Escolar Documentos

Profissional Documentos

Cultura Documentos

AV6+ BypassGeneralDescription

Enviado por

Gaurav ChauhanDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

AV6+ BypassGeneralDescription

Enviado por

Gaurav ChauhanDireitos autorais:

Formatos disponíveis

CCI AG Switzerland

Im Link 11

P.O. Box 65

CH-8404 Winterthur

TELEFON ++41-(0)52-264 95 00

TELEFAX ++41-(0)52-264 95 01

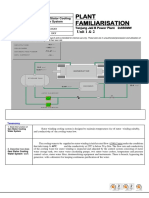

Function description

HP/LP Bypass Automation

1.

Introduction

30 years experience with Sulzer Bypass

Systems, including controls and safety

functions, show that the bypass-controller is

neither a integrated part of the boiler

controls nor the turbine controls. The Sulzer

bypass system is rather an independent

system which serves the operational

requirements of the complete plant (i.e.

boiler and turbine). The number of active

signals between the bypass controller and

other systems is small. Much more important

is a bypass controller which fulfils exactly

the requirements of the bypass operation and

allows the easy implementation of safety

functions or other quick opening or quick

closing functions. The life conserving

operation of the heavily stressed valves and

pipework, especially by accurate steam

desuperheating in all operating modes and

transients, poses a special challenge for the

Sulzer bypass controller.

2.

HP bypass controller

HP HP HP

HP

PS PS PS

PT

BPE1 BPE2

TT

TT

(Option)

Signal Conditioning

Operator

Safety

function

Test

Setpoint Generation

Control

Interface

Valve Positioners

BP1 BP2 BPE1BPE2 BD1 BD2

Figure 1 HP-Bypass controller (2 lines)

including safety function

With a few standardized interface signals the

Sulzer bypass controller can be tied easily

into an overall plant automation. The duty of

the HP bypass controller can be summarized

for the different operating conditions as

follows:

Boiler start up

The Sulzer HP bypass controller is an

integrated system with the functions signal

conditioning, control and valve positioning

(Figure 1). The type of operator interface

can be tailored to the needs of the individual

plant. The below described functions for

start up as well as for shut down are fully

automated.

The controller has to control and increase

the boiler steam pressure according to the

steam production of the boiler. The bypass

has to divert the steam flow to the reheater,

thus ensuring a proper steam flow through

superheater and reheater. The bypass

controller has to control the temperature of

the steam to the reheater whenever steam is

flowing through the bypass.

Turbine start up

The HP bypass controller has to control the

steam pressure until the boiler master

controller can take over the pressure control.

640/30.04.04/Ri

D1_HDNDe

1/4

Load operation

2.1

The bypass is closed but the controller is

ready to prevent excessive live steam

pressure or excessive pressure gradients.

Figure 3 shows in more detail the structure

of the pressure controller and the pressure

setpoint generator. The different functions

and operating modes of the pressure

controller are represented again in the start

up diagram of Figure 4.

Turbine load rejection/trip

The controller opens the bypass valves, if

necessary with the help of the quick opening

devices, in order to prevent excessive live

steam pressure and controls the pressure

until the turbine picks up load again.

Safety Function

Regulations of various countries allow the

use of the HP Bypass valves as safety valves

for the HP part of the boiler without any

additional conventional safety valves on the

HP side. for this the HP Bypass has to be

equipped with a hardwarewise fully

independent safety system. Functionally this

system is fully integrated into the bypass

controller to ensure smooth transients

between safety and control function.

Main Steam Line

PT

PS

PS

HP Turbine

PS

1/3

Pressure control

At the begin of a cold start the minimum

opening (Ymin) is active. It ensures

immediately after ignition an open path and

therefore a steam flow through the

superheater and reheater.

When there is enough steam production to

reach a predetermined minimum pressure

(pmin) the controller begins to control the

live steam pressure by opening the bypass

valves.

When the valve positions reach a

predetermined value Ym (determined by the

desired steam flow during boiler start up) the

setpoint generator begins to increase the

pressure setpoint in accordance with the

steam production of the boiler, but with a

limited maximum gradient.

Safety

System

YT

OP!

BPE1

BP1

OP!

Pressure

Controller

BPE2

YT

Temperature

Controller

Pressure

Controller

Rate Limiter

Ym

RTL

Pressure Transmitter

Temperature Transmitter

Position Transmitter

Pressure Switch

M

A

X

SCO

Cold Reheat Line

M

A

X

PS

Pmin

YT

Ymin

start up follow

HP-Bypass System with Safety Function

(two line system)

Basic control diagram

Operating modes:

Figure 2 shows the main elements of a two

line HP bypass with the main control

functions:

PT

TT

Reheater

Figure 2

BD2

BP2

TT

PT

TT

YT

PS

Setpoint

Generator

BD1

pressure controller

temperature controller

injection water isolation valve control

safety function

640/30.04.04/Ri

fixed value

Figure 3

D1_HDNDe

pressure control (fixed pr. Ps)

start up

follow (Bypass closed)

S

set value

HP-Bypass pressure controller

2/4

Pressure/Load/Flow

factor for the heavily stressed walls of the

valves and piping.

