Escolar Documentos

Profissional Documentos

Cultura Documentos

Bradley Smallgoods: Case Study: "Sausages Made To Order?"

Enviado por

Ariyanto BudidarmoDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Bradley Smallgoods: Case Study: "Sausages Made To Order?"

Enviado por

Ariyanto BudidarmoDireitos autorais:

Formatos disponíveis

SCM , Team I

Case Study: Sausages Made To Order?

About the Company

Bradley Smallgoods

A meat-processing company in Melbourne, Australia.

Formed in 1947, a subsidiary of a large food-processing company.

Annual turnover of Aus$110 million from sales of 14,000 tonnes of product.

Sell to national markets (predominantly made in the state of Victoria) and some exports.

Has been making fresh sausages from meat trimmings, grain and seasonings filled into a

casing for almost 50 years. Originally made only pork sausages and they were primarily sold

through corner shops and delicatessens. Customers of the deli counter in a supermarket want

a variety of sausages such as bratwurst, pork, honey and soy, beef and tomato, and chicken.

Bradleys processes in brief:

Bradley purchases boned pig meats,

processes them into a range of cured, preserved and fresh meat products known as

smallgoods,

sells the sausages to 3 market segments: supermarkets (60%), delicatessen shops (20%) and

other food manufacturers (20%).

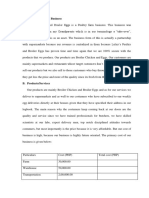

Bradleys Manufacturing process:

Bradleys typical schedule for its sausage production:

Scheduled production of sausage produce to stock (tonnes)

SCM , Team I

Bradleys Supply Chain

The integrated supply chain diagram

Materials flow:

Information flow:

Bradley purchases the pigs from a piggery in

northern Victoria, which then are slaughtered and

a week. It estimates its requirements a month in

dressed at an abattoir adjacent to it.

advance but without any commitment.

The carcasses are delivered to Apollo Meats,

Bradley has a weekly requirement that Apollo

processes a number of carcasses for delivery

meat is then refrigerated and delivered to Bradley

every 2 working days. This number is changed

twice a week.

without notice when Bradley so wishes, on the

Bradley distributes its sausages from its chilled

Friday before a working week.

Production scheduling is carried out at Bradley

Delivery for Safeway Supermarket, its major

using a stand-alone spreadsheet. The scheduler

customer, is to Safeways cold store by using

uses this sheet to plan production 4 weeks

pans (pantechnicons) pulled by a prime mover.

ahead, but there are daily changes to the

Bradley hires a transport company to deliver

schedule as customers exact needs are obtained.

these pans to Safeways Distribution Center in a

where Apollo will bone and trim the meat. This

store at the end of the production line.

Safeway places orders for sausage varieties twice

The only computer information Bradley has on

narrow time slot.

the stocks of sausages is the financial value of

Safeway is the largest supermarket chain in

the pallet loads in its despatch store. To find out

Australia, with 150 stores in Victoria. Its

stocks of individual varieties, sales staff have to

customers buy sausages to keep in the freezer

ask the store person.

until needed. The majority buy sausages for a

particular occasion, such as a barbeque.

Safeway has detailed information about its

sausage stocks at its cold store but does not

share this with Bradley. Delivery information is

compiled from the loads assembled in despatch.

SCM , Team I

The Personnel

Bradley Smallgoods

Safeway Supermarket

Paul Liddy, Operations Manager

Gwen Davies, Senior Buyer

Mikhail, Production Supervisor

Rachel, Order Clerk

Chris, Production Scheduler

Apollo Meats

General Manager

Brian, Manager

Shift Supervisors

Zoltan, Boning Supervisor

The Case

Background:

Paul want to try to improve the process since Bradleys profit is too low. The long-term objective

is to streamline operations so that customer service levels will increase and costs will be

reduced, so he introduces the concept of changing the sausages production to Make-to-Order

and Just-in-Time approach.

