Escolar Documentos

Profissional Documentos

Cultura Documentos

Delphiinjectortestplans 12WEB

Enviado por

kampeeDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Delphiinjectortestplans 12WEB

Enviado por

kampeeDireitos autorais:

Formatos disponíveis

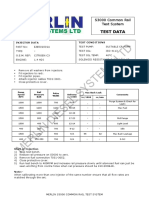

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA

TEST CONDITIONS

PART No:

EJBR01001A

TEST PUMP:

SUITABLE CR PUMP

TYPE:

TEST OIL:

ISO 4113

O.E.M. REF:

CITROEN C3

TEST OIL TEMP:

40C

ENGINE:

1.4 HDI

SOLENOID RESISTANCE @ 20C

0.4

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipes.

Attach injector cables T031-3401.

Close protective cover.

Pump

Speed

RPM

Rail

Pressure

BAR

Pulse

Width

1000

1000

700

N/A

1500

1600

1600

1500

1200

1500

Delivery

cc/1000

Max Back Leak

cc/1000

Comments

cc/min

Purge System & Check for

Leaks

58-65

Max Fuel

1200

42-48

800

600

17-23

Mid Range

1500

400

600

12-14

Light Load

400

250

700

8-12

Idle

1500

1350

900

N/A

400

150-250

700

N/A

55

82

-

Max Back Leakage

S.O.I

Start of Injection

1) Stop test bench.

2) Reduce rail pressure on S3000 to zero.

3) Remove fuel connection T031-3052.

4) Close protective cover.

5) Run test bench to 400RPM and increase rail pressure slowly until atomised fuel can just be

seen emitting from nozzle holes when rail pressure should be 150-200BAR.

Note:When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

LT

D

TEST DATA

Injector Designation:- EJBR01401z

Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

Manufacturer I.D.:- RENAULT

EM

Test Oil Temperature- 40 C

Engine:- K9K

SY

ST

Solenoid Resistance @ 20C - 0.4

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

Rail Pressure

BAR

Pulse Width

1000

1000

1200

2000

1500

1500

1600

1500

1200

1500

Comments

Purge System

N/A

Check for Leaks

1600

65-70

Max Fuel

1200

43-48

800

600

17.0-20.0

Mid Range

400

600

12.0-13.0

Light Load

250

700

10.0-11.0

Idle

900

50

Max Back leakage

400

Delivery

cc/1000

1200

IE

S

1500

1500

EL

Pump Speed

RPM

1350

ER

LI

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 140-170BAR.

Note:When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

LT

D

TEST DATA

Injector Designation:- EJBR01701Z

Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

Manufacturer I.D.:- RENAULT

EM

Test Oil Temperature- 40 C

Engine:- K9K

SY

ST

Solenoid Resistance @ 20C - 0.4

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

Rail Pressure

BAR

Pulse Width

1000

1000

1200

2000

1500

1500

1600

1500

1200

1500

Comments

Purge System

N/A

Check for Leaks

1600

65-70

Max Fuel

1200

43-48

800

600

17.0-20.0

Mid Range

400

600

12.0-13.0

Light Load

250

700

10.0-11.0

Idle

900

50

Max Back leakage

400

Delivery

cc/1000

1200

IE

S

1500

1500

EL

Pump Speed

RPM

1350

ER

LI

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 140-170BAR.

Note:When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

LT

D

TEST DATA

Injector Designation:- EJBR02101Z

Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

Manufacturer I.D.:- RENAULT

EM

Test Oil Temperature- 40 C

Engine:- K9K

SY

ST

Solenoid Resistance @ 20C - 0.4

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

Rail Pressure

BAR

Pulse Width

1000

1000

1200

2000

1500

1500

1600

1500

1200

1500

Comments

Purge System

N/A

Check for Leaks

1600

65-70

Max Fuel

1200

43-48

800

600

17.0-20.0

Mid Range

400

600

12.0-13.0

Light Load

250

700

10.0-11.0

Idle

900

50

Max Back leakage

400

Delivery

cc/1000

1200

IE

S

1500

1500

EL

Pump Speed

RPM

1350

ER

LI

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 140-170BAR.

Note:When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

LT

D

TEST DATA

Injector Designation:- EJBR02201Z

Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

Manufacturer I.D.:- FORD

EM

Test Oil Temperature- 40 C

Engine:- DURATORQ 1.8 TDCI

SY

ST

Solenoid Resistance @ 20C - 0.4

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

Rail Pressure

BAR

Pulse Width

1000

1000

1200

2000

1500

1500

1600

1500

1200

1500

1500

Purge System

N/A

Check for Leaks

1600

87-90

Max Fuel

1200

55-60

800

600

32-37

Mid Range

400

600

16.0-18.0

Light Load

250

700

12.0-13.5

Idle

900

55

Max Back leakage

400

Comments

1200

IE

S

1500

Delivery

cc/1000

EL

Pump Speed

RPM

1350

ER

LI

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 140-170BAR.

Note:When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

LT

D

TEST DATA

Injector Designation:- EJBR02601Z

Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

Manufacturer I.D.:- SSANGYONG

EM

Test Oil Temperature- 40 C

Engine:- D27DT

SY

ST

Solenoid Resistance @ 20C - 0.4

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width

1000

1000

1200

2000

1500

1500

1600

1500

800

EL

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

1500

Comments

Purge System

1200

N/A

1600

97-102

Max Fuel

600

35-40

Mid Range

250

700

12.0-14.0

Idle

1350

900

55

Max Back leakage

IE

S

400

Delivery

cc/1000

Check for Leaks

LI

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 140-180BAR.

ER

Note:When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

Injector Designation:- EJBR02801D

(WAS EJBR02301Z)

Type Designation:-

LT

D

TEST DATA

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Manufacturer I.D.:- KIA/HYUNDAI

EM

Test Oil Temperature- 40 C

Engine:- 2.9

SY

ST

Solenoid Resistance @ 20C - 0.4

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

Rail Pressure

BAR

Pulse Width

1000

1000

1200

2000

1500

1500

1600

1500

1200

1500

Comments

Purge System

N/A

Check for Leaks

1600

112-117

Max Fuel

1200

75-80

800

600

35-40

Mid Range

400

600

17-20

Light Load

250

700

11.0-14.0

Idle

900

55

Max Back leakage

400

Delivery

cc/1000

1200

IE

S

1500

1500

EL

Pump Speed

RPM

1350

ER

LI

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 140-180BAR.