%

100

3.

80

Ymin Pmin Start up

60

press.

contr.

40

SH

Pressure

20

Steam

Flow

Turbine

Load

Time

Valve position

%

100

50

Ym

Ymin

Time

Figure 4

Cold start up with HP-Bypass

The Sulzer LP bypass controller is an

integrated system with the functions signal

conditioning, control and valve positioning

(Figure 5). The type of operator interface

can be tailored to the needs of the individual

plant. With a few standardized interface

signals the Sulzer bypass controller can be

tied easily into an overall plant automation.

Although independent in operation from the

HP bypass controller the LP bypass

controller must operate in conjunction with

the HP Bypass system and allow the excess

steam flow which is not admitted to the

turbine to pass to the condenser.

Once the target pressure for starting the

turbine (psynch) is reached, the setpoint

generator switches to (fixed) pressure

control. As the turbine starts to accept steam

the bypass will start to close until the turbine

consumes all the steam produced by the

boiler and the bypass is fully closed.

As soon as the bypass is closed the pressure

setpoint tracks the actual pressure plus a

threshold dp which keeps the bypass closed

(follow mode). The maximum gradient of the

pressure setpoint is still limited. If the life

steam pressure exceeds this gradient, the

bypass will start to open and the controller

returns to pressure control mode. The

pressure is controlled by the bypass until

normal operation has been restored and the

bypass is closed again.

2.2

LP bypass controller

follow

PT

RH

RH

PT

PT

TT

(Option)

Signal Conditioning

Setpoint Generation

Control

Operator

Interface

Valve Positioners

LPI1 LPI2

Figure 5

LP1

LP2

LPE1 LPE2

LP-Bypass controller (2 lines)

Temperature control

Regarding temperature control it should be

mentioned here only that accurate control of

the steam temperature under all operating

conditions requires a controller well matched

to the wide range of operating conditions of

a HP bypass (low load, quick opening at full

load, etc.). Accurate control of the

temperature under all this operating

conditions is an important life conserving

640/30.04.04/Ri

3.1

Pressure Control

The duty of the LP bypass pressure

controller for the different operating modes

can be summarized as follows:

D1_HDNDe

3/4

Boiler start up

The controller has to control the steam

pressure in the reheater system. The

injection controller has, when ever the LP

bypass is open, to control the desuperheating

of the steam so that it can be accepted by the

condenser.

Load operation

The bypass is closed but the controller

monitors the reheat steam pressure in order

to open and control the pressure whenever

an unacceptable pressure increase is

monitored.

Condenser protection

Whenever the condenser is not able to accept

the steam or the injection water system is

unavailable, the controller has to close the

bypass through a separate safe channel in

order to protect the condenser.

HP Turbine

Reheater

PT

1st stage pr.

TT

Cond.

protection

PT

If power operated reheater safety valves are

provided (e.g. Sulzer MSV valves),

coordinated operation of the reheater safety

valves with the LP bypass can further

improve plant operation for the case of

turbine trip or load rejection at high load.

The Sulzer LP bypass controller can provide

the necessary signals for operation of the

reheater safety valves.

3.2

Injection water control

Because the steam conditions after the LP

bypass desuperheater are usually near or at

saturation condition, the temperature after

the desuperheater cannot be used as control

signal. The necessary injection water flow

and valve position of the injection valve

must therefore be calculated from the steam

flow and steam conditions. The steam flow

is in turn a function of the steam conditions

and the valve position of the bypass valve.

The LP bypass controller provides the

necessary computing functions to perform

this calculations and uses the calculated

injection water demand as setpoint for the

water flow controller.

LP-Bypass

isolating valves

T RH

PT

F

Setpoint

generator

Pressure

Controller

T RH

P RH

P RH

YT

LP-Bypass

control valves

YT

FT

C

FT

PT

Condenser

Figure 6

LP-Bypass system (2 lines)

Basic control diagram

During load operation the first stage pressure

of the turbine serves as load signal for the

setpoint generator which generates a load

dependent (sliding) pressure setpoint.

With large bypass valves, their flow capacity

at high reheater pressure can exceed the

absorption capacity of the condenser. For

such cases the steam flow to the condenser

must be limited by the bypass controller.

640/30.04.04/Ri

D1_HDNDe

4/4

Functional description

Function description HP Bypass control

1.

Overview (Diagram D)

The HP-Bypass Controller consists of the following parts

Pressure setpoint generation (Diagrams DA/RA)

Pressure controller (Diagram DB/TB)

Temperature controller (Diagram DC)

Spraywater isolation control (diagram DF)

2.

