Escolar Documentos

Profissional Documentos

Cultura Documentos

Chenille

Enviado por

Carlos AguirreDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Chenille

Enviado por

Carlos AguirreDireitos autorais:

Formatos disponíveis

S.

Ulku,

H.G. Ortlek,

S. Omerolu

Uluda University

Department of Textile Engineering

16059 Gorukle-Bursa, Turkey

Fax +90 224 442 80 21

E-mail: hgazi@uludag.edu.tr

The Effect of Chenille Yarn Properties

on the Abrasion Resistance

of Upholstery Fabrics

Abstract

In this study, we have examined the effect of chenille yarn properties, pile length, twisting rate, and weaving construction on the abrasion resistance of upholstery fabrics.

Different acrylic chenille yarns have been produced at three different twist levels with

0.7, 0.8 and 1.0 mm callipers. These yarns were then used in three different weaving

constructions as weft yarn. All the samples were tested to observe abrasion resistance

on the Martindale Abrasion Tester. The results indicate that twist levels, pile lengths,

and weaving constructions have significant effect on the abrasion resistance of upholstery fabrics.

Key words: abrasion resistance, chenille yarn, pile length, twist level.

Introduction

A fancy yarn is one that differs from the

normal construction of single and folded

yarns by deliberately produced irregularities in its construction [5]. Fancy yarns

help to create decorative effects in the

fabrics. The use of fancy yarns is solely

for aesthetic effects. The first such yarns,

such as slubbed, bouchl, and knop

types, became established textile novelties in the last century, but it was only

in the 1970s that non-traditional yarns

experienced a boom in the market [7].

Today, fancy yarns are a very important

product of spinning and twisting processes [3].

Chenille is a pile fancy yarn that has been

produced commercially since the 1970s.

Modern machinery was introduced in

Europe and North America in the early

1990s, and todays chenille is a reliable

and beautiful yarn that is gaining in

popularity with each passing day.

Chenille yarn consists of short lengths

of spun yarn or filament that are held

together by two ends of highly twisted

fine strong yarn. The short lengths are

called the pile and the highly twisted

yarns are called the core or lock yarn.

38

Chenille yarn can be made from many

different types of fibres and yarns, most

commonly cotton, viscose, acrylic, and

polypropylene. The lock and pile yarn

can be of the same or a different material. However, filament yarns should not

be used as lock yarn, because of easy pile

loss due to the low friction between filament yarns and pile yarns. Chenille yarn

can be made in many different sizes,

ranging from as heavy as Nm 0.2 to as

fine as Nm 15.0 [2-4].

Chenille yarn is manufactured on a machine designed to bring the pile yarns and

lock yarns together. During manufacture,

the pile yarns are wrapped around a short

stem of polished metal called a calliper

or gauge, through which a blade passes

to cut the pile yarns into short lengths.

The lock yarns are pressed onto the short

lengths with a rotating wheel which is

also called plywood. Basically, the calliper and plywoods are represented in

Figure 1 [3].

The resulting yarn is then fed onto a

traditional ring-twisting take-up mechanism. In the twisting process, the two

ends of lock yarn twist and trap the short

ends of pile between the lock yarns. The

size of the calliper determines the diameter of the resulting yarn. The count of

the lock and pile yarns, the number of the

pile yarns and how many of them are fed

onto the lock yarns determines the count

of the chenille yarns.

After the twisting process, chenille yarns

are rewound onto a cone or dye tube. An

electronic clearer is located in the yarn

path in order to detect lengths of yarn that

are missing pile in this rewinding process. When the electronic clearer detects

a section of missing pile greater than the

minimum setting specified (usually 3

mm), a cutter is electronically activated.

The yarn is cut, and the winder operator

then pulls the yarn back and cuts out the

missing pile section, reties the yarn, and

continues winding the package [2].

