Escolar Documentos

Profissional Documentos

Cultura Documentos

Quality Control Plan (For Study) PDF

Enviado por

Robin GuDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Quality Control Plan (For Study) PDF

Enviado por

Robin GuDireitos autorais:

Formatos disponíveis

Project: NINGBO 6RTGs

Rev No. 0

No.

Description

QUALITY CONTROL PLAN

Quality Control Activity

QA Document

Acceptance

Standard

Verifying Documents

Job No. 1201

Inspection Activity

NCSC

Client/Third

Party

Note

This Quality Control Plan (QCP) describes the most important process steps for fabrication and erection of the main steel structure and

mechanical parts of RTG cranes. Associated with the processes are the QA/QC - activities based on ISO 9001, the corresponding acceptance

criteria according to NCSC requirements, e.g. product standards or other regulations and the verifying documents necessary for documentation of

the test and inspection results.

At least the specified process steps (their sequence is just informal) are to be executed and documented by the charged sub-contractor (SC) for

fabrication. Additional and more stringent own requirements of the sub-contractor are not terminated by these NCSC regulations. If necessary, the

listed and attached NCSC- standard documents like weld sketch and test instructions are to be completed by more detailed documents of the subcontractor.

Sub contractors without certified quality system have to prove by adequate means before being charged with the contract, that their processes are

ruled by QA and only those structures are delivered which comply with the specified requirements with no limitation.

The European and American standards, mentioned for qualification and execution of welding and inspection work are considered to be equal.

To this Quality Assurance Plan (QAP) additional Quality Inspection Plans (QIP) with specific regulations for the particular structure will be added if

needed.

(QCP) RTG ISO 9001

NCSC .

() NCSC

NCSC

,

(QCP)

Page 1 of 10

Project: NINGBO 6RTGs

Rev No. 0

No.

Description

QUALITY CONTROL PLAN

Quality Control Activity

QA Document

Acceptance

Standard

Job No. 1201

Verifying Documents

Inspection Activity

NCSC

Client/Third

Party

/

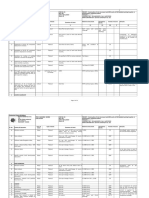

1.0 PRE-FABRICATION

Review specification, finalize

deviations, amendments

Confirm compliance with

specification

Confirm compliance with

specification and validity,

qualify tackers and welders

if necessary

1.1

Fabrication specification and

drawing

1.2

Welding Procedure Qualification

1.3

Welding personnel qualification

1.4

QC personnel Qualification

Confirm compliance with

specification and validity

1.5

Calibration (if necessary)

Confirm the calibration

status and validity of main

equipment

QP-PD-02

WI-PD-02

AWS D1.1

WPS and PQR

WI-PD-02

AWS D1.1

Certificates

WI-QA-13

QC personnel List

and NDT certificate

NDT

QP-QA-06

Calibration record

2.0 RECEIVING INSPECTION

2.1

Approved supplier/Subcontractor

Confirm the material supplier

/sub-contractor approved,

otherwise QA Audit

/

QP-PU-01

QP-PU-02

Page 2 of 10

Approved Supplier

List or QA Audit

Note

Project: NINGBO 6RTGs

Rev No. 0

No.

Description

2.2

Material receiving inspection

2.3

Non-conforming material

2.4

Identification of material in

stockyard

2.5

Material Issuing

2.6

Material tracing

2.7

Testing & Inspection

QUALITY CONTROL PLAN

Quality Control Activity

Confirm material received

meets the requirements of

the specification, purchase

order, project specification

and delivery note. Check mill

certificate with material

received. Visual inspection

or NDT

Non-conforming Material to

be limited or forbidden

Confirm Job number, type

and batch No. identified on

Material and Mill Cer.

Confirm material issuing in

accordance with the shop

application and drawing.