Pressure setpoint generation

2.1

Startup

2.1.1

Mode Selection (Diagram RA)

The startup mode is set by the operator or by the signal Boiler fire on from the

DCS. When the startup mode is selected, the setpoint generator can be in three

different operating conditions:

min pressure

pressure ramp

restart

The min pressure is active whenever the main steam pressure is below Pmin.

The pressure ramp is active when the main steam pressure is above Pmin and

below Psync.

The restart is active when the pressure is above Pmin and the BP valve is closed.

The signal start sequence is generated when the operating min pressure or

pressure ramp is on.

The startup mode is deselected as soon as the pressure reaches Psync and the BP

valve is open. The startup mode is also deselected when the signal HP Turbine

loaded is active or when the pressure controller is switched to manual.

The fixed pressure mode is active when the startup mode, the follow mode and

the shut down mode is not active.

The follow mode is active when the BP valve is closed and the DEH signal HP

Turbine loaded is on or the DCS signal Boiler fire on is off . or when the. Further

the Follow mode is on when BP controller is in manual.

0640/06.12.04 Bi

Rev. 0

HP_Bypass.doc

1/5

Functional description

2.1.2

Setpoint Generator (Diagram DA)

At startup, with no pressure in the boiler the setpoint generator is in the min pressure

condition. The pressure setpoint Ps actual is then set at pressure value Pmin. And

the pressure controller open the BP valve to a minimum position value Ymin (see: 3.

Pressure Controller).

As soon as the main steam pressure is above Pmin the pressure ramp condition is

activated. The pressure setpoint Ps demand is increased, whenever the BP valve

position Yset exceed the position value Ym. The increase of the pressure setpoint

is limited by the gradient limiter and only positive pressure gradient are allowed

during pressure ramp operation, decrease of the pressure setpoint Ps actual is not

permitted in this operation mode.

As soon as the main steam pressure reaches Psync the startup mode is deselected

and the fixed pressure mode is activated. The pressure setpoint Ps demand is set at

the current last pressure setpoint Ps actual. In fixed pressure mode the Pressure

setpoint can be adjusted by the operator.

When the HP turbine loaded the BP valve will close automatically due to pressure

drop. As soon the BP valve is closed the setpoint generator will switch over to follow

mode (see: 2.2 Load Operation). In this mode pressure setpoint Ps actual will

follow main steam pressure.

In case of pressurized boiler at startup the restart condition is selected while the BP

valve is closed. In the restart condition the pressure setpoint Ps actual is following

the main steam pressure but only negative pressure gradients are allowed. As soon as

the boiler pressure starts to increase the bypass valve will start to open. When the BP

valve open the setpoint generator will go to pressure ramp condition if the pressure

is still below Psync or to fixed pressure mode if the pressure at startup is already

above Psync.

P re s s u r e / L o a d / F lo w

S ta rt S e q u e n c e .

100 %

M in

P re s s

80 %

Turbine on

P re s s u re

Ram p

F ix e d

P r e s s u re .

F o llo w

60 %

40 %

P sync

S H -P r e s s u r e P S H

T u r b in e L o a d

20 %

P m in

S t e a m F lo w

F ire o n

T im e

T u rb in e lo a d e d

B P v a lv e

100 %

Y BP

50 %

Ym

Y m in

T im e

0640/06.12.04 Bi

Rev. 0

HP_Bypass.doc

2/5

Functional description

2.2

Load Operation (Diagram /DA/RA)

During load operation, i.e. when the HP turbine is taking over all the produced steam,

the bypass valves are closed. The follow mode is activated.

In the follow mode the pressure setpoint Ps actual is following the actual main

steam pressure. The maximum pressure gradient is limited, depending on the actual

main steam pressure. A differential pressure dP is added to the pressure setpoint Ps

actual to keep the BP valve closed (see: 3. Pressure Controller).

If the main steam pressure is increasing above the Bypass controller setpoint Ps

actual + dP the BP valve starts to open. The setpoint generator is switched over to

fixed Pressure mode.

D e s ig n P re s s u re (P m a x + d P m a x )

P re s s .

M a x . P re s s u re

(P m a x )

B yp a s s fa s t o p e n in g

(P s a c tu a l + d P m a x )

B yp a s s C o n tro lle r S e tp o in t

(P s a c tu a l + d P )

P re s s u re s e tp o in t

(P s a c tu a l)

M o d ifie d S lid in g P re s s u re

Load

2.3

Shut down

2.3.1

Mode selection (Diagram RA)

When a plant shutdown is planned the Shut down mode can be selected by the

operator. The Shut down mode can only be selected when the DEH signal HP

Turbine loaded is active and the BP controller is on auto. As soon as the DEH signal

HP Turbine loaded is deactivated the Shut down mode is deselected and the

setpoint generator change to fixed pressure mode.

