Escolar Documentos

Profissional Documentos

Cultura Documentos

Alternative Fuel Systems - Sales and Technical Guide

Enviado por

JDPSoaresTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Alternative Fuel Systems - Sales and Technical Guide

Enviado por

JDPSoaresDireitos autorais:

Formatos disponíveis

Alternative Fuel Systems - sales and technical guide

Section 1 - Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Section 2 - Digester and landfill gases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.1 Definition and sources . . . . . . . . . . . .

2.2 Characteristics of digester gas . . . . . . .

2.3. Digester/landfill gas system evaluation.

2.4. Components. . . . . . . . . . . . . . . . . . .

2.5. Control Schemes. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Section 3 - Fuels requiring special engineering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Section 4 - Unacceptable fuels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1

01-12

Alternative Fuel Systems

SECTION 1: INTRODUCTION

Cleaver-Brooks defines alternative fuel(s) as that which is other than standard

commercially available fuel; used with a burner/boiler combination. Standard,

commercially available fuels include natural gas, light oil, and heavy oil. Hence, all

other fuels including but not limited to digester gas, landfill gas, solvents, waste

oils, hydrogen, town gas, or biogas are considered nonstandard, waste, or

alternative.

Over the years, Cleaver-Brooks has offered alternative fuel systems and gained

considerable experience in this field, including custom designs engineered around

specific onsite requirements.

We have developed standard systems to fire digester and landfill gas. All other fuels

will require up-front evaluation.

SECTION 2: DIGESTER AND LANDFILL GASES

2.1 Definition and sources

Digester gas typically refers to gas produced by the fermentation of organic matter

such as manure, wastewater sludge, municipal solid waste, or any other

biodegradable feedstock, under anaerobic (absence of oxygen) conditions. Digester

gas is also called biogas, swamp gas, landfill gas, or sewer gas, depending on

where it is produced. Each variant has different levels of methane and carbon

dioxide with other minor gases. However, in general the heating value and

composition of these gases is essentially known, and therefore they can be used as

a fuel in Cleaver-Brooks boilers.

2.2 Characteristics of digester gas

Characteristics of digester gas vary depending on the source. Typical chemical

breakdown variations and properties are presented in the following tables.

Table 1. Typical analysis of digester gas

Component

Methane

Carbon Dioxide

Hydrogen Sulfide

Water Vapor

Other Gases

Chemical Formula

CH4

CO2

H2S

H2O

CO, N2, O2

2

01-12

% Vol

50-65

35-50

Trace 2

3-6

1-10

Alternative Fuel Systems

Table 2. Digester and natural gas comparison

Characteristic

Units

Digester Gas

Natural gas

Heating Value

Btu/Scf

500-600

950-1100

Specific gravity (Air = 1.0)

N/A

0.85 0.95

0.6 0.64

Hydrogen Sulfide

% Vol

Trace - 2

None

Water Vapor

% Vol

36

(Saturated)

None

Temperature

degF

75-120

Ambient

6-15

27.7 277 (1 10

PSIG)

Supply Pressure

IWC

2.3. Digester/landfill gas system evaluation

2.3.1. Digester gas has only about half the heating value of natural gas, is heavier

than natural gas, and is typically supplied at a lower pressure than natural gas.

These facts create the need for a system that can handle high flow rates of gas with

minimum pressure drop.

2.3.2. The higher flow rates also have a major impact on burner design and

performance. A special burner should be used to provide adequate gas velocities for

good mixing but without excessive pressure drop.

2.3.3. Digester gas usually contains some hydrogen sulfide (H2S), and is saturated

with water. These characteristics create a corrosive environment for the gas piping,

valving, exhaust breeching and stack, should condensation occur. We therefore

require (contact) components be resilient to these conditions, using materials such

as stainless steel, providing better corrosion resistance than carbon steel.

2.3.4. Digester gas systems are usually hot water or low pressure steam systems

because they are often used for heating at the site location. These boilers produce

low flue gas exit temperatures adding to the corrosive issues in the boiler system.

2.3.5. The digester gas supply is not always reliable and can be frequently

interrupted. Therefore, the boiler system must be capable of responding to

interruptions or inadequate supply of digester gas while continuing to meet the

plants heat demand.

2.3.6. Often natural gas is used as a primary backup when digester gas supply

interruptions occur. Normally, this is accomplished by the use of a dual canister gas

burner housing with a control system that can automatically change over to the

backup fuel.

