Escolar Documentos

Profissional Documentos

Cultura Documentos

Control Rods of Rubber Flexible Joint

Enviado por

dedikartiwa_dkDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Control Rods of Rubber Flexible Joint

Enviado por

dedikartiwa_dkDireitos autorais:

Formatos disponíveis

CONNECTORS

CONTROL RODS FOR EXPANSION JOINTS

INSTALLATION AND MAINTENANCE INSTRUCTIONS

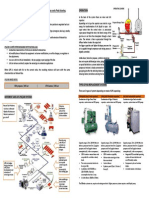

Series ASM With Control Rods

5

Series ATM With Control Rods

1.

2.

3.

4.

5.

6.

ROD

PLATE

NUT

HEAD NUT

STEEL WASHER

RUBBER WASHER

5 6

2 4

Anchor

Pipe Guides

(Typical)

Flow

Series ASM with Control Rods

Expansion Joints

with Control Units

Pump

Pipe Sleeve

Anchor

Solid Foundation

Series ATM with Control Rods

Figure 1. Typical piping layout showing the use of Control Rods with

Expansion Joints, when proper system anchoring is limited.

WARNING

Expansion joints may operate in pipelines or equipment

carrying fluids and or gases at elevated temperatures and

pressures. Normal precautions should be taken to make

sure these parts are installed correctly and inspected

regularly. Caution should be taken to protect personnel in

the event of leakage of fluids or gasses.

FUNCTION

Expansion joints are not designed to withstand excessive

end thrusts, wide temperature fluctuations or high pressure

changes (i.e. starting a pump). When pressures or

temperatures exceed the units design capability,

premature failure of the expansion joint will occur. To

prevent excessive movement, Expansion joints must be

installed in an anchored system, between two fixed anchor

points in a piping system, to control expansion or contraction of the line. Piping anchors must be capable of

withstanding the line thrust generated by internal pressure

or wide temperature fluctuations. The failure of these

anchors can cause excessive pipeline motion. When

proper anchoring cannot be provided, control rods are

required (See Figure 1).

A control rod assembly is a set of two or more control rods

placed across an expansion joint, from flange to flange, to

minimize or prevent damage to the expansion joint caused

by excessive extension, compression or motion of a

pipeline and to absorb static pressure thrust. Control rods

allow specified expansion joint movement (axial extension)

and pipe contraction (axial compression) which will then

preclude the possibility of motion that would over-elongate

and damage the joint. The control rod assembly can also

be set at the maximum allowable expansion and or

contraction of the expansion joint. Control rods are not

required in systems that are anchored. However, when

used in this manner, control units are an additional safety

factor and minimizes possible damage to adjacent

equipment. Control rods are always required in unanchored

systems.

- 246 -

INSTALLATION AND MAINTENANCE INSTRUCTIONS

CONTROL RODS MOUNTING INSTRUCTIONS

Anchors are required whenever a piping system

changes direction. Expansion joints should be

located as close as possible to anchor points. If an

anchoring system is not used, it is recommended that

control rods be installed on the expansion join to

prevent excessive movement from occurring due to

pressure thrust in the line (See Figure 1).

To determine end thrust, multiply thrust factor by

operating pressure of system. This is the end thrust

in PSIG.

Vacuum rating is based on installed length, without

external load. Product should not be installed

extended on vacuum applications.

Joints must be precompressed approximately 1/8 to

3/16 in order to obtain a correct installed face-toface dimension. During installation, the

precompression should not exceed 3/16 (5 mm).

The alignment of the piping system should be

adjusted and secured with fixation points as close as

possible on each side of the expansion joint at a

distance less than three times the pipes nominal

diameter.

These fixation points must be installed when

mounting an expansion joint with control rods or an

elbow pipe. If there is considerable distance between

two fixation points, guiding points can be installed in

order to support and guide the pipe (cf. installation

scheme).

- 247 -

Before installation, check the interior, exterior and

flange faces of the expansion joint for cuts and

gouges.