When the boiler shuts down, the DCS signal Boiler fire on is deactivated, the BP

valve will close and the setpoint generator is switched to follow mode

0640/06.12.04 Bi

Rev. 0

HP_Bypass.doc

3/5

Functional description

2.3.2

Setpoint Generator (Diagram DA)

At Shut down mode the pressure setpoint Ps actual is following the main steam

pressure but only negative gradients are allowed. As soon as the boiler pressure starts

to increase the BP valve start to open.

After the Shut down mode is deselected the setpoint generator is on fixed pressure

mode. At fixed pressure mode the setpoint generator controls the actual pressure.

As soon the boiler shuts down the BP valve is closing and the pressure generator is

switched to follow mode. In follow mode the pressure setpoint will again follow

the actual main steam pressure.

P re s s u re / L o a d / F lo w

100 %

80 %

F o llo w

m ode

Shut

down

m ode

F ix e d

p re s s u re

F o llo w m o d e

P r e s s .-S e tp o in t

60 %

M a in S te a m P r e s s u r e

40 %

20 %

T u r b in e L o a d

S te a m F lo w

T u rb in e o ff

F ire o ff

T im e

B P v a lv e

100 %

50 %

3.

Y BP

Pressure Controller (Diagram DB)

The pressure controller is receiving the actual main steam pressure signal and the

pressure setpoint Ps actual from the setpoint generator. It is generating the BP valve

position demand signal.

The pressure controller has one M/A station to control the BP valve.

At signals BP open the BP valve will open to 100%. During this signal controller is

set manual and follow the valve position. After the signal the controller set automatic

At signal BP close trip the BP valve will be closed by the close command signal to

to the valve. The controller is set to manual.

0640/06.12.04 Bi

Rev. 0

HP_Bypass.doc

4/5

Functional description

In follow mode when the dP on is active a differential pressure is added to the

pressure setpoint Ps actual to keep BP valve close.

At startup mode when the min pressure condition is active the BP valve are

opened to a minimum position Ymin. The Ymin on is deselcted when position is

above the minimum position Ymin.

4.

Fast open / close logic (Diagram TB)

The BP open command for the BP valve is generated from DEH signals Turbine

trip or Generator switch trip or when the main steam pressure has reached the

quick opening pressure threshold dp max above the pressure setpoint Ps actual.

The BP open is blocked when pressure is below the pressure Pfo and the startup

sequence is active or when the BP close trip is active.

The BP close trip command is generated when the BP outlet temperature exeed the

pressure Tmax.

5.

Temperature control (Diagram DC)

The temperature controller is receiving the actual signal HP-BP outlet temperature

from the transmitter and the Temp setpoint set by the operator. The controller is

generating the spraywater valve position demand signal.

The feed forward signal is generated from Main steam pressure and BP valve

position and is added to the valve position demand signal. With the adjustable value

wpl the feed forward signal can be adapted.

The temperature controller has one M/A station to control the sprayvalve BPE valve.

The temperature controller is set automatic mode as soon the BP valve is open.

When the BP valve closes the spraywater valve closes also, and the temperature

controller is set to manual.

6.

Spraywater isolation valve control (Diagram DF)

The spraywater isolation valve is open as soon the BP valve is open. When the BP

valve is closed the spraywater isolation valve is closed again.

0640/06.12.04 Bi

Rev. 0

HP_Bypass.doc

5/5

Functional description

Parameter list HP Bypass control

Function

Minimum pressure

DWG Unity

/DA

[Mpa]

Denom. Default

Pmin

1

Definition/Description

Min. range of pressure set point

Maximum pressure

/DA

[Mpa]

Pmax

20

Max. range of pressure set point

Syncronisation

pressure

/RA

[Mpa]

Psync

Minimum pressure, at which

turbine can be started and

syncronised

Fast opening release

pressure

/TB

[Mpa]

Pfo

15

General release for fast opening

Pressure gradient

/DA

/DA

/DA

/DA

/DA

[Mpa]

[Mpa]

[Mpa/min]

[Mpa/min]

[Mpa/min]

P1

P2

GRD1

GRD2

GRD3

5

6

0.4

1.2

0.2

/DA

[Mpa/min] GRD4

0.2

/DA

[Mpa/min] GRD5

0.4

/DA

[Mpa/min] GRD6

0.6

Fixed point 1 for Gradient

Fixed point 2 for Gradient

Gradient 1 f(P1)

Gradient 2 f(P2)

Gradient 3

Gradient in min pressure

Gradient 4

Gradient in pressure ramp

Gradient 4

Gradient inrestart

Gradient 4

Gradient in shut down

Fast opening

/TB

[Mpa]

dp max

0.5

Control deviation fast opening

P steam high

Follow up

/DB

[Mpa]

dP

0.5

Additional dP to the setpoint to

produces a neg. control deviation

to keep the valve closed

Minimum opening

Medium opening

/DB

/DA

[%]

[%]

Ymin

Ym

10

30

Is set at start up

Equilibrium in pressure ramp

at constant steam procuction

Feedforward

/DC

[-]

wpl

0.5

Feed forward signal

0640/06.12.04 Bi

Rev. 0

HP_Para.doc

1/1

Functional description

Function description LP Bypass control

1.