Paul arranges meeting with Brian from Apollo, and Gwen from Safeway to discuss his

improvement project. Pauls statement: I want to move from making sausages in large batches

in advance, to making exactly the varieties and quantities you want when you order them.

Result from the first meeting:

Gwens comments:

That sounds like a good proposition. We

would get fresher sausage, provided you

can react quickly to our afternoon order.

Brians comments:

My boning room is not set up to deliver

meat exactly when you want it.

I only operate one crew of butchers, so I

We could not tolerate any drop in delivery

need to arrange my production schedule a

performance. Already we have seen 8% of

week in advance

deliveries miss the required time this year.

Paul and the rest conduct their study and propose below changes:

the increased frequency of Safeway ordering,

the increased number of sausage batches, and

the extra shifts needed at Apollo.

SCM , Team I

The study findings, showing the current situation and the expected changes:

Reactions to the Proposal:

Bradley

Safeway

The GM is entirely in favors of

Gwen accepts the main

Apollo

Brian is quite negative about

the change.

results of the study, and

his ability to bone some

However, Bradleys shift

agrees that orders could be

carcasses for Bradley during

supervisors were not

placed every 4 hours during

every shift.

convinced, as they could see

the working day.

problems in changing over,

Zoltan pointed out that

Expected benefits: getting

traceability and cleanliness

which they didnt want to do

fresher sausage and fewer

would be compromised by

during the Easter period, in 2

delivery failures.

changing from boning for a

However, she cannot predict

food service company to

the size of individual orders.

Bradley products during every

Her biggest problem will be to

operating shift. He would

argue that a lot of their work

get her superior and store

have to stop the entire

is related to the batch of

managers to accept Pauls

operation for 15 minutes, and

sausages made. So, more

proposals.

he could face an industrial

weeks time.

They could not envisage the

real savings in their area, and

batches equal more work.

dispute from the boners.

Pauls Dilemma: to go or not to go?

Should he go ahead with his proposal to make sausages to order?

What are important factors to consider, in order for him to implement the change successfully?

Please come to our presentation for the answers on Wednesday, 14th October 2015.

See you there!!

4

Você também pode gostar

- Shan FoodsDocumento13 páginasShan FoodsHaseeb Ahmed100% (1)

- Meat Shop Business Plan FinalDocumento21 páginasMeat Shop Business Plan FinalJenirose Racaza75% (4)

- Case 1 - Pret A MangerDocumento4 páginasCase 1 - Pret A MangerAjay Chandar100% (1)

- La Lardé's Meat Shop: Business PlanDocumento21 páginasLa Lardé's Meat Shop: Business Plangeorjalynjoy100% (1)

- TQM Project CdoDocumento6 páginasTQM Project CdoMel De VeraAinda não há avaliações

- Quality PracticesDocumento4 páginasQuality PracticesCharity VenusAinda não há avaliações

- Business Plan SOLOMON Calvin Jay A.Documento37 páginasBusiness Plan SOLOMON Calvin Jay A.Jay Lord Tayong100% (2)

- A Food Grade Warehouse Business Plan: 473 3 Avenue, Prince George, British Columbia MarketDocumento14 páginasA Food Grade Warehouse Business Plan: 473 3 Avenue, Prince George, British Columbia MarketOmaya Tariq100% (1)

- Supply Chain Management (Report)Documento10 páginasSupply Chain Management (Report)tahshan tonmoyAinda não há avaliações

- Asignment-Paolo Jollibee 2Documento3 páginasAsignment-Paolo Jollibee 2Felizardo Tapleras Demayuga Jr.Ainda não há avaliações

- 4 Chicken RunDocumento9 páginas4 Chicken RuntrishaweepatsparatatsAinda não há avaliações

- Credit Suisse - India Packaged Foods SectorDocumento37 páginasCredit Suisse - India Packaged Foods SectorVishal MAinda não há avaliações

- Jollibee Foods CorporationDocumento61 páginasJollibee Foods CorporationMadeleine Velasco67% (3)

