant of edible oil and fat

distillation, fractioning and esterification of various raw materials

Doc.: TI-700_eng-R1 - iNook.doc

SCHNEIDER Engineering GmbH

Email / Internet

Hildburghauser Strae 79

12249 Berlin

Tel.: +49-30-75 44 93 99-0

Fax: +49-30-75 44 93 99-21

info@schneider-kessel.com

www.schneider-kessel.com

no.

: TI-700_eng

rev.

: 1

date

: 14.10.10

TECHNICAL INFORMATION

page

: 5 von 6

SCHNEIDER-High Pressure Steam Generator

for closed circuits - Series iNook

5. Manufacturing and Equipment

Design and fabrication of the iNOOK is in accordance with the German Technical Regulation for

Steam Boiler (TRD) respectively Euronorm EN-12953 in connection with the Pressure Vessel Directive DGRL 97/23/EG as stationary boiler (land-based boiler).

The fabrication is supervised and monitored by TV the German Steam Boiler Supervision Authority. In addition we are able to deliver in compliance with standards such as ASME, BS, Vincotte,

Stoomwezen, APAVE, ISPESL, DOSH, Australia, New Zealand, Japan, etc.

Boiler equipment and control systems are certified by the respective classification authorities.

Depending on the specific requirements the iNook is equipped with the matching equipment. Decisive for the selection of the equipment are:

required level of automation i.e. supervision free operation

required control and monitoring grade

required grade of minimizing of operational costs

required grade of plant efficiency

required grade of plant safety and plant availability

fuel availability

Basic equipment of the iNook

pressure body including boiler casing and insulation

firing system in monobloc design for

gaseous fuels such as natural gas L and H, bio gas, LPG

liquid fuels such as LFO, HFO, bio diesel

control box including the control system such as

o

pressure control

burner control

boiler safety chain with emergency push button

main power supply connection

safety valve with rupture disk and leakage control

low water level limiter

Doc.: TI-700_eng-R1 - iNook.doc

SCHNEIDER Engineering GmbH

Email / Internet

Hildburghauser Strae 79

12249 Berlin

Tel.: +49-30-75 44 93 99-0

Fax: +49-30-75 44 93 99-21

info@schneider-kessel.com

www.schneider-kessel.com

no.

: TI-700_eng

rev.

: 1

date

: 14.10.10

TECHNICAL INFORMATION

page

: 6 von 6

SCHNEIDER-High Pressure Steam Generator

for closed circuits - Series iNook

pressure switch

pressure limiter

pressure transmitter

direct reading pressure gauge with gauge valve

flame sensor

test valve for water level

feed and drain valve with check valve

Optional equipment for the iNook

firing system in monobloc design for additional 2 alternative fuels including control system

cascade control when more than one (1) boiler are in operation

feed forward control i.e. by product temperature

2nd safety valve including rupture disk and leakage control

exhaust gas temperature limiter

boiler water filling pump including equipment.

6. Technical Data

We supply the iNook in the capacity range from 150 kW up to 4000 kW. Boilers for larger capacities are available upon request and will be custom designed.

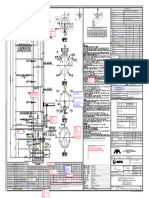

For further technical Information we kindly refer to the following data sheets:

SCHNEIDER high-pressure steam generator as natural circulation boiler

Type iNook

f DB-402 iNook (Dimensions)

f DB-406 iNook (PID)

Doc.: TI-700_eng-R1 - iNook.doc

SCHNEIDER Engineering GmbH

Email / Internet

Hildburghauser Strae 79

12249 Berlin

Tel.: +49-30-75 44 93 99-0

Fax: +49-30-75 44 93 99-21

info@schneider-kessel.com

www.schneider-kessel.com

Você também pode gostar

- Ritter Solar GMBH & Co. KGDocumento30 páginasRitter Solar GMBH & Co. KGMagdyAinda não há avaliações

- WKG Surface Condenser Systems GuideDocumento2 páginasWKG Surface Condenser Systems GuideJuan MendozaAinda não há avaliações

- Aluminium Plate-Fin Heat Ex Changers - LindeDocumento12 páginasAluminium Plate-Fin Heat Ex Changers - LindesoxalAinda não há avaliações

- Efficient and environmentally friendly compact chillersDocumento6 páginasEfficient and environmentally friendly compact chillersMohd NaserAinda não há avaliações

