Escolar Documentos

Profissional Documentos

Cultura Documentos

Cast Iron Electrodes - Nickel 99, Nickel 55 & Non-Nickel Est Alloys

Enviado por

Khin Aung ShweTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Cast Iron Electrodes - Nickel 99, Nickel 55 & Non-Nickel Est Alloys

Enviado por

Khin Aung ShweDireitos autorais:

Formatos disponíveis

<NEXT

NEXT>

<INDEX

Stoody Industrial & Welding Supply, Inc.- San Diego (619) 234-6750/ Victorville (760) 530-0765 WWW.STOODYIND.COM

CAST IRON ELECTRODES Nickel 99, Nickel 55 & Non-Nickel EST Alloys

WASHINGTON ALLOY

NICKEL 99

WASHINGTON ALLOY

NICKEL 55

WASHINGTON

ALLOY EST

AWS/SFA 5.15 Eni-Cl

AWS/SFA 5.15 Class ENiFe-Cl

AWS/SFA 5.15 EST

1 LB CONTAINER

10 LB CONTAINER

1 LB CONTAINER

10 LB CONTAINER

1 LB CONTAINER

THIS

PAGE

AVAILABLE

10 LB CONTAINER

SIZE PART No.

PRICE

PART No.

PRICE

SIZE PART No.

PRICE

PART No.

PRICE

PART No.

PRICE

PART No.

PRICE

3/32 99-332-1

$25.50

99-332-10

$195.00

3/32 55-332-1

$19.95

55-332-10

$148.00

3/32 EST-332-1

$8.25

EST-332-10

$36.50

1/8

$25.50

99-18-10

$190.00

1/8

$19.95

55-18-10

$143.00

1/8

$8.25

EST-18-10

$32.00

5/32 99-532-1

$25.50

99-532-10

$190.00

5/32 55-532-1

$19.95

55-532-10

$143.00

5/32 EST-532-1

$8.25

EST-532-10

$32.00

3/16 99-316-1

$25.50

99-316-10

$190.00

3/16 55-316-1

$19.95

55-316-10

$143.00

3/16

99-18-1

55-18-1

SIZE

EST-18-1

DESCRIPTION

DESCRIPTION

DESCRIPTION

Washington Alloy Nickel 99 is recommended

for all-position welding of thin cast iron sections

where maximum machinability is required. Since

the core wire is approximately 99% nickel, weld

deposits are basically "soft" and can be shaped,

milled, drilled, or tapped, while the color will

match that of cast iron. Washington Alloy Nickel

99 is specifically suited for repairing cracked or

porous castings and to weld cast iron to itself or

dissimilar metals such as low alloy and carbon

steels.

Washington Alloy Nickel 55 is designed for allposition joining and surfacing of cast iron,

malleable iron and ductile iron to itself or dissimilar

metals such as mild steel, stainless steel, wrought

alloys or high nickel alloys. A core wire chemistry

of approximately 55% nickel and 45% iron

produces weld deposits with much lower weld

shrinkage stress which in turn reduces the

possibility of weld or heat affected zone cracking.

Washington Alloy Nickel 55 produces high

strength, ductile weld deposits even when welding

low grade cast iron containing excessive levels of

phosphorus or other contaminants.

Washington Alloy EST is a non-nickel, nonmachinable cast iron electrode. It is the most

economical way to go for repairing various kinds of

cast iron products - providing that machinability of

the weld deposit is not required and where weld

shrinkage stress is not a concern. Since the core

wire is steel, the weld deposits will have a higher

tensile strength (65,000 psi) than Nickel 99,

however a color match of the base metal should

not be expected. Washington Alloy EST melts at

relatively low temperatures which permit the use of

low welding currents. This electrode may be used

in any position utilizing AC or DC (reverse polarity).

APPLICATIONS

APPLICATIONS

Washington Alloy Nickel 55 is especially suited

for welding heavy sections such as motor blocks,

housings, machine parts, frames, defective

castings and building-up worn sections. Weld

deposits are machinable and the deposit color will

approximate that of cast iron.

Commonly used on gears, motor housings,

machine parts, farm equipment, large fames or any

other cast iron part where appearance of the weld

deposit is not important.

APPLICATIONS

The weld deposits produced by Washington

Alloy Nickel 99 have lower strength and ductility

than those of 55% nickel cast iron electrodes.