3

01-12

Alternative Fuel Systems

Figure I5-1. Dual Canister Burner

2.4. Components

Sulfur in any gas can be combined with hydrogen in the combustion process

resulting in (corrosive) hydrogen sulfide. During cold startups, and if the

combustion gas is cooled below its dew point, condensation occurs and the

hydrogen sulfide condenses with the water vapor. This product is extremely

damaging to carbon steel and to some gasket materials. Therefore, it is imperative

the correct materials are selected to ensure long life of the equipment.

2.4.1. Gas Train - Separate gas trains are supplied for natural gas and digester gas.

Corrosion resistant components are used for valves and switches on the digester gas

train. In addition, all digester gas trains are supplied with two automatic safety shut

off valves regardless of insurance requirements This is to ensure that the corrosive

gas does not leak into the boiler when not in use. These automatic shut off valves

have electric or pneumatic spring-return actuators.

2.4.2. Gas Pressure Regulator - Since digester gas is usually supplied at relatively

low pressure (6-15 W.C.), the gas pressure regulator must be capable of operation

at high gas flow rates with minimum pressure drop. Since most regulator suppliers

sizing data is based on natural gas, a correction factor is used to properly size the

regulator.

2.4.3. Dual gas burner - For integral head firetube boilers firing digester gas with a

4

01-12

Alternative Fuel Systems

backup gas, Cleaver-Brooks uses our patented dual canister housing burner (see

figure 1). The design of this burner system allows separate combustion control for

two gases with different fuel characteristics.

The dual canister burner components are sized such that the digester gas system

components are designed based on the digester gas fuel composition. The backup

fuel system is separately designed based on the backup fuel composition.

Hence, different materials may be used for each fuel to ensure long component life,

maximum burner efficiencies, and safety.

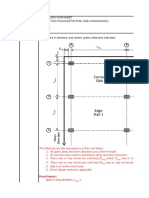

Figure I5-2. Dual Gas Train Schematic

Table 3. Gas Train Components

Natural Gas

Tag #

PCV-010

HV-010A

PSL-010

FV-010A

FV-010B

FV-010C

PSH-010

HV-010B

CV-010

NA

NA

Digester Gas

Tag #

PCV-020

HV-020A

PSL-020A

FV-020A

FV-020B

FV-020C

PSH-020

HV-020B

CV-020

PSL-020B

T-020

Function

Gas Pressure Regulator

Manual Shut Off Valve

Low Gas Pressure Switch

Automatic Shut Off Valve

Vent valve

Automatic Shut Off Valve

High Gas Pressure Switch

Manual Shut Off Valve

Firing Rate Modulating Valve

Automatic Fuel Changeover Switch *

Flame Arrester with Check Valve*

* Optional components

5

01-12

Alternative Fuel Systems

2.5. Control Schemes

Over the years Cleaver-Brooks has used many different control schemes for firing

digester gas. Most of these schemes were customized to the specific customer

needs. Control scheme selection can be based on a number of factors including

digester gas pressure, boiler size, number of boilers in a plant, and availability of

digester gas. The most common control schemes are described below.

2.5.1. Automatic fuel changeover - The purpose of this control scheme is to

automatically switch from digester gas to a back up fuel whenever digester gas

supply becomes insufficient to meet the control settings. This option requires an

automatic fuel changeover pressure switch, which is typically installed prior to the

digester gas pressure regulator. When the boiler demand exceeds availability of the

digester gas fuel, digester gas pressure drops, tripping the changeover pressure

switch. The controls will modulate to the minimum firing position. Once minimum

burner position is proven, the burner shuts down and then re-starts, firing the back

up fuel. When digester gas pressure is restored, the aforementioned sequence is

reversed, and the burner re-starts, firing digester gas.

2.5.2. Preferential firing - The purpose of this control scheme is to fire all the

digester gas available. In order for this control scheme to work, another boiler is

required to maintain adequate steam pressure (water temperature) when the

digester gas supply cannot meet heat/process load demand.

Figure I5-3. Preferential Firing Control Scheme

Pressure/Temperature controller PTC-030 receives boiler outlet temperature signal

from temperature transmitter TT-040 and digester gas pressure signal from

6

01-12

Alternative Fuel Systems

pressure transmitter PT-020. Output to the firing rate control valve CV-020 is based

on these two signals. When digester gas pressure is above set point, firing rate is

based on the heat demand, i.e. boiler outlet pressure/temperature. When digester

gas pressure drops below set point, firing rate signal is reduced to maintain digester

gas pressure. Hence the control scheme ensures that all available digester gas can

be burned. Automatic fuel changeover and low fire hold is incorporated into the

control algorithm of PTC-030.

2.5.3. Simultaneous Firing - This control scheme will require up-front evaluation on

a job-to-job basis.