- ICI Caldaie Catalogue ENGDocumento102 páginasICI Caldaie Catalogue ENGaxs00Ainda não há avaliações

- Fabrication of Industrial Thermocouple PDFDocumento2 páginasFabrication of Industrial Thermocouple PDFMarvinAinda não há avaliações

- Heat ExchangerDocumento12 páginasHeat ExchangeremergingengineerAinda não há avaliações

- Incalzire Industriala Prin Pardoseala Uponor - UPOTERMDocumento32 páginasIncalzire Industriala Prin Pardoseala Uponor - UPOTERMUPOTERMAinda não há avaliações

- Einhell Air ConditionnerDocumento29 páginasEinhell Air ConditionnerAbdou RamziAinda não há avaliações

- Marellibrochurecplte 072011 UKDocumento73 páginasMarellibrochurecplte 072011 UKAkbar GhifariAinda não há avaliações

- Technical Specification 92835016 - 02 040516 PDFDocumento27 páginasTechnical Specification 92835016 - 02 040516 PDFDuong BuiAinda não há avaliações

- German innovation powers efficient data centre coolingDocumento2 páginasGerman innovation powers efficient data centre coolingSoLiTaRiO33Ainda não há avaliações

- STULZ CyberCool2 Brochure 0913 enDocumento0 páginaSTULZ CyberCool2 Brochure 0913 enEmmanuel MunozAinda não há avaliações

- Individual Solutions: Air-Cooled Heat ExchangersDocumento22 páginasIndividual Solutions: Air-Cooled Heat ExchangersMiguel SoteloAinda não há avaliações

- Schuco-TH CTE220 Collector CH2-P3523Documento4 páginasSchuco-TH CTE220 Collector CH2-P3523MSEGLLCAinda não há avaliações

- Vitosol 100-F TDMDocumento4 páginasVitosol 100-F TDMthermosol5416Ainda não há avaliações

- Wkze AhuDocumento18 páginasWkze AhuShahrukh AnsariAinda não há avaliações

- PANEADocumento20 páginasPANEAAndrey TazAinda não há avaliações

- Project Submission StandardDocumento4 páginasProject Submission StandardAshique Muhammed T MAinda não há avaliações

- Sinter Cooler Design by Paul Wurth : ISSN 2176-3135Documento12 páginasSinter Cooler Design by Paul Wurth : ISSN 2176-3135Rodrigo Santos MoreiraAinda não há avaliações

- CoolingDocumento16 páginasCoolingyuvrajAinda não há avaliações

- Danfoos District Cooling Interface ModuleDocumento2 páginasDanfoos District Cooling Interface ModuleatiqulaAinda não há avaliações

- Natalini Producst LineDocumento12 páginasNatalini Producst LineVisan GheorgheAinda não há avaliações

- Heat Recovery Steam Generators Design and Operation (2nd Edition) PDFDocumento93 páginasHeat Recovery Steam Generators Design and Operation (2nd Edition) PDFKimberly ConleyAinda não há avaliações

- Incalzire Industrială ENGLEZADocumento32 páginasIncalzire Industrială ENGLEZAalid1234Ainda não há avaliações

- Ferroli Commercial and Industrial Boilers GuideDocumento36 páginasFerroli Commercial and Industrial Boilers Guidedongta123Ainda não há avaliações

- Process Air Fans: Movement by PerfectionDocumento25 páginasProcess Air Fans: Movement by PerfectionsukamtoAinda não há avaliações

- Tugas BoilerDocumento33 páginasTugas BoilerAgus Dwi Nurcahyo JemberAinda não há avaliações

- eBroc-Shell and Tube Heat Exchangers Model Series and Customer Oriented Solutions, FunkeDocumento18 páginaseBroc-Shell and Tube Heat Exchangers Model Series and Customer Oriented Solutions, FunkeMoly69xAinda não há avaliações

- Ewyq FDocumento54 páginasEwyq FRicardo Molina SánchezAinda não há avaliações

- Coolex Catalog Concealed Ducted Split Units R22Documento20 páginasCoolex Catalog Concealed Ducted Split Units R22Mohammad Abdul Aziz40% (5)

- Chips Melting FurnaceDocumento2 páginasChips Melting Furnacerazen_inAinda não há avaliações

- Air-Cooled Heat ExchangersDocumento16 páginasAir-Cooled Heat Exchangersalex200301Ainda não há avaliações

