Escolar Documentos

Profissional Documentos

Cultura Documentos

Gas Turbine Engine Test Cell

Enviado por

explorer8111Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Gas Turbine Engine Test Cell

Enviado por

explorer8111Direitos autorais:

Formatos disponíveis

IllllllllllllllllIlllilllllllllllllllllllllllllllllllllllllllllllllllllllll

USOO5293775A

United States Patent [19]

[111

Clark et al.

[45]

[54]

GAS TURBINE ENGINE TEST CELL

I

ve n m m

.r,

.mrou

n.

[73] Assignee: United Technologies Corporation,

73/117.4

[21] App1.No.: 970,214

Nov. 2, 1992

[ 5 1281] IUmFsm.mQ0 MmemMb

05I

m

,

mm1, Mv.12. {hB mamm

eT

0emMD.N

q3

"7".3m@171 3MQA7%my/. lMUM

/

References Cited

Primary Examiner-Jerry w- Myra:1c

ABSTRACT

[57

Inlet vortex ingestion is deterred when testing an engine

(12) in a test cell (10). Ramp structures (26) are installed

on the walls blocking 30% to 50% of the flow area. The

apex (42) of these ramps is located adjacent the engine

inlet (24) with the upstream faces (46) at about a 45

angle.

U.S. PATENT DOCUMENTS

2,975,632 3/1961 Ganahl

nM

Attorney, Agent, or Firm-Edward L. Kochey, Jr.

Hartford, Conn.

[56]

Mar. 15, 1994

TWRM WPM m umBWm kMmJZMHOEb;hamnw? Zena;LMn .mnuMean , CACInrAwmMJ mEnOM J. EH,% Ukm LEJ A.m ITP SQMH.m mcco1Dmm

e.01 3 smAaH ,iomm M0PO.HfWc-I

5.sf

5,293,775

4,537,066 8/1985 Simpson

.m

e1

[22] Filed:

Patent Number:

Date of Patent:

73/ I16

11 Claims, 3 Drawing Sheets

US. Patent

FIG. I

Mar. 15, 1994

Sheet 1 of 3

5,293,775

US. Patent

Mar. 15, 1994

Sheet 2 of 3

5,293,775

US. Patent

Mar. 15, 1994

Sheet 3 of 3

5,293,775

36

5,293,775

downstream of the gas turbine inlet and is not ingested

therein.

GAS TURBINE ENGINE TEST CELL

Experience has shown that bypass ratios greater than

TECHNICAL FIELD

The invention relates to test cells for testing gas tur

0.75 or 0.8 are acceptable. In order to test an engine of

a given thrust and having a particular air flow, at least

1.8 times the engine required flow must be handled by

bine engines and in particular to increasing the ability of

the test cell. For a given test cell size it follows that

such a cell to be used with larger engines.

larger engines have two problems. One, the extremely

high air velocities create considerable noise and exces

BACKGROUND OF THE INVENTION

Gas turbine engines for aircraft are normally guaran

teed for thrust performance. A newly manufactured

engine must be tested to determine compliance with the

guarantee, for example, a production test green run.

10 sive forces on the various structure required for the test

cell. Second, the approach velocities increase requiring

substantial thrust correction.

In accordance with prior art concepts the only solu

Thrust measurement is also important during develop

ment. Furthermore, later in life, thrust performance

.tion to such a problem is to build a new and larger test

testing of an engine is required to evaluate its current

which permits the testing of larger higher thrust engines

cell.

It is an object of the invention to establish a structure

status, particularly after a major engine overhaul.

in a given size engine test cell.

An indoor test cell offers several advantages in per

forming a test. Such test is less affected by variable wind 20

SUMMARY OF THE INVENTION

or unreliable weather conditions and the noise can be

In accordance with the invention acceleration of the

attenuated to avoid excessive disturbances.

bypass flow is accomplished by a partial blockage of the

Certain corrections must be applied to the various

test readings in a test cell in order to determine the

test cell flow area by inlet ramps. These ramps are sized

and located so as to not infringe on the peripheral

equivalent outdoor operation. Preferably these correc 25 streamline of the air entering the engine. While these

tions should be as low, stable and repetitive as possible

attempt to some extent to streamline the inlet, they fall

to avoid introduction of error. One of the corrections

involved is that of the inlet momentum correction.