SECTION 3. FUELS REQUIRING SPECIAL ENGINEERING.

The following is a list of fuels which will require special engineering:

Hydrogen

Refinery gases

Contaminated air

Coke oven gas

Solvents

Waste oil

SECTION 4. UNACCEPTABLE FUELS.

The following fuels are not acceptable for use in Cleaver-Brooks boilers:

Solid fuels

Acids

Radioactive material

Caustics

7

01-12

Você também pode gostar

- IncineratorDocumento24 páginasIncineratorDhemas Dhamar AdhikaAinda não há avaliações

- 750-392-Cbex-De10 OkDocumento124 páginas750-392-Cbex-De10 OkPedro RojasAinda não há avaliações

- Blowdown System Boiler BookDocumento16 páginasBlowdown System Boiler BookMatias MancillaAinda não há avaliações

- Ger 4189B PDFDocumento20 páginasGer 4189B PDFCarlos Ruiz DiazAinda não há avaliações

- Steam Boiler Spec.Documento17 páginasSteam Boiler Spec.bandithaguru6338100% (1)

- FMDS0604Documento17 páginasFMDS0604Henry SuarezAinda não há avaliações

- StartupOperating&MaintSTD - RFG1 Fuel Gas SkidDocumento14 páginasStartupOperating&MaintSTD - RFG1 Fuel Gas Skidczekjo100% (1)

- Boiler Learning ModuleDocumento158 páginasBoiler Learning ModuleMallinatha PNAinda não há avaliações

- Technical Report ExampleE-GasDocumento28 páginasTechnical Report ExampleE-Gaszubair1951Ainda não há avaliações

- Thermal and Catalytic CombustionDocumento67 páginasThermal and Catalytic CombustionParas ChahalAinda não há avaliações

- Bladder Accum - Gas PermeationDocumento6 páginasBladder Accum - Gas Permeationahbipn1Ainda não há avaliações

- 0519 - R304P - Westinghouse Technology 15.3 Gaseous Radioactive Waste Processing SystemsDocumento22 páginas0519 - R304P - Westinghouse Technology 15.3 Gaseous Radioactive Waste Processing SystemsRAMI HAMADAinda não há avaliações

- Mex 30201Documento24 páginasMex 30201Yousef Adel HassanenAinda não há avaliações

- Visbreaking Unit PDFDocumento17 páginasVisbreaking Unit PDFMarcos Maldonado100% (1)

- LNG Boil-Off Re-Liquefaction Plants and Gas Combustion UnitsDocumento7 páginasLNG Boil-Off Re-Liquefaction Plants and Gas Combustion UnitsAshish SawantAinda não há avaliações

- Chapter 2 Single Burner Boilers: Boiler and Combustion Systems Hazards CodeDocumento12 páginasChapter 2 Single Burner Boilers: Boiler and Combustion Systems Hazards CodeJosé Olivier RománAinda não há avaliações

- Fire HeatDocumento231 páginasFire HeatprabhuarunkumarAinda não há avaliações

- Module 5 - Fuel Cell SystemsDocumento32 páginasModule 5 - Fuel Cell Systemsjim chimaicoAinda não há avaliações

- Project Standards and Specifications Fuel Systems Rev01Documento11 páginasProject Standards and Specifications Fuel Systems Rev01Francis BoeyAinda não há avaliações

- Oilon 3 ENDocumento32 páginasOilon 3 ENHrishikesh RokadeAinda não há avaliações

- Engineering Guide To Modern Fuel SystemsDocumento28 páginasEngineering Guide To Modern Fuel SystemsmohmdAinda não há avaliações

- Fuel Burner & Firebox Operation & ControlDocumento33 páginasFuel Burner & Firebox Operation & ControlMohammad Rawoof50% (2)

- Ant) - Ok3Documento36 páginasAnt) - Ok3zainudin simonAinda não há avaliações

- Jeep Grand Cherokee WJ - 14a-3.1 TD - Sistema InyecciónDocumento38 páginasJeep Grand Cherokee WJ - 14a-3.1 TD - Sistema Inyecciónpakiturbo2papeles100% (3)

- Refrigerant Piping Rev2Documento31 páginasRefrigerant Piping Rev2123john123Ainda não há avaliações

- Final and Final Draft Main BodyDocumento58 páginasFinal and Final Draft Main BodyHailemariam WeldegebralAinda não há avaliações

- Final and Final Draft Main BodyDocumento57 páginasFinal and Final Draft Main BodyTolasa NamomsaAinda não há avaliações