- Showcases District Cooling StockholmDocumento4 páginasShowcases District Cooling StockholmBalasundaramSrinivasaRajkumarAinda não há avaliações

- E401 1000 Air Cooled CondensersDocumento4 páginasE401 1000 Air Cooled CondensersNguyen Anh TuanAinda não há avaliações

- Hidria Air Handling Units en 2012 Web 1Documento35 páginasHidria Air Handling Units en 2012 Web 1Dan RollorataAinda não há avaliações

- Backup Vaporizers for Olefin PlantsDocumento4 páginasBackup Vaporizers for Olefin PlantsNana TwumAinda não há avaliações

- Self-Limiting Heat Tracing Cable Type PSB / HSB : 1 ApplicationDocumento2 páginasSelf-Limiting Heat Tracing Cable Type PSB / HSB : 1 ApplicationNicolas150956Ainda não há avaliações

- Catalogue CF For CTI 2.00 15dec2015Documento104 páginasCatalogue CF For CTI 2.00 15dec2015X-flies0% (1)

- Improve Tropicool Chiller PerformanceDocumento5 páginasImprove Tropicool Chiller Performancegauravking26Ainda não há avaliações

- Chillers & Fan Coil Units: Catalogue 2012Documento20 páginasChillers & Fan Coil Units: Catalogue 2012birlograresAinda não há avaliações

- Ferroli Commercial Range Guide 2012Documento48 páginasFerroli Commercial Range Guide 2012MUBASHIRAinda não há avaliações

- Commercial Boiler GuideDocumento36 páginasCommercial Boiler GuideMUBASHIRAinda não há avaliações

- 122 Slimkon GBDocumento8 páginas122 Slimkon GBDursun ÇakrakAinda não há avaliações

- Electric Surface Heating en (Main Bag House)Documento22 páginasElectric Surface Heating en (Main Bag House)Alejandra A. Nuñez Vidal100% (1)

- Euroclima ZHK INOVA Englisch 11 2022 InternetDocumento16 páginasEuroclima ZHK INOVA Englisch 11 2022 InternetXIN NIUNIUAinda não há avaliações

- FOGTEC Technical InformationDocumento46 páginasFOGTEC Technical InformationFlorin GeorgeAinda não há avaliações

- OUEEN_BROn.fh11 2/27/10 2:54 PM Page 1Documento4 páginasOUEEN_BROn.fh11 2/27/10 2:54 PM Page 1anescuveronicaAinda não há avaliações

- Long Span FloorsDocumento28 páginasLong Span FloorsAshish HoodaAinda não há avaliações

- Chiller - CarrierDocumento27 páginasChiller - CarrierJose Francisco Varela CruzAinda não há avaliações

- Airflow Duplex 15000 H RVDocumento8 páginasAirflow Duplex 15000 H RVAnthony AmarraAinda não há avaliações

- Boldrocchi GroupDocumento19 páginasBoldrocchi GroupNguyenHoangNamTuAinda não há avaliações

- Ccea-Slb001-E4 - 0606 (Ccea 5se - Size 5)Documento8 páginasCcea-Slb001-E4 - 0606 (Ccea 5se - Size 5)abioduncityAinda não há avaliações

- Manual of Modern Hydronics Section 1 4 PDFDocumento58 páginasManual of Modern Hydronics Section 1 4 PDFBorkoBGAinda não há avaliações

- PreviewDocumento20 páginasPreviewgian garaAinda não há avaliações

- CUX Commercial CO2 Coolers 1.5-7.1kWDocumento4 páginasCUX Commercial CO2 Coolers 1.5-7.1kWRodrigo GonçalvesAinda não há avaliações

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsNo EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsNota: 5 de 5 estrelas5/5 (1)

- Ejectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsNo EverandEjectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsAinda não há avaliações

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesNo EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesNota: 3.5 de 5 estrelas3.5/5 (3)

- 117 Excerpts 2004Documento7 páginas117 Excerpts 2004Anonymous DJrec2Ainda não há avaliações

- The Business Model CanvasDocumento1 páginaThe Business Model CanvasAnonymous DJrec2Ainda não há avaliações

- Factor of Safety On The Geotechnical Information WebsiteDocumento2 páginasFactor of Safety On The Geotechnical Information WebsiteAnonymous DJrec2Ainda não há avaliações

- Development and Future of Circulating Fluidized Bed Boilers in ChinaDocumento4 páginasDevelopment and Future of Circulating Fluidized Bed Boilers in ChinaAnonymous DJrec2Ainda não há avaliações