It is known that under certain conditions inlet vorti

ces can form which are then ingested into the gas tur

bine engine. This can result in an engine surge event and

prevent useful testing from being conducted. In some

cases this can even result in compressor blade damage.

Within a bounding stream line the air is accelerated

into the entrance of the gas turbine. The secondary

airflow between this streamline and the cell walls decel

erates with static pressure increase. At a deceleration

velocity ratio on the order of 0.4 or 0.5 separation at the

cell wall occurs. The separation is non-uniform. This

far short of this so that a given size ramp structure may

be used'with different size inlets. The size, furthermore,

is smaller, they may be easily moved, and the construc

tion is less critical.

Such ramps also establish at their apex a sudden en

largement which establishes flow separation at that

location. Since the flow separation is established at the

same axial location around the periphery, the shear

forces do not exist in the peripheral direction establish

ing the formation of vortexes.

The test cell has a plurality of parallel walls de?ning

an air flow duct. The gas turbine engine may be sup

ported within the duct. An exhaust collector passage

provides sufficient shear gradient in the direction trans 40 removes air from the duct. There are a plurality of ramp

verse to the flow to promote the formation of a vortex.

structures installed on at least two and preferably four

This vortex may then be ingested into the engine.

Two methods are known to avoid the damaging ef

fects of vortex formation. One approach involves the

streamlining of the duct upstream of the engine with a

fairing approaching the shape of the outer streamline

perimeter directing all of the air flow to the engine inlet.

opposing walls of the air flow duct with these ramp

structures blocking between 30-50% of the air ?ow

This inherently accelerates the air ?ow to the full inlet

velocity before it enters the engine, thereby requiring a

substantial performance inlet momentum correction. 50

Little or no bypass air is required with this approach.

area. This blockage is a location at or adjacent the inlet

of the gas turbine engine when the gas turbine engine is

supported in the duct. The upstream face of each ramp

structure is established at an angle of approximately 45"

from the axis.

BRIEF DESCRIPTION OF THE DRAWINGS

FIG. 1 is an illustration of the prior art showing an

Such a structure is expensive to build, and forces on

the structure must be isolated from the measured force.

ingested vortex;

Speci?c adaption must be made for each engine being

with the ramps installed;

tested. Furthermore, this structure can not be easily 55

FIG. 3 is a side elevation of an engine in a test cell;

and

moved or removed for access to the engine or for

changing the engines.

A more customary solution is the provision of ade

quate bypass flow or secondary flow around the engine.

The exhaust from the gas turbine engine enters an ex

haust collector passage. This operates as an inductor to

draw air into the passage in addition to the exhaust from

the gas turbine engine. Accordingly, excess flow is

FIG. 2 is an isometric view of an engine in a test cell

FIG. 4 is an isometric of an engine in a test cell show

ing more detail of the ramps in the area of the engine

inlet.

DESCRIPTION OF THE PREFERRED

EMBODIMENT

FIG. 1 shows a prior art test cell 10 with the gas

supplied beyond that needed by the gas turbine engine.

turbine engine 12 supported therein. An exhaust collec

Because of this excess flow the velocity ratio is higher

and there is less deceleration of the secondary air and a

reduced potential for separation at the walls. Further

more, any separation that does occur is convected

tion passage 14 removes air from the duct. As the air

flow 16 passes through the duct, a portion passes into

the engine and a portion bypasses the engine. The de

crease in velocity and concomitant pressure increase of

5,293,775

the by passing air results in a wall separation stagnation

of the secondary air indicated by line 18. The shear

force in a direction transverse to the directional ?ow of

the air results in a swirl 20 about an axis perpendicular

to that of the engine center line, leading to a vortex 22

said plurality of walls comprising four walls.