Confirm material used in

main structure can be traced

Authenticate materials and

components quality

QA Document

Acceptance

Standard

Verifying Documents

Job No. 1201

Inspection Activity

NCSC

Client/Third

Party

/

QP-QA-05

Specification

Mill certificates

RI

QP-QA-12

QP-QA-13

NCR

QP-LD-05

WI-LD-05

SAP system

RI

RI

QP-PD-03

Material issuing

record

RI

QP-PD-04

Material tracing list

RI

RI

SP23

Page 3 of 10

Test report

Note

Project: NINGBO 6RTGs

Rev No. 0

No.

Description

QUALITY CONTROL PLAN

Quality Control Activity

2.8

Matl. NoN-Destructive test

UT of tubes and plates

2.9

Gearbox,Drum,coupling,Brake,S

heave,Rope, spreader, wheel,

wheel rim, twistlock etc.

,,,,,,

,,,,

Visual inspection, confirm

type, size, test

report/inspection report

,,,

/

2.10

Electrical components( Gensets,

Motors, Registors, transformer

cabin,E-house etc)

( ,,

, ,,).

Visual inspection, confirm

type, test report

,

2.11

Hydraulic Equipment(Hydraulic

power units, cylinders etc)

(, )

Visual inspection,

cleanliness report, pressure

report

,

2.12

Non conformity reports

QA Document

Acceptance

Standard

Verifying Documents

Job No. 1201

Inspection Activity

NCSC

Client/Third

Party

/

QP-QA-05

Specificati

on,

NDT Report

NDT

RI

QP-QA-05

Specificati

on and

purchasing

Drawing

Cretificate of

conformity

RI

QP-QA-05

Specificati

on and

Application

certificate of

conformity

QP-QA-05

Specificati

on and

Application

certificate of

conformity

RI

Source of imperfection

rectified

QP-QA-05

Standard

requireme

nts

Non conformity

report

Measure profiledry film

thickness and visual grade

WI-PD-05

Specificatio

n

RI

RI

3.0 FABRICATION

3.1

Material pre-treatment

Page 4 of 10

Paint Inspection

Record

Note

Project: NINGBO 6RTGs

Rev No. 0

No.

3.2

3.3

3.4

3.5

3.6

Description

NC cutting and material

preparation inspection

UT-lamination test acc.

to indications in fabrication

drawings

Fitting inspection

Welding Control

Welding inspection

QUALITY CONTROL PLAN

Quality Control Activity

Inspect the dimension,

grade of material prepared

and NDT according to part

list and drawing.

,

Joints area with tensile load

in thickness direction

Visual and dimension

inspection of fit-up and tack

welds according to drawing

and relevant requirement

Control consumable storage

and delivery, check welding

process according to WPS,

check welders qualification

Visual inspection according

to drawing and standard

QA Document

Acceptance

Standard

Job No. 1201

Verifying Documents

Part list and NC

cutting Record

Inspection Activity

NCSC

Client/Third

Party

RI

RI

QP-PD-03

ISO9013

QP-PD-03

Contract

or GB

standards

/AWSD1.1

/AWS

D1.1

QP-QA-11

WI-PD-07

QP-PD-04

Drawing

and WPS

RI/I

QP-QA-11

WI-LD-01

WI-PD-03

WPS

Consumable

Certificate and

Consumable Baking

and Issue Record

RI

RI

WI-QA-02

QP-PD-04

Drawing

and AWS

D1.1:2000

ISO5817

Visual Inspection

Report

RI/I

Page 5 of 10

NDT record

NDT

Note

Project: NINGBO 6RTGs

Rev No. 0

No.

3.7

3.8

Description

QUALITY CONTROL PLAN

Quality Control Activity

QA Document

Acceptance

Standard

Job No. 1201

Verifying Documents

Inspection Activity

NCSC

Client/Third

Party

/

Structure dimension Inspection

Check the dimension and

distortion of welding

structure according to

drawing, standard and

relevant requirement

WI-QA-06

QP-PD-04

Drawing

ISO 13920

Dimension

Inspection Report

RI/I

NDT

Applied UT/RT/MT/PT to

weld seam /

//

WI-QA01/03/04/05

AWS

D1.1:2000

& As Per

Drawing

NDT Report

WI-QA-08

Leak Test Report

RI

RI

WI-QA-14

RI

WI-QA-06

Drawing

ISO2768

Dimension

Inspection Report

(machining)

RI

QP-QA-03

WI-QA-07

Release Report

3.9

Leak Test

3.10

Cleanness of fuel tank

3.11

Machining Inspection

3.12

Release

Applied leak test to the

sealed structure

Check the cleanness of fuel

tank and sealing before

release

Check alignment before

machining and check final

dimension after machining

Review all inspection reports

and quality documents,

release structure to painting

shop

4.0 Painting

Page 6 of 10

Note

Project: NINGBO 6RTGs

Rev No. 0

No.