The chenille manufacturing process creates pile that lies in one direction. When

woven into a fabric, chenille reflects light

differently when viewed from different

directions. This is known as the reflection effect, and is one of the unique

and desirable characteristics of chenille

goods. Because of this, strict control of

the pile direction must be maintained during manufacturing, as must all subsequent

Calliper

Neck

Calliper

Centre

Hole

a)

Lock Yarn 1

Lock Yarn 2

b)

Figure 1. a) The calliper and plywood,

b) Location of the calliper and plywoods.

FIBRES & TEXTILES in Eastern Europe July / September 2003, Vol. 11, No. 3 (42)

processes required to convert the chenille

into a finished article also be [2].

12

11

During the last decade, chenille yarns

have found a wide range of application

areas including outerwear fabrics, sweaters, furnishing fabrics, car interiors, blankets, and area rugs in the textile industry.

Especially, furnishing fabric designers

choose chenille yarns for many items because of their beautiful shiny appearance,

reflection effect and softness.

In the literature, there are few studies

about the fundamental parameters that

characterise chenille yarns and their

usage properties; thus the aim of this

study is to fill this gap.

Materials and Methods

For chenille upholstery fabrics, the most

important property is abrasion resistance

due to occurring pile loss. Therefore in

this study, the abrasion resistance of

upholstery fabrics was related to some

chenille yarn properties and weaving

construction.

In order to investigate this relationship,

we initially produced Nm 4 count 100%

acrylic chenille yarns with different

twist levels and pile lengths. Then these

yarns were used as weft yarns to produce

upholstery fabrics with three different

weaving constructions.

The chenille yarns were produced using

Ne 20/1 count, two lock and one pile

yarn (650 T/m - Z) on a Giessi AC 91/E

model chenille yarn machine with twist

levels of 800, 850, 900 T/m and with pile

lengths of 0.7, 0.8 and 1.0 mm. To ensure

all the chenille yarns had the same count,

that the head speeds on the machine were

adjusted to 10 800, 9 800 and 9 400 rpm

for 0.7, 0.8 and 1.0 mm pile lengths respectively. Production speed was held

constant at 8 m/min.

Upholstery fabrics, which are doublecloth structure, were produced with

three different constructions on a rapier

weaving machine fitted with a jacquard.

These constructions are given in Figure

2. Chenille weft yarns pointed with odd

numbers in the Figure 2 were interlaced

every six, eight and twelve warp yarns

for A, B, and C weaving constructions

respectively at the face of double-cloths

upholstery fabrics. Ne 10 count cotton

yarns pointed with even numbers in Figure 2 were also used as weft yarns. All

10

9

8

7

6

5

4

3

warp

weft

Figure 2. Constructions of upholstery fabrics used in the work.

samples have 66 ends/cm warp density

and 21 pics/cm weft density. 150 denier

polyester yarns were used as warp yarns.

Abrasion tests were performed on a Martindale Abrasion Tester. Before starting

the abrasion tests, primary trials were

made to determine the rubbing cycles

that would be applied to the specimens

of upholstery fabrics. Since the number

of rubs at which specimen breakdown

occurred between 10 000 - 15 000 rubbing cycles for our samples, mass loss

values were determined at the end of

5000, 7500, and 10 000 rubbing cycles,

according to BS EN ISO 12947-3 standards. Three tests were made for each set

of samples. The results were also tested

for significance in differences using

three-way repeated measures analysis of

variance, and the means were compared

by Student-Newman-Keuls (SNK) tests

at 0.05 level in the COSTAT statistical

package.

Results and Discussion

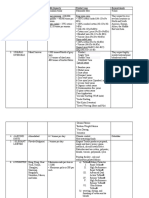

The results of the analysis of the variance

for mass loss values are summarised in

Table 1. The P values in Table 1 show

that there are statistically significant

differences between mass loss values

for different twist levels and weaving

constructions at all rubbing cycles. The

effects of interactions between twist

level and weaving construction, and also

Table 1. Analysis of variance for mass loss values.