3. A test cell as in claim 2 further comprising:

said plurality of ramp structures comprising 4 ramp

ingested into the inlet 24 of the gas turbine engine.

FIGS. 2 and 3 together show the air flow perfor

structures.

4. A test cell as in claim 3 further comprising:

mance with ramp structures 26 of the invention in place.

Streamline 28 de?nes the periphery of ?ow 30 passing

into the gas turbine engine 12. Support 32 adjustably

each ramp structure having an upstream facing sur

face at an angle between 40 and 50 from said axis.

2. A test cell as in claim 1 further comprising:

each ramp structure having an apex being the portion

0

supports the engine in the center of the test duct 10.

The air flow duct 10 is formed of a plurality of planar

walls including ceiling 34, floor 36 and sidewalls 38 and

40. In this case the duct is square with a height and

width each of 10 meters. Each ramp 26 has an apex 42

with a distance D of 1.06 meter located at or adjacent

the inlet bell mouth 44 of the engine. This is selected to

provide a blockage of the total ?ow area of the duct of

of said ramp structure most removed from the

walls on which it is installed; and

the apex of all ramps being in a common plane which

is perpendicular to said axis.

5. A test cell as in claim 4 further comprising;

said duct having a width W and a height H;

said apex being upstream of the inlet of an installed

engine less than 0.1 H or 0.1 W which ever is less;

said ramps being axially moveable along said walls to

various preselected locations;

between 30-50%, and preferably between 36-40%.

one of said walls being a ?oor;

The upstream facing surface or ramp 46 is at an angle

a of about 45 with the axis 48 of the duct. This pro

vides acceleration of the bypass flow 50 as it approaches

the engine inlet without the ramp infringing on stream

line 28 of the inlet ?ow.

the ramp structure on said ?oor being a floor ramp

structure; and

said ramp structure hinged adjacent one of said side

walls, whereby said floor ramp structure may be

swung toward a side wall clearing the central por

tion of the air ?ow duct for access; and

said ramp structures blocking between 36% and 40%

A non-uniform separation of the flow from the wall

surface is thereby avoided by maintaining a reasonably

high velocity upstream of apex 42. Separation occurring

of said flow area.

6. A test cell as in claim 3 further comprising

one of said walls being a floor;

the ramp structure on said floor being a floor ramp

immediately downstream of this apex is in a common

plane perpendicular to the axis and therefore does not

tend to establish inlet vortices.

It can be seen that the apex 42 is a substantial distance

away from the inlet 44 and accordingly various size

engines may be tested using the same ramp structure.

The apex 42 may be moved to a distance not more than

l/ 10 of the width of the airflow duct (or height if less)

upstream of the bell mouth inlet or a distance l/ 100 the

width downstream of the inlet. In the described duct,

this is less than 1 meter upstream and 0.1 meters down

stream.

Referring to FIG. 4, track 60 and actuators 62 can be

seen for moving the ramp axially with respect to an

installed engine. Divisions 64 in the wall ramps can be

seen with hinges 66 being located on one wall. The floor

ramps and the lower portion of the wall ramps can 45

therefore be rotated against wall 40 leaving the floor 36

clear for access for installing, removing or maintaining

an engine.

I claim:

1. A test cell for testing a gas turbine engine compris

mg:

structure; and

said ramp structure hinged adjacent one of said side

walls, whereby said floor ramp structure may be

swing toward a side wall clearing the central por

tion of the air flow duct for access.

7. A test cell as in claim 2 further comprising;

said duct having a width W and a height H;

each ramp structure having an apex being the portion

of said ramp structure most removed from the wall

on which it is installed; portion of said ramp struc

ture most removed from the wall on which it is

installed;

said apex being upstream of the inlet of an installed

engine less than 0.1 H or 0.1 W which ever is less.

8. A test cell as in claim 7 further comprising:

the apex of all ramps being in a common plane which

is perpendicular to said axis.