When installing, make sure that the rubber expansion

joints do not support compression or extension due

to the weight of the upstream or downstream pipe.

When installing the rubber expansion joint, make sure

that the connector is not twisted (especially for Series

AUM).

Mounting order: (1) upstream pipe anchor,

(2) downstream pipe anchor, (3) expansion joint.

Verify that the upstream and downstream pipe

alignment does not deviate more than 1/8" (3 mm)

and that the expansion joint does not support heavy

weight.

To prevent damage to the expansion joint surface,

verify that the surfaces, coming in contact with the

expansion joint, are clean and without cutting edges

(pipe).

Avoid direct contact with the expansion joint rubber

surface by inserting the bolts on the arch side of the

joint.

If welding is carried out within close range, cover or

dismount the expansion joint.

Do not paint or coat the joint with insulation.

Store the joint in a flat position avoiding humidity and

extreme temperatures.

Bolt tightness should be checked daily within the first

month after services and checked periodically

CONNECTORS

CONTROL RODS FOR EXPANSION JOINTS

Você também pode gostar

- Bellow Design 1Documento5 páginasBellow Design 1zingalala100% (2)

- Rubber Expansion Joints Installation GuideDocumento3 páginasRubber Expansion Joints Installation GuideLudi D. LunarAinda não há avaliações

- Expension Joints Engineering AppliancesDocumento30 páginasExpension Joints Engineering AppliancesAcid BurnsAinda não há avaliações

- Bellow Installation Guideline For Expansion BellowsDocumento5 páginasBellow Installation Guideline For Expansion BellowsPravin SatheAinda não há avaliações

- Bellow: Do's Dont'sDocumento10 páginasBellow: Do's Dont'sjohnvemAinda não há avaliações

- Accommodating Expansion in Piping SystemsDocumento52 páginasAccommodating Expansion in Piping SystemsBeomHee LeeAinda não há avaliações

- Method Statement of Gasket, Flange, Fittings and Valves Tightening SequenceDocumento6 páginasMethod Statement of Gasket, Flange, Fittings and Valves Tightening SequenceRuel CabonceAinda não há avaliações

- Orifice Flange Union Assembly and Orifice Run Installation and Operation ManualDocumento8 páginasOrifice Flange Union Assembly and Orifice Run Installation and Operation ManualNithin CpAinda não há avaliações

- 4: Location of Supports and Restraints: 321.1.1 Objectives (From ANSI B31.3 Code)Documento2 páginas4: Location of Supports and Restraints: 321.1.1 Objectives (From ANSI B31.3 Code)prasadgssAinda não há avaliações

- Piping Connection ConsiderationsDocumento11 páginasPiping Connection ConsiderationsGrundfosEgyptAinda não há avaliações

- Series V100 Ball ValveDocumento20 páginasSeries V100 Ball ValvejenniferAinda não há avaliações

- Hco Parte ViiiDocumento33 páginasHco Parte ViiiWilliam Manuel Forero IbañezAinda não há avaliações

- Installation Flex EJIndustrial MetalDocumento2 páginasInstallation Flex EJIndustrial MetalMuhammad WaheedAinda não há avaliações

- FIS113eng Hi Temp BellowsDocumento8 páginasFIS113eng Hi Temp Bellowsmahesh_eilAinda não há avaliações

- Iron Balancing Valves IOM For Hattersley ColourDocumento8 páginasIron Balancing Valves IOM For Hattersley ColourMuhammad ElbarbaryAinda não há avaliações

- CVS Type 667 Diaphragm Actuator: Instruction ManualDocumento8 páginasCVS Type 667 Diaphragm Actuator: Instruction Manualsalmo83:18Ainda não há avaliações

- Pipe SupportDocumento7 páginasPipe SupportSAHTEESHKUMARAinda não há avaliações

- Installation of Ductile-Iron Water Mains and Their AppurtenancesDocumento6 páginasInstallation of Ductile-Iron Water Mains and Their Appurtenancesmailmaverick0% (1)

