Escolar Documentos

Profissional Documentos

Cultura Documentos

Well Killing Operation

Enviado por

mohanad0 notas0% acharam este documento útil (0 voto)

105 visualizações3 páginasWell Killing Operation

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

DOCX, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoWell Killing Operation

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOCX, PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

105 visualizações3 páginasWell Killing Operation

Enviado por

mohanadWell Killing Operation

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOCX, PDF, TXT ou leia online no Scribd

Você está na página 1de 3

Well Killing Operation:

Killing well jobs comes before TCP

Operation if there is high Pressure

Gas production from perforation

zones:

Well Killing Preparation Procedures:

Killing well with normal circulation is method applicable to high

pressure gas wells.

Killing well with reverse circulation is method applicable to high

pressure oil wells with large production; its difficult to apply normal

circulation.

When perforation zones product high pressure gas production like

(AG-7C perforation zones),the Rig Engineer & crew must M/U & N/U

the Tubing head (spool) hold pressure until 3000 psi according to the

pressure of perforation zones in well program, under BOP hold

pressure until 5000 psi before TCP jobs.

Rig Engineer & crew should confirm the surface lines is connect &

opened from the check valve in the pump to the tubing down, up

casing to Return valve in casing to Return tank.

The Rig Engineer should determine the percentage of killing fluid

(KCL)( Prepare X m of Y ppg KCL Kill fluid.) according to well

program (the pressure of perforation zones) to crew, before mixed

KCL in the tank because if crew add the killing fluid more than well

program the oil escape from the perforation zones.

M/U pressure test to all surface lines in killing well (down Tubing up

casing) about 10 minutes if there is no leakage in the inlet valve &

outlet valve (Return valve that means this Pressure Test is OK.

CNLC Separator Flow Test Engineer should Shut In Tubing Pressure

(SITP) shot up to 2700 Psi; Bleed off well through separator to 1700

Psi.

CNLC Separator Flow Test Engineer should observed that, If the

pressure of perforation zones increase to X Psi more than 2000 psi

for example, he must tell the Rig Engineer & crew to mix & increase

the concentration of killing fluid (KCL) to 15% and crew must

continue pump killing fluid.

The crew should pump x m3 from (KCL), if the pressure increase to Y

psi wait for X hrs to pressure drop & Bleed off the pressure through

separator to Y1 Psi.

The assistant driller should pump killing fluid & fill the tubing with

Killing Fluid meanwhile the crew POOH.

Packer Engineer must Unset Packer before the crew POOH & pumps

Killing Fluid to circulate wellbore.

The crew should POOH & observed if there is kick or high gas

production by observed killing fluid in tubing (the quantity of KCL &

speed of KCL meanwhile killing fluid exit from the tubing).

If the quantity of gas is high the crew must closed BOP (Pipe Ram) &

connect safety valve and kill the well by above procedures.

Prepared by:

Ala-eldin Saad Awadallah.

Trainee Engineer.

Supervised by:

Eng. Ahmed Adil.

Você também pode gostar

- Drilling Out Cement OperationDocumento5 páginasDrilling Out Cement OperationmohanadAinda não há avaliações

- Completion (Natural Flow)Documento3 páginasCompletion (Natural Flow)Mohammed Ali YoussefAinda não há avaliações

- Generic Well Test ProgramDocumento9 páginasGeneric Well Test Programinyene ekereAinda não há avaliações

- TCP Perforating ProgrammeDocumento3 páginasTCP Perforating ProgrammeYougchu LuanAinda não há avaliações

- 22 - IWCF Review Questions 2014 - MSA PDFDocumento9 páginas22 - IWCF Review Questions 2014 - MSA PDFFoued NasriAinda não há avaliações

- Gas Lift - Unloading (Leslie Thompson)Documento59 páginasGas Lift - Unloading (Leslie Thompson)Reza RamadhanAinda não há avaliações

- Burst and Pressure - Full ReportDocumento18 páginasBurst and Pressure - Full ReportEspion BenAinda não há avaliações

- Workover Program KE23B2Documento14 páginasWorkover Program KE23B2Malau Arief100% (1)

- Reciprocating Pump CatalogDocumento109 páginasReciprocating Pump Catalogmetasoniko2014100% (2)