4.1

Description

All the welds, damaged areas,

burns and rust etc. should be reblasted to Sa2.5, and other

undamaged areas will be

cleaned and sweep blasted

,,

SA2.5 ,

4.2

Painting Inspection

4.3

Cleanness of fuel tank and

corrosion protection

QUALITY CONTROL PLAN

Quality Control Activity

QA Document

Acceptance

Standard

Inspect sweep blast cleaning

quality and blast profile.

/.

Verifying Documents

Inspection Activity

NCSC

Client/Third

Party

/

ISO 85011:1988

Blasting Inspection

Report

RI/I

WI-PD-05

SP01

Specification

Painting Inspection

Report

RI/I

WI-QA-14

Inspection Report

RI

QP-QA-11

WI-PD-07

Drawing

WPS

FEM

RI/I

QP-QA-11

WI-QA-02

WI-QA-04

Drawing

and AWS

D1.1:2000

ISO5817

Visual Inspection

Report and NDT

Report

RI

WI-QA-05

SP01

Check Primer, intermediate

and top coat according to

painting procedure, contract

and relevant standard

Check the cleanness of fuel

tank and corrosion

protection before release

Job No. 1201

5.0 Erection

5.1

5.2

Fitting Inspection

Welding Inspection

Visual and dimension

inspection of fit-up and tack

welds according to drawing

and relevant requirement

Control welding procedure

and applied inspection of

visual and NDT to the weld

seam

Page 7 of 10

Note

Project: NINGBO 6RTGs

Rev No. 0

No.

Description

5.3

Assembly Dimension Inspection

5.4

Painting Inspection

5.5

Mechanism Installation

Inspection

5.6

Gantry Travel System

5.7

High Strength Bolt Installation

QUALITY CONTROL PLAN

Quality Control Activity

Inspect structure dimension

according to relevant

requirement, assure each

erection step under control

Check touch up and top coat

according to painting

procedure, contract and

relevant standard

Check equipment type,

quality certificate, installation

procedure, relevant

dimension and data

according to drawing and

requirement

After gantry wheel installed,

check the span and the

straightness of wheel

Check the type, dimension

of bolt, torque and screw

sequence ,

,

QA Document

Acceptance

Standard

Verifying Documents

Job No. 1201

Inspection Activity

NCSC

Client/Third

Party

/

WI-QA-06

Drawing

ISO 13920

FEM

Dimension

Inspection Report

RI/I

WI-PD-05

Contract

SIS

Painting Inspection

Report

RI/I

QP-PD-07

FEM

Inspection Report

R/I

Drawing

Inspection Report

Inspection Report

RI/I

QP-QA-11

QP-QA-11

Page 8 of 10

Note

Project: NINGBO 6RTGs

Rev No. 0

No.

Description

5.8

Cleanness of Fuel Tank

5.9

Cleanness of Hydraulic System

5.10

Electrical System Inspection

5.11

Commissioning Test

5.12

Punch list

QUALITY CONTROL PLAN

Quality Control Activity

Before fuel filling, check

cleanness to keep tank from

dirty, rust and all things may

cause jam

Flush the system and check

on line

Check equipment type,

quality certificate, cabling,

installation procedure, and

insulation resistance etc.

relevant data according to

drawing and requirement

Test crane according to

commissioning report

QA Document

Acceptance

Standard

Job No. 1201

Verifying Documents

Inspection Activity

NCSC

Client/Third

Party

/

WI-QA-14

Inspection Report

QP-QA-11

WI-QA-19

WI-PD-08

IEC

Inspection Report

RI

RI

Commissi

oning

report

Commissioning/Acc

eptance report

standard

and

contract

Check opened item

QM-2000

Point out all defects of crane

list in the punch list table

and confirmed before

shipping

QM-2000

Page 9 of 10

Note

Project: NINGBO 6RTGs

Rev No. 0

No.