- Installation and Service Instructions Lateral - Expansion JointDocumento2 páginasInstallation and Service Instructions Lateral - Expansion JointA. VenugopalAinda não há avaliações

- Dosing PumpDocumento10 páginasDosing PumpniceseshaAinda não há avaliações

- Pipe Support Design GuidelinesDocumento9 páginasPipe Support Design GuidelineskarunaAinda não há avaliações

- Checks To Be Carried Out On Receipt of The Actuator: ! - #$ Flow ControlDocumento4 páginasChecks To Be Carried Out On Receipt of The Actuator: ! - #$ Flow ControlSyko GuyAinda não há avaliações

- Manual TenarisDocumento28 páginasManual TenarisCamilo Moreno100% (1)

- Torquing ManualDocumento17 páginasTorquing ManualZool HilmiAinda não há avaliações

- General Guidelines of Pump Piping LayoutDocumento8 páginasGeneral Guidelines of Pump Piping LayoutbainAinda não há avaliações

- Hattersley+A5+IOM+Fig.370+&+Fig.371+Colour 0119 WEBDocumento4 páginasHattersley+A5+IOM+Fig.370+&+Fig.371+Colour 0119 WEBFareethAbdullahAinda não há avaliações

- Inspection & Testing of Pressure Vessels and Pressure Relieving Devices - 4Documento7 páginasInspection & Testing of Pressure Vessels and Pressure Relieving Devices - 4DeepakAinda não há avaliações

- Technical Data Sheet & Part ListDocumento24 páginasTechnical Data Sheet & Part ListM Farid Fakhrudduja100% (1)

- So If: Recommendations For The Installation, Fabrication, Testing and Cleaning of Air, Gas or Steam PipingDocumento1 páginaSo If: Recommendations For The Installation, Fabrication, Testing and Cleaning of Air, Gas or Steam PipingKarim MohamedAinda não há avaliações

- Standard Practices Tubing, Hoses and Fittings Maintenance PracticesDocumento12 páginasStandard Practices Tubing, Hoses and Fittings Maintenance PracticesWalter TorenaAinda não há avaliações

- PTFE Expansion Joint Instructions 1Documento1 páginaPTFE Expansion Joint Instructions 1DDAinda não há avaliações

- Taf Truss Manual en EsDocumento14 páginasTaf Truss Manual en Esagustin senoffAinda não há avaliações

- Pump Vibration AnalysisDocumento12 páginasPump Vibration AnalysisSamir Benabdallah100% (1)

- In-Line Hydraulic TesterDocumento5 páginasIn-Line Hydraulic TesterMasterrAinda não há avaliações

- A Primer On Pipe Supports - Hydraulics Content From Machine DesignDocumento8 páginasA Primer On Pipe Supports - Hydraulics Content From Machine DesignSharun SureshAinda não há avaliações

- Armstrong Installation43.80 VIL I&ODocumento14 páginasArmstrong Installation43.80 VIL I&Osas999333Ainda não há avaliações

- Safety Valves For Power PlantDocumento56 páginasSafety Valves For Power Planttek_surinder100% (1)

- Installation Instructions Spool Type Elastomer Expansion JointsDocumento2 páginasInstallation Instructions Spool Type Elastomer Expansion JointsAmina TaissaAinda não há avaliações

- Control Unit InstructionsDocumento1 páginaControl Unit Instructionsmanoj_sitecAinda não há avaliações

- Single Line Installation and System Startup/trouble Shooting Bulletin SL-300Documento4 páginasSingle Line Installation and System Startup/trouble Shooting Bulletin SL-300Torres Toledo JttAinda não há avaliações

- Convertidor Mechanical S108KDocumento8 páginasConvertidor Mechanical S108KALBERTOAinda não há avaliações