P value

Parameter

Main effect

Interaction

0-5000

0-7500

0-10 000

Twist level (T)

0.0000

0.0000

0.0000

Pile length (P)

0.0022

0.0353

0.0635 ns

Weaving const. (W)

0.0000

0.0000

0.0000

TxP

0.0065

0.0289

0.1880 ns

TxW

0.0000

0.0000

0.0000

PxW

0.0202

0.0407

0.0408

P xT x W

0.0002

0.0009

0.0023

Table 2. Effects of pile lengths and twist levels of chenille yarns and weaving construction

of upholstery fabrics on abrasion resistance, Student-Newman-Keuls Test.

Average mass loss, mg

Parameter

Twist level, T/m

Pile length, mm

Weaving construction

FIBRES & TEXTILES in Eastern Europe July / September 2003, Vol. 11, No. 3 (42)

0-5000

0-7500

0-10 000

800

13.740 a

23.555 a

32.333 a

850

7.814 b

13.740 b

19.333 b

900

4.555 c

8.037 c

10.925 c

0.7

10.111 a

16.592 a

22.296 a

0.8

8.629 ab

14.481 b

20.444 a

1.0

7.370 b

14.259 b

19.851 a

12.333 a

21.666 a

29.592 a

8.481 b

14.629 b

20.444 b

5.296 c

9.037 c

12.555 c

39

A Construction

B Construction

C Construction

Figure 3. Average mass loss values versus rubbing cycles for different twist levels (a,b,c), and for different pile lengths (d,e,f).

between pile length and weaving construction, are statistically significant for

mass loss values.

The SNK test results given in Table 2

show that the average mass loss has a

tendency to decrease with increasing

twist level. Figure 3 (a,b,c) show that

this tendency is the same in all weaving

constructions. Based on these results, we

may postulate that as the twist level of

chenille yarn decreases, pile yarns may

not be held well by lock yarns and can

be easily pulled out. In other words, the

twist level of chenille yarns affects the

degree of pile packing.

According to the ANOVA results, pile

length was a significant factor affecting

lengths can be attributed to the fact that

short piles can be easily removed from

the twists of lock yarn as compared with

long piles.

The mass loss values of fabrics also

changed when different weaving constructions were used. The results from

the analysis of variance show that there

is a statistically significant difference between different weaving constructions for

mass loss readings at all rubbing cycles.

As a result, we can conclude that the surface characteristics of upholstery fabrics

exposed to abrasion are very important

for abrasion resistance. The interactions

of weaving construction with twist level

and pile length also have significant effects on abrasion resistance for all rubbing cycle, as shown in Table 1.

We plotted the average mass loss values

versus rubbing cycles for all the weaving

constructions in Figure 4. It can be seen

that as the existence of chenille yarns on

the fabrics surface increases, mass loss

also increases.

40

upholstery fabrics abrasion resistance

at the 5000 and 7500 rubbing cycles.

However, the effect of pile length has

a tendency to decrease with increasing

rubbing cycle. For the 10 000 rubbing

cycle, pile length was not a significant

factor on abrasion resistance. Similarly,

the interaction between twist level and

pile length was an insignificant factor

at the 10 000 rubbing cycle. Since all

the chenille yarns used in our work have

the same linear density, Nm 4, the difference of mass loss values decreases with

the increase in the rubbing cycle. Figure

3 (d,e,f) illustrates the mass loss values

of fabrics versus rubbing cycles for three

different pile lengths at three different

weaving constructions. The reduction

in mass loss values with increased pile

Figure 4. Average

mass loss values

versus rubbing cycles for the weaving

constructions.

Conclusions

Our findings show that there is a tendency to an increase in the pile loss read-

FIBRES & TEXTILES in Eastern Europe July / September 2003, Vol. 11, No. 3 (42)

ings with the decrease in the twist level

of chenille yarns, since individual fibres

of pile in low twist level can be easily pulled out from between lock yarns.

Yarn twist affects both yarn shape and

the degree of pile packing. Because of

the low twist, chenille yarns tend to flatten; a greater surface may be exposed to

abrasion, while the higher twist chenille

yarn maintains its roundness and cohesiveness.