Note:When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA

TEST CONDITIONS

PART No:

EJBR02901D / R02901D

TEST PUMP:

SUITABLE CR PUMP

TYPE:

TEST OIL:

ISO 4113

O.E.M. REF:

HYUNDAI/KIA

TEST OIL TEMP:

40C

ENGINE:

2.9 CDRI

SOLENOID RESISTANCE @ 20C

0.4

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipes.

Attach injector cables T031-3401.

Close protective cover.

Pump

Speed

RPM

Rail

Pressure

BAR

Pulse

Width

1000

1000

700

N/A

1500

1600

1600

60-65

1500

1200

1200

1500

800

600

47-52

Mid Range

1500

400

600

Light Load

400

250

700

16-20

Idle

1500

1350

900

N/A

400

150-250

700

N/A

Delivery

cc/1000

Max Back Leak

cc/1000

55

82

55

82

-

Comments

cc/min

Purge System & Check for

Leaks

Max Fuel

Max Back Leakage

S.O.I

Start of Injection

1) Stop test bench.

2) Reduce rail pressure on S3000 to zero.

3) Remove fuel connection T031-3052.

4) Close protective cover.

5) Run test bench to 400RPM and increase rail pressure slowly until atomised fuel can just be

seen emitting from nozzle holes when rail pressure should be 150-200BAR.

Note:When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

LT

D

TEST DATA

Injector Designation:- EJBR03101D

Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

Manufacturer I.D.:- Daimler Benz

EM

Test Oil Temperature- 40 C

Engine:- E-Class OM646

SY

ST

Solenoid Resistance @ 20C - 0.4

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

Rail Pressure

BAR

Pulse Width

1000

1000

1200

2000

1500

1500

1600

1500

1200

1500

1500

Purge System

N/A

Check for Leaks

1600

65-70

Max Fuel

1200

45-50

800

600

22-26

Mid Range

400

600

10-11

Light Load

250

700

6.5-7.5

Idle

1350

900

55

Max Back leakage

400

Comments

1200

IE

S

1500

Delivery

cc/1000

EL

Pump Speed

RPM

ER

LI

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 140-170BAR.

Note:When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA

TEST CONDITIONS

PART No:

EJBR03902D

TEST PUMP:

SUITABLE CR PUMP

TYPE:

TEST OIL:

ISO 4113

O.E.M. REF:

HYUNDAI / KIA

TEST OIL TEMP:

40C

ENGINE:

2.9L

SOLENOID RESISTANCE @ 20C

0.4

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipes.

Attach injector cables T031-3401.

Close protective cover.

Pump

Speed

RPM

Rail

Pressure

BAR

Pulse

Width

1000

1000

700

N/A

1500

1600

1600

1500

1200

1500

Delivery

cc/1000

Max Back Leak

cc/1000

Comments

cc/min

Purge System & Check for

Leaks

105-115

Max Fuel

1200

74-82

800

600

19-25

Mid Range

1500

400

600

7-11

Light Load

400

250

700

4.5-6.5

Idle

1500

1350

900

N/A

400

150-250

700

N/A

55

82

-

Max Back Leakage

S.O.I

Start of Injection

1) Stop test bench.

2) Reduce rail pressure on S3000 to zero.

3) Remove fuel connection T031-3052.

4) Close protective cover.

5) Run test bench to 400RPM and increase rail pressure slowly until atomised fuel can just be

seen emitting from nozzle holes when rail pressure should be 150-200BAR.

Note:When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA

TEST CONDITIONS

PART No:

EJBR04001D

TEST PUMP:

SUITABLE CR PUMP

TYPE:

TEST OIL:

ISO 4113

O.E.M. REF:

RENAULT

TEST OIL TEMP:

40C

ENGINE:

K9K

SOLENOID RESISTANCE @ 20C

0.4

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipes.

Attach injector cables T031-3401.

Close protective cover.

Pump

Speed

RPM

Rail

Pressure

BAR

Pulse

Width

1000

1000

700

N/A

1500

1600

1600

1500

1200

1500

Delivery

cc/1000

Max Back Leak

cc/1000

Comments

cc/min

Purge System & Check for

Leaks

65-70

Max Fuel

1200

40-44

800

600

20-24

Mid Range

1500

400

600

13-17

Light Load

400

250

700

12-16

Idle

1500

1350

900

N/A

400

150-250

700

N/A

55

82

-

Max Back Leakage

S.O.I

Start of Injection

1) Stop test bench.

2) Reduce rail pressure on S3000 to zero.

3) Remove fuel connection T031-3052.

4) Close protective cover.

5) Run test bench to 400RPM and increase rail pressure slowly until atomised fuel can just be

seen emitting from nozzle holes when rail pressure should be 150-200BAR.

Note:When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

LT

D

TEST DATA

Injector Designation:- EJBR04101D

Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

Manufacturer I.D.:- RENAULT

EM

Test Oil Temperature- 40 C

Engine:- K9K

SY

ST

Solenoid Resistance @ 20C - 0.4

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

Rail Pressure

BAR

Pulse Width

1000

1000

1200

2000

1500

1500

1600

1500

1200

1500

Comments

Purge System

N/A

Check for Leaks

1600

65-70

Max Fuel

1200

43-48

800

600

17.0-20.0

Mid Range

400

600

12.0-13.0

Light Load

250

700

10.0-11.0

Idle

900

50

Max Back leakage

400

Delivery

cc/1000

1200

IE

S

1500

1500

EL

Pump Speed

RPM

1350

ER

LI

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 140-170BAR.

Note:When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

LT

D

TEST DATA

Injector Designation:- EJBR04201D

Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

Manufacturer I.D.:- Daimler Benz

EM

Test Oil Temperature- 40 C

Engine:- E-Class OM646

SY

ST

Solenoid Resistance @ 20C - 0.4

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

Rail Pressure

BAR

Pulse Width

1000

1000

1200

2000

1500

1500

1600

1500

1200

1500

Comments

Purge System

N/A

Check for Leaks

1600

100-110

Max Fuel

1200

70-75

800

600

28-33

Mid Range

400

600

11-12

Light Load

250

700

4.5-5.5

Idle

900

55

Max Back leakage

400

Delivery

cc/1000

1200

IE

S

1500

1500

EL

Pump Speed

RPM

1350

ER

LI

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 160-190BAR.