- 1.2.2 Treater Burner Management System and Firetube Upgrades SJD 2 PDFDocumento3 páginas1.2.2 Treater Burner Management System and Firetube Upgrades SJD 2 PDFbasselAinda não há avaliações

- Controlling Fired Heaters: INTRODUCTION. The Purpose of A FiredDocumento24 páginasControlling Fired Heaters: INTRODUCTION. The Purpose of A FiredAntonio MezzopreteAinda não há avaliações

- Steam Generation PlantDocumento38 páginasSteam Generation PlantsenaAinda não há avaliações

- Martinsville User ManualDocumento116 páginasMartinsville User Manualharry_chemAinda não há avaliações

- 01 30 71 210Documento17 páginas01 30 71 210Han Han0% (1)

- Gaseous Fuel Systems - Application & Installation GuideDocumento36 páginasGaseous Fuel Systems - Application & Installation GuidelamAinda não há avaliações

- Combustion Heavy DutyDocumento28 páginasCombustion Heavy DutyIvan Poma Montes100% (1)

- Site Visit ReportDocumento7 páginasSite Visit ReportAhmad0% (1)

- Naini Tissues FDSDocumento20 páginasNaini Tissues FDSHarshit SharmaAinda não há avaliações

- Ref N° 4 - FUEL GAS SYSTEM - DESIGN PHILOSOPHYDocumento12 páginasRef N° 4 - FUEL GAS SYSTEM - DESIGN PHILOSOPHYlxz861020100% (1)

- Fuel Oil SystemDocumento14 páginasFuel Oil Systemcherrym805Ainda não há avaliações

- Boiler Fuel Firing SystemDocumento44 páginasBoiler Fuel Firing Systemrashm006ranjanAinda não há avaliações

- Indice Curso de Vapor Spirax SarcoDocumento20 páginasIndice Curso de Vapor Spirax SarcoDavidAinda não há avaliações

- Ashrae Handbook 2000 CHDocumento14 páginasAshrae Handbook 2000 CHKazuto NakazatoAinda não há avaliações

- Boiler Book CBEX Premium 100-800Documento19 páginasBoiler Book CBEX Premium 100-800fauzi endraAinda não há avaliações

- Gaseous Fuel Systems (Lebw5336-04)Documento36 páginasGaseous Fuel Systems (Lebw5336-04)Mormor Omerta100% (1)

- Dual BurnerDocumento8 páginasDual Burnergintosaju_792849166Ainda não há avaliações

- DZH Installation and Operation ManualDocumento34 páginasDZH Installation and Operation ManualvijayAinda não há avaliações

- Lab 3 Experiment 2Documento10 páginasLab 3 Experiment 2Jads CayabyabAinda não há avaliações

- 1.B.2.c Venting and Flaring GB2009Documento15 páginas1.B.2.c Venting and Flaring GB2009elijbbAinda não há avaliações

- Overview of Gas Conditioning and ProcessingDocumento14 páginasOverview of Gas Conditioning and ProcessingJOSE GONZALEZ VALEROAinda não há avaliações

- Burner, Series 300-700Documento32 páginasBurner, Series 300-700Luthfi Adri Angkasa PutraAinda não há avaliações

- Oto 01061Documento254 páginasOto 01061Yolanda Marcela Enríquez MéndezAinda não há avaliações

- Boiler Istructional Manual PDFDocumento74 páginasBoiler Istructional Manual PDFcynaiduAinda não há avaliações

- Chapter 2-ME Laws-EquipmentDocumento4 páginasChapter 2-ME Laws-EquipmentPhilip Anthony MasilangAinda não há avaliações

- NashDocumento127 páginasNashHassan FarazAinda não há avaliações

- TA Handbook 3 EngDocumento56 páginasTA Handbook 3 EngmkalamarasAinda não há avaliações

- Modeling, Control, and Optimization of Natural Gas Processing PlantsNo EverandModeling, Control, and Optimization of Natural Gas Processing PlantsNota: 5 de 5 estrelas5/5 (1)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingNo EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingNota: 5 de 5 estrelas5/5 (3)

- Automotive Air Conditioning and Climate Control SystemsNo EverandAutomotive Air Conditioning and Climate Control SystemsNota: 4 de 5 estrelas4/5 (6)

- Fluid Mechanics Munson 7th Solutions FluDocumento3 páginasFluid Mechanics Munson 7th Solutions Flumaj15% (13)

- Firing Boiler Performance DiagramDocumento1 páginaFiring Boiler Performance DiagramJDPSoaresAinda não há avaliações

- An Independent Engineering Evaluation of Waste-To-Energy TechnologiesDocumento7 páginasAn Independent Engineering Evaluation of Waste-To-Energy TechnologiesJDPSoaresAinda não há avaliações