For this reason Washington Alloy Nickel 99 should

only be used where maximum machinability of

highly diluted weld metal is required or where

weld stresses are not overly severe such as

found in light and medium-sized castings.

Common uses include thin plates, machinery

parts, frames and housings.

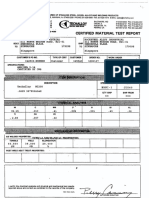

TYPICAL WELD METAL CHEMISTRY ( %)

C

Si

Mn

P

S

Fe

Ni

1.000

0.700

0.200

0.005

0.005

3.000

Balance

TYPICAL MECHANICAL PROPERTIES OF

WELD METAL (as welded)

Tensile strength (psi) ......................... 50,000

Yield strength (psi) ............................. 40,000

Elongation in 2" (%) ................................3-4

Hardness (Brinell) ................................... 200

SIZES AND RECOMMENDED CURRENT

RANGES*

Sizes (in.)

3/32 (2.4 mm) x 12

1/8 (3.2 mm) x 14

5/32 (4.0 mm) x 14

3/16 (4.8 mm) x 14

AC

50-90

90-120

120-150

130-170

DC (Rev.

Polarity)

40-80

80-120

100-140

120-170

*These settings are for flat or downhand positions.

For overhead welding reduce 5-15 amps and for

vertical welding reduce 10-20 amps.

TYPICAL WELD METAL CHEMISTRY (%)

C

Si

Mn

P

S

Ni

Fe

1.500

0.500

0.300

0.005

0.002

53.000

Balance

TYPICAL MECHANICAL PROPERTIES OF

WELD METAL (as welded)

Tensile strength (psi) .......................... 80,000

Yield strength (psi)............................... 60,000

Elongation in 2" (%) ................................ 6-12

Hardness (Brinell) .................................... 300

SIZES AND RECOMMENDED CURRENT

RANGES*

Sizes (in.)

3/32 (2.4 mm) x 12

1/8 (3.2 mm) x 14

5/32 (4.0 mm) x 14

3/16 (4.8 mm) x 14

AC

50-65

80-95

110-135

130-155

DC (Rev.

Polarity)

40-65

70-95

100-135

120-155

TYPICAL WELD METAL CHEMISTRY (%)

C

Si

Mn

P

S

Fe

0.950

0.640

0.450

0.018

0.008

Balance

TYPICAL MECHANICAL PROPERTIES OF

WELD METAL (as welded)

Tensile strength (psi) .......................... 65,000

Yield strength (psi) .............................. 50,000

Elongation in 2" (%) ..................................... 5

Hardness (Brinell) ............................. 300-330

SIZES AND RECOMMENDED CURRENT

RANGES

AC & DC

Sizes (in.)

(Rev. Polarity)

3/32 (2.4mm) x 12 ...............................60-90

1/8 (3.2 mm) x 14 ...............................90-130

5/32 (4.0 mm) x 14 ............................120-160

These settings are for flat or downhand positions.

For overhead welding reduce 5-15 amps and for

vertical welding reduce 10-20 amps.

*These settings are for flat or downhand positions.

For overhead welding reduce 5-15 amps and for

vertical welding reduce 10-20 amps.

Stoody Industrial & Welding Supply, Inc. (SIWS) is not sponsored, affiliated or in any way related to "STOODY COMPANY", a division of THERMADYNE

INDUSTRIES, INC.

352

Você também pode gostar

- Austenitic Ductile Iron For Low Temperature ApplicationDocumento6 páginasAustenitic Ductile Iron For Low Temperature ApplicationKhin Aung ShweAinda não há avaliações

- Microscopy With Light and ElectronsDocumento36 páginasMicroscopy With Light and ElectronsCORE Materials100% (1)

- ERNI-1 Cast Iron ElectrodeDocumento1 páginaERNI-1 Cast Iron ElectrodeKhin Aung ShweAinda não há avaliações

- Experimental Investigation On Weld Ability of Cast IronDocumento5 páginasExperimental Investigation On Weld Ability of Cast IronKhin Aung ShweAinda não há avaliações

- Fracture and Crack Propagation in WeldmentsDocumento66 páginasFracture and Crack Propagation in WeldmentsKhin Aung ShweAinda não há avaliações

- Focus On Proper Weld Size When Developing WPS Parameter Ranges - Fabricating and MetalworkingDocumento4 páginasFocus On Proper Weld Size When Developing WPS Parameter Ranges - Fabricating and MetalworkingKhin Aung ShweAinda não há avaliações