Note:When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA

TEST CONDITIONS

PART No:

EJBR04401D

TEST PUMP:

SUITABLE CR PUMP

TYPE:

TEST OIL:

ISO 4113

O.E.M. REF:

SSANGYONG

TEST OIL TEMP:

40C

ENGINE:

2.7L

SOLENOID RESISTANCE @ 20C

0.4

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipes.

Attach injector cables T031-3401.

Close protective cover.

Pump

Speed

RPM

Rail

Pressure

BAR

Pulse

Width

1000

1000

700

N/A

1500

1600

1600

1500

1200

1500

Delivery

cc/1000

Max Back Leak

cc/1000

Comments

cc/min

Purge System & Check for

Leaks

97-103

Max Fuel

1200

70-75

800

600

19-24

Mid Range

1500

400

600

7-10

Light Load

400

250

700

4-6

Idle

1500

1350

900

N/A

400

150-250

700

N/A

55

82

-

Max Back Leakage

S.O.I

Start of Injection

1) Stop test bench.

2) Reduce rail pressure on S3000 to zero.

3) Remove fuel connection T031-3052.

4) Close protective cover.

5) Run test bench to 400RPM and increase rail pressure slowly until atomised fuel can just be

seen emitting from nozzle holes when rail pressure should be 150-200BAR.

Note:When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA

TEST CONDITIONS

PART No:

EJBR04501D / R04501D

TEST PUMP:

SUITABLE CR PUMP

TYPE:

TEST OIL:

ISO 4113

O.E.M. REF:

SSANGYONG KYRON

TEST OIL TEMP:

40C

ENGINE:

2.0 XDI

SOLENOID RESISTANCE @ 20C

0.4

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipes.

Attach injector cables T031-3401.

Close protective cover.

Pump

Speed

RPM

Rail

Pressure

BAR

Pulse

Width

1000

1000

700

N/A

1500

1600

1600

102-107

1500

1200

1200

77-83

1500

800

600

27-33

Mid Range

1500

400

600

11-15

Light Load

400

250

700

6-9

Idle

1500

1350

900

N/A

400

150-250

700

N/A

Delivery

cc/1000

Max Back Leak

cc/1000

55

82

55

82

-

Comments

cc/min

Purge System & Check for

Leaks

Max Fuel

Max Back Leakage

S.O.I

Start of Injection

1) Stop test bench.

2) Reduce rail pressure on S3000 to zero.

3) Remove fuel connection T031-3052.

4) Close protective cover.

5) Run test bench to 400RPM and increase rail pressure slowly until atomised fuel can just be

seen emitting from nozzle holes when rail pressure should be 150-200BAR.

Note:When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA

TEST CONDITIONS

PART No:

EJBR04701D

TEST PUMP:

SUITABLE CR PUMP

TYPE:

TEST OIL:

ISO 4113

O.E.M. REF:

SSANGYONG KYRON

TEST OIL TEMP:

40C

ENGINE:

2.0 XDI

SOLENOID RESISTANCE @ 20C

0.4

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipes.

Attach injector cables T031-3401.

Close protective cover.

Pump

Speed

RPM

Rail

Pressure

BAR

Pulse

Width

1000

1000

700

N/A

1500

1600

1600

1500

1200

1500

Delivery

cc/1000

Max Back Leak

cc/1000

Comments

cc/min

Purge System & Check for

Leaks

96-106

Max Fuel

1200

70-75

800

600

25-30

Mid Range

1500

400

600

11-15

Light Load

400

250

700

6-9

Idle

1500

1350

900

N/A

400

150-250

700

N/A

55

82

-

Max Back Leakage

S.O.I

Start of Injection

1) Stop test bench.

2) Reduce rail pressure on S3000 to zero.

3) Remove fuel connection T031-3052.

4) Close protective cover.

5) Run test bench to 400RPM and increase rail pressure slowly until atomised fuel can just be

seen emitting from nozzle holes when rail pressure should be 150-200BAR.

Note:When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

LT

D

TEST DATA

Injector Designation:- EJBR05101D

Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

Manufacturer I.D.:- RENAULT

Test Oil Temperature- 40 C

EM

Engine:- MEGANE 2

1.5DCI

SY

ST

Solenoid Resistance @ 20C - 0.4

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

Rail Pressure

BAR

Pulse Width

1000

1000

1200

2000

1500

1500

1600

1500

1200

1500

Comments

Purge System

N/A

Check for Leaks

1600

60-65

Max Fuel

1200

40-45

800

600

17-22

Mid Range

400

600

8.0-12.0

Light Load

250

700

7.0-10.0

Idle

900

55

Max Back leakage

400

Delivery

cc/1000

1200

IE

S

1500

1500

EL

Pump Speed

RPM

1350

ER

LI

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 140-180BAR.

Note:When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

LT

D

TEST DATA

Injector Designation:- EJBR05102D

Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

Manufacturer I.D.:- RENAULT

Test Oil Temperature- 40 C

EM

Engine:- MEGANE 2

1.5DCI

SY

ST

Solenoid Resistance @ 20C - 0.4

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

Rail Pressure

BAR

Pulse Width

1000

1000

1200

2000

1500

1500

1600

1500

1200

1500

Comments

Purge System

N/A

Check for Leaks

1600

60-65

Max Fuel

1200

40-45

800

600

17-22

Mid Range

400

600

8.0-12.0

Light Load

250

700

7.0-10.0

Idle

900

55

Max Back leakage

400

Delivery

cc/1000

1200

IE

S

1500

1500

EL

Pump Speed

RPM

1350

ER

LI

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 140-180BAR.

Note:When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA

TEST CONDITIONS

PART No:

EJDR06001D / R03801D

TEST PUMP:

SUITABLE CR PUMP

TYPE:

TEST OIL:

ISO 4113

O.E.M. REF:

PEUGEOT/CITROEN

TEST OIL TEMP:

40C

ENGINE:

2.0 L

SOLENOID RESISTANCE @ 20C

0.4

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipes.