- Biogas Operational ParametersDocumento5 páginasBiogas Operational ParametersJDPSoaresAinda não há avaliações

- Flow SwitchDocumento16 páginasFlow Switchsales1068100% (1)

- Case Study On Operational Inspection of A Fluidised Bed Combustion BoilerDocumento31 páginasCase Study On Operational Inspection of A Fluidised Bed Combustion Boilerparthi20065768Ainda não há avaliações

- Module 1.6 Settling and SedimentationDocumento37 páginasModule 1.6 Settling and SedimentationLong EAinda não há avaliações

- Laporan Material Teknik 2021Documento23 páginasLaporan Material Teknik 2021Rasendriya JettaAinda não há avaliações

- Mini Labo Flyer PDFDocumento2 páginasMini Labo Flyer PDFSinan ÇağlanAinda não há avaliações

- Welding Visual ReportDocumento6 páginasWelding Visual ReportFerdie OSAinda não há avaliações

- PVC Butterfly Valve (Lever)Documento4 páginasPVC Butterfly Valve (Lever)Elias SusantoAinda não há avaliações

- Product Data Sheet 3900 3900vp General Purpose PH Orp Sensors Rosemount en 70722Documento20 páginasProduct Data Sheet 3900 3900vp General Purpose PH Orp Sensors Rosemount en 70722KishorAinda não há avaliações

- Designing For Fire Protection: W D & B SDocumento4 páginasDesigning For Fire Protection: W D & B Scorrine tanAinda não há avaliações

- Remote Earth Cathodic ProtectionDocumento2 páginasRemote Earth Cathodic ProtectionankiAinda não há avaliações

- Electrical Installation in Hazardous Area PresentationDocumento79 páginasElectrical Installation in Hazardous Area PresentationAlfa Mirza100% (1)

- Value EngineeringDocumento20 páginasValue EngineeringSakshi SinghAinda não há avaliações

- Assignment Neutralisation ReactionDocumento1 páginaAssignment Neutralisation ReactionMaridjan WiwahaAinda não há avaliações

- Staining of Tissue Pigments and DepositsDocumento4 páginasStaining of Tissue Pigments and DepositsAnonymous 8rsxG4100% (2)

- Australian/New Zealand Standard: Built-In Components For Masonry Construction Part 1: Wall TiesDocumento7 páginasAustralian/New Zealand Standard: Built-In Components For Masonry Construction Part 1: Wall TiesTulus Ztx ZaputroAinda não há avaliações

- Joseph Abrusci - Professional Homemade Cherry BombsDocumento26 páginasJoseph Abrusci - Professional Homemade Cherry BombsLê Nguyên ĐứcAinda não há avaliações

- Nuratherm PIR TDSDocumento2 páginasNuratherm PIR TDSNathan BlythAinda não há avaliações

- 3 - Mini Frac TestsDocumento45 páginas3 - Mini Frac TestsDeepak RanaAinda não há avaliações

- SECTION 05530 Gratings Rev 1Documento17 páginasSECTION 05530 Gratings Rev 1Mohsin ShaikhAinda não há avaliações

- Mineralogy 100A Syllabus 2016-EditDocumento4 páginasMineralogy 100A Syllabus 2016-Editnot realAinda não há avaliações

- PC Lexan HP6NR Healthcare - ProspectorDocumento5 páginasPC Lexan HP6NR Healthcare - ProspectorcountzeroaslAinda não há avaliações

- Method Statement For Cement Board Dry Wall PartitionsDocumento10 páginasMethod Statement For Cement Board Dry Wall PartitionsComet GroupAinda não há avaliações

- Bolt Depot CatalogDocumento104 páginasBolt Depot Catalogalexmontell100% (2)

- Modified Phosphate and Silica Waste in Pigment PaintDocumento12 páginasModified Phosphate and Silica Waste in Pigment PaintDani M RamdhaniAinda não há avaliações

- Masterflex 700 PGDocumento3 páginasMasterflex 700 PGHaresh BhavnaniAinda não há avaliações

- Materialqualitaeten EDocumento2 páginasMaterialqualitaeten EjvilamaiorAinda não há avaliações

- DIFC Commissioning Schedule - 18.10.2023Documento15 páginasDIFC Commissioning Schedule - 18.10.2023Mohamed AshrafAinda não há avaliações

- Weld Metal CertificateDocumento1 páginaWeld Metal CertificatePhương Do QuangAinda não há avaliações

- Flat SlabDocumento69 páginasFlat Slabmukhlesh100% (1)