- Full-Faced Expansion Joints: InstallationDocumento3 páginasFull-Faced Expansion Joints: InstallationChiranjeevi AnilAinda não há avaliações

- SCE Ganesh Kirdak-220m0011 PED 1Documento35 páginasSCE Ganesh Kirdak-220m0011 PED 1GANESHAinda não há avaliações

- Plunger Pump Service Manual: Installation and Start-Up InformationDocumento6 páginasPlunger Pump Service Manual: Installation and Start-Up InformationSubhendu KarAinda não há avaliações

- INSTALLATION OPERATION AND MAINTENANCE MANUAL-MilwakeeDocumento10 páginasINSTALLATION OPERATION AND MAINTENANCE MANUAL-MilwakeeMASOUDAinda não há avaliações

- Beltway Scale Manual 2009Documento56 páginasBeltway Scale Manual 2009morris_timAinda não há avaliações

- O&M and Drawing PDFDocumento2 páginasO&M and Drawing PDFhguptabhelAinda não há avaliações

- Expansion JointsDocumento43 páginasExpansion Jointsvermaakash22100% (1)

- Relief Valves: Gases and Gas EquipmentDocumento22 páginasRelief Valves: Gases and Gas EquipmentInspection EngineerAinda não há avaliações

- SC Bulk Hose Handling Guidance DocumentDocumento24 páginasSC Bulk Hose Handling Guidance DocumentLeonardo AlvarezAinda não há avaliações

- Cooling Fan Belt TensionerDocumento13 páginasCooling Fan Belt Tensionerakuncbm.hillconAinda não há avaliações

- Wire Rope-Steel TechnicalDocumento37 páginasWire Rope-Steel TechnicalAndreea LucaAinda não há avaliações

- Hot-Tap Saddle: Installation InstructionsDocumento2 páginasHot-Tap Saddle: Installation InstructionsSusan Sue Berrospi MerinoAinda não há avaliações

- Pipes and Hoses PDFDocumento6 páginasPipes and Hoses PDFDinu Aditya SaputraAinda não há avaliações

- Hose Selection: Selection, Installation and Maintenance of Hose and Hose AssembliesDocumento2 páginasHose Selection: Selection, Installation and Maintenance of Hose and Hose AssembliesAbdul JunaediAinda não há avaliações

- Tenaris Running Manual 01Documento20 páginasTenaris Running Manual 01advantage025Ainda não há avaliações

- Damages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsNo EverandDamages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsNota: 4.5 de 5 estrelas4.5/5 (2)

- Prevention of Actuator Emissions in the Oil and Gas IndustryNo EverandPrevention of Actuator Emissions in the Oil and Gas IndustryAinda não há avaliações

- MP&MH 2012 (Apr-Nov)Documento1 páginaMP&MH 2012 (Apr-Nov)dedikartiwa_dkAinda não há avaliações

- Standards For Material Handling, Storage, and DisposalDocumento13 páginasStandards For Material Handling, Storage, and Disposaljeb13Ainda não há avaliações

- Pipe Flow Friction Factor CalculationsDocumento14 páginasPipe Flow Friction Factor Calculationsdedikartiwa_dkAinda não há avaliações

- Movement JointsDocumento4 páginasMovement JointsArnold TunduliAinda não há avaliações

- Removal of Expansion Join's Bolts & Nuts: No. Photos Before Photos After No. Photos Photos AfterDocumento3 páginasRemoval of Expansion Join's Bolts & Nuts: No. Photos Before Photos After No. Photos Photos Afterdedikartiwa_dkAinda não há avaliações

- Collar TypeDocumento1 páginaCollar Typededikartiwa_dkAinda não há avaliações

- Underground LPG SDocumento1 páginaUnderground LPG Sdedikartiwa_dkAinda não há avaliações

- 21 TSRT PR 21 Mechanical PrecommissionngDocumento8 páginas21 TSRT PR 21 Mechanical Precommissionngdedikartiwa_dkAinda não há avaliações

