Escolar Documentos

Profissional Documentos

Cultura Documentos

Structural Rep Contents

Enviado por

btcong93Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Structural Rep Contents

Enviado por

btcong93Direitos autorais:

Formatos disponíveis

1.

Introduction

Describe the purpose of the report.

2.0

Background

Provide limited detail on the project background and identify why these calculations are

required. Be specific to the structural scope of work only, dont clutter the report with

superfluous information on drilling, pipeline, reservoir data etc

3.0

3.1

External Design Constraints

Site and Physical

3.2

Existing Structures

Note any adjacent structures. This could be topside work such as access restrictions, limited

height and working area or subsea pipelines, crossings, work in side other manifolds,

retrofitting

3.3

Specific Plant and Equipment

If the structure is design to accommodate certain items of plant and equipment provide details

of these. Sizes, weights, fixing details, supplied by who. Specific vendor requirements,

access to certain areas of equipment. Items used on previous projects, corrals, spreader

frames, lay spreads, reels, carousels, chutes, SIT frames, installations aids, Free issue item,

wet welding, friction stud welding. Crane masters. ROVs TMS.

3.4

Project and Commercial

Delivery dates, design completion dates, formal issues to subcontractors to begin fabrication.

4.1

4.2

Project Specific Design Criteria

Design Objective and Requirements

Client Provided Data

Discuss the requirements of the design. What does it need to do, why do we need it

4.3

Design Assumptions

4.0

Note any external constraints which have an effect on the design. This may include

geotechnical restrictions such as soft soil, allowable bearing pressures, areas of special

interest (protected sabeleria tube worms), fishing area restrictions. Client restrictions on the

design, such as no site welding or the need to be dismantled and stored. Road transportable

design (cut in half and bolted/welded). Vessel restrictions, deck space, crane capacity, deck

strength. Diver or ROV access. Clear access points. Large buttons or handles. Weight

restriction. Installation restrictions in terms of vessel, method or crane. Hook height

Information from the Client Basis of Design which is pertinent to the design should be listed.

Design Life, marine growth, water depth. Water depth varies with storm (LAT, MSL, Max 1 yr

storm LAT+ xm, Max 50yr storm LAT + Xm), current profile. Storm surge current (HSE Fig 9)

If there is no information available and you have made assumptions in order to progress the

design then these should be listed and the basis for choice described. Geotechnical

requirements or limits. Marine Growth levels. Significant waves, associated period,

underlying current, item weights, structures, equipment. Which vessel will be used or has

been assumed. Hook height. Crane operating with heave comp.

4.4

Abbreviations

A basic list of abbreviations contained within the report.

4.5

Structural Materials

4.6

Reference Drawings and Documentation

4.7

Design Codes and Standards Adopted

e.g steel to BS EN 10225, or 10025, 10027,10210 etc. Bolts grade 8.8 to BS 3692 ISO metric

precision bolts, nuts Grade 8 nuts, washers, grating grade, steel GRP, ballast, lead, concrete

grade, timber for packing, Anodes, grout bags, frond mats. Modulus of elasticity, yield stress,

ultimate stress, density, poisson ratio, welding and electrode strength. Mechanical properties

List all of the project documents and drawings you have referenced during the design. This

could also include installation procedures and any pertinent aspects.

Specify which code the design is carried out to primarily.

Listing all the standards consulted during the design process and for what purpose

e.g. [1] NORSOK. Subsea Production Systems. Norsok U-001. Norwegian Technology

Centre, Rev 3, October 2002.

5.0

5.1

Design Philosophy and Approach

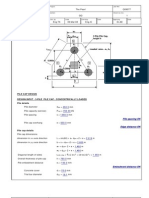

Structural Concept, Load Transfer and Stability

5.2

Analysis Methodology

Hand calculations or computer based. Elastic, plastic, elasto-plastic for impact, local damage

tolerated not to detriment of overall structure. Working stress or ultimate limit state, LRFD.

Parallel hand calculations to support computer based analysis. Sensitivity analysis performed

by varying components such as wave height, heading etc

Design Load Cases

Identify all the possible loads which may be applied to your structure. These may be from

dead weight, imposed loads from plant or operational? Live floor loads? Are there dynamic

effects? Seismic effects? Wind loading? Hydrodynamic effects? Accidental loads such as

impact? Does it need to be lifted?

6.1

Design Factors

Identify any load factors used such as dynamic amplification, boom tip acceleration, ultimate

limit factors is used, consequence factors, specific design code requirements, weight growth

factors, rigging design factors, load factors, material factors, gravity factors

6.2

Self Weight

Refer Weight Control, manual or inventor. Primary steelwork, secondary steelwork, roof

panels, floor panels, grating, side panels, pipe supports control supports, valve supports,

valves, anodes, controls, control tubing/wiring/cable trays, mudmats, installation equipment

(gyros, transponders, bullseye levels etc), ballast insitu and post installed, future expansion

loads, additional piping

6.0

Identify the concept of how the structure will work. Is it going to be stable? Is it braced or

moment resisting? How do you want your structure to work bearing in mind you want to

transfer your forces to a foundation of some description? Do you have degrees of

redundancy? Progressive collapse. If sitting on vessel deck give location in relation to frame

numbers, identify which frames are taking the load.