Overview (Diagram D)

The LP-Bypass Controller consists of the following parts

Pressure setpoint generation (Diagrams DG)

Pressure controller (Diagram DH)

Condenser protection (Diagram DM)

Temperature controller (Diagram DK1/DK2)

Spraywater isolation control (Diagram DL)

2.

Pressure setpoint generation (Diagram DG)

In the min pressure operation the turbine is not on load. The pressure setpoint Ps

RHH actual is set to the pressure Pmin. The minimum pressure setpoint can also be

increased by the operator if an higher setpoint is required.

At load pressure operation the pressure setpoint Ps RHH actual is generated from

the transmitter signal Turbine 1st stage pressure. The pressure setpoint Ps RHH

actual changes in function of the turbine load of the unit.

P re s s u re / L o a d / F lo w

100 %

80 %

L o a d P re s s u re

M in P re s s u re

60 %

H o t re h e a t p re s s

40 %

P m in

20 %

T u r b in e L o a d

S te a m F lo w

F ire o n

T im e

T u rb in e lo a d e d

B P v a lv e

100 %

Y LBP

50 %

T im e

0640/06.12.04 Bi

Rev. 0

LP_Bypass.doc

1/3

Functional description

3.

Pressure controller (Diagram DH)

The pressure controller is receiving the actual hot reheat steam pressure signal (1 out

of 2 selection of two transmitter signals) and the pressure setpoint Ps RHH actual

from the setpoint generator. It is generating the LBP valves position demand signal.

Each LBP valve has one M/A station.

At signal LBP close trip from condenser protection the LBP valves will be closed by

the close command to the valves and the controller is set to manual.

The PI controller is set to manual when both LBP valves are set to manual. The

controller then is tracking the max valve position.

The maximal LBP valve opening is limited by the steam flow to the condensator. As

soon the LBP steam flow the LBP valve start to close.

4.

Condenser protection (Diagram /DM)

The LBP close trip command for the LBP valve is generated from condenser

protection switches. Each one of the following criteria are activating the LBP close

trip command:

- Condenser press. high (2 out of 3)

- Condenser temp. high

- Condenser level high

- LBP spraywater pressure low.

5.

Temperature controller (Diagram /DK1/DK2)

The temperature controller is receiving the actual signal Fw LBP spraywater flow

from the transmitter. The spraywater setpoint Fws is calculated out of the steam

pressure, steam temperature and LBP valve position . The controller is generating the

spraywater valve position demand signal.

The temperature controller has one M/A station to control the sprayvalve LP-BPE

valve.

The temperature controller is set to automatic mode as soon the LBP valve is open.

When the LBP valve is closed the spraywater valve is also closed, the controller is set

to manual.

6.

Spraywater isolation valve control (Diagram DL)

0640/06.12.04 Bi

Rev. 0

LP_Bypass.doc

2/3

Functional description

The spraywater isolation valve is open as soon the LBP valve is open. When the LBP

valve is closed the spraywater isolation valve is closed again.

0640/06.12.04 Bi

Rev. 0

LP_Bypass.doc

3/3

Functional description

Parameter list LP Bypass control

Function

Pressure setpoint

DWG

/DG

/DG

/DG

/DG

/DG

/DG

Unity

[Mpa]

[Mpa]

[MPa]

[MPa]

[MPa]

[MPa]

Denom.

Pmin

Pmax

P1

P2

Ps1

Ps2

Calculation of

Spraywater

/DK

/DK

/DK

[m3/h]

[KJ/Kg]

[KJ/Kg]

kvs

Ew

Ek

0640/06.12.04 Bi

Rev. 0

LP_Para.doc

Default

0.2

5

0

20

0

5

Definition/Description

Min. range of pressure set point

Max. range of pressure set point

Fixed point 1 for Setpoint

Fixed point 2 for Setpoint

Setpoint 1 Ps = f(P1st)

Setpoint 2 Ps = f(P1st)

kv at 100% valve stroke

Enthalpy spraywater

Enthalpy steam after LBP

1/1

Você também pode gostar

- Bypass ControllerDocumento4 páginasBypass Controllernjc6151Ainda não há avaliações

- HP/LP Bypass Automation: Function DescriptionDocumento14 páginasHP/LP Bypass Automation: Function DescriptionMohit GohilAinda não há avaliações

- 1-4 Start Up Boost LeafletDocumento4 páginas1-4 Start Up Boost LeafletsdiamanAinda não há avaliações

- 28990-Turbinebypass Prds PDFDocumento12 páginas28990-Turbinebypass Prds PDFbuddhivasu100% (2)