Description

6.DOCUMENTATION

Final Dossier

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Note

H - hold point

QUALITY CONTROL PLAN

Quality Control Activity

QA Document

Acceptance

Standard

Job No. 1201

Verifying Documents

Inspection Activity

NCSC

Client/Third

Party

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

Compilation of dossier to include

:

Quality Plan

QC and NDT personnel

qualificatons

Welders Certificates List

Mill Certificates

Paint Certificates

Welding consumables Certificates

Technical Query Reports

Visual Inspection records

NDT reports

Pressure Test Report

Dimensional Inspection Reports

Blasting and Paint Inspection

Reports

Gantry inspection reports

Final acceptance testing record

Punch list

R - review

RI - RandomInsepction

W - witness

Page 10 of 10

- inform

Note

Você também pode gostar

- ITP For Domestic Water Piping InstallationDocumento1 páginaITP For Domestic Water Piping InstallationBelal AlrwadiehAinda não há avaliações

- QUALITY CONTROL PLAN-Rev-CDocumento10 páginasQUALITY CONTROL PLAN-Rev-Csivagnanam s100% (1)

- 5 Formwork ChecklistDocumento81 páginas5 Formwork ChecklistAlphaAinda não há avaliações

- Welding Quality Control Plan (WQCP) Requirements in Accordance With "Welding Quality Control"Documento2 páginasWelding Quality Control Plan (WQCP) Requirements in Accordance With "Welding Quality Control"Go MocAinda não há avaliações

- SITE-SPECIFIC QC PLANDocumento3 páginasSITE-SPECIFIC QC PLANloveanbu24100% (1)

- LPS-01-HTI-ITP-EL-005 - Point WiringDocumento5 páginasLPS-01-HTI-ITP-EL-005 - Point WiringJomy JohnyAinda não há avaliações

- Project Quality Template (Att. IV)Documento16 páginasProject Quality Template (Att. IV)aslam.ambAinda não há avaliações

- Mumbai Trans Harbour Link Project Non-Conforming Item ProcedureDocumento15 páginasMumbai Trans Harbour Link Project Non-Conforming Item ProcedureDeepak UpadhayayAinda não há avaliações

- Quality assurance plan for steel structure constructionDocumento1 páginaQuality assurance plan for steel structure constructionRamesh F SinghAinda não há avaliações

- Inspection Test Plan For FabricationDocumento4 páginasInspection Test Plan For FabricationAshwani Dogra100% (9)

- Quality Plan 2 PDF FreeDocumento21 páginasQuality Plan 2 PDF FreeEng.arifAinda não há avaliações

- ITP For Caprentry & Joinery WorksDocumento2 páginasITP For Caprentry & Joinery Worksexia19920% (2)

- Quality InductionDocumento15 páginasQuality InductionaleemmurtazaAinda não há avaliações

- ItpDocumento7 páginasItpJose Sherin100% (1)

- QA/QC Procedure Ensures High Quality ConstructionDocumento18 páginasQA/QC Procedure Ensures High Quality Constructionerwin hidayat100% (1)

- Quality Control PlanDocumento13 páginasQuality Control PlanMohammad Taqi HamidiAinda não há avaliações

- Inspection & Test Plan for Civil and Structural SteelDocumento33 páginasInspection & Test Plan for Civil and Structural SteelAhmed Mohsin100% (1)

- 5 Contractor Quality Control Plan For Steel StructureDocumento3 páginas5 Contractor Quality Control Plan For Steel Structurebehzad esAinda não há avaliações

- 03 Rebar InspectionDocumento1 página03 Rebar InspectionDawit SolomonAinda não há avaliações

- Itp Bored Pile Rev 1Documento10 páginasItp Bored Pile Rev 1Pandar HasibuhanAinda não há avaliações