Based on the results, we also conclude

that pile length is one of the properties

of chenille yarn which affect the abrasion resistance of upholstery fabrics. It is

hard to remove longer fibres incorporated

into the twists of the chenille yarns than

short fibres. Pile loss readings show a

tendency to decrease with increasing pile

length. But this tendency changes with

an increase in the rubbing cycle, since all

the chenille yarns have the same linear

density.

Also, the appearance rate of chenille

yarns on the surface of upholstery fabrics related to weaving constructions is

another important factor on the abrasion

resistance, since chenille yarn is very

vulnerable yarn to rubbing.

Acknowledgements

We would like to thank Villa Tekstil Co. for their

support in undertaking this work, particularly

for producing upholstery fabrics used for testing. We are also grateful to Fista Co. for

their assistance in producing chenille yarns.

References

1. British Standard, Textiles - Determination

of the Abrasion Resistance of Fabrics by

the Martindale Method. Part 3. BS EN

ISO 12947-3:1999.

2. Chenille Background Brochure. Chenille

International Manufacturers Association

(CIMA), Italy. 2000, pp1-3.

3. Grabowska, K, E., Fibres & Textiles in

Eastern Europe, January/March 2000,

pp 26-28.

4. Kalaolu F & Demir E, Textile Asia. 2001,

3, 37.

5. McIntyre, J.E., and Daniels, P. N., Textile Terms and Definitions, 10th ed., The

Textile Institute Terms and Definitions

Committee, Biddles Ltd., U.K., 1995.

6. zdemir O & Ceven K, The Effect of

Material and Machine Parameters on

Chenille Yarn Properties. Proceedings,

12th Romanian Textile and Leather Conference, 2002, 184.

7. Testore, F., and Minero, G., J. Textile Inst.

79 (4), 606, 1988.

Received 03.01.2003

Reviewed 30.04.2003

FIBRES & TEXTILES in Eastern Europe July / September 2003, Vol. 11, No. 3 (42)

41

Você também pode gostar

- LycraDocumento7 páginasLycraFiaz juttAinda não há avaliações

- yARN TWIST ANGLEDocumento8 páginasyARN TWIST ANGLESabeeh Ul Hassan100% (1)

- Chenille Fancy YarnsDocumento18 páginasChenille Fancy YarnsSadia TabassumAinda não há avaliações

- Qualifications Pack Production SupervisorDocumento33 páginasQualifications Pack Production SupervisorANKITAinda não há avaliações

- Sectional Warping Machine PDFDocumento17 páginasSectional Warping Machine PDFRajkumar50% (2)

- YarnDocumento15 páginasYarnyuvaramrajAinda não há avaliações

- Lenzing Tencel - Courtesy: LenzingDocumento38 páginasLenzing Tencel - Courtesy: LenzingSENTHIL KUMARAinda não há avaliações

- Modern Cotton Spinning Machinery, Its Principles and ConstructionNo EverandModern Cotton Spinning Machinery, Its Principles and ConstructionAinda não há avaliações

- Ecoverde BrochureDocumento12 páginasEcoverde BrochureRicardina Rosibel Rodriguez MendozaAinda não há avaliações

- Yarn Numbering System Yarn Count Direct Count System Indirect Count SystemDocumento3 páginasYarn Numbering System Yarn Count Direct Count System Indirect Count SystemTanmay JagetiaAinda não há avaliações

- Count Conversion and CalculationsDocumento3 páginasCount Conversion and Calculationsstylish eagleAinda não há avaliações

- Spinning Section Trutzschler: ITMA 2019 New Machinery / New Innovations DisplayedDocumento8 páginasSpinning Section Trutzschler: ITMA 2019 New Machinery / New Innovations DisplayedPadmanaban PasuvalingamAinda não há avaliações

- Special YarnDocumento4 páginasSpecial Yarnshadath072Ainda não há avaliações

- Rapier LoomDocumento19 páginasRapier LoomMayur PatilAinda não há avaliações

- Spin PlanDocumento2 páginasSpin PlanMd. Saleh Uddin100% (1)

- Spin Plan - Synthetic YarnDocumento1 páginaSpin Plan - Synthetic Yarnardhendu1Ainda não há avaliações