- IB-14 - SCON - TBG Punch - Scope of Work Rev 00Documento11 páginasIB-14 - SCON - TBG Punch - Scope of Work Rev 00Samson ObinnaAinda não há avaliações

- Performing A Leak-Off TestDocumento1 páginaPerforming A Leak-Off TestemiljuchiacAinda não há avaliações

- Asset Integrity Management System (AIMS) Well IntegrityDocumento23 páginasAsset Integrity Management System (AIMS) Well IntegrityMohd RezalAinda não há avaliações

- Caltec Jet Pump 02 1bDocumento2 páginasCaltec Jet Pump 02 1bpolaris44Ainda não há avaliações

- Artificial Lift MethodsDocumento60 páginasArtificial Lift MethodsPurwanti HandayaniAinda não há avaliações

- Well Tests SummarisedDocumento108 páginasWell Tests SummarisedKolawole Adisa100% (3)

- Chapter 4-DDocumento14 páginasChapter 4-DMahrouz MadoAinda não há avaliações

- Workover Kill Fluid Density CalculationDocumento3 páginasWorkover Kill Fluid Density CalculationSanny Astari100% (1)

- Drilling in Vietnam: Volume 2 - Drilling Operations Procedure ManualDocumento55 páginasDrilling in Vietnam: Volume 2 - Drilling Operations Procedure ManualMotlatsi RaiyoAinda não há avaliações

- Commissioning Check List For HP Bypass SystemDocumento8 páginasCommissioning Check List For HP Bypass SystemGansehAinda não há avaliações

- 5.2. Clean Up A Well's DiscussionDocumento16 páginas5.2. Clean Up A Well's DiscussionHermilih SiregarAinda não há avaliações

- Unit Start Up ProcedureDocumento14 páginasUnit Start Up ProceduredineshmehtaAinda não há avaliações

- Pipesim 2006.1 Fundamentals GasliftDocumento13 páginasPipesim 2006.1 Fundamentals GasliftamulyanaAinda não há avaliações

- Well Control - Combined Stripping and Volumetric MethodDocumento3 páginasWell Control - Combined Stripping and Volumetric MethodAbdul Hameed Omar100% (1)

- Diaphram Plunger Injection PumpDocumento8 páginasDiaphram Plunger Injection PumpengrtahirAinda não há avaliações

- To Carry Out Cleanup ActivityDocumento4 páginasTo Carry Out Cleanup Activitysarojdubey0107Ainda não há avaliações

- ABO & LightupDocumento5 páginasABO & Lightupsrigirisetty208Ainda não há avaliações

- HP BypassDocumento15 páginasHP Bypass150819850Ainda não há avaliações

- MTP Multiphase Transfer Pump Brochure LFDocumento8 páginasMTP Multiphase Transfer Pump Brochure LFDeddy IrawanAinda não há avaliações

- Gas Lift Valve InjDocumento3 páginasGas Lift Valve InjMikhaelrams RamsAinda não há avaliações

- Accumulator Draw Down TestDocumento8 páginasAccumulator Draw Down Testadeelsn100% (4)

- Reverse Circulation Pump PDFDocumento4 páginasReverse Circulation Pump PDFthawdarAinda não há avaliações

- Minute of Meeting 1Documento1 páginaMinute of Meeting 1PanduAinda não há avaliações

- AG-101 Frac Design Proposal V2Documento30 páginasAG-101 Frac Design Proposal V2ayman morsyAinda não há avaliações

- Gas Lift ValvDocumento2 páginasGas Lift ValvMikhaelrams Rams0% (1)

- Compressors OperationDocumento35 páginasCompressors OperationSalim Chohan100% (1)

- 660mw Sop LancoDocumento17 páginas660mw Sop Lancokalyanm203515Ainda não há avaliações

- Agenda: Well Testing Overview Safety & Pom Well Test Types Clean Up Well Test Data Surface Testing EquipmentDocumento23 páginasAgenda: Well Testing Overview Safety & Pom Well Test Types Clean Up Well Test Data Surface Testing EquipmentFarouq EngAinda não há avaliações

- Nitrogen and Accumulator ChargingDocumento3 páginasNitrogen and Accumulator ChargingKarthikeyanAinda não há avaliações