- Quality PlanDocumento21 páginasQuality PlanQianlei ZhuAinda não há avaliações

- FQP GeneralDocumento21 páginasFQP GeneralgaladrialAinda não há avaliações

- Marriot Grand Ballroom Project Inspection and Test PlanDocumento3 páginasMarriot Grand Ballroom Project Inspection and Test PlanImho Tep75% (4)

- QA QC Daily ReportDocumento2 páginasQA QC Daily Reportanon_688841981Ainda não há avaliações

- MARAFIQ Project Quality Plan OverviewDocumento6 páginasMARAFIQ Project Quality Plan OverviewNABEEL ABDUL GAFFARAinda não há avaliações

- Itp For Installation of FormworksDocumento1 páginaItp For Installation of FormworksImho TepAinda não há avaliações

- Non - Conformance ReportDocumento2 páginasNon - Conformance ReportXOXOXOXO XOXOXOXOAinda não há avaliações

- Project Quality PlanDocumento44 páginasProject Quality Planmd_rehan_2100% (1)

- ITP Fencing Rev - 00 PDFDocumento3 páginasITP Fencing Rev - 00 PDFanon_987276020Ainda não há avaliações

- Fabrication ProcedurDocumento7 páginasFabrication ProcedurHarry PangestuAinda não há avaliações

- Quality Plan for GPL Construction ProjectDocumento23 páginasQuality Plan for GPL Construction Projectmayank dixitAinda não há avaliações

- Work Inspection Request: DESCRIPTION OF WORK INSPECTION (Input by The Contractor)Documento3 páginasWork Inspection Request: DESCRIPTION OF WORK INSPECTION (Input by The Contractor)Pawan jatAinda não há avaliações

- Appendix H: Design and Construction Manual Design RequirementsDocumento17 páginasAppendix H: Design and Construction Manual Design RequirementsPageduesca RouelAinda não há avaliações

- ELECT-TIC-2.8 (Torque Testing and Final Inspection)Documento4 páginasELECT-TIC-2.8 (Torque Testing and Final Inspection)Muhammad IrfanAinda não há avaliações

- LPS-01-HTI-MST-EL-009 - Light FixturesDocumento18 páginasLPS-01-HTI-MST-EL-009 - Light FixturesJomy JohnyAinda não há avaliações

- ITP For Steel Structure1Documento3 páginasITP For Steel Structure1吴兴泊Ainda não há avaliações

- Project Quality Plan: Mps Integrated Service LimitedDocumento18 páginasProject Quality Plan: Mps Integrated Service LimitedOGBONNAYA MARTINSAinda não há avaliações

- WI Dimensional Control Sign1Documento6 páginasWI Dimensional Control Sign1gusyahri001Ainda não há avaliações

- PQP EpldtDocumento8 páginasPQP Epldtmartin leeAinda não há avaliações

- 5A QA PL 01rev00 Project Quality ManualDocumento21 páginas5A QA PL 01rev00 Project Quality Manualirzaldy100% (2)

- Contractor Quality Control Plan For Fix or Stationery Equipment Installation Inspection and Test Plan For Fix or Stationery Equipment InstallationDocumento5 páginasContractor Quality Control Plan For Fix or Stationery Equipment Installation Inspection and Test Plan For Fix or Stationery Equipment InstallationSergey KichenkoAinda não há avaliações

- Inspection Request FormDocumento1 páginaInspection Request FormHoneylyn IgnacioAinda não há avaliações

- Typical Project Quality Plan & ITP CPCDocumento15 páginasTypical Project Quality Plan & ITP CPCnice guy100% (1)

- Request For Inspection of MaterialDocumento3 páginasRequest For Inspection of MaterialSopi Labu100% (1)

- QC Sample Manual GenericDocumento34 páginasQC Sample Manual GenericIan Stewart PorterAinda não há avaliações

- Project Quality Plan - For SatropDocumento22 páginasProject Quality Plan - For Satropvinothkumar100% (3)

- QES PEVC-ENG237 - Checklist For PSS Fencing DetailsDocumento2 páginasQES PEVC-ENG237 - Checklist For PSS Fencing DetailsRupesh Khandekar100% (1)