- S 774201Documento34 páginasS 774201Ben KerryAinda não há avaliações

- HindalcoDocumento28 páginasHindalcoSiddhant Satpathy100% (1)

- Chapter 9Documento15 páginasChapter 9Harjith Vaibav100% (1)

- GE Power Systems Fundamentals of Speedtronic Mark V Control SystemDocumento34 páginasGE Power Systems Fundamentals of Speedtronic Mark V Control SystemHung NgoAinda não há avaliações

- SOP Simulator BoilerDocumento10 páginasSOP Simulator BoilerBambang SetiajiAinda não há avaliações

- SGC Hpsu (LP Bypass) Logic DiagramDocumento21 páginasSGC Hpsu (LP Bypass) Logic DiagramKhushboo PandeyAinda não há avaliações

- GEH-Mark VIe and Mark VIeS Control System - Vol - II-General-purpose ApplicationsDocumento1.052 páginasGEH-Mark VIe and Mark VIeS Control System - Vol - II-General-purpose ApplicationstestvsptestAinda não há avaliações

- Controls & Instrumentation FOR 660 MW Supercritical Unit at TirodaDocumento23 páginasControls & Instrumentation FOR 660 MW Supercritical Unit at TirodaAakash kumar ShrivastavaAinda não há avaliações

- Tsi FinalDocumento41 páginasTsi FinalAnand KumarAinda não há avaliações

- Plant Familiarisation: Unit 1 & 2Documento6 páginasPlant Familiarisation: Unit 1 & 2Herbert H.Ainda não há avaliações

- Write-Up On TsiDocumento4 páginasWrite-Up On TsiKhushboo PandeyAinda não há avaliações

- GT - GTG - STG Cooling Air SystemDocumento17 páginasGT - GTG - STG Cooling Air SystemLeelanandaAinda não há avaliações

- Leveltrol MasoneilanDocumento34 páginasLeveltrol MasoneilanChristopher GeorgeAinda não há avaliações

- Ger 4222a New High Efficiency Simple Cycle Gas Turbine Lms100Documento20 páginasGer 4222a New High Efficiency Simple Cycle Gas Turbine Lms100raghavendran raghuAinda não há avaliações

- Guided Wave Radar in Steam Boiler Service: Measuring Water Level Accurately Despite ChallengesDocumento14 páginasGuided Wave Radar in Steam Boiler Service: Measuring Water Level Accurately Despite ChallengesRoger SeaverAinda não há avaliações

- Turbine Bypass SystemsDocumento10 páginasTurbine Bypass SystemsZaqPoilmAinda não há avaliações

- 158ADocumento113 páginas158AashokAinda não há avaliações

- Chapter 1 GeneralDocumento65 páginasChapter 1 GeneralGloria Del Carmen MuñozAinda não há avaliações

- GE Industrial SystemsDocumento20 páginasGE Industrial Systemsfishzee100% (2)

- 1aha052263 ADocumento19 páginas1aha052263 ATanmay MajhiAinda não há avaliações

- Write Up On LPBP SystemDocumento9 páginasWrite Up On LPBP SystemKhushboo PandeyAinda não há avaliações

- Cooling Water System Control Philosophy (25Mw) : ObjectiveDocumento8 páginasCooling Water System Control Philosophy (25Mw) : ObjectiveEric TaylorAinda não há avaliações

- Turbine Steam Flow ControlDocumento3 páginasTurbine Steam Flow ControlKalyan Maji100% (1)

- Turbine & Cooling System: Presented by - AVIJEET PRATAP 07ME12 Iet AgraDocumento28 páginasTurbine & Cooling System: Presented by - AVIJEET PRATAP 07ME12 Iet AgraAd Man GeTig100% (1)

- GTG#2Documento6 páginasGTG#2joymotiAinda não há avaliações

- Density Compensation For Steam Drum Level Measurement - Integrated SystemsDocumento9 páginasDensity Compensation For Steam Drum Level Measurement - Integrated SystemsPravivVivpraAinda não há avaliações

- Fisher ProdOvervueDocumento88 páginasFisher ProdOvervueduongleanhAinda não há avaliações

- Sealoiloperation1 1Documento2 páginasSealoiloperation1 1harkiranrandhawa100% (1)

- Cold Start Up 1Documento16 páginasCold Start Up 1Hassan SamiAinda não há avaliações

- Paper 5-CMC Implementation Unchahar PDFDocumento48 páginasPaper 5-CMC Implementation Unchahar PDFumeshAinda não há avaliações

- Turbine Control and Efficiency ImporovementDocumento6 páginasTurbine Control and Efficiency ImporovementUdhayakumar Venkataraman100% (1)

- Turbine Control PINDocumento4 páginasTurbine Control PINAnonymous NwnJNO100% (1)

- Power from knowledge: Boiler protection handbookDocumento67 páginasPower from knowledge: Boiler protection handbookarjunsen2009Ainda não há avaliações