- Functional Specification Export Gas Compressor PDFDocumento7 páginasFunctional Specification Export Gas Compressor PDFdndudcAinda não há avaliações

- Operation Procedures For MDBFPDocumento7 páginasOperation Procedures For MDBFPJackSparrow86100% (1)

- Gas Lift2022 PDFDocumento196 páginasGas Lift2022 PDFkasemelk1990Ainda não há avaliações

- QuestionnaireDocumento4 páginasQuestionnaireQayyum KhanAinda não há avaliações

- Gas Lift ProductionDocumento63 páginasGas Lift Productionashrafsaber100% (1)

- Drying of TransformerDocumento9 páginasDrying of TransformerL P KUSHWAHA100% (7)

- Cold Startup ProcedureDocumento8 páginasCold Startup ProcedureRahul KurmiAinda não há avaliações

- Sample 03.62 Water System Validation - SOPDocumento44 páginasSample 03.62 Water System Validation - SOPKenechukwu Igwagu100% (2)

- L11-Leak Off Test, Kick Tolerance & Kick Circulation MethodsDocumento45 páginasL11-Leak Off Test, Kick Tolerance & Kick Circulation MethodsLaxmi Kant PrasadAinda não há avaliações

- Steam BlowingDocumento17 páginasSteam BlowingDinesh Bhardwaj100% (1)

- Equipment IWCF CourseDocumento42 páginasEquipment IWCF Coursejinyuan7480% (10)

- 02.understanding Process Equipment For Operators & Engineers-50Documento5 páginas02.understanding Process Equipment For Operators & Engineers-50rahulAinda não há avaliações

- Whoc08 202008 307 Pdvsa Paper Pcp's Orinoco BeltDocumento8 páginasWhoc08 202008 307 Pdvsa Paper Pcp's Orinoco BeltNick DonohoeAinda não há avaliações

- SPE-176195-MS Coiled Tubing Gas Lift Design and Troubleshooting - Case HistoryDocumento6 páginasSPE-176195-MS Coiled Tubing Gas Lift Design and Troubleshooting - Case HistoryManuel ChAinda não há avaliações

- Well Test ProcedureDocumento6 páginasWell Test Procedureinyene ekereAinda não há avaliações

- SSA 11 Kes Evoy - Workover Well KillDocumento7 páginasSSA 11 Kes Evoy - Workover Well KillDavide Boreaneze100% (1)

- Principles of Gas LiftDocumento31 páginasPrinciples of Gas LiftAbhi ShettyAinda não há avaliações

- Cementing Thru CT 53244Documento5 páginasCementing Thru CT 53244islam atifAinda não há avaliações

- Gas Lift Presentation #1Documento242 páginasGas Lift Presentation #1Jorge Alberto Quiza Polania100% (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitAinda não há avaliações

- Oil and Gas Artificial Fluid Lifting TechniquesNo EverandOil and Gas Artificial Fluid Lifting TechniquesNota: 5 de 5 estrelas5/5 (1)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGAinda não há avaliações

- Bridging The Industry-Academia Gap and Knowledge Management: Need of HourDocumento6 páginasBridging The Industry-Academia Gap and Knowledge Management: Need of HourmohanadAinda não há avaliações

- 893484Documento45 páginas893484mohanadAinda não há avaliações

- Unu GTP 1995 04Documento24 páginasUnu GTP 1995 04mohanadAinda não há avaliações

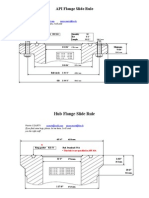

- API Flange Slide Rule: Pierre COURTYDocumento3 páginasAPI Flange Slide Rule: Pierre COURTYmohanadAinda não há avaliações

- Morning & Afternoon Report FromDocumento1 páginaMorning & Afternoon Report FrommohanadAinda não há avaliações

- ISC HydroCom ComparisonDocumento22 páginasISC HydroCom Comparisonrahilshah100Ainda não há avaliações

- Acer AL1516 Service Guide: Downloaded From Manuals Search EngineDocumento48 páginasAcer AL1516 Service Guide: Downloaded From Manuals Search Enginerudra_1Ainda não há avaliações