- Building InspectionsDocumento2 páginasBuilding InspectionsSuresh DevarajanAinda não há avaliações

- ITP Check List For Metal Deck InstallationDocumento2 páginasITP Check List For Metal Deck InstallationJoyce GordonioAinda não há avaliações

- Structural Steel Work Check ListDocumento1 páginaStructural Steel Work Check ListAhmad Bilal100% (1)

- Proposed Quality Control PlanDocumento3 páginasProposed Quality Control PlanMohamad Rafik50% (2)

- Request For Inspection: Fixing of Tower Crane Tie-Ins at ColumnsDocumento3 páginasRequest For Inspection: Fixing of Tower Crane Tie-Ins at ColumnsUr FriendAinda não há avaliações

- Inspection and Test Plan for Fuel Oil Piping SystemDocumento2 páginasInspection and Test Plan for Fuel Oil Piping Systemachusanachu100% (1)

- Road Construction Essentials QA/QC PlanDocumento10 páginasRoad Construction Essentials QA/QC Planrafiullah amireeAinda não há avaliações

- QA Non Conformance Report Word TemplateDocumento2 páginasQA Non Conformance Report Word TemplateTomi Kazuo100% (1)

- ITP ErectionDocumento3 páginasITP Erectionjanpaul2481Ainda não há avaliações

- Structural Steel Checklist 17Documento2 páginasStructural Steel Checklist 17mgb2010hotmailcomAinda não há avaliações

- Wps Mig PDF FreeDocumento3 páginasWps Mig PDF Freehanz bermejoAinda não há avaliações

- Itp - Inspection and Testing Plan (Creation and Management)Documento10 páginasItp - Inspection and Testing Plan (Creation and Management)Luffy11100% (1)

- ISO 3834-6 Documents RequiredDocumento3 páginasISO 3834-6 Documents RequiredEdilson SantosAinda não há avaliações

- Ferrite Content Effect On Autenitic Ss Weld at Cryogenic TempDocumento12 páginasFerrite Content Effect On Autenitic Ss Weld at Cryogenic TemparunkumarAinda não há avaliações

- Astm A 967 - 01 - Chemical Passivation Stainless Steel PDFDocumento7 páginasAstm A 967 - 01 - Chemical Passivation Stainless Steel PDFElwe SingoloAinda não há avaliações

- AWS D10 4 86R Recommended Practices PDFDocumento44 páginasAWS D10 4 86R Recommended Practices PDFwi100% (1)

- Pickling HandbookDocumento32 páginasPickling HandbookPradeepAinda não há avaliações

- Shipbuilding Quality Standard GuideDocumento59 páginasShipbuilding Quality Standard Guidenyaungzin100% (2)

- EngineeringWithCladSteel2ndEd PDFDocumento24 páginasEngineeringWithCladSteel2ndEd PDFUNIISCRIBDAinda não há avaliações

- Is Welding Stainless Steel For LNG Application EasyDocumento7 páginasIs Welding Stainless Steel For LNG Application EasyRobin GuAinda não há avaliações

- LR - Construction Monitoring Procedure PDFDocumento30 páginasLR - Construction Monitoring Procedure PDFYong KimAinda não há avaliações

- Astm A 967 - 01 - Chemical Passivation Stainless Steel PDFDocumento7 páginasAstm A 967 - 01 - Chemical Passivation Stainless Steel PDFElwe SingoloAinda não há avaliações

- 10-Materials and Components For GTT Mark III & Mark V Cargo Containment SystemDocumento22 páginas10-Materials and Components For GTT Mark III & Mark V Cargo Containment SystemRobin GuAinda não há avaliações

- Clad Steel PlateDocumento4 páginasClad Steel PlateRobin GuAinda não há avaliações

- 7-DNV Training Course 1-LNG Vessel Hull Structure AnalysisDocumento123 páginas7-DNV Training Course 1-LNG Vessel Hull Structure AnalysisRobin GuAinda não há avaliações

- 8-DNV Training Course 2-LNG Vessel Hull Structure AnalysisDocumento127 páginas8-DNV Training Course 2-LNG Vessel Hull Structure AnalysisRobin GuAinda não há avaliações