- Investigation of The Cause of Reinforcing Steel Fracture Induced by Alkali-Silica Reaction and Study On MaintenanceDocumento10 páginasInvestigation of The Cause of Reinforcing Steel Fracture Induced by Alkali-Silica Reaction and Study On MaintenanceKhin Aung ShweAinda não há avaliações

- JK Stereo1Documento26 páginasJK Stereo1Yongliang LiuAinda não há avaliações

- Effect of Heat Input To Weld Residual StressDocumento4 páginasEffect of Heat Input To Weld Residual StressSurya DharmaAinda não há avaliações

- Theweldignofaluminiumcastingsoctober2011 111210001526 Phpapp02Documento68 páginasTheweldignofaluminiumcastingsoctober2011 111210001526 Phpapp02Khin Aung ShweAinda não há avaliações

- Lab Exericise 3 For MicroscopeDocumento9 páginasLab Exericise 3 For MicroscopeKhin Aung ShweAinda não há avaliações

- Welding of Nonferrous Metal and Their AlloysDocumento62 páginasWelding of Nonferrous Metal and Their AlloysKhin Aung ShweAinda não há avaliações

- Manual de Servicio Olympus SZ-IIIDocumento18 páginasManual de Servicio Olympus SZ-IIIcarlosibaAinda não há avaliações

- Safety of Machinery - Principles of Risk AssessmentDocumento27 páginasSafety of Machinery - Principles of Risk AssessmentKhin Aung ShweAinda não há avaliações

- Mo SteelDocumento0 páginaMo SteelSamsi B HanifAinda não há avaliações

- အမ်ားသံုး ျမန္မာ-အဂၤလိပ္-ပါဠိ အဘိဓါန္ PDFDocumento1.080 páginasအမ်ားသံုး ျမန္မာ-အဂၤလိပ္-ပါဠိ အဘိဓါန္ PDFKo Lin96% (45)

- Lampiran PQR 003Documento3 páginasLampiran PQR 003Khin Aung ShweAinda não há avaliações

- DryerDocumento80 páginasDryerAaron Paulo Bernardo100% (2)

- Cast Iron Welding AlloysDocumento4 páginasCast Iron Welding AlloysKhin Aung ShweAinda não há avaliações

- Fundamentals of Metal CastingDocumento14 páginasFundamentals of Metal CastingKhin Aung ShweAinda não há avaliações

- Braze Cast Iron - Videos, Tips and ProceduresDocumento5 páginasBraze Cast Iron - Videos, Tips and ProceduresKhin Aung ShweAinda não há avaliações

- Brazil: "PLANTAR" Project: Sustainable Fuelwood and Charcoal Production and Substitution of Coke in Pig Iron ProductionDocumento33 páginasBrazil: "PLANTAR" Project: Sustainable Fuelwood and Charcoal Production and Substitution of Coke in Pig Iron ProductionKhin Aung ShweAinda não há avaliações

- Material Grade Comparison Chart PDFDocumento1 páginaMaterial Grade Comparison Chart PDFHelen Kate Saccuan100% (1)

- Casting Material WCBDocumento8 páginasCasting Material WCBYusri WyeuserieyAinda não há avaliações

- Effect of Pouring Temperature and Stirring Speed OnDocumento6 páginasEffect of Pouring Temperature and Stirring Speed OnInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- The Crucible PowerpointDocumento11 páginasThe Crucible PowerpointKhin Aung Shwe100% (1)

- Boiler Furnace TheoryDocumento8 páginasBoiler Furnace TheoryArun YogaAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (120)

- Cast Iron Material Comparison Chart ASTM CompilationDocumento1 páginaCast Iron Material Comparison Chart ASTM CompilationCésar Cristov León OrtegaAinda não há avaliações

- What Are The Different Types of Gold in Jewelry?Documento4 páginasWhat Are The Different Types of Gold in Jewelry?Abdul Rashid100% (1)

- The Metallurgy of Power BoilersDocumento4 páginasThe Metallurgy of Power Boilersagniva dattaAinda não há avaliações

- Codigos de Soldadura AwsDocumento7 páginasCodigos de Soldadura AwsAlberto Enrique Rios RamosAinda não há avaliações

- Thermodynamic of Cyanidation of Gold: TermodinamikaDocumento14 páginasThermodynamic of Cyanidation of Gold: TermodinamikaJonas Lodewyk HutapeaAinda não há avaliações