- Friction SpinningDocumento8 páginasFriction SpinningJoshi ParthAinda não há avaliações

- Cotton Ginning MachinesDocumento3 páginasCotton Ginning MachinesTemesgen RegassaAinda não há avaliações

- Bi ComponentDocumento13 páginasBi ComponentA.K.M. Rashedul IslamAinda não há avaliações

- Yarn Manufacturing Tandem CardingDocumento5 páginasYarn Manufacturing Tandem CardingIndrajit BoseAinda não há avaliações

- Textile Reference Book For SpinningDocumento202 páginasTextile Reference Book For SpinningAshan PrabudAinda não há avaliações

- Friction SpinningDocumento39 páginasFriction SpinningPåñdît ẞhyãmãñtãk MãñîAinda não há avaliações

- Gujarat Technological University: W.E.F. AY 2018-19Documento2 páginasGujarat Technological University: W.E.F. AY 2018-19Rushi TannaAinda não há avaliações

- United Towels: Production CapacityDocumento10 páginasUnited Towels: Production CapacityAli HaiderAinda não há avaliações

- Terry Towel Weaving MachineDocumento29 páginasTerry Towel Weaving Machinehamza hanif100% (2)

- Training Report of Gcti Tarinees MS WORDDocumento55 páginasTraining Report of Gcti Tarinees MS WORDAakash NagpalAinda não há avaliações

- Objects of Carding in Spinning MillDocumento1 páginaObjects of Carding in Spinning MillDaksh PuraniAinda não há avaliações

- Study On Multiphase Weaving Machine.Documento11 páginasStudy On Multiphase Weaving Machine.Naimul Hasan100% (1)

- Air Jet Spinning of Cotton YarnsDocumento9 páginasAir Jet Spinning of Cotton YarnsUsman GillAinda não há avaliações

- SP15 - 1, Testing and Grading of Textile FibresDocumento300 páginasSP15 - 1, Testing and Grading of Textile FibresAnonymous UoRu4sAinda não há avaliações

- Textile ScienceDocumento22 páginasTextile ScienceAbhinav VermaAinda não há avaliações

- U Z HL400 HairinessDocumento16 páginasU Z HL400 HairinessarunmythreyeeAinda não há avaliações

- Lecture Three Natural Bast FiberDocumento46 páginasLecture Three Natural Bast FiberGemeda GebinoAinda não há avaliações

- Solved QP of Knit Tech April 2023Documento4 páginasSolved QP of Knit Tech April 2023RajendrakumarAinda não há avaliações

- Development in Sizing Machine: By: Tanveer Malik, P.K.Roy & H.K.SinghDocumento24 páginasDevelopment in Sizing Machine: By: Tanveer Malik, P.K.Roy & H.K.SinghAnonymous Pt7NHkat9Ainda não há avaliações

- Conversion of Weight Units: Useful Informations To The SpinnersDocumento5 páginasConversion of Weight Units: Useful Informations To The SpinnersGautam SootgirniAinda não há avaliações

- Garden Profile NDocumento19 páginasGarden Profile NParitosh VermaAinda não há avaliações

- The Effects of The Twist Are TwofoldDocumento9 páginasThe Effects of The Twist Are TwofoldFahima RashidAinda não há avaliações

- Yarn Manufacturing 3Documento12 páginasYarn Manufacturing 3Muhammad Farooq Kokab0% (1)

- Ring Spinning SectionsDocumento24 páginasRing Spinning SectionsFajar Pitarsi DharmaAinda não há avaliações

- Blowroom: Basic Operations in The BlowroomDocumento3 páginasBlowroom: Basic Operations in The BlowroomIndu VikasiniAinda não há avaliações

- Spairality of Weft Knit FabricDocumento5 páginasSpairality of Weft Knit FabricObak Prithibi100% (1)

- Airjet PracDocumento12 páginasAirjet PracJunaid SuhailAinda não há avaliações

- Effect of First Heater Temperature Variations On The Polyester Yarn Properties of False Twist Texturing TechniquesDocumento5 páginasEffect of First Heater Temperature Variations On The Polyester Yarn Properties of False Twist Texturing TechniquesIberê Cruz Freitas100% (1)