6.3

Fabrication Loads

Temporary propping causes different structural behaviour, warping stresses due to hot dip

galvanising, residual stress from welding, post weld heat treatment (stress relief) in thick

materials.

6.4

Environmental

Maximum wave heights and associated periods. General circulation currents, tidal currents.

Limit of wave theory. Which one most applicable, airy, stokes, cnoidal. Basis for assessment

of added mass and drag (circular members API/DNV non circular DNV). Wave Loader

software. Wind loads? Ice?. VIV on circular members, resonance and natural frequency

analysis. Seismic

6.5

Lifting and Installation

Skew loads, DNV rules, including loadout and offshore deployment. Design of slings and

FOS. DAF 1.3 onshore DAF 2.0 Offshore. Natural frequency of structure check (compare

against roll period of vessel). Resonance and vibration. Installation loads, lift and shift loads,

pull in loads, wind load induced sway, loadout and mobilisation. Lift and deployment for a

range of Tz to suit one Hs. Vessel heading for lift and deployment (vary if required). DAF 3.0

used for ROV installations. Orcaflex, MACSI or Simo for lift analysis. Heave compensated

systems (active or passive), slamming, slack rigging. Loadout

6.6

Transportation

On what basis have the seafastenings been calculated. What heading for the vessel, where

on the deck is the structure, what stiffeners have been used, is the deck adequate (specific

checks on deck tees, torsion), Roll heave pitch acceleration, greenwater loading, on what

basis, RAOs Noble Denton DNV Lloyds etc

Road transportability requirements. CMotion software. Sideways slam on overhanging

structures (related to vessel speed) DNV ship rules deck equipment pt3 ch 1 sec4 C500.

initial laydown on deck ~(bearing contact pressure). Total weight not exceeding deck

allowable 10t/m2

6.7

In Situ/Operational/Functional

Pipeline thrusts, displacement loads 25mm, ROV loads due to thrusts on panels, expansion

loads, contraction loads. Pressure, temperature. Uneven footing, only 3 of four supports

used, imposed floor loading 5kN/m2

6.8

Accidental/Abnormal

Overtrawlability, anchor impact, fishing snag loads, trawl board impact, , Dropped Object on

roof panel and steelwork. different impact areas and energies Norsok, DNV RP C204

(accidental loads), Vertical impact 10% weight, lateral impact 5% weight

6.9

Fatigue Analysis

Fatigue Sensitive structures (less than 25N/mm^2 max ignore). Joint fatigue. Low cycles not

an issue

6.10

Recovery/Decommissioning

On bottom suction, dismantling loads, lack of stability, loads induced by removal of members

causing deflection. Structural integrity during lifting. Demolition sequence. Member capacity

reduction due to corrosion and damage.

7.0

Design Load Combinations

Identify all the different design load case combinations considered along with the relevant

factors. For lifting, transportation and in situ, heave and roll, heave and pitch etc, positive and

negative

8.0

Detailed Design and Results

Discussion on the design undertaken. Critical members. Code checks. URs, maximum

stresses global and local. Can break down in either load combination or member type with

critical load case.

8.1

Primary Steelwork

Member design, joint checks. Through thickness loading of joints (padeyes and joints).

Piling. If local reinforcement is required describe on what basis. Welds and bolts.

8.2

Secondary Steelwork

Diver access platforms, ballast arrangements, grating supports, ROV grab bars

8.3

Equipment Supports

Piping, anodes, controls all spares included, also futures.

8.4

Hydrostatic Collapse

For tubular members., drain holes with cross cut rubber grommets

8.5

Impact Analysis

e.g Tubular member, overall structure, individual member, plates , grating

8.6

Lifting Points

Through thickness properties of attached member? Different spec EN 10225?

8.7

8.8

Lift Rigging

Results Summary and Discussion

8.9

Serviceability Issues

Could include discussion on Material deterioration, corrosion, abrasion erosion, fatigue,

weathering, deflection, cracking, integrity, condensation, transmission (noise, thermal)

vibration, creep deformation, fatigue, wear (surface, adhesive, abrasive, corrosive), Thermal

Shock. Lamellar tearing

8.10

8.11

Operational Aspects

Installation Aids

Structure markings, SWL on lift points and padeyes

9.0

Weight Control and Material Take Off

10.0

Design restrictions on Installation Procedure

Maximum forces and stresses I which members. Identify the critical members and under

which load case this occurs. Give maximum ur values.

e.g specific installation method, method of work, design issues member 1 bracing member 2,

demolition procedure

11.0

Interface with other Disciplines

Fabrication specifications, piping, vessels for deck layout and transport location. Welding

procedures and qualifications. Different types of metal to metal welding. CP and anodes.