9. A test cell as in claim 2 further comprising:

said ramps being axially moveable along said walls to

various preselected locations.

a plurality of planar walls de?ning an air ?ow duct,

having an axis, a flow area and an upstream end;

a support for supporting a gas turbine engine having

an inlet, within said duct;

55

an exhaust collector passage for removing air from

said duct;

a plurality of ramp structures installed on at least two

opposing walls of said air flow duct;

said ramp structures blocking between 30% and 50%

of said ?ow area at a location at or adjacent the

inlet of said gas turbine engine, when the gas tur

10. A test cell as in claim 9 further comprising:

one of said walls being a floor;

the ramp structure on said floor being a floor ramp

structure; and

said ramp structure hinged adjacent one of said side

walls, whereby said floor ramp structure may be

swung toward a side wall clearing the central por

tion of the air flow duct for access.

11. A test cell as in claim 1 further comprising:

said ramp structures blocking between 36% and 40%

of said flow area.

bine engine is supported in said duct; and

65

Você também pode gostar

- Appendix C ShockwavesDocumento6 páginasAppendix C Shockwavesexplorer8111Ainda não há avaliações

- Airbus A350-900 BookletDocumento215 páginasAirbus A350-900 Bookletexplorer811193% (14)

- Sidewall Effects SupersonicDocumento11 páginasSidewall Effects Supersonicexplorer8111Ainda não há avaliações

- Milton Keynes - Luton AirportDocumento8 páginasMilton Keynes - Luton Airportexplorer8111Ainda não há avaliações

- Aerospace Engineering Univ in The UKDocumento4 páginasAerospace Engineering Univ in The UKexplorer8111Ainda não há avaliações

- Cranfield Departmental PresentationDocumento20 páginasCranfield Departmental Presentationexplorer8111Ainda não há avaliações

- Longitudinal Aircraft Stability Image - 1 PageDocumento1 páginaLongitudinal Aircraft Stability Image - 1 Pageexplorer8111Ainda não há avaliações

- Aircraft Stability and ControlDocumento21 páginasAircraft Stability and Controlexplorer8111Ainda não há avaliações

- Scheme of Trimmed Aircraft and C.G. Determination - 1 PageDocumento1 páginaScheme of Trimmed Aircraft and C.G. Determination - 1 Pageexplorer8111Ainda não há avaliações

- Flight Stability & Control - D.V. CaugheyDocumento153 páginasFlight Stability & Control - D.V. CaugheyKhairul Nizam100% (1)

- Installation Ansys 10Documento3 páginasInstallation Ansys 10explorer8111Ainda não há avaliações

- Scheme of Trimmed Aircraft and C.G. Determination - 1 PageDocumento1 páginaScheme of Trimmed Aircraft and C.G. Determination - 1 Pageexplorer8111Ainda não há avaliações

- Installation Ansys 10Documento3 páginasInstallation Ansys 10explorer8111Ainda não há avaliações

- GrammCAEProficiency TEST EntryTestDocumento8 páginasGrammCAEProficiency TEST EntryTestTiffany NelsonAinda não há avaliações

- Cambridge First Certificate in English 5Documento130 páginasCambridge First Certificate in English 5Tomáš Procházka50% (2)

- GrammCAEProficiency TEST EntryTestDocumento8 páginasGrammCAEProficiency TEST EntryTestTiffany NelsonAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Class 1Documento27 páginasClass 1KALYAMPUDI MANOHARAinda não há avaliações

- Efis Sil 2 99 EGPWSDocumento23 páginasEfis Sil 2 99 EGPWStesAinda não há avaliações

- Murray Fire 9-7-22 UPDATEDocumento1 páginaMurray Fire 9-7-22 UPDATENBC MontanaAinda não há avaliações

- The Impact of Shamal Winds On Tall Building Design in The Gulf RegionDocumento11 páginasThe Impact of Shamal Winds On Tall Building Design in The Gulf RegionihpeterAinda não há avaliações