- Yarn DivisionDocumento143 páginasYarn DivisionAyushi Pal100% (1)

- BSL PrintDocumento62 páginasBSL Printrishi100% (1)

- Single Jersey FabricDocumento4 páginasSingle Jersey FabricMrcr Kapzap0% (1)

- Aspects of Productivity in Cotton Spinning PDFDocumento4 páginasAspects of Productivity in Cotton Spinning PDFlalit kashyapAinda não há avaliações

- Renewable Energy Resources: Textile ProcessingDocumento17 páginasRenewable Energy Resources: Textile ProcessingrohithAinda não há avaliações

- Investigation of Air Permeability of Cotton & Modal Knitted FabricsDocumento6 páginasInvestigation of Air Permeability of Cotton & Modal Knitted FabricsAhmad SamerAinda não há avaliações

- Study of Structure and Properties of Air Jet Textured YarnDocumento15 páginasStudy of Structure and Properties of Air Jet Textured Yarnpraveen kumarAinda não há avaliações

- Spinning Maths-1Documento12 páginasSpinning Maths-1tsukuyomi03Ainda não há avaliações

- Q: What Is Technical Textiles?Documento7 páginasQ: What Is Technical Textiles?SantoshAinda não há avaliações

- Masha and The BearDocumento3 páginasMasha and The Bearcolomomaria7494100% (1)

- Adiós (Cerati) PDFDocumento4 páginasAdiós (Cerati) PDFCarlos Aguirre100% (2)

- Chenille 3Documento55 páginasChenille 3Carlos Aguirre100% (2)

- Crowded House PDFDocumento100 páginasCrowded House PDFCarlos Aguirre100% (1)

- The Police - The Very Best of Sting and The PoliceDocumento83 páginasThe Police - The Very Best of Sting and The PoliceCarlos AguirreAinda não há avaliações

- Crowded House PDFDocumento100 páginasCrowded House PDFCarlos Aguirre100% (1)

- Paralamas CifrasDocumento6 páginasParalamas CifrasCarlos AguirreAinda não há avaliações

- CSTU Evaluation Rev 5.0 enDocumento89 páginasCSTU Evaluation Rev 5.0 enMuhammad AliAinda não há avaliações

- Staple or FilamentDocumento30 páginasStaple or Filamentapi-232403733Ainda não há avaliações

- Common Fabric TypesDocumento24 páginasCommon Fabric TypesRajesh DwivediAinda não há avaliações

- Common Defects of FabricsDocumento4 páginasCommon Defects of FabricsDeepika SandeepAinda não há avaliações

- Yarn Faults: Types Causes RemediesDocumento20 páginasYarn Faults: Types Causes Remediesஹரி கிருஷ்ணன் வாசு71% (7)

- Chapter-7 - Knitting DerivativesDocumento39 páginasChapter-7 - Knitting DerivativesMD Shakil Khan0% (1)

- Textile Yarns PDFDocumento35 páginasTextile Yarns PDFVu Ngo Tuan100% (1)

- Cutting Room Terminologies in Apparel IndustryDocumento2 páginasCutting Room Terminologies in Apparel IndustrySatadeep DattaAinda não há avaliações

- YARN and ITS ConstructionDocumento11 páginasYARN and ITS Constructionreshma_alexanderAinda não há avaliações

- Integrated Term Project: Submitted By: Nikhil Sharma Seemta ChoudharyDocumento24 páginasIntegrated Term Project: Submitted By: Nikhil Sharma Seemta ChoudharyNikhil Sharma75% (4)

- Woven Fabric Defects and InspectionDocumento37 páginasWoven Fabric Defects and InspectionShresha DasAinda não há avaliações

- CreelDocumento2 páginasCreelZillur Rahman SaykatAinda não há avaliações

- Fabric Manufacturing I WindingDocumento30 páginasFabric Manufacturing I WindingSanjay Saha100% (2)

- F Br-Ring Spinning Frame LowresDocumento20 páginasF Br-Ring Spinning Frame LowresAshique100% (2)