Attach injector cables T031-3401.

Close protective cover.

Pump

Speed

RPM

Rail

Pressure

BAR

Pulse

Width

1000

1000

700

N/A

1500

1600

1600

1500

1200

1500

Delivery

cc/1000

Max Back Leak

cc/1000

Comments

cc/min

Purge System & Check for

Leaks

94-100

Max Fuel

1200

67-73

800

600

32-37

Mid Range

1500

400

600

10-14

Light Load

400

250

700

5-9

Idle

1500

1350

900

N/A

400

150-250

700

N/A

55

82

-

Max Back Leakage

S.O.I

Start of Injection

1) Stop test bench.

2) Reduce rail pressure on S3000 to zero.

3) Remove fuel connection T031-3052.

4) Close protective cover.

5) Run test bench to 400RPM and increase rail pressure slowly until atomised fuel can just be

seen emitting from nozzle holes when rail pressure should be 150-200BAR.

Note:When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

LT

D

TEST DATA

Injector Designation:- EJDR00301Z

Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

Manufacturer I.D.:- FORD

EM

Test Oil Temperature- 40 C

Engine:- DURATORQ 2.0 TDCi

SY

ST

Solenoid Resistance @ 20C - 4

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

Rail Pressure

BAR

Pulse Width

1000

1000

1200

2000

1500

1500

1600

1500

1200

1500

1500

Purge System

N/A

Check for Leaks

1600

80-85

Max Fuel

1200

52-57

800

600

25-30

Mid Range

400

600

15.0-18.0

Light Load

250

700

9.0-11.0

Idle

900

55

Max Back leakage

400

Comments

1200

IE

S

1500

Delivery

cc/1000

EL

Pump Speed

RPM

1350

ER

LI

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

LT

D

TEST DATA

Injector Designation:- EJDR00401Z

Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

Manufacturer I.D.:- FORD

EM

Test Oil Temperature- 40 C

Engine:- DURATORQ 2.0 TDCi

SY

ST

Solenoid Resistance @ 20C - 4

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

Rail Pressure

BAR

Pulse Width

1000

1000

1200

2000

1500

1500

1600

1500

1200

1500

1500

Purge System

N/A

Check for Leaks

1600

80-85

Max Fuel

1200

52-57

800

600

25-30

Mid Range

400

600

15.0-18.0

Light Load

250

700

9.0-11.0

Idle

900

55

Max Back leakage

400

Comments

1200

IE

S

1500

Delivery

cc/1000

EL

Pump Speed

RPM

1350

ER

LI

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

LT

D

TEST DATA

Injector Designation:- EJDR00402Z

Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

Manufacturer I.D.:- FORD

EM

Test Oil Temperature- 40 C

Engine:- DURATORQ 2.0 TDCi

SY

ST

Solenoid Resistance @ 20C - 4

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

Rail Pressure

BAR

Pulse Width

1000

1000

1200

2000

1500

1500

1600

1500

1200

1500

Comments

Purge System

N/A

Check for Leaks

1600

78.0-82.0

Max Fuel

1200

800

600

Mid Range

400

600

Light Load

250

700

9.0-11.0

Idle

900

55

Max Back leakage

400

Delivery

cc/1000

1200

IE

S

1500

1500

EL

Pump Speed

RPM

1350

ER

LI

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

TEST CONDITIONS

PART No:

EJDR00501Z

TEST PUMP:

SUITABLE CR PUMP

TYPE:

TEST OIL:

ISO 4113

O.E.M. REF:

JAGUAR

TEST OIL TEMP:

40C

ENGINE:

2.0L, 130 BHP, X404

SOLENOID RESISTANCE @ 20C

LT

INJECTOR DATA

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipes.

Attach injector cables T031-3401.

Close protective cover.

Rail

Pressure

BAR

1000

1000

1500

1600

1500

1200

1500

800

1500

400

Max Back Leak

cc/1000

Comments

cc/min

-

Purge System & Check for

Leaks

80-85

Max Fuel

55-60

600

22-27

Mid Range

400

600

15-20

Light Load

250

700

9-13

Idle

1350

900

N/A

150-250

700

N/A

N/A

1600

1200

IE

700

55

82

-

Max Back Leakage

S.O.I

ER

400

Delivery

cc/1000

1500

Pulse

Width

SE

L

Pump

Speed

RPM

LI

SY

ST

EM

0.4

Start of Injection

1) Stop test bench.

2) Reduce rail pressure on S3000 to zero.

3) Remove fuel connection T031-3052.

4) Close protective cover.

5) Run test bench to 400RPM and increase rail pressure slowly until atomised fuel can just be

seen emitting from nozzle holes when rail pressure should be 150-200BAR.

Note:When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

LT

D

TEST DATA

Injector Designation:- EJDR00502Z

Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

Manufacturer I.D.:-

EM

Test Oil Temperature- 40 C

Engine:-

SY

ST

Solenoid Resistance @ 20C - 0.4

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors (Remove White Spacer fit seal only). Close protective

cover.

Rail Pressure

BAR

1000

1000

2000

1500

1500

1600

1500

400

Purge System

N/A

Check for Leaks

75-80

Max Fuel

1200

1200

50-55

800

600

21-25

Mid Range

400

600

15.5-17.5

Light Load

250

700

10.0-12.0

Idle

1350

900

55

Max Back leakage

1500

1200

Comments

1600

1500

Delivery

cc/1000

1200

IE

S

1500

Pulse Width

EL

Pump Speed

RPM

ER

LI

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

LT

D

TEST DATA

Injector Designation:- EJDR00504Z

Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

Manufacturer I.D.:- FORD

EM

Test Oil Temperature- 40 C

Engine:- DURATORQ 2.0 TDCi 125HP

SY

ST

Solenoid Resistance @ 20C - 0.4

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

Rail Pressure

BAR

Pulse Width

1000

1000

1200

2000

1500

1500

1600

1500

1200

1500

1500

Purge System

N/A

Check for Leaks

1600

80-85

Max Fuel

1200

57-62

800

600

30-32

Mid Range

400

600

13.5-14.5

Light Load

250

700

6.5-8.0

Idle

900

55

Max Back leakage

400

Comments

1200

IE

S

1500

Delivery

cc/1000

EL

Pump Speed

RPM

1350

ER

LI

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

LT

D

TEST DATA

Injector Designation:- EJDR00701D

Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

Manufacturer I.D.:- JAGUAR X TYPE

EM

Test Oil Temperature- 40 C

Engine:- 2.2L 155PS PUMA (EURO 4)