- LG Bs-Q096wea4 - LG Electronics LKDocumento18 páginasLG Bs-Q096wea4 - LG Electronics LKAvk Sanjeevan50% (2)

- STORMASTER ESE Air Terminal: Lightning Protection International Pty LTDDocumento6 páginasSTORMASTER ESE Air Terminal: Lightning Protection International Pty LTDRuchir ChaturvediAinda não há avaliações

- Water Logging - SalinityDocumento13 páginasWater Logging - SalinityVedant Patel100% (1)

- Volcanic Facies PDFDocumento56 páginasVolcanic Facies PDFFidelis Daia100% (2)

- JHA - Welding WorksDocumento2 páginasJHA - Welding Worksjohn jaycoh veranoAinda não há avaliações

- A320 Normal Procedure Flow v1.3Documento39 páginasA320 Normal Procedure Flow v1.3allenAinda não há avaliações

- TC Material - 632Documento1 páginaTC Material - 632Mouse LALAAinda não há avaliações

- Full OLL GuideDocumento7 páginasFull OLL GuideLmao100% (8)

- Dwnload Full Structural Steel Design A Practice Oriented Approach 2nd Edition Aghayere Solutions Manual PDFDocumento36 páginasDwnload Full Structural Steel Design A Practice Oriented Approach 2nd Edition Aghayere Solutions Manual PDFpauljohnsonirkczwoeym100% (9)

- Air Pollution Dispersion Modeling PDFDocumento6 páginasAir Pollution Dispersion Modeling PDFadcaAinda não há avaliações

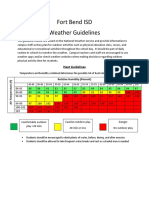

- Fort Bend ISD Weather GuidelinesDocumento4 páginasFort Bend ISD Weather GuidelinesBrien JeffersonAinda não há avaliações

- Ncert Solutions Science Class 8Documento4 páginasNcert Solutions Science Class 8Raj AnandAinda não há avaliações

- Group 2 Biogeochemical CyclesDocumento56 páginasGroup 2 Biogeochemical CyclesEverette Drake ObilleAinda não há avaliações

- Mathcad - InPEX Masela FLNG Korea-Batam (Calm)Documento5 páginasMathcad - InPEX Masela FLNG Korea-Batam (Calm)fahmyits100% (1)

- VP2024T16Documento18 páginasVP2024T16Tejas AthawaleAinda não há avaliações

- Landslide HazardsDocumento4 páginasLandslide HazardstifannyAinda não há avaliações

- Module 5 Advanced MechanicsDocumento22 páginasModule 5 Advanced MechanicsVictor GuanAinda não há avaliações

- Dinosaurs Are A Diverse Group Of: (Note 1)Documento4 páginasDinosaurs Are A Diverse Group Of: (Note 1)SpardaAinda não há avaliações

- Meteo MidtDocumento3 páginasMeteo MidtJovzAinda não há avaliações

- CWTS 12 Reflection Paper - Typhoon Odette (Cañada)Documento3 páginasCWTS 12 Reflection Paper - Typhoon Odette (Cañada)Jude CañadaAinda não há avaliações

- Hydrostatic EquationDocumento3 páginasHydrostatic EquationRay-Ray Carino AraoAinda não há avaliações

- Post Cardiac Arrest CareDocumento28 páginasPost Cardiac Arrest CareAkib ArmanAinda não há avaliações

- G-11 Bio For RevisionDocumento38 páginasG-11 Bio For RevisionSai Hla MyoAinda não há avaliações

- Research Activity-DRRMDocumento6 páginasResearch Activity-DRRMJacinthe Angelou D. PeñalosaAinda não há avaliações

- Casio Manual, Operation Guide 2894Documento0 páginaCasio Manual, Operation Guide 2894cboutsAinda não há avaliações

- Bali Pass Trek in Uttarakhand - Trekking RouteDocumento8 páginasBali Pass Trek in Uttarakhand - Trekking RouteCharita NegiAinda não há avaliações