- Session Defect Classification and Rating Areas - GarmentsDocumento16 páginasSession Defect Classification and Rating Areas - GarmentsAdithya RamAinda não há avaliações

- HR Practises at VardhmanDocumento49 páginasHR Practises at Vardhmankarma negiAinda não há avaliações

- Spinning Section Trutzschler: ITMA 2019 New Machinery / New Innovations DisplayedDocumento8 páginasSpinning Section Trutzschler: ITMA 2019 New Machinery / New Innovations DisplayedPadmanaban PasuvalingamAinda não há avaliações

- Mill DirectoryDocumento12 páginasMill DirectoryjasleenthukralAinda não há avaliações

- Woven Fabric DefectsDocumento28 páginasWoven Fabric DefectsGreeshma75% (4)

- Textile Yarn and Type of Textile YarnDocumento10 páginasTextile Yarn and Type of Textile YarnARYAN RATHOREAinda não há avaliações

- Sales PromotionDocumento7 páginasSales PromotionSharifMahmudAinda não há avaliações

- Fabric Defect Reading MaterialDocumento6 páginasFabric Defect Reading MaterialAnoop Singh100% (1)

- Khadi Yarn KnittingDocumento4 páginasKhadi Yarn KnittingManpreet Manshahaia SidhuAinda não há avaliações

- 20 Woven Fabric Defects With PicturesDocumento23 páginas20 Woven Fabric Defects With PicturesMayan DynastyAinda não há avaliações

- ProjectDocumento12 páginasProjectJoshi ParthAinda não há avaliações

- Fabric InspectionDocumento20 páginasFabric InspectionHarrison Kan100% (1)

- Proteinase McqsDocumento12 páginasProteinase McqsPatel KrupaAinda não há avaliações

- Earth Day Tote Crochet PatternDocumento7 páginasEarth Day Tote Crochet PatternCammy87Ainda não há avaliações

- 10 Weft Breakage ReportDocumento113 páginas10 Weft Breakage ReportHAMMADHRAinda não há avaliações

- Textiles Design st6 Syl+textilesDocumento29 páginasTextiles Design st6 Syl+textilesGurlieAinda não há avaliações

- Crochet Cute Dolls with Mix-and-Match Outfits: 66 Adorable Amigurumi PatternsNo EverandCrochet Cute Dolls with Mix-and-Match Outfits: 66 Adorable Amigurumi PatternsNota: 4 de 5 estrelas4/5 (5)

- Wear It Well: Reclaim Your Closet and Rediscover the Joy of Getting DressedNo EverandWear It Well: Reclaim Your Closet and Rediscover the Joy of Getting DressedNota: 5 de 5 estrelas5/5 (1)

- Bulletproof Seduction: How to Be the Man That Women Really WantNo EverandBulletproof Seduction: How to Be the Man That Women Really WantNota: 4.5 de 5 estrelas4.5/5 (170)

- 250 Japanese Knitting Stitches: The Original Pattern Bible by Hitomi ShidaNo Everand250 Japanese Knitting Stitches: The Original Pattern Bible by Hitomi ShidaNota: 5 de 5 estrelas5/5 (7)

- The Magic of Crystals and Gems: Unlocking the Supernatural Power of Stones (Magical Crystals, Positive Energy, Mysticism)No EverandThe Magic of Crystals and Gems: Unlocking the Supernatural Power of Stones (Magical Crystals, Positive Energy, Mysticism)Nota: 4 de 5 estrelas4/5 (7)

- The Ultimate Book of Outfit Formulas: A Stylish Solution to What Should I Wear?No EverandThe Ultimate Book of Outfit Formulas: A Stylish Solution to What Should I Wear?Nota: 5 de 5 estrelas5/5 (23)

- Creative Polymer Clay: Over 30 Techniques and Projects for Contemporary Wearable ArtNo EverandCreative Polymer Clay: Over 30 Techniques and Projects for Contemporary Wearable ArtAinda não há avaliações

