Escolar Documentos

Profissional Documentos

Cultura Documentos

Automate lab exercises with ASRS and robotic arms

Enviado por

saadbinsadaqat123456Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Automate lab exercises with ASRS and robotic arms

Enviado por

saadbinsadaqat123456Direitos autorais:

Formatos disponíveis

TASK FOR LAB EXERCISE - 1

1. Make a program of ASRS on station 1. Pick the material from rack 37 read bar code and place it on

rack 1.

2. Define the following:

Templates

ASRS robotic arm

Teach pendant

3. Write the procedure of ASRS system.

4. Write advantages and disadvantages of ASRS system.

5. Describe the homing routine of ASRS robotic Arm. Note the order in which the axes moved, fast or

slow dialog boxes and message on the screen.

6. In this activity the program flow changed as a result of an input signal. Describe an industrial

application in which an input signal changes the action in the work-cell.

7.

TASK FOR LAB EXERCISE 2

Q1: Refer to the actual SCORBOT-ER 4u robot. In the figure on the worksheet, mark the

following parts of the robot:

Robot joints: base, shoulder, elbow, wrist pitch, wrist roll

Gripper

Motors and encoders

Q2: What are the three key elements in the definition of a robot?

Q3: To work on station 1, which system and software you will operate?

Q4: What allows a flexible automation system to perform different operations?

Q5: what is difference between station 3 and station 4?

Q6: How many types of robot are using in the CIM lab?

TASK FOR LAB EXERCISE 3

Q 1: What are the four most important components in a robotic system?

Q 2: What allows a flexible automation system to perform different Operations?

Q 3: Describe the homing routine. Note the order in which the axes moved, fast or slow motion,

dialog boxes and messages on the screen?

Q 4: Describe the system response to the encounter between the robot arm and the table?

Q 5: What effect does the Close Gripper command have on the gripper?

Q 6: What kind of objects can the SCORBOT gripper grasp?

Q 7: What is the robot home position and why is it needed?

Q 8: What did you observe? Was it easier to manipulate the robot at a slower or faster speed?

Q 9: Modify the program so that the robot returns the object from the Place position to the Pick

position. Include both programs in the report.

TASK FOR LAB EXERCISE 4

1.

2.

3.

4.

Investigate ALL Milling Machine G and M codes for the controller being used in the Lab

Make a new Program design in Mill CAM Designer Software

Interpret the G&M codes generated by the software

Fill the programming work sheet (sample given below) and write the program manually for the

given profile. (assume suitable values which are not given)

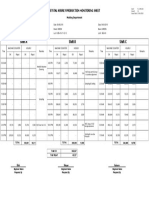

Drg No.

MATERIAL:

PROGRAMMING SHEET

TITLE:

Description

WRITTEN BY

Line

Prep Misc

Number Code Code

N

G

M

Metric

10

Tool Change

20

Rapid Position

30

Axis Coordinates

X

Y

Z

SHEET No.

Feed Spindle

Rate Speed

F

S

OF

Tool

No.

T

21

6

0

1

0.000

Spindle CW

40

Rapid Position

50

Linear Interpolation

60

Linear Interpolation

70

Rapid Position

80

Rapid Position

90

Spindle Off

Program Stop

and Tool Change

100

110

30

0.000 30.000

3500

10.000 70.000

2.000

(1.000)

40.000

300

30.000

0.000

150

0.000

TASK FOR LAB EXERCISE - 5

1. What is difference between CIM Manager and Station manager?

2. CIM uses computers to do which of the three tasks?

3. Discuss whether or not automation increases or reduces human intervention in the manufacturing

process?

4. Can Open CIM perform online tracking of the production process?

5. Once simulation of the production cycle has begun, can it be paused and restarted only once?

6. Which viewing option redefines the center of graphic viewing image?

7. What is difference between

Manufacturing order and Customer order

Real mode and simulation mode

Part and pallet

Você também pode gostar

- Embedded System Design and DevelopmentDocumento6 páginasEmbedded System Design and DevelopmentMukesh BollineniAinda não há avaliações

- Programming A Fanuc Industrial Robot For Incremental Sheet FormingDocumento11 páginasProgramming A Fanuc Industrial Robot For Incremental Sheet Forming501705016Ainda não há avaliações

- Robotics QB1Documento4 páginasRobotics QB1Abhilash NandakumarAinda não há avaliações

- Robotics Lab Report Group 8 PDFDocumento16 páginasRobotics Lab Report Group 8 PDFSourabh AgrawalAinda não há avaliações

- MCU LAB GUIDEDocumento26 páginasMCU LAB GUIDEssmtejani2Ainda não há avaliações

- ABB - Prog - Manual 1.5Documento203 páginasABB - Prog - Manual 1.5Juan Pedro Tobias Vzkz VillanuevaAinda não há avaliações