- TIASA - Thermal Insulation HandbookDocumento58 páginasTIASA - Thermal Insulation HandbookSirGawain99Ainda não há avaliações

- Kaeser ASD SeriesDocumento5 páginasKaeser ASD SeriesSachith VidanapathiranaAinda não há avaliações

- Request For Field InspectionDocumento1 páginaRequest For Field Inspectiondedikartiwa_dkAinda não há avaliações

- SDS - Alkydprimer - Marine - Protective - English (Uk) - UniteDocumento6 páginasSDS - Alkydprimer - Marine - Protective - English (Uk) - UniteAndres Fitria FarrelAinda não há avaliações

- ViskositasDocumento1 páginaViskositasnawrim_sugaAinda não há avaliações

- Metering StandardsDocumento101 páginasMetering StandardsJonathan Narh-DometeyAinda não há avaliações

- Equipment Commissioning ChecklistDocumento20 páginasEquipment Commissioning ChecklistDheeraj Yadav100% (2)

- Quality Measurement Tool & Tester ListDocumento1 páginaQuality Measurement Tool & Tester Listdedikartiwa_dkAinda não há avaliações

- LPG Air Mixing 2 A3Documento1 páginaLPG Air Mixing 2 A3ambientinstal instalAinda não há avaliações

- EHS-00031-F4 R2 - Monitoring Device Calibration ChecklistDocumento1 páginaEHS-00031-F4 R2 - Monitoring Device Calibration Checklistdedikartiwa_dkAinda não há avaliações

- 24-Road Vehicle SafetyDocumento12 páginas24-Road Vehicle Safetydedikartiwa_dkAinda não há avaliações

- Velocity Profile Circular PipeDocumento4 páginasVelocity Profile Circular Pipededikartiwa_dkAinda não há avaliações

- SDS - Barrier - Comp. B - Marine - Protective - Indonesian (IdDocumento7 páginasSDS - Barrier - Comp. B - Marine - Protective - Indonesian (Iddedikartiwa_dkAinda não há avaliações

- SDS - Aluflex - Marine - Protective - English (Uk) - United KiDocumento5 páginasSDS - Aluflex - Marine - Protective - English (Uk) - United KiAndres Fitria FarrelAinda não há avaliações

- Quotation Pressure Tank RO SSDocumento2 páginasQuotation Pressure Tank RO SSdedikartiwa_dkAinda não há avaliações

- Pressure Drop Excel VB FormatDocumento4 páginasPressure Drop Excel VB Formatsiva242245Ainda não há avaliações

- Piping Identification and Valve Tagging PDFDocumento5 páginasPiping Identification and Valve Tagging PDFdedikartiwa_dkAinda não há avaliações

- RIT Pipe Lmnabeling Painting and Valve Tag Standard 03 01 2013Documento3 páginasRIT Pipe Lmnabeling Painting and Valve Tag Standard 03 01 2013dedikartiwa_dk100% (1)

- Piping Identification and Valve Tagging StandardDocumento6 páginasPiping Identification and Valve Tagging Standardmanox007Ainda não há avaliações

- Piping Identification and Valve Tagging PDFDocumento5 páginasPiping Identification and Valve Tagging PDFdedikartiwa_dkAinda não há avaliações

- Panjang Kotak (A) Tinggi Huruf (B) Jumlah Huruf (C) X (Inch) Y (Inch) Z (Inch) Nominal Pipe Size Outside Diameter Ukuran Huruf Ukuran PanahDocumento1 páginaPanjang Kotak (A) Tinggi Huruf (B) Jumlah Huruf (C) X (Inch) Y (Inch) Z (Inch) Nominal Pipe Size Outside Diameter Ukuran Huruf Ukuran Panahdedikartiwa_dkAinda não há avaliações

- F120 - F160 Peco ManualDocumento44 páginasF120 - F160 Peco ManualBernie WireAinda não há avaliações