SY

ST

Solenoid Resistance @ 20C - 0.4

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

Rail Pressure

BAR

Pulse Width

1000

1000

1200

2000

1500

1500

1600

1500

1200

1500

Comments

Purge System

N/A

Check for Leaks

1600

95-100

Max Fuel

1200

65-70

800

600

28-32

Mid Range

400

600

12-14

Light Load

250

700

6.5-8.0

Idle

900

55

Max Back leakage

400

Delivery

cc/1000

1200

IE

S

1500

1500

EL

Pump Speed

RPM

1350

ER

LI

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

LT

D

TEST DATA

Injector Designation:- EJDR00801D

Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

Manufacturer I.D.:- FORD

EM

Test Oil Temperature- 40 C

Engine:- MONDEO 2.0 TDCi

SY

ST

Solenoid Resistance @ 20C - 0.4

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

Rail Pressure

BAR

Pulse Width

1000

1000

1200

2000

1500

1500

1600

1500

1200

1500

1500

Purge System

N/A

Check for Leaks

1600

80-85

Max Fuel

1200

57-62

800

600

28-32

Mid Range

400

600

11.5-12.5

Light Load

250

700

6.2-6.6

Idle

900

55

Max Back leakage

400

Comments

1200

IE

S

1500

Delivery

cc/1000

EL

Pump Speed

RPM

1350

ER

LI

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

LT

D

TEST DATA

Injector Designation:- EJDR01101D

Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

Manufacturer I.D.:-

EM

Test Oil Temperature- 40 C

Engine:-

SY

ST

Solenoid Resistance @ 20C - 0.4

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

Rail Pressure

BAR

Pulse Width

1000

1000

1200

2000

1500

1500

1600

1500

1200

1500

Comments

Purge System

N/A

Check for Leaks

1600

95-105

Max Fuel

1200

65-70

800

600

27-32

Mid Range

400

600

10.5-11.5

Light Load

250

700

13.0-14.0

Idle

900

55

Max Back leakage

400

Delivery

cc/1000

1200

IE

S

1500

1500

EL

Pump Speed

RPM

1350

ER

LI

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 140-180BAR.

Note:When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA

TEST CONDITIONS

PART No:

EMBR00002D

TEST PUMP:

SUITABLE CR PUMP

TYPE:

TEST OIL:

ISO 4113

O.E.M. REF:

MERCEDES SPRINTER, E220 +

TEST OIL TEMP:

40C

ENGINE:

2.2 L (OM651)

SOLENOID RESISTANCE @ 20C

0.4

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipes.

Attach injector cables T031-3401.

Close protective cover.

Pump

Speed

RPM

Rail

Pressure

BAR

Pulse

Width

1000

1000

700

N/A

1500

1600

1600

1500

1200

1500

Delivery

cc/1000

Max Back Leak

cc/1000

Comments

cc/min

Purge System & Check for

Leaks

90-100

Max Fuel

1200

76-80

800

600

27-33

Mid Range

1500

400

600

12-16

Light Load

400

250

700

7-11

Idle

1500

1350

900

N/A

400

150-250

700

N/A

55

82

-

Max Back Leakage

S.O.I

Start of Injection

1) Stop test bench.

2) Reduce rail pressure on S3000 to zero.

3) Remove fuel connection T031-3052.

4) Close protective cover.

5) Run test bench to 400RPM and increase rail pressure slowly until atomised fuel can just be

seen emitting from nozzle holes when rail pressure should be 150-200BAR.

Note:When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

LT

D

TEST DATA

Injector Designation:- EMBR00101D

Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

Manufacturer I.D.:- FORD/PSA

EM

Test Oil Temperature- 40 C

Engine:- 2.0 TDCI, 2.0 HDI

SY

ST

Solenoid Resistance @ 20C - 0.4

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

Rail Pressure

BAR

Pulse Width

1000

1000

1200

2000

1500

1500

1600

1500

1200

1500

N/A

Comments

Purge System

Check for Leaks

97-102

1200

72-77

800

600

23-27

Mid Range

400

600

9-13

Light Load

250

700

4-8

900

55

400

1200

Delivery

cc/1000

1600

IE

S

1500

1500

EL

Pump Speed

RPM

1350

Max Fuel

Idle

Max Back leakage

ER

LI

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

Você também pode gostar

- Inyectores Delphi Tabla ValoresDocumento30 páginasInyectores Delphi Tabla Valoresbruttus139Ainda não há avaliações

- Siemens Pump Test Plans 4Documento10 páginasSiemens Pump Test Plans 4DJAMel LAinda não há avaliações

- Merlin Diesel Systems Ltd injector calibration and testing documentationDocumento126 páginasMerlin Diesel Systems Ltd injector calibration and testing documentationLucas Man100% (2)

- Siemens Injector Test Data New6 PDFDocumento20 páginasSiemens Injector Test Data New6 PDFJose HasinAinda não há avaliações

- S3000 Common Rail Test System DataDocumento28 páginasS3000 Common Rail Test System DataFernando SanchezAinda não há avaliações

- Bosch CR Pumps Test Data PDFDocumento146 páginasBosch CR Pumps Test Data PDFInyectronix Vyh100% (2)

- Siemens Injector Test Data New6 PDFDocumento20 páginasSiemens Injector Test Data New6 PDFJuan David Cepeda GonzalesAinda não há avaliações

- Boschinjectortestplans 29 WEBDocumento156 páginasBoschinjectortestplans 29 WEBedward06Ainda não há avaliações

- Delphi Injector Test Plans 9 WebDocumento26 páginasDelphi Injector Test Plans 9 WebAdrian MacayaAinda não há avaliações

- Bosch Pump Test Plans 4 Web 3232Documento146 páginasBosch Pump Test Plans 4 Web 3232Eduardo Alvarez HuizaAinda não há avaliações