- Industrial Robot Lab SEODocumento17 páginasIndustrial Robot Lab SEOJesus Said Mercado VegaAinda não há avaliações

- 8051 MICROCONTROLLER LABORATORY MANUALDocumento20 páginas8051 MICROCONTROLLER LABORATORY MANUALjasoneinsteinAinda não há avaliações

- Question BankDocumento5 páginasQuestion BanknrekhaAinda não há avaliações

- Emebbedd Question BankDocumento25 páginasEmebbedd Question Banksujith100% (3)

- Ac 2012-3073: Practical Hands-On Industrial Robotics Lab-Oratory DevelopmentDocumento10 páginasAc 2012-3073: Practical Hands-On Industrial Robotics Lab-Oratory DevelopmentMerced HernandezAinda não há avaliações

- Understanding SCOREBASE Robotics Control SoftwareDocumento34 páginasUnderstanding SCOREBASE Robotics Control SoftwarezxcvbnmAinda não há avaliações

- Laboratorio DroneDocumento7 páginasLaboratorio DroneFernando MontanhaAinda não há avaliações

- Scorbot Er 4uDocumento12 páginasScorbot Er 4uYogeshSinghLatherAinda não há avaliações

- Qps 2Documento3 páginasQps 220EUMT047 NARENDRAN M SAinda não há avaliações

- Fundamentals of Computing and Programming Question BankDocumento12 páginasFundamentals of Computing and Programming Question BankPreethiGajendranAinda não há avaliações

- St.Joseph's College System Software ClassesDocumento10 páginasSt.Joseph's College System Software Classesdupr2002Ainda não há avaliações

- P.M.R Engineering College: Important Two Marks QuestionDocumento6 páginasP.M.R Engineering College: Important Two Marks QuestionShankarAinda não há avaliações

- 8 ES QB - FiNALDocumento5 páginas8 ES QB - FiNALmanoj kumar reddy busireddysAinda não há avaliações

- System Software 2 Mark Questions Unit 1Documento6 páginasSystem Software 2 Mark Questions Unit 1sumathi gnanasekaranAinda não há avaliações

- Exp 1Documento6 páginasExp 1Aryan TiwariAinda não há avaliações

- System Programming and Operating System Question BankDocumento3 páginasSystem Programming and Operating System Question BankAryan Roy (Dishu)Ainda não há avaliações

- Punalkulam: Department of Computer Science and EngineeringDocumento6 páginasPunalkulam: Department of Computer Science and EngineeringPrakash NatarajanAinda não há avaliações

- Assignment 1 C-Prog: Centre For Development of Advanced Computing HyderabadDocumento8 páginasAssignment 1 C-Prog: Centre For Development of Advanced Computing Hyderabadanantla bhargavAinda não há avaliações

- COMPUTER CONCEPTS C PROGRAMMING ASSIGNMENTDocumento5 páginasCOMPUTER CONCEPTS C PROGRAMMING ASSIGNMENTKiran KumarAinda não há avaliações

- ES Question Bank 7CT PDFDocumento7 páginasES Question Bank 7CT PDFvishal sharmaAinda não há avaliações

- Syllabus - Embedded Systems PracticalDocumento4 páginasSyllabus - Embedded Systems PracticalalbertAinda não há avaliações

- Tm446 Acopos Smart Process TechnologyDocumento36 páginasTm446 Acopos Smart Process TechnologyEdward Armijo100% (1)

- Robot Programming: Amirkabir University of Technology Computer Engineering & Information Technology DepartmentDocumento35 páginasRobot Programming: Amirkabir University of Technology Computer Engineering & Information Technology Departmentiliekp8Ainda não há avaliações

- Rapid ProgrammingDocumento18 páginasRapid ProgrammingCarlosAinda não há avaliações

- M.Tech ES ARM LABDocumento14 páginasM.Tech ES ARM LABdownloadscribdpdfAinda não há avaliações

- Active Robot Training ManualDocumento114 páginasActive Robot Training ManualGuillermo Alejandro MontielAinda não há avaliações

- 06025563Documento4 páginas06025563Muhammad AbkaAinda não há avaliações

- 1 To 10Documento10 páginas1 To 10Prabhu DoraiAinda não há avaliações

- Question Bank For Es-1Documento4 páginasQuestion Bank For Es-1AAYUSH RATHODAinda não há avaliações

- Microprocessor Lab ManualDocumento83 páginasMicroprocessor Lab ManualjeetendrasidhiAinda não há avaliações

- Robotics Programming and ApplicationsDocumento38 páginasRobotics Programming and ApplicationsShanti Lal MeenaAinda não há avaliações

- Robotics SeminarDocumento38 páginasRobotics SeminarMohamed AbdirahmanAinda não há avaliações