- Zulhairi Bin MD - Dawam 721121016501002Documento11 páginasZulhairi Bin MD - Dawam 721121016501002Zulhairi Md DawamAinda não há avaliações

- Problems With Frozen Lamb and Recommendations On Countermeasuring ItDocumento7 páginasProblems With Frozen Lamb and Recommendations On Countermeasuring ItSyamsul RadzieAinda não há avaliações

- Catch: Fresh Fish For Your DishDocumento13 páginasCatch: Fresh Fish For Your DishChaudhary Hassan ArainAinda não há avaliações

- Case Study Johnsonville Sausage Co Group 4Documento5 páginasCase Study Johnsonville Sausage Co Group 4David Košić0% (2)

- Franchising Term Paper GuideDocumento16 páginasFranchising Term Paper GuideMary Abigail BautistaAinda não há avaliações

- Peculiar Taste of Frozen Lamb: To: Anuar Bin Edon, Store ManagerDocumento13 páginasPeculiar Taste of Frozen Lamb: To: Anuar Bin Edon, Store ManagerBello SyanilAinda não há avaliações

- As The Store Manager For The Gemilang Hyper MarketDocumento9 páginasAs The Store Manager For The Gemilang Hyper MarketZekiel KushanAinda não há avaliações

- Taaza Gosht Profile - 2Documento7 páginasTaaza Gosht Profile - 2Imagiacian UKAinda não há avaliações

- Restaurant Fast Food Service Meat-Sweet DietDocumento10 páginasRestaurant Fast Food Service Meat-Sweet DietPrachi BoranaAinda não há avaliações

- Case Study Qualifications For Receiving Staff MembersDocumento4 páginasCase Study Qualifications For Receiving Staff MembersChristian Manrique MansillaAinda não há avaliações

- A Visit To Royal Food (Case)Documento13 páginasA Visit To Royal Food (Case)Delawar BarekzaiAinda não há avaliações

- Oumh2203 English For Workplace Communication 730817055044002Documento12 páginasOumh2203 English For Workplace Communication 730817055044002Mariah RaniAinda não há avaliações

- Meat Shop Business Plan Final DocDocumento21 páginasMeat Shop Business Plan Final DocGanggang PacalundoAinda não há avaliações

- Chapter 1 - MarketingDocumento15 páginasChapter 1 - MarketingEumar FabruadaAinda não há avaliações

- All Sections A-H - Prod and Op MGTDocumento20 páginasAll Sections A-H - Prod and Op MGTapi-302135579Ainda não há avaliações

- Victoria Samuels, Agricultural Science School Based Asessment - Business Plan, 10 HDocumento13 páginasVictoria Samuels, Agricultural Science School Based Asessment - Business Plan, 10 HRetikleAinda não há avaliações

- KFC Warehouse SystemDocumento10 páginasKFC Warehouse SystemZainAinda não há avaliações

- Launching The Hygenic Frozen FoodsDocumento14 páginasLaunching The Hygenic Frozen FoodsirfanAinda não há avaliações

- A033Documento24 páginasA033PRANAV GOYALAinda não há avaliações

- New Product Development, Marketing Project of Ta'amDocumento13 páginasNew Product Development, Marketing Project of Ta'ammubie100% (4)

- Business ReportDocumento7 páginasBusiness ReportFaizan AliAinda não há avaliações

- Aom Case StudiesDocumento16 páginasAom Case StudiessamimakhtarAinda não há avaliações

- Agricultural Science Business PlanDocumento18 páginasAgricultural Science Business PlanMalik MuhammadAinda não há avaliações

- Nutrition Over Calories: Prepared and Designed By: Anita Dhakar Anjali Mangal Payal KumawatDocumento22 páginasNutrition Over Calories: Prepared and Designed By: Anita Dhakar Anjali Mangal Payal Kumawatkumawat.payal076Ainda não há avaliações

- Poultry FarmDocumento4 páginasPoultry FarmClintAinda não há avaliações

- Quezon City: Jolly Foods Holdings IncorporatedDocumento1 páginaQuezon City: Jolly Foods Holdings IncorporatedShane Mycah PostranoAinda não há avaliações