- SRN Brochure UK 03 Aprile18Documento84 páginasSRN Brochure UK 03 Aprile18Marco100% (1)

- 8 Operation Instruction: 8.1. Before StartDocumento10 páginas8 Operation Instruction: 8.1. Before StartJRC DIESELAinda não há avaliações

- Bk2q-9k546-Ag 20190701 112041 PDFDocumento2 páginasBk2q-9k546-Ag 20190701 112041 PDFคุณชายธวัชชัย เจริญสุขAinda não há avaliações

- Piezo CR Bosch Manual - Nozzle Assembling Disassembling and Injector AdjustingDocumento10 páginasPiezo CR Bosch Manual - Nozzle Assembling Disassembling and Injector AdjustingZdravko DudicAinda não há avaliações

- StanadyneDocumento4 páginasStanadynemurillo_rodriguez8382Ainda não há avaliações

- 093400-5350 Mitsubishi PDFDocumento2 páginas093400-5350 Mitsubishi PDFBaytolgaAinda não há avaliações

- Unidades HeuiDocumento50 páginasUnidades HeuiagnaldoAinda não há avaliações

- Boletin Tecnico VDO PDFDocumento8 páginasBoletin Tecnico VDO PDFJuan Carlos Casale100% (1)

- 0599Documento2 páginas0599Edinson Ariel Chavarro Quintero100% (1)

- Control Elec Ecd-V3Documento21 páginasControl Elec Ecd-V3Fabian Henao Calle100% (1)

- Common-rail nozzle injectors applicationsDocumento3 páginasCommon-rail nozzle injectors applicationsTamer RabieAinda não há avaliações

- Common Rail Nozzle TypeDocumento4 páginasCommon Rail Nozzle TypeJean LucasAinda não há avaliações

- 3042f843 Plano de TesteDocumento1 página3042f843 Plano de TesteJose Alexandre Sunhega100% (1)

- vp44 Pump Detail Schematic PDF FreeDocumento7 páginasvp44 Pump Detail Schematic PDF Freepablo pérezAinda não há avaliações

- DENSO Rastavljanje DizneDocumento22 páginasDENSO Rastavljanje Diznegalaxy63Ainda não há avaliações

- ERIKC Update CRDi Catalog-Diesel Injector Spare PartsDocumento63 páginasERIKC Update CRDi Catalog-Diesel Injector Spare PartsЕкатерина КалашниковаAinda não há avaliações

- Adjustment Procedures For RSV Type Hybrid (Cam Lock) Governor Equipped Injection Pump For Komatsu: Part 2Documento11 páginasAdjustment Procedures For RSV Type Hybrid (Cam Lock) Governor Equipped Injection Pump For Komatsu: Part 2duongbk24 luu quang duongAinda não há avaliações

- CZ 2012 2013 DieselDocumento14 páginasCZ 2012 2013 DieselSoeAyeAinda não há avaliações

- HL070 (En)Documento104 páginasHL070 (En)Ryo ChannelAinda não há avaliações

- TK1026 01 ManualDocumento79 páginasTK1026 01 ManualTifacor100% (1)

- Modifikacii HP 3Documento5 páginasModifikacii HP 3pankituna5487Ainda não há avaliações

- Common Railmod3Documento261 páginasCommon Railmod3Edinson Ariel Chavarro Quintero100% (1)

- 2010-08 CR ContinentalDocumento3 páginas2010-08 CR Continentalrevisione turbine turbo turbocompressoriAinda não há avaliações

- Denso Control Valve & Rod 2016Documento4 páginasDenso Control Valve & Rod 2016Екатерина КалашниковаAinda não há avaliações

- 8096CRSN3 25 - Factsheet e PDFDocumento2 páginas8096CRSN3 25 - Factsheet e PDFLuis MirandaAinda não há avaliações

- DATODocumento1 páginaDATOMiguel RojasAinda não há avaliações

- 0445404977Documento3 páginas0445404977m_najmanAinda não há avaliações

- Catalogue 2016 EngDocumento256 páginasCatalogue 2016 Engdiagnopro100% (2)

- Test Plan: 9521A030: Pump SpecificationDocumento3 páginasTest Plan: 9521A030: Pump Specificationjohnny sabinAinda não há avaliações

- EPS 205 Frequently Asked Questions 2 8.28 PDFDocumento32 páginasEPS 205 Frequently Asked Questions 2 8.28 PDFDarshan Diesel100% (2)

- Toberas Common Rail FBDocumento3 páginasToberas Common Rail FBАмурдеталь БлаговещенскAinda não há avaliações

- Nantai Products 2014Documento40 páginasNantai Products 2014Alex Pakito100% (1)

- CRT075-EN BOSCH Third Measuring Tool 9pcs KitDocumento8 páginasCRT075-EN BOSCH Third Measuring Tool 9pcs KitLuc Mutombo MukuluAinda não há avaliações

- Injection P Ump Test Specifications 196000-327#Documento4 páginasInjection P Ump Test Specifications 196000-327#Manuel João JoãoAinda não há avaliações

- Bosch Inline Piezo Injector Delivery PlanDocumento9 páginasBosch Inline Piezo Injector Delivery PlandieseldvAinda não há avaliações

- Ricambi DensoDocumento10 páginasRicambi DensoSprinter Transit Van100% (1)

- Manual Diesel Test BenchDocumento18 páginasManual Diesel Test BenchMelchor EstradaAinda não há avaliações

- Siemens Part List: Shenzhen Shumatt Technology Co.,LtdDocumento3 páginasSiemens Part List: Shenzhen Shumatt Technology Co.,LtdSprinject Calibration0% (1)

- A5 Common RailDocumento24 páginasA5 Common RailanshelAinda não há avaliações

- Ford HSDI pump specification and ISO test procedureDocumento2 páginasFord HSDI pump specification and ISO test proceduretaniaAinda não há avaliações

- 740 4010Documento6 páginas740 4010Miguel ChaconAinda não há avaliações

- Pe and Tics Type Injection Pump Connector Part Numbers For North AmericaDocumento9 páginasPe and Tics Type Injection Pump Connector Part Numbers For North AmericaSubhojit Samonta100% (1)

- Injection Pump Specification ©Documento4 páginasInjection Pump Specification ©murillo_rodriguez8382100% (1)