- Technical Feedback EhtcDocumento9 páginasTechnical Feedback EhtcPrashant Kumar ChoudharyAinda não há avaliações

- NTPC Simhadri DDCMIS Testing ScheduleDocumento19 páginasNTPC Simhadri DDCMIS Testing ScheduleSandip GaraiAinda não há avaliações

- Mark VI DescriptionDocumento22 páginasMark VI Descriptionprasobh_mr100% (1)

- Speed TronicDocumento3 páginasSpeed Tronicscribdkhatn0% (1)

- Stage-I ALARMSDocumento73 páginasStage-I ALARMSNikhilAinda não há avaliações

- 0000868263Documento611 páginas0000868263Raden MasAinda não há avaliações

- General Electric Power Business Unit: Strategic Analysis Tools and Techniques - Coursework 2Documento13 páginasGeneral Electric Power Business Unit: Strategic Analysis Tools and Techniques - Coursework 2Ibilola IbisankaleAinda não há avaliações

- GENERator Auxilary System MonitoringDocumento10 páginasGENERator Auxilary System MonitoringdhirendracommonAinda não há avaliações

- Speedtronic™ Mark Vi TMR: GE Industrial SystemsDocumento19 páginasSpeedtronic™ Mark Vi TMR: GE Industrial Systemsnboulegroune100% (1)

- Governing Systems MSRMDocumento10 páginasGoverning Systems MSRMBIRANCHIAinda não há avaliações

- Deh Governing-LancoDocumento35 páginasDeh Governing-LancoPRAMOD KUMAR NANDAAinda não há avaliações

- 3 System Process Outline - SLP R2Documento56 páginas3 System Process Outline - SLP R2Pirun SirimangkaloAinda não há avaliações

- DCS & MisDocumento61 páginasDCS & MisParmeshwar Nath Tripathi100% (1)

- Lecture 27 Model Steam Turbine Gov SystemDocumento60 páginasLecture 27 Model Steam Turbine Gov Systempk cfctkAinda não há avaliações

- Gas Turbine Tutorials - Gas Turbine Fuel SystemDocumento11 páginasGas Turbine Tutorials - Gas Turbine Fuel SystemShahzad JamesAinda não há avaliações

- Device SummaryDocumento13 páginasDevice SummaryguerrezAinda não há avaliações

- 2VAA001623 en S Control SPDSO14 Digital Output ModuleDocumento51 páginas2VAA001623 en S Control SPDSO14 Digital Output ModuleanbarasanAinda não há avaliações

- Durgapur Steel Plant 11kV Switchboard Replacement Tender SpecificationDocumento180 páginasDurgapur Steel Plant 11kV Switchboard Replacement Tender SpecificationKanupriya AgarwalAinda não há avaliações

- Bleed ValveDocumento8 páginasBleed Valvejanju81Ainda não há avaliações

- Main Steam Turbine Controls Retrofit ISA FinalDocumento13 páginasMain Steam Turbine Controls Retrofit ISA Finalvankayalasurya100% (1)

- Turbine Gland Steam CondenserDocumento4 páginasTurbine Gland Steam CondenserSai Swaroop100% (1)

- HP & LP Bypass System - Steam Turbine Power PlantDocumento4 páginasHP & LP Bypass System - Steam Turbine Power Plantamer_arauf100% (13)

- HPBP Writeup Dadri-IIDocumento17 páginasHPBP Writeup Dadri-IIrajan_me083Ainda não há avaliações

- 12 Transformer Factory Tests Briefly ExplainedDocumento7 páginas12 Transformer Factory Tests Briefly ExplainedGaurav ChauhanAinda não há avaliações

- Economiser & DrumDocumento75 páginasEconomiser & DrumGaurav ChauhanAinda não há avaliações

- Case Expansion Transducer Systems Datasheet 141598-01 DatasheetDocumento6 páginasCase Expansion Transducer Systems Datasheet 141598-01 DatasheetGaurav ChauhanAinda não há avaliações

- CRS For Instrument Hook UpDocumento4 páginasCRS For Instrument Hook UpGaurav ChauhanAinda não há avaliações

- AGC GoverningDocumento20 páginasAGC GoverningGaurav ChauhanAinda não há avaliações

- Basic Noise CalculationsDocumento15 páginasBasic Noise Calculationsapi-270822363Ainda não há avaliações

- s710 CatalogDocumento6 páginass710 CatalogGaurav ChauhanAinda não há avaliações

- S700 PDFDocumento16 páginasS700 PDFGaurav ChauhanAinda não há avaliações

- RGMODocumento35 páginasRGMOGaurav Chauhan75% (4)

- Ind. Training Report - NTPC DADRIDocumento61 páginasInd. Training Report - NTPC DADRIAbhinav Srivastav71% (7)

- AGC GoverningDocumento20 páginasAGC GoverningGaurav ChauhanAinda não há avaliações