- Operations Mangement PaperDocumento11 páginasOperations Mangement PaperChioma Nwokedi MomahAinda não há avaliações

- Burger King Vs McDonalds Final PaperDocumento14 páginasBurger King Vs McDonalds Final Papershriti83% (6)

- Butcher Shop BusinessDocumento44 páginasButcher Shop BusinessHaile KebedeAinda não há avaliações

- KFCDocumento14 páginasKFCYūkiHaseAinda não há avaliações

- In Processed Meat Industry Alimentos Cárnicos de Panamá S.A."Documento27 páginasIn Processed Meat Industry Alimentos Cárnicos de Panamá S.A."jorge_carreraAinda não há avaliações

- Flora PoultryDocumento20 páginasFlora Poultryflorence elenwa100% (2)

- Foodservice ProjectDocumento7 páginasFoodservice Projectapi-301595401Ainda não há avaliações

- Cannies PagenumberDocumento38 páginasCannies PagenumberJamie BagundolAinda não há avaliações

- Brasspigspp FinalDocumento27 páginasBrasspigspp Finalapi-533745238Ainda não há avaliações

- Harvard Business Case Study On The Saxonville Sausage Company CaseDocumento7 páginasHarvard Business Case Study On The Saxonville Sausage Company Casesg8397Ainda não há avaliações

- ResearchxchickenpastilDocumento19 páginasResearchxchickenpastilReinn EscarioAinda não há avaliações

- Smith Foods CaseDocumento9 páginasSmith Foods CaseLuke SnapeAinda não há avaliações

- Are There Any Parts in The Supply Chain That Could Be Outsourced? and Why?Documento5 páginasAre There Any Parts in The Supply Chain That Could Be Outsourced? and Why?katia1993Ainda não há avaliações

- SD - MEGqfS7 FZBBQN - U - KW - IIoT Case Project - LearnerDocumento5 páginasSD - MEGqfS7 FZBBQN - U - KW - IIoT Case Project - LearnerMahrane AIDIAinda não há avaliações

- BigskyolympicdininghallDocumento23 páginasBigskyolympicdininghallapi-301716754Ainda não há avaliações

- A SUCCESSFUL POULTRY PROJECT: MAKE MONEY OUT OF CHICKENSNo EverandA SUCCESSFUL POULTRY PROJECT: MAKE MONEY OUT OF CHICKENSAinda não há avaliações

- Slow Cooker Recipes Complete Cookbook (Boxed Set): 3 Books In 1 Over 100 Great Tasting Slow Cooker RecipesNo EverandSlow Cooker Recipes Complete Cookbook (Boxed Set): 3 Books In 1 Over 100 Great Tasting Slow Cooker RecipesNota: 3 de 5 estrelas3/5 (1)

- Raising Beef Cattle: A Beginner’s Starters Guide to Raising Beef CattleNo EverandRaising Beef Cattle: A Beginner’s Starters Guide to Raising Beef CattleAinda não há avaliações

- 30 Minute Cookbook: MY FOOD IS READY ALREADY? - Quick and Easy Recipes For All Dieters Packed With Protein and Nutrition While Low on CaloriesNo Everand30 Minute Cookbook: MY FOOD IS READY ALREADY? - Quick and Easy Recipes For All Dieters Packed With Protein and Nutrition While Low on CaloriesAinda não há avaliações

- Caregiving - Course DesignDocumento12 páginasCaregiving - Course DesigngilissaAinda não há avaliações

- Session 4 & 5Documento20 páginasSession 4 & 5SatYam VaRmaAinda não há avaliações

- Final Report Butabika Hospital Fys 200405 and 200506Documento15 páginasFinal Report Butabika Hospital Fys 200405 and 200506Bukari HamidAinda não há avaliações

- Agri Manufacturers List - Davao RegionDocumento18 páginasAgri Manufacturers List - Davao RegionYsmael Alongan B. MangorsiAinda não há avaliações