- Rip It!: How to Deconstruct and Reconstruct the Clothes of Your DreamsNo EverandRip It!: How to Deconstruct and Reconstruct the Clothes of Your DreamsNota: 3.5 de 5 estrelas3.5/5 (10)

- Basic Black: 26 Edgy Essentials for the Modern WardrobeNo EverandBasic Black: 26 Edgy Essentials for the Modern WardrobeNota: 4 de 5 estrelas4/5 (10)

- 50 Fat Quarter Makes: Fifty Sewing Projects Made Using Fat QuartersNo Everand50 Fat Quarter Makes: Fifty Sewing Projects Made Using Fat QuartersAme VersoNota: 3.5 de 5 estrelas3.5/5 (6)

- Make Your Mind Up: My Guide to Finding Your Own Style, Life, and Motavation!No EverandMake Your Mind Up: My Guide to Finding Your Own Style, Life, and Motavation!Nota: 3.5 de 5 estrelas3.5/5 (391)

- DIY Updos, Knots, & Twists: Easy, Step-by-Step Styling Instructions for 35 Hairstyles—from Inverted Fishtails to Polished Ponytails!No EverandDIY Updos, Knots, & Twists: Easy, Step-by-Step Styling Instructions for 35 Hairstyles—from Inverted Fishtails to Polished Ponytails!Nota: 3.5 de 5 estrelas3.5/5 (7)

- The Black Pullet: Science of Magical TalismanNo EverandThe Black Pullet: Science of Magical TalismanNota: 4.5 de 5 estrelas4.5/5 (23)

- Japanese Knitting Stitch Bible: 260 Exquisite Patterns by Hitomi ShidaNo EverandJapanese Knitting Stitch Bible: 260 Exquisite Patterns by Hitomi ShidaNota: 4.5 de 5 estrelas4.5/5 (35)

- Adorable Baby Knits: 25 Patterns for Boys and GirlsNo EverandAdorable Baby Knits: 25 Patterns for Boys and GirlsNota: 4.5 de 5 estrelas4.5/5 (3)

- A Lapidary of Sacred Stones: Their Magical and Medicinal Powers Based on the Earliest SourcesNo EverandA Lapidary of Sacred Stones: Their Magical and Medicinal Powers Based on the Earliest SourcesNota: 4.5 de 5 estrelas4.5/5 (2)

- Friendship Bracelets: All Grown Up Hemp, Floss, and Other Boho Chic Designs to MakeNo EverandFriendship Bracelets: All Grown Up Hemp, Floss, and Other Boho Chic Designs to MakeNota: 4 de 5 estrelas4/5 (5)

- No More Codependency, Healthy Detachment Strategies To Break The Patterns, Discover How To Stop Struggling With Codependent Relationships, Obsessive Jealousy And Narcissistic AbuseNo EverandNo More Codependency, Healthy Detachment Strategies To Break The Patterns, Discover How To Stop Struggling With Codependent Relationships, Obsessive Jealousy And Narcissistic AbuseNota: 4.5 de 5 estrelas4.5/5 (3)

- Fabric Manipulation: 150 Creative Sewing TechniquesNo EverandFabric Manipulation: 150 Creative Sewing TechniquesNota: 4.5 de 5 estrelas4.5/5 (13)

- Knitting In the Sun: 32 Projects for Warm WeatherNo EverandKnitting In the Sun: 32 Projects for Warm WeatherNota: 4.5 de 5 estrelas4.5/5 (8)

- Freehand Fashion: Learn to sew the perfect wardrobe – no patterns required!No EverandFreehand Fashion: Learn to sew the perfect wardrobe – no patterns required!Nota: 5 de 5 estrelas5/5 (3)

- How To Make Jewelry With Beads: An Easy & Complete Step By Step GuideNo EverandHow To Make Jewelry With Beads: An Easy & Complete Step By Step GuideNota: 3 de 5 estrelas3/5 (12)

- The Mary Brooks Picken Method of Modern DressmakingNo EverandThe Mary Brooks Picken Method of Modern DressmakingNota: 5 de 5 estrelas5/5 (1)