- GTT TAMI Testing For LNG CarriersDocumento17 páginasGTT TAMI Testing For LNG CarriersRobin GuAinda não há avaliações

- SGS-LeakTesting of LNG Carrier TanksDocumento1 páginaSGS-LeakTesting of LNG Carrier TanksRobin GuAinda não há avaliações

- MGIT 10065 LNG A 05.2+R1+Secondary+Barrier+Global+Tightness+Test+ (GTT) 171213Documento8 páginasMGIT 10065 LNG A 05.2+R1+Secondary+Barrier+Global+Tightness+Test+ (GTT) 171213Robin GuAinda não há avaliações

- GTT InsideDocumento2 páginasGTT InsideRobin GuAinda não há avaliações

- Sample - Inspection & Test Plan (ITP)Documento3 páginasSample - Inspection & Test Plan (ITP)Morjhan MJ100% (7)

- 10-Materials and Components For GTT Mark III & Mark V Cargo Containment SystemDocumento22 páginas10-Materials and Components For GTT Mark III & Mark V Cargo Containment SystemRobin GuAinda não há avaliações

- ISO TR 15608 2013, Welding, GuidelinesDocumento12 páginasISO TR 15608 2013, Welding, Guidelinesuday narayan singhAinda não há avaliações

- Astm A 967 - 01 - Chemical Passivation Stainless Steel PDFDocumento7 páginasAstm A 967 - 01 - Chemical Passivation Stainless Steel PDFElwe SingoloAinda não há avaliações

- 9-General Approval and Supply of Materials and ComponentDocumento7 páginas9-General Approval and Supply of Materials and ComponentRobin GuAinda não há avaliações

- Weld Filler Metal SelectionDocumento7 páginasWeld Filler Metal SelectionsusanwebAinda não há avaliações

- Minimum Requirements For The Education, Examination and QualificationDocumento34 páginasMinimum Requirements For The Education, Examination and QualificationАнтон ХруцкийAinda não há avaliações

- Requirements and properties of structural steel hollow sectionsDocumento1 páginaRequirements and properties of structural steel hollow sectionsRobin GuAinda não há avaliações

- Dissimilar Metal Weldability Concepts Alber SadekDocumento45 páginasDissimilar Metal Weldability Concepts Alber SadekMohammad AliAinda não há avaliações

- Welding Metallurgy Module 3 GuideDocumento151 páginasWelding Metallurgy Module 3 GuideRey Luis Teh100% (1)

- AWS-Guide To Weldability Carbon and Low Alloy SteelsDocumento64 páginasAWS-Guide To Weldability Carbon and Low Alloy SteelsRobin GuAinda não há avaliações

- 5-讲interface-Abs-Topside Structure Fatigue Assessment ForDocumento21 páginas5-讲interface-Abs-Topside Structure Fatigue Assessment ForRobin GuAinda não há avaliações

- 3-BV NR467-Rules For The Classification of Steel ShipsDocumento2.657 páginas3-BV NR467-Rules For The Classification of Steel ShipsRobin GuAinda não há avaliações

- 4.10) Arch Shaped Self Supporting Trussless Roof SpecificationsDocumento11 páginas4.10) Arch Shaped Self Supporting Trussless Roof Specificationshebh123100% (1)

- SysDocumento43 páginasSysqwerdsaw1100% (1)

- Kuwait Ministry of Communications Telecom Infrastructure SpecificationDocumento66 páginasKuwait Ministry of Communications Telecom Infrastructure SpecificationPrashanth Gopinath44% (9)

- TE40 Mazraa QualityDocumento8 páginasTE40 Mazraa QualityTareq AkhdarAinda não há avaliações

- Arcol Polyol 1105 S - en - 06766706 18666794 21029598Documento3 páginasArcol Polyol 1105 S - en - 06766706 18666794 21029598parthAinda não há avaliações

- Itb - CCW Crane Upgrade RevDocumento41 páginasItb - CCW Crane Upgrade RevElavarasan JayachandranAinda não há avaliações