- Travel Guide: 24 Hours in ParisDocumento3 páginasTravel Guide: 24 Hours in ParisThe Travel Magazine100% (1)

- New Microsoft Word Document EasternDocumento57 páginasNew Microsoft Word Document EasternVISHNUKnpAinda não há avaliações

- BROWNIES Entrepreneurship SubjectDocumento12 páginasBROWNIES Entrepreneurship Subjectputri waznahAinda não há avaliações

- Kristoff Dale'S Baptism: OCTOBER 7,2018 ST - Peter Parish Church, Quezon CityDocumento20 páginasKristoff Dale'S Baptism: OCTOBER 7,2018 ST - Peter Parish Church, Quezon CityMaurice ReblezaAinda não há avaliações

- Hotel Operations-1 (Chapter-6)Documento14 páginasHotel Operations-1 (Chapter-6)VishnuNarayanan Viswanatha PillaiAinda não há avaliações

- Vrdfcu8508 - Allocation - August 18-BVILDocumento404 páginasVrdfcu8508 - Allocation - August 18-BVILSamsRsAinda não há avaliações

- Mcdonalds in IndiaDocumento20 páginasMcdonalds in IndiaAnupam KhandreAinda não há avaliações

- Xavier University - Ateneo de Cagayan School of Business and Management Department of Business AdministrationDocumento8 páginasXavier University - Ateneo de Cagayan School of Business and Management Department of Business AdministrationClara OpssAinda não há avaliações

- Organic Cherry Tomato NewDocumento2 páginasOrganic Cherry Tomato NewMiguerose OguimasjrAinda não há avaliações

- Ananda KumarDocumento3 páginasAnanda KumarreddyAinda não há avaliações

- Children in Danger: Malnutrition Disaster and ICDS in Madhya PradeshDocumento58 páginasChildren in Danger: Malnutrition Disaster and ICDS in Madhya PradeshVikas SamvadAinda não há avaliações

- New ResumeDocumento2 páginasNew Resumeapi-240904851Ainda não há avaliações

- A World Guide To Good MannersDocumento3 páginasA World Guide To Good MannersAnonymous yGiNwtAinda não há avaliações

- 1 Naturland - Intro - EN - 2022Documento28 páginas1 Naturland - Intro - EN - 2022arif mukhtar hasbiAinda não há avaliações

- Gum Arabic Policy Note Final PDFDocumento45 páginasGum Arabic Policy Note Final PDFnazarmustafaAinda não há avaliações

- Feasibility Study (Moringa Custard Donuts)Documento57 páginasFeasibility Study (Moringa Custard Donuts)Eunalyn JuriaAinda não há avaliações

- Hong Kong Travel Guide For Food Lovers ONv1Documento95 páginasHong Kong Travel Guide For Food Lovers ONv1iammissdAinda não há avaliações

- A Study of Supply Chain of Wal-Mart: PDPM Iiitdm-JabalpurDocumento15 páginasA Study of Supply Chain of Wal-Mart: PDPM Iiitdm-JabalpurjizozorAinda não há avaliações

- Additional Practice QuestionsDocumento4 páginasAdditional Practice QuestionsLeejat Kumar PradhanAinda não há avaliações

- Tiger Tales First Issue 2011Documento28 páginasTiger Tales First Issue 2011Graylink BizAinda não há avaliações

- 02 - Personal Quality Checklist (Edited)Documento2 páginas02 - Personal Quality Checklist (Edited)Azalea AragonAinda não há avaliações

- Environment Analysis of Zomato: Never Have A Bad MealDocumento25 páginasEnvironment Analysis of Zomato: Never Have A Bad MealSophia ChauhanAinda não há avaliações

- Quest Story PDFDocumento2 páginasQuest Story PDFTarannum Yogesh DobriyalAinda não há avaliações

- NSF International / Nonfood Compounds Registration ProgramDocumento1 páginaNSF International / Nonfood Compounds Registration ProgramMichaelAinda não há avaliações