- PortFolioEqtDocumento1 páginaPortFolioEqtSumedh ShendeAinda não há avaliações

- PMS A10aDocumento6 páginasPMS A10aVinay TrivediAinda não há avaliações

- Wall Thickness Calculation Followed B31.8 PDFDocumento3 páginasWall Thickness Calculation Followed B31.8 PDFBPCL HCULOBS100% (1)

- Group 14 : Strainers, Traps, Fine-Mesh Filters Filling Device For Methanol Drain DeviceDocumento3 páginasGroup 14 : Strainers, Traps, Fine-Mesh Filters Filling Device For Methanol Drain DeviceLPG Equipment Consulting and ServicesAinda não há avaliações

- Qa3 PC800-6 Pump No.2 (HPV95+95)Documento1 páginaQa3 PC800-6 Pump No.2 (HPV95+95)Nurwa crcAinda não há avaliações

- Kobelco Mark IV: Return To ContentsDocumento53 páginasKobelco Mark IV: Return To ContentsVictor Hugo Mezquita100% (4)

- Piping and Instrumentation Diagram (P&id)Documento95 páginasPiping and Instrumentation Diagram (P&id)Ahmed Abd ElmegeedAinda não há avaliações

- Part5 Q A Marine EngineerDocumento10 páginasPart5 Q A Marine Engineer12345Ainda não há avaliações

- KuzeYboru PE100 Pipes 2015 Price ListDocumento2 páginasKuzeYboru PE100 Pipes 2015 Price ListSusan Sue Berrospi MerinoAinda não há avaliações

- General Notes: Legends: Abbreviations:: Reference DrawingsDocumento1 páginaGeneral Notes: Legends: Abbreviations:: Reference DrawingsmuthuvelaaAinda não há avaliações

- PMS Sheet GRE PipeDocumento3 páginasPMS Sheet GRE PipeSOPANAinda não há avaliações

- Plano Hidráulico EXCAVADORA 324DDocumento2 páginasPlano Hidráulico EXCAVADORA 324Dgerardo100% (1)

- Applications of The Bernoulli EquationDocumento13 páginasApplications of The Bernoulli EquationSalim ChohanAinda não há avaliações

- ValvesDocumento46 páginasValvesashirAinda não há avaliações

- A3 (A) : Elements of Water Supply Network Design.: Pipe FlowDocumento4 páginasA3 (A) : Elements of Water Supply Network Design.: Pipe Flowpradeep987Ainda não há avaliações

- Blackmer Parts List Pump Model: Np2FDocumento2 páginasBlackmer Parts List Pump Model: Np2FWilliam ValenciaAinda não há avaliações

- 3-Inch Arkal Leader Filter with Detachable SpineDocumento2 páginas3-Inch Arkal Leader Filter with Detachable Spinealdo919Ainda não há avaliações

- Flow Around Bluff Bodies With Corner Modifications On Cross-SectiDocumento104 páginasFlow Around Bluff Bodies With Corner Modifications On Cross-SectiLuis RiosAinda não há avaliações

- CATALOGO DE EXCAVADORA CASE 160 CX 7-29031R0-Linked PDFDocumento596 páginasCATALOGO DE EXCAVADORA CASE 160 CX 7-29031R0-Linked PDFDaniel GalvisAinda não há avaliações

- Pressure Drop and Vacuum One LessonDocumento3 páginasPressure Drop and Vacuum One LessonYasir AliAinda não há avaliações

- Flow Divider: 1 DescriptionDocumento6 páginasFlow Divider: 1 DescriptionCarlos AugustoAinda não há avaliações

- VibracionDocumento8 páginasVibracionRICARDO ALEXIS LARA GALLEGOAinda não há avaliações

- Pipe Flow Expert User GuideDocumento182 páginasPipe Flow Expert User Guidelilbie100% (1)

- Karcher Pressure Washer Parts and Basic Repair Service Manual Pump 785 HD2500G HD2500MTD HD2600DK HD2700DH HD2701DRDocumento17 páginasKarcher Pressure Washer Parts and Basic Repair Service Manual Pump 785 HD2500G HD2500MTD HD2600DK HD2700DH HD2701DRt_zonne855750% (2)

- Piping System RevDocumento32 páginasPiping System Revapi-25999517100% (9)

- PUMP CALCULATION SHEETDocumento2 páginasPUMP CALCULATION SHEETAJAY1381Ainda não há avaliações

- B.3.8 - Safety Valves SpecDocumento8 páginasB.3.8 - Safety Valves SpecEmiel RoestenburgAinda não há avaliações

- Fire Plant Room BoqDocumento16 páginasFire Plant Room BoqRashel HasanAinda não há avaliações

- Flow Measurement Techniques ExplainedDocumento31 páginasFlow Measurement Techniques ExplainedNora ZuraAinda não há avaliações