- Bosch ESI (Tronic) 1Q.2015 News PDFDocumento2 páginasBosch ESI (Tronic) 1Q.2015 News PDFAdrián Molina MiguelAinda não há avaliações

- Siemens FIRAD CatalogueDocumento9 páginasSiemens FIRAD CatalogueWinston Wolf100% (1)

- S3000 Common Rail Test DataDocumento20 páginasS3000 Common Rail Test Dataaddelyn_robescu8794100% (7)

- Delphi Injector Test PlansDocumento21 páginasDelphi Injector Test PlansZauron Kent Touchit67% (6)

- Delphi Pump Test Plans 4 WebDocumento54 páginasDelphi Pump Test Plans 4 WebAspro Brazil Se Iglesias100% (4)

- Siemens Injector Test Data New6Documento20 páginasSiemens Injector Test Data New6cartronix2010100% (2)

- BMW Code SheetDocumento338 páginasBMW Code SheetAleksey Lakomov76% (29)

- Dodge Trouble Codes PDFDocumento12 páginasDodge Trouble Codes PDFbelchiorAinda não há avaliações

- Boschinjectortestplans 29 WEBDocumento156 páginasBoschinjectortestplans 29 WEBedward06Ainda não há avaliações

- SK140XM 12MDocumento2 páginasSK140XM 12MkampeeAinda não há avaliações

- Mazda Trouble Codes - Fault Codes For MX5 / MiataDocumento4 páginasMazda Trouble Codes - Fault Codes For MX5 / MiataJordanAinda não há avaliações

- 3000EM Common Rail Test StandDocumento1 página3000EM Common Rail Test StandkampeeAinda não há avaliações

- Thai Study JEPDocumento8 páginasThai Study JEPkampeeAinda não há avaliações

- Model: 10 Years/120,000 Miles As Determined by The Vehicle's Original In-Service DateDocumento11 páginasModel: 10 Years/120,000 Miles As Determined by The Vehicle's Original In-Service DatekampeeAinda não há avaliações

- Auwel global leading power provider fuel injection pump partsDocumento89 páginasAuwel global leading power provider fuel injection pump partsImtiaz Alam100% (3)

- 001-04 Merlin Equipment and Accessories Catalogue 0810 - On Web 0211Documento173 páginas001-04 Merlin Equipment and Accessories Catalogue 0810 - On Web 0211kampeeAinda não há avaliações

- Ac Neumatic Solenoid ValveDocumento6 páginasAc Neumatic Solenoid ValvekampeeAinda não há avaliações

- Dodge Trouble Codes PDFDocumento12 páginasDodge Trouble Codes PDFbelchiorAinda não há avaliações

- Wrangler PDFDocumento11 páginasWrangler PDFkampeeAinda não há avaliações

- 13 Diesel EnginesDocumento5 páginas13 Diesel EngineskampeeAinda não há avaliações

- Car and Van CoverDocumento2 páginasCar and Van CoverkampeeAinda não há avaliações

- 1KD Engine Coolan Drain PlugDocumento2 páginas1KD Engine Coolan Drain Plugkampee100% (1)

- Global Electric Generator ManufacturerDocumento4 páginasGlobal Electric Generator ManufacturerkampeeAinda não há avaliações

- Trouble Codes OBDIIDocumento55 páginasTrouble Codes OBDIIdaniwesa100% (1)

- P0088Documento1 páginaP0088kampeeAinda não há avaliações

- Mazda BT50 Workshop Repair Manual 2012.25 MY Chapter IndexDocumento1 páginaMazda BT50 Workshop Repair Manual 2012.25 MY Chapter Indexkampee100% (3)

- Big Camera 2017Documento20 páginasBig Camera 2017kampeeAinda não há avaliações

- It Direct 20507Documento80 páginasIt Direct 20507kampeeAinda não há avaliações

- UD Trucks Condor PK 16 250Documento4 páginasUD Trucks Condor PK 16 250kampee0% (1)

- New CR Connector Flyer2Documento1 páginaNew CR Connector Flyer2kampeeAinda não há avaliações

- Basic Electronics TutorialsDocumento39 páginasBasic Electronics TutorialsDedi PurwantoAinda não há avaliações

- Sony XR-CA420XDocumento56 páginasSony XR-CA420XkampeeAinda não há avaliações

- Manual 0305Documento33 páginasManual 0305kampee100% (3)

- Isuzu D-Max Australian SpecsDocumento4 páginasIsuzu D-Max Australian SpecsWenda WidodoAinda não há avaliações

- hl2135w 1 UserManualDocumento150 páginashl2135w 1 UserManualNoventa MinutosAinda não há avaliações

- Sony DCRTRV38Documento212 páginasSony DCRTRV38kampeeAinda não há avaliações

- 924GDocumento2 páginas924GGe Dominic67% (6)

- Web STEAM HIGH TEMPERATURE STERILIZER EN - 01 PDFDocumento24 páginasWeb STEAM HIGH TEMPERATURE STERILIZER EN - 01 PDFEyad AlarjawiAinda não há avaliações

- Two Phase Flow Lab ManualDocumento5 páginasTwo Phase Flow Lab ManualkandalamvenkateshAinda não há avaliações

- R-32 Air Cooled Chiller with Inverter Scroll CompressorsDocumento63 páginasR-32 Air Cooled Chiller with Inverter Scroll CompressorsFrancisco BelloAinda não há avaliações

- Equipments installation安装指南Documento4 páginasEquipments installation安装指南rogermantilla08Ainda não há avaliações

- Variable Primary Flow Systems: An Alternative Chilled Water System SolutionDocumento35 páginasVariable Primary Flow Systems: An Alternative Chilled Water System Solutionquang stcAinda não há avaliações

- Bermad C10 Air ValveDocumento4 páginasBermad C10 Air ValveWayne SeamanAinda não há avaliações

- Report On Chloro Caustic GroupDocumento79 páginasReport On Chloro Caustic Grouppankaj verma100% (2)

- LT36333 IP FH239 Installation InstructionsDocumento18 páginasLT36333 IP FH239 Installation InstructionsRisal KaromaAinda não há avaliações