- Split Type AcuDocumento40 páginasSplit Type AcuKristine Ann ReclosadoAinda não há avaliações

- Setra 400 Class - 415 416 Euro 5 ManualDocumento620 páginasSetra 400 Class - 415 416 Euro 5 ManualAshley Cardwell100% (3)

- Asme B31.8-2007Documento6 páginasAsme B31.8-2007SUHANI CHANDELAinda não há avaliações

- STC-1000 Temperature Controller Operating Manual: or or orDocumento1 páginaSTC-1000 Temperature Controller Operating Manual: or or orziandAinda não há avaliações

- Power Plant and Calculations - Boiler Calculations For Boiler Operation Engineer Exam (BOE)Documento12 páginasPower Plant and Calculations - Boiler Calculations For Boiler Operation Engineer Exam (BOE)RajeshAinda não há avaliações

- 001-008 Camshaft: InstallDocumento6 páginas001-008 Camshaft: InstallNaing Min HtunAinda não há avaliações

- flowIT FTBGDW-16Documento1 páginaflowIT FTBGDW-16technicalsupportAinda não há avaliações

- Iso 2503 2009 en PDFDocumento11 páginasIso 2503 2009 en PDFВикторAinda não há avaliações

- YamahaDocumento27 páginasYamahaabduallah muhammadAinda não há avaliações

- ZoellerDocumento4 páginasZoellerWharfedaleAinda não há avaliações

- Module 2Documento43 páginasModule 2Manchimsetty Sri NidhiAinda não há avaliações

- Axera D07Documento79 páginasAxera D07Percy Chero100% (2)

- 490 SSAB Automotive Final PDFDocumento33 páginas490 SSAB Automotive Final PDFyujian331Ainda não há avaliações

- Lock-O-Ring FlangeDocumento6 páginasLock-O-Ring FlangeAm EAinda não há avaliações

- Pipe BranchDocumento761 páginasPipe Branchjnmanivannanmech50% (2)

- Fea 2 Marks and AnswersDocumento20 páginasFea 2 Marks and AnswerssnvijayanAinda não há avaliações

- 2018 Ninja400 SM-Update FinalDocumento653 páginas2018 Ninja400 SM-Update FinalThomas Zoumboulias100% (1)

- Pipe Jacking Force PDFDocumento417 páginasPipe Jacking Force PDFSajjad AnwarAinda não há avaliações

- Detroit Parts 8V71 & 12V71Documento47 páginasDetroit Parts 8V71 & 12V71indra100% (2)

- Grundfos CRT 8 5 A P A e AuueDocumento9 páginasGrundfos CRT 8 5 A P A e AuueRajesh KanalaAinda não há avaliações

- Mfaf BK: ScopeDocumento23 páginasMfaf BK: ScopesbalajimAinda não há avaliações

- Thermowell InstallationDocumento8 páginasThermowell Installationprasoon_eilAinda não há avaliações

- Yamaha ServiceDocumento57 páginasYamaha ServicesantonsAinda não há avaliações

- Thermodynamics-1 Semester AssignmentDocumento9 páginasThermodynamics-1 Semester AssignmentShahZaib AnwarAinda não há avaliações

- Thw500 Tds (TT - 0416) EnglishDocumento2 páginasThw500 Tds (TT - 0416) EnglishMasood KhanAinda não há avaliações

- BOSCH - Master Brake Cylinder & EPDM SealsDocumento3 páginasBOSCH - Master Brake Cylinder & EPDM Sealsgautamnaveen1986Ainda não há avaliações

- Viscometer Test PDFDocumento2 páginasViscometer Test PDFAshishJamadarAinda não há avaliações

- Simplified Analysisof Continuous BeamsDocumento8 páginasSimplified Analysisof Continuous BeamsMin Thiha NaingAinda não há avaliações

- Raw Pareto Week 51Documento349 páginasRaw Pareto Week 51Ahmat RamadaniAinda não há avaliações