- Evolution of Management ThoughtDocumento17 páginasEvolution of Management ThoughtAnonymous DJrec2Ainda não há avaliações

- Bearing Capacity Factors On The Geotechnical Information WebsiteDocumento2 páginasBearing Capacity Factors On The Geotechnical Information WebsiteAnonymous DJrec2Ainda não há avaliações

- Cohesion On The Geotechnical Information WebsiteDocumento2 páginasCohesion On The Geotechnical Information WebsiteAnonymous DJrec2Ainda não há avaliações

- Foundation Code 2004Documento64 páginasFoundation Code 2004Patie Zheng100% (2)

- External Friction Angle On The Geotechnical Information WebsiteDocumento2 páginasExternal Friction Angle On The Geotechnical Information WebsiteAnonymous DJrec2100% (1)

- 4 - Technical Specifications For Piling Works - Pile Foundation For Tanks - ParadeepDocumento48 páginas4 - Technical Specifications For Piling Works - Pile Foundation For Tanks - Paradeepvignesh_freeboterAinda não há avaliações

- Foundation Code 2004Documento64 páginasFoundation Code 2004Patie Zheng100% (2)

- CFD Simulation On CFBC BoilerDocumento6 páginasCFD Simulation On CFBC BoilerAnonymous DJrec2Ainda não há avaliações

- BEM Code of Ethics - Ir. Yim Hon WaDocumento53 páginasBEM Code of Ethics - Ir. Yim Hon WaAnonymous DJrec2Ainda não há avaliações

- Managing A Safe Work PlaceDocumento3 páginasManaging A Safe Work PlaceAnonymous DJrec2Ainda não há avaliações

- 0217 PresentationDocumento73 páginas0217 PresentationHector RodriguezAinda não há avaliações

- Malaysia Kia Sportage Price List 2012Documento1 páginaMalaysia Kia Sportage Price List 2012Anonymous DJrec2Ainda não há avaliações

- The Nature and Purpose of Accounting ExplainedDocumento16 páginasThe Nature and Purpose of Accounting ExplainedSubashiиy PяabakaяaиAinda não há avaliações

- Understanding MarketingDocumento5 páginasUnderstanding MarketingAnonymous DJrec2Ainda não há avaliações

- Power Amps Efficiency PFDocumento5 páginasPower Amps Efficiency PFAnonymous DJrec2Ainda não há avaliações

- Engineers in Construction Industry - Ir. Choo Kok BengDocumento22 páginasEngineers in Construction Industry - Ir. Choo Kok BengAnonymous DJrec2Ainda não há avaliações

- BEM Code of EthicsDocumento11 páginasBEM Code of EthicsAbdul Hakim AbdullahAinda não há avaliações

- The Nature and Purpose of Accounting ExplainedDocumento16 páginasThe Nature and Purpose of Accounting ExplainedSubashiиy PяabakaяaиAinda não há avaliações

- Industrial LowbayDocumento8 páginasIndustrial LowbayAnonymous DJrec2Ainda não há avaliações

- Dry-Type Transformers: Codes and Standards Enhancement (CASE) StudyDocumento22 páginasDry-Type Transformers: Codes and Standards Enhancement (CASE) StudyAnonymous DJrec2Ainda não há avaliações

- HarmonicsDocumento7 páginasHarmonicsAnonymous DJrec2Ainda não há avaliações

- Motor Load and Efficiency PDFDocumento16 páginasMotor Load and Efficiency PDFwfjerrAinda não há avaliações

- Basics of Power CableDocumento7 páginasBasics of Power CableAnonymous DJrec2Ainda não há avaliações

- Third Quarter 2016 Investment Outlook: Asset Class SectorDocumento6 páginasThird Quarter 2016 Investment Outlook: Asset Class SectorAnonymous DJrec2Ainda não há avaliações

- CiMB Research Report On REITDocumento6 páginasCiMB Research Report On REITAnonymous DJrec2Ainda não há avaliações

- Largest House of Hydraulics Process & Instrumentation Pumps & Valve Automation Filter & Seals Lub - Sys.& Spares Hoses & Fitting Importer& ExporterDocumento2 páginasLargest House of Hydraulics Process & Instrumentation Pumps & Valve Automation Filter & Seals Lub - Sys.& Spares Hoses & Fitting Importer& Exportersanjeev267Ainda não há avaliações