Galvanising painting specs

12.0

Computer Model History

Useful for large designs. Keeps a list of the filename for each model and details of the model.

Also can be used to list the history of changes between various revisions of the model.

13.0

Design Risk Assessment

Identify any major risks that have been removed, reduced by design changes. Pass on

information relating to residual risks which have not been eliminated. Eliminate, Reduce,

Inform, Control. MHASAWR

APPENDICES

Client Drawings, vendor drawings, subsea 7 drawings, all calculations, computer inputs,

analysis and outputs, hand calcs, mathcad sheets, graphical software outputs with URs

deflections , vibration, natural frequency plots etc.

Você também pode gostar

- CDCDDCDocumento1 páginaCDCDDCbtcong93Ainda não há avaliações

- Photos/As-Built Drawings of Work Done With Signature of Client/ CM Inspection Minutes For Main Works Inspection Minutes For Material Main Piling WorkDocumento1 páginaPhotos/As-Built Drawings of Work Done With Signature of Client/ CM Inspection Minutes For Main Works Inspection Minutes For Material Main Piling Workbtcong93Ainda não há avaliações

- Construction Inspection Minutes & Client SignaturesDocumento1 páginaConstruction Inspection Minutes & Client Signaturesbtcong93Ainda não há avaliações

- 35 PRDocumento2 páginas35 PRbtcong93Ainda não há avaliações

- 4.3 Site Preparation: WWW - Epa.gov/owow/nps/lid/lidnatl. PDF Publicworks/planningdesign/bmpindex - HTMDocumento17 páginas4.3 Site Preparation: WWW - Epa.gov/owow/nps/lid/lidnatl. PDF Publicworks/planningdesign/bmpindex - HTMAnonymous pFXVbOS9TWAinda não há avaliações

- Bien Phap1Documento1 páginaBien Phap1btcong93Ainda não há avaliações

- Project Saigon South Serviced ApartmentDocumento3 páginasProject Saigon South Serviced Apartmentbtcong93Ainda não há avaliações

- Q 2 e 2Documento58 páginasQ 2 e 2Roberto LuisAinda não há avaliações

- Pile Cap Design 1Documento6 páginasPile Cap Design 1kjpatel2100% (2)

- ACI 304R-00 Guide For Measuring, Mixing, Transporting, and Placing ConcreteDocumento41 páginasACI 304R-00 Guide For Measuring, Mixing, Transporting, and Placing Concretebonnico75% (4)

- Aashto T22Documento18 páginasAashto T22Arfian Surya MeganandaAinda não há avaliações

- P at Any Depth Z May Be Expressed AsDocumento4 páginasP at Any Depth Z May Be Expressed Asbtcong93Ainda não há avaliações

- Lean FullDocumento6 páginasLean Fullbtcong93Ainda não há avaliações

- Bored Pile - Method StatementDocumento13 páginasBored Pile - Method Statementbtcong93100% (2)

- NoteDocumento1 páginaNotebtcong93Ainda não há avaliações

- Internship Certificate 24/7/2014Documento1 páginaInternship Certificate 24/7/2014btcong93Ainda não há avaliações

- MasterDocumento194 páginasMasterbtcong93Ainda não há avaliações

- Arup in Vietnam Brochure 2013 EngDocumento32 páginasArup in Vietnam Brochure 2013 Engbtcong93Ainda não há avaliações

- Boc Khoi LuongDocumento22 páginasBoc Khoi Luongbtcong93Ainda não há avaliações

- Cover Letter 1 RevisedDocumento2 páginasCover Letter 1 Revisedbtcong93Ainda não há avaliações

- 2016 US Presidential Election Key DatesDocumento1 página2016 US Presidential Election Key Datesbtcong93Ainda não há avaliações

- I Love SomeoneDocumento1 páginaI Love Someonebtcong93Ainda não há avaliações

- FYP Report Format FinalDocumento7 páginasFYP Report Format Finalbtcong93Ainda não há avaliações

- RomeoDocumento1 páginaRomeowoeabrwmAinda não há avaliações

- Bowles' Formula for Modulus of Subgrade Reaction ksDocumento1 páginaBowles' Formula for Modulus of Subgrade Reaction ksbtcong93Ainda não há avaliações

- PTC Excavator Mounted Vibrodrivers Vibratory HammersDocumento20 páginasPTC Excavator Mounted Vibrodrivers Vibratory HammersDanyitbarekAinda não há avaliações