- MOST Specifications For Road & BridgesDocumento654 páginasMOST Specifications For Road & Bridgespbalakrishnan90% (59)

- PCI Guide Specification-Glass Fiber Reinforced Concrete-10!11!11Documento18 páginasPCI Guide Specification-Glass Fiber Reinforced Concrete-10!11!11wil98100% (1)

- Final FIM Contract Template - 10102022 Outotec Comments - Points AcceptableDocumento94 páginasFinal FIM Contract Template - 10102022 Outotec Comments - Points AcceptableSuraj ShettyAinda não há avaliações

- 650,000 BPSD Refinery and 830,000 TPA Polypropylene Plant at Lekki Free Trade Zone, NigeriaDocumento1.236 páginas650,000 BPSD Refinery and 830,000 TPA Polypropylene Plant at Lekki Free Trade Zone, NigeriaAthar DanishAinda não há avaliações

- Astm A304 (2016)Documento48 páginasAstm A304 (2016)SK AAinda não há avaliações

- STR Part B FinalDocumento8 páginasSTR Part B FinalLakhwant Singh KhalsaAinda não há avaliações

- Mil STD 1540cDocumento135 páginasMil STD 1540cjeddins_1Ainda não há avaliações

- NMR602.10 SAT Plan & ProcedureDocumento43 páginasNMR602.10 SAT Plan & ProcedureSorin Oprea0% (1)

- Power Information Technology Company (Pitc) : TENDER DOCUMENT No: PITC/G-224 (60) /05-2021Documento50 páginasPower Information Technology Company (Pitc) : TENDER DOCUMENT No: PITC/G-224 (60) /05-2021Engineer WaseemAinda não há avaliações

- Introduction to Requirement EngineeringDocumento29 páginasIntroduction to Requirement EngineeringNimra SaleemAinda não há avaliações

- Astm A872Documento4 páginasAstm A872Srinivasan KrishnamoorthyAinda não há avaliações

- FFFS Tender Doc1Documento410 páginasFFFS Tender Doc1brumanciaAinda não há avaliações

- Detailed Design of View Tower at Padam PokhariDocumento41 páginasDetailed Design of View Tower at Padam Pokharisuman subediAinda não há avaliações

- Software Test Plan TemplateDocumento13 páginasSoftware Test Plan TemplateAustria AbielAinda não há avaliações

- Build an IEEE SRS Document for Student Management SystemDocumento10 páginasBuild an IEEE SRS Document for Student Management SystemBugbearAinda não há avaliações

- X9 BAI Codes Version 2 Cash Management Balance Reporting.Documento92 páginasX9 BAI Codes Version 2 Cash Management Balance Reporting.Ranjith Kumar CAAinda não há avaliações

- NITK Tender for Metal 3D PrinterDocumento31 páginasNITK Tender for Metal 3D PrinterAdithya HegdeAinda não há avaliações

- Volume-Vi: O/O Chief Engineer (Procurement) MPPTCL, JabalpurDocumento76 páginasVolume-Vi: O/O Chief Engineer (Procurement) MPPTCL, JabalpurRamphani NunnaAinda não há avaliações

- Office Use FormDocumento41 páginasOffice Use Formbra9tee9tiniAinda não há avaliações

- Presentation Slides - Mark VIEDocumento33 páginasPresentation Slides - Mark VIEolegprikhodko2809Ainda não há avaliações

- Test Specifications and Item Writer Guidelines in A Multilingual World: Issues and SolutionsDocumento27 páginasTest Specifications and Item Writer Guidelines in A Multilingual World: Issues and SolutionsLina MukhopadhyayAinda não há avaliações

- DNIT01Documento146 páginasDNIT01Anonymous wfgcPmJYAinda não há avaliações

- Astm C140Documento27 páginasAstm C140Ashraf Tomizeh100% (1)

- Specification For Carbon Steel Electrodes and Fluxes For Submerged Arc WeldingDocumento48 páginasSpecification For Carbon Steel Electrodes and Fluxes For Submerged Arc WeldingSantiago Cuichán VelascoAinda não há avaliações