- TCV 101Documento1 páginaTCV 101Juan Krloz CastañedaAinda não há avaliações

- Piping GuideDocumento10 páginasPiping GuidezenpraveenAinda não há avaliações

- Rules of thumb for pump selection and operationDocumento6 páginasRules of thumb for pump selection and operationSarjit ChoksiAinda não há avaliações

- DEARATOR Post Manual FR (R)Documento138 páginasDEARATOR Post Manual FR (R)Ehtisham ul haqAinda não há avaliações

- G10 - Solids and FluidsDocumento46 páginasG10 - Solids and FluidsOliver VillanuevaAinda não há avaliações

- AXERA 5 126 Oil Circuit PartsDocumento20 páginasAXERA 5 126 Oil Circuit PartsLiliana Rebeca Santos santosAinda não há avaliações

- Graspit Gcse Write OnDocumento5 páginasGraspit Gcse Write OnKausar AhmedAinda não há avaliações

- QUIZ-Hazardous Area ClassificationDocumento2 páginasQUIZ-Hazardous Area ClassificationPillai Sreejith100% (4)

- Mass & Heat BalanceDocumento14 páginasMass & Heat BalanceTruth SeekerAinda não há avaliações

- 4274-CD-VD-LG201000019D1004001 - US CommentedDocumento1 página4274-CD-VD-LG201000019D1004001 - US CommentedUnmesh ShuklaAinda não há avaliações

- Compact Chem-Tech Series 100/150 Dosing Pumps GuideDocumento2 páginasCompact Chem-Tech Series 100/150 Dosing Pumps GuidechindycinAinda não há avaliações

- Effect of Blade Profiles On The Performance of BidDocumento9 páginasEffect of Blade Profiles On The Performance of BidSthefanoAinda não há avaliações

- Direct Fired Vaporizer UpgradesDocumento5 páginasDirect Fired Vaporizer UpgradesYogi MaulanaAinda não há avaliações

- Heat & Thermodynamics - Test - pdf-1Documento10 páginasHeat & Thermodynamics - Test - pdf-1VishalAinda não há avaliações

- Acid Dew Point - Encyclopedia Article - CitizendiumDocumento4 páginasAcid Dew Point - Encyclopedia Article - Citizendiuminsult2injury100% (1)

- Engineering All in OneDocumento245 páginasEngineering All in OneozchrisAinda não há avaliações

- Evaporation 2Documento18 páginasEvaporation 2Kuma Gloria100% (1)

- VTG Iom 2013 0815Documento96 páginasVTG Iom 2013 0815nishant361Ainda não há avaliações

- Aerodynamics, Aeronautics, and Flight Mechanics: Barnes W. Mccormick, PH.DDocumento5 páginasAerodynamics, Aeronautics, and Flight Mechanics: Barnes W. Mccormick, PH.DFabio SplendorAinda não há avaliações

- LCI LS300 Users ManualDocumento8 páginasLCI LS300 Users ManualberlysvAinda não há avaliações

- Format No SWPL-0221-QA-FRMT-010Documento53 páginasFormat No SWPL-0221-QA-FRMT-010Swathy Nath PAinda não há avaliações

- Class 9 Matter in Our Surroundings McqsDocumento3 páginasClass 9 Matter in Our Surroundings McqsHariharan VIIA1Ainda não há avaliações

- Gujarat Technological UniversityDocumento2 páginasGujarat Technological UniversityChavda jayesh laljibhaiAinda não há avaliações

- Fractional Distillation: Fractional Distillation Is The Separation of A Mixture Into Its Component Parts, orDocumento11 páginasFractional Distillation: Fractional Distillation Is The Separation of A Mixture Into Its Component Parts, orDhaval SakariyaAinda não há avaliações

- Diamatre Teava - PEDDocumento72 páginasDiamatre Teava - PEDAlin TomozeiAinda não há avaliações

- Mecánica de Fluidos: Problema 1Documento4 páginasMecánica de Fluidos: Problema 1JUAN DAVID MAYA ZAMORAAinda não há avaliações

- Pneumatic HammerDocumento45 páginasPneumatic HammerKarthi KeyanAinda não há avaliações

- Refrigerant SafetyDocumento4 páginasRefrigerant SafetyPratikno SajaAinda não há avaliações

- ScheduleDocumento2 páginasSchedulecbcyouthygnAinda não há avaliações