- New Text DocumentDocumento1 páginaNew Text Documentbtcong93Ainda não há avaliações

- I Love SomeoneDocumento1 páginaI Love Someonebtcong93Ainda não há avaliações

- Jfesp: JFE Steel Sheet PilesDocumento15 páginasJfesp: JFE Steel Sheet Pilesbtcong93Ainda não há avaliações

- Bore Pile SequenceDocumento1 páginaBore Pile Sequencebtcong93100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Basalt FiberDocumento19 páginasBasalt FiberShariqKhanAinda não há avaliações

- The Phosphates Processing HandbookDocumento29 páginasThe Phosphates Processing HandbookweiningwuAinda não há avaliações

- TFP220 - K 11.2 Storage ListedDocumento8 páginasTFP220 - K 11.2 Storage ListedMohamed Rafi MAinda não há avaliações

- TN1361R2Documento22 páginasTN1361R2ClydeUnionAinda não há avaliações

- Boeing SSQ22680 (Rev L)Documento329 páginasBoeing SSQ22680 (Rev L)Antonio Lopez100% (2)

- Bearing Materials - AST BearingsDocumento4 páginasBearing Materials - AST BearingsximicayAinda não há avaliações

- Sulphidation of Copper Coolers in PGM SmeltersDocumento220 páginasSulphidation of Copper Coolers in PGM SmelterstramAinda não há avaliações

- Desicorr Vpci Pouches/ Desicorr NW Vpci: CorporationDocumento2 páginasDesicorr Vpci Pouches/ Desicorr NW Vpci: CorporationSefa ZumbulAinda não há avaliações

- Otimo Tem Tudo PDFDocumento978 páginasOtimo Tem Tudo PDFCicero Gomes de Souza100% (1)

- Cogbill Construction - RedLine HDC Wear Pads BrochureDocumento1 páginaCogbill Construction - RedLine HDC Wear Pads BrochureCogbillConstructionAinda não há avaliações

- Interline 967+ds+eng PDFDocumento4 páginasInterline 967+ds+eng PDFMohamed NouzerAinda não há avaliações

- Nitocote NT550Documento4 páginasNitocote NT550Venkata Raju KalidindiAinda não há avaliações

- Technical Specs for 5-Unit Air Cooler SystemDocumento9 páginasTechnical Specs for 5-Unit Air Cooler SystemSladjan UgrenovicAinda não há avaliações

- Materials Science & Metallurgy: Titanium AlloysDocumento13 páginasMaterials Science & Metallurgy: Titanium AlloysMarisa RobertsAinda não há avaliações

- Dura Cooler InstallationDocumento20 páginasDura Cooler InstallationTeteloAinda não há avaliações

- Guide to Surface Preparation for Ship Hull CoatingsDocumento21 páginasGuide to Surface Preparation for Ship Hull CoatingsTushar Kumar100% (1)

- Class 10 Assignment Phy Chem 3Documento5 páginasClass 10 Assignment Phy Chem 3vaishnavisriAinda não há avaliações

- Corrosion Inhibition FormulaDocumento239 páginasCorrosion Inhibition FormuladiwakarngmAinda não há avaliações

- Method of Statement Material Handling, Preservation and StorageDocumento8 páginasMethod of Statement Material Handling, Preservation and StoragefazalrehmanAinda não há avaliações

- 000-Za-E-09303 - 0 Packing and Marking ProcedureDocumento251 páginas000-Za-E-09303 - 0 Packing and Marking Procedurealinor_tnAinda não há avaliações

- Urea Brochure PDFDocumento21 páginasUrea Brochure PDFKuldeep28883Ainda não há avaliações

- Chap 1Documento19 páginasChap 1Tapas Banerjee100% (1)

- Bs 7371 6 1998Documento10 páginasBs 7371 6 1998sdd1965Ainda não há avaliações

- Osseointegration - A ReviewDocumento7 páginasOsseointegration - A ReviewDilesh PradhanAinda não há avaliações

- 9.57405-Eng - Plating Std.Documento20 páginas9.57405-Eng - Plating Std.Baravkar Auto Parts100% (1)

- Astm G 139Documento10 páginasAstm G 139Lichi leonAinda não há avaliações

- ELFR Plant and ALFRED Demonstrator AnalysisDocumento42 páginasELFR Plant and ALFRED Demonstrator AnalysisLazarescu ElenaAinda não há avaliações

- Aisc-The Material SteelDocumento48 páginasAisc-The Material Steelropin14Ainda não há avaliações

- Brake MechanismDocumento48 páginasBrake MechanismSanjay GuptaAinda não há avaliações

- CUI Inspection Guide for Ammonia, Urea and Utility PlantsDocumento29 páginasCUI Inspection Guide for Ammonia, Urea and Utility PlantsProfessional TrustAinda não há avaliações