- 10 kVA - PI044E PDFDocumento9 páginas10 kVA - PI044E PDFYogi PurchasingAinda não há avaliações

- Diagnosis Dan Tatalaksana Pasien Dengan Insufisiensi Akomodasi - Sri Hudaya WidihasthaDocumento13 páginasDiagnosis Dan Tatalaksana Pasien Dengan Insufisiensi Akomodasi - Sri Hudaya WidihasthamalaAinda não há avaliações

- Govt. College of Nusing C.R.P. Line Indore (M.P.) : Subject-Advanced Nursing PracticeDocumento17 páginasGovt. College of Nusing C.R.P. Line Indore (M.P.) : Subject-Advanced Nursing PracticeMamta YadavAinda não há avaliações

- 6 5 Nerves Hormones and HomeostasisDocumento19 páginas6 5 Nerves Hormones and Homeostasisapi-235355872Ainda não há avaliações

- CMC Business PlanDocumento32 páginasCMC Business PlanRobert ShisokaAinda não há avaliações

- The BoarderDocumento3 páginasThe BoarderAnonymous iX6KV9LZzoAinda não há avaliações

- Unit 2 Installation and Configuration of AndroidDocumento23 páginasUnit 2 Installation and Configuration of AndroidAtharv KadamAinda não há avaliações

- 2005 BHS YearbookDocumento82 páginas2005 BHS YearbookDallas County R-I SchoolsAinda não há avaliações

- Cimt in Children WTH CP: Sample Measures/ FindingsDocumento6 páginasCimt in Children WTH CP: Sample Measures/ Findingsapi-253994356Ainda não há avaliações

- Sayre Materia Medica-1Documento108 páginasSayre Materia Medica-1ven_bams584075% (4)

- Data Structures - Python 3.9.6 DocumentationDocumento15 páginasData Structures - Python 3.9.6 DocumentationShahab-ud-din KhanAinda não há avaliações

- Agriculture SectorDocumento66 páginasAgriculture SectorAyesha KhanAinda não há avaliações

- Spare Parts ListDocumento29 páginasSpare Parts ListRonaldAinda não há avaliações

- Systematic Review Dissertation ExamplesDocumento4 páginasSystematic Review Dissertation ExamplesCheapestPaperWritingServiceBaltimore100% (1)

- Doors & People ManualDocumento32 páginasDoors & People ManualOscar Ayala100% (1)

- ThingworxDocumento610 páginasThingworxSiriporn PansriAinda não há avaliações

- Graphics View FrameworkDocumento7 páginasGraphics View FrameworkTxkti BabelAinda não há avaliações

- 2021 Moon Calendar-Cosmic RevolutionDocumento47 páginas2021 Moon Calendar-Cosmic RevolutionYahira NoeliAinda não há avaliações

- UNITRONICS V200-18-E1Documento10 páginasUNITRONICS V200-18-E1eddieipenzaAinda não há avaliações

- Father William - Poem by Lewis CarrollDocumento1 páginaFather William - Poem by Lewis CarrollRachid AfrznaneAinda não há avaliações

- From The Explorer's DaughterDocumento2 páginasFrom The Explorer's DaughterMisho DragnevAinda não há avaliações

- January 15, 1986Documento6 páginasJanuary 15, 1986Accompaniment WorldAinda não há avaliações

- Training Wall Height On Convergent Stepped SpillwaysDocumento10 páginasTraining Wall Height On Convergent Stepped Spillwayschutton681Ainda não há avaliações

- BCM Notes Unit No. IIDocumento14 páginasBCM Notes Unit No. IIMahesh RamtekeAinda não há avaliações

- Nts Tevta Test 22-03-15 Paper BDocumento2 páginasNts Tevta Test 22-03-15 Paper BBeTechieAinda não há avaliações

- Form ICRA HAIs FarmasiDocumento13 páginasForm ICRA HAIs Farmasimarcella budimanAinda não há avaliações

- Ata 21 AirconditionDocumento198 páginasAta 21 Airconditionviney1130Ainda não há avaliações

- Wap-3101 Um V1.0 PDFDocumento34 páginasWap-3101 Um V1.0 PDFhtweakAinda não há avaliações