- A Textbook of Machine Design R.S.KHURMI AND J.K.GUPTA 14ed - 1Documento2 páginasA Textbook of Machine Design R.S.KHURMI AND J.K.GUPTA 14ed - 1Muruganantham Majestic100% (1)

- Din 6330Documento1 páginaDin 6330PatriciaeRafael AlmeidaAinda não há avaliações

- Combination Flame Arrester & Free VentDocumento4 páginasCombination Flame Arrester & Free Ventyulianus_srAinda não há avaliações

- Kennametal MasterCatalog SEM Preview en MinchDocumento119 páginasKennametal MasterCatalog SEM Preview en MinchBeto CovasAinda não há avaliações

- Steel ChemistryDocumento22 páginasSteel ChemistryAmit Kumar UkeAinda não há avaliações

- Completed Non-Ferrous Alloys ProjectDocumento9 páginasCompleted Non-Ferrous Alloys ProjectCarlin Sylvester100% (2)

- Reyes Activity 5 MPDDocumento17 páginasReyes Activity 5 MPDMariel Enhaynes ReyesAinda não há avaliações

- Righton LTD Stainless Steel 3S144 394Documento1 páginaRighton LTD Stainless Steel 3S144 394Arjun PrajapatiAinda não há avaliações

- Material para BombasDocumento3 páginasMaterial para BombasPeñaloz GustavoAinda não há avaliações

- 17) Welding Visual Inspection Report PDFDocumento9 páginas17) Welding Visual Inspection Report PDFMuhammad Fitransyah Syamsuar Putra100% (1)

- Sae Specifications: Sae No. C MN Si CR Ni Mo S en Eqvt PDocumento26 páginasSae Specifications: Sae No. C MN Si CR Ni Mo S en Eqvt PNeeraj DhariaAinda não há avaliações

- Ductile Cast IronDocumento9 páginasDuctile Cast Ironander_sarettaAinda não há avaliações

- 4 Selectarc 308l 16 309l 16 316l 16 FT Web AnglaisDocumento1 página4 Selectarc 308l 16 309l 16 316l 16 FT Web Anglaisamir moniriAinda não há avaliações

- Effects of Alloying Elements in SteelDocumento3 páginasEffects of Alloying Elements in SteelfaizalzolAinda não há avaliações

- Triton Alloys Hardox 400 - Hardox 400 Plate-Triton Alloys IncDocumento8 páginasTriton Alloys Hardox 400 - Hardox 400 Plate-Triton Alloys IncAnonymous hj68hZmoAinda não há avaliações

- E527-12 Standard Practice For Numbering Metals and Alloys in The Unified Numbering System (UNS)Documento7 páginasE527-12 Standard Practice For Numbering Metals and Alloys in The Unified Numbering System (UNS)Walter TrajadaAinda não há avaliações

- Specific Gravity of Steel TableDocumento12 páginasSpecific Gravity of Steel TableAlmario SagunAinda não há avaliações

- 2-Nit Reference Electrode 31012016Documento21 páginas2-Nit Reference Electrode 31012016SaiPraneeth100% (1)

- Stainless Steel For Bridge ApplicationDocumento57 páginasStainless Steel For Bridge ApplicationDtscAinda não há avaliações

- What Is Steel?: 1. Integrated (Blast Furnace and Basic Oxygen Furnace) - 2. Electric Arc Furnace (EAF)Documento6 páginasWhat Is Steel?: 1. Integrated (Blast Furnace and Basic Oxygen Furnace) - 2. Electric Arc Furnace (EAF)Prabhakar KattulaAinda não há avaliações

- B31.3 Table 330.1.1 Preheat TempDocumento1 páginaB31.3 Table 330.1.1 Preheat TempHusam AhmedAinda não há avaliações

- ERNiCrFeAl-1 (Alloy 693)Documento1 páginaERNiCrFeAl-1 (Alloy 693)haran2000Ainda não há avaliações

- PENAWARAN HARGA UPAH PASANG AC - PIPA-rev 1Documento2 páginasPENAWARAN HARGA UPAH PASANG AC - PIPA-rev 1Agus SofiansyahAinda não há avaliações

- VGRBTH 000 - sfddsfsfsgdsfhgw4Documento1 páginaVGRBTH 000 - sfddsfsfsgdsfhgw4RameshAinda não há avaliações