- 01 Chemical ProcessDocumento333 páginas01 Chemical ProcessDavid ValladaresAinda não há avaliações

- 2014-15 PetroSkills Facilities CatalogDocumento84 páginas2014-15 PetroSkills Facilities CatalogMichael MorrisonAinda não há avaliações

- Oil Sampling SOPDocumento9 páginasOil Sampling SOPTorres Toledo JttAinda não há avaliações

- Operating Data Specification: Faixa de AplicaçãoDocumento1 páginaOperating Data Specification: Faixa de AplicaçãoScaramouche SualkAinda não há avaliações

- PDB R1 Therma VDocumento51 páginasPDB R1 Therma VAleksander CanjugaAinda não há avaliações

- 414 SYS ExactoServe-BR-R26Documento36 páginas414 SYS ExactoServe-BR-R26li geneAinda não há avaliações

- Berg SystemDocumento390 páginasBerg SystemMohamed Mohamed100% (1)

- Manual AWWA M51 Air Valves PDFDocumento50 páginasManual AWWA M51 Air Valves PDFJorge Blacio AguilarAinda não há avaliações

- Research Proposal For Axial Compressor BladeDocumento18 páginasResearch Proposal For Axial Compressor BladeHein Thiha SanAinda não há avaliações

- Diagram Alir Orientasi PKSDocumento7 páginasDiagram Alir Orientasi PKSYudha MaulanaAinda não há avaliações

- Stokes-Booster-Product-Manual mv-615Documento54 páginasStokes-Booster-Product-Manual mv-615lucasAinda não há avaliações

- Trojan Type A - 3Documento2 páginasTrojan Type A - 3Cairo Oil Refining Co.Ainda não há avaliações

- Pedersen 2005Documento6 páginasPedersen 2005Wisnu WijanarkoAinda não há avaliações

- Doosan DX170W Rubber Tyred ExcavatorDocumento20 páginasDoosan DX170W Rubber Tyred ExcavatorGogyAinda não há avaliações

- STS 6000 SX-F - ManualDocumento21 páginasSTS 6000 SX-F - ManualDavidAinda não há avaliações

- Multi Frac Pump Control ManualDocumento33 páginasMulti Frac Pump Control ManualRyan YoungerAinda não há avaliações

- Spob Musi Prosperity - Dock Repair List Owner EstimateDocumento3 páginasSpob Musi Prosperity - Dock Repair List Owner Estimatenugroho sulistiyadiAinda não há avaliações

- ABOVEGROUND FUEL STORAGEDocumento12 páginasABOVEGROUND FUEL STORAGEGabriel Gabriel100% (1)

- Hydraulic Separator PDFDocumento4 páginasHydraulic Separator PDFsloba68Ainda não há avaliações

- Water 15 04004 1Documento11 páginasWater 15 04004 1bajkiszonAinda não há avaliações

- Two Stage High/Low Hydraulic Pumps: Concentric ABDocumento8 páginasTwo Stage High/Low Hydraulic Pumps: Concentric ABZakAinda não há avaliações

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerNo EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerNota: 4.5 de 5 estrelas4.5/5 (53)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestNo EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestNota: 4 de 5 estrelas4/5 (28)

- Across the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsNo EverandAcross the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsAinda não há avaliações

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyNo EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyNota: 5 de 5 estrelas5/5 (1)

- ASE A1 Engine Repair Study Guide: Complete Review & Test Prep For The ASE A1 Engine Repair Exam: With Three Full-Length Practice Tests & AnswersNo EverandASE A1 Engine Repair Study Guide: Complete Review & Test Prep For The ASE A1 Engine Repair Exam: With Three Full-Length Practice Tests & AnswersAinda não há avaliações

- Build Your Own Electric Vehicle, Third EditionNo EverandBuild Your Own Electric Vehicle, Third EditionNota: 4.5 de 5 estrelas4.5/5 (3)

- Understanding Automotive Electronics: An Engineering PerspectiveNo EverandUnderstanding Automotive Electronics: An Engineering PerspectiveNota: 3.5 de 5 estrelas3.5/5 (16)

- The RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVNo EverandThe RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVNota: 5 de 5 estrelas5/5 (2)

- Making Toys, Revised Edition: Heirloom Cars & Trucks in WoodNo EverandMaking Toys, Revised Edition: Heirloom Cars & Trucks in WoodNota: 4 de 5 estrelas4/5 (3)

- Official CDL Study Guide: Commercial Driver’s License Guide: Exam Prep, Practice Test Questions, and Beginner Friendly Training for Classes A, B, & C.No EverandOfficial CDL Study Guide: Commercial Driver’s License Guide: Exam Prep, Practice Test Questions, and Beginner Friendly Training for Classes A, B, & C.Ainda não há avaliações

- 700 Driving Theory Test Questions & Answers: Updated Study Guide With Over 700 Official Style Practise Questions For Cars - Based Off the Highway CodeNo Everand700 Driving Theory Test Questions & Answers: Updated Study Guide With Over 700 Official Style Practise Questions For Cars - Based Off the Highway CodeAinda não há avaliações

- How to Design and Install In-Car Entertainment SystemsNo EverandHow to Design and Install In-Car Entertainment SystemsNota: 5 de 5 estrelas5/5 (1)

- LS Swaps: How to Swap GM LS Engines into Almost AnythingNo EverandLS Swaps: How to Swap GM LS Engines into Almost AnythingNota: 3.5 de 5 estrelas3.5/5 (2)

- Why We Drive: Toward a Philosophy of the Open RoadNo EverandWhy We Drive: Toward a Philosophy of the Open RoadNota: 4 de 5 estrelas4/5 (6)

- Construction Vehicles to Crochet: A Dozen Chunky Trucks and Mechanical Marvels Straight from the Building SiteNo EverandConstruction Vehicles to Crochet: A Dozen Chunky Trucks and Mechanical Marvels Straight from the Building SiteNota: 5 de 5 estrelas5/5 (2)

- How to Design, Build & Equip Your Automotive Workshop on a BudgetNo EverandHow to Design, Build & Equip Your Automotive Workshop on a BudgetNota: 4 de 5 estrelas4/5 (10)

- Modern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingNo EverandModern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingNota: 4.5 de 5 estrelas4.5/5 (9)