- ITECOMPSYSL Activity 4 - Character Input and Password Protected ProgramDocumento6 páginasITECOMPSYSL Activity 4 - Character Input and Password Protected ProgramKimCanillasVincereAinda não há avaliações

- Robotic Arm Manipulation - MUGUNTHANDocumento7 páginasRobotic Arm Manipulation - MUGUNTHANMugun ThanAinda não há avaliações

- QB Et7104Documento9 páginasQB Et7104JEEVAAinda não há avaliações

- Book1: o When A Table Is Very Large and You Want To Access The Table by Key OnlyDocumento11 páginasBook1: o When A Table Is Very Large and You Want To Access The Table by Key OnlySAP E-learnAinda não há avaliações

- MVPS's Rajarshi Shahu Maharaj Polytechnic, Nashik: Department of Information TechnologyDocumento20 páginasMVPS's Rajarshi Shahu Maharaj Polytechnic, Nashik: Department of Information TechnologyVaibhav Bhagwat100% (1)

- Testing The PIC Microcontroller 16F84ADocumento4 páginasTesting The PIC Microcontroller 16F84AMatt Imri100% (2)

- People Soft Important Interview QuestionsDocumento6 páginasPeople Soft Important Interview QuestionspeterlaskingAinda não há avaliações

- Lecture 2 - Robot ProgrammingDocumento54 páginasLecture 2 - Robot ProgrammingCamilo HerreraAinda não há avaliações

- Embedded SystemsDocumento3 páginasEmbedded Systems1balamanianAinda não há avaliações

- What Is ROBOLAB? The Concept of Programming and ControlDocumento22 páginasWhat Is ROBOLAB? The Concept of Programming and ControlMonse DclAinda não há avaliações

- CNC Machine Programming CourseDocumento33 páginasCNC Machine Programming CourseHemant MeenaAinda não há avaliações

- Fanuc Training ReportDocumento18 páginasFanuc Training Reportamit100% (3)

- Microprocessors: Familiarization With The Edsim51 Simulator and The 8051 Instruction SetDocumento11 páginasMicroprocessors: Familiarization With The Edsim51 Simulator and The 8051 Instruction SetDioselle CastilloAinda não há avaliações

- Activty 7 and 8Documento11 páginasActivty 7 and 8Je ApigoAinda não há avaliações

- MPMC Lab ManualDocumento97 páginasMPMC Lab ManualDjangoAinda não há avaliações

- 06 Programming in 8085Documento10 páginas06 Programming in 8085Dipak55550% (2)

- Technological Resources HamburgerDocumento43 páginasTechnological Resources HamburgerÉrika Saavedra MonsalveAinda não há avaliações

- CS2304 - SYSTEM SOFTWARE Question BankDocumento7 páginasCS2304 - SYSTEM SOFTWARE Question BankVaishnavi RaghavanAinda não há avaliações

- C Programming for the PIC Microcontroller: Demystify Coding with Embedded ProgrammingNo EverandC Programming for the PIC Microcontroller: Demystify Coding with Embedded ProgrammingAinda não há avaliações

- Intermediate C Programming for the PIC Microcontroller: Simplifying Embedded ProgrammingNo EverandIntermediate C Programming for the PIC Microcontroller: Simplifying Embedded ProgrammingAinda não há avaliações

- SAP interface programming with RFC and VBA: Edit SAP data with MS AccessNo EverandSAP interface programming with RFC and VBA: Edit SAP data with MS AccessAinda não há avaliações

- Saad Bin Sadaqat: ObjectiveDocumento3 páginasSaad Bin Sadaqat: Objectivesaadbinsadaqat123456Ainda não há avaliações

- Netstal Hourly Production Monitoring Sheet 08-08-2018Documento1 páginaNetstal Hourly Production Monitoring Sheet 08-08-2018saadbinsadaqat123456Ainda não há avaliações

- Netstal Hourly Production Monitoring Sheet 09-08-2018Documento1 páginaNetstal Hourly Production Monitoring Sheet 09-08-2018saadbinsadaqat123456Ainda não há avaliações

- Saad Bin Sadaqat ResumeDocumento2 páginasSaad Bin Sadaqat Resumesaadbinsadaqat123456Ainda não há avaliações

- Sadaqat Hussain: Summary of QualificationsDocumento3 páginasSadaqat Hussain: Summary of Qualificationssaadbinsadaqat123456Ainda não há avaliações

- Netstal Hourly Production Monitoring Sheet 08-08-2018Documento1 páginaNetstal Hourly Production Monitoring Sheet 08-08-2018saadbinsadaqat123456Ainda não há avaliações

- Setup Operator ResponsibilitiesDocumento4 páginasSetup Operator Responsibilitiessaadbinsadaqat123456Ainda não há avaliações

- Sameer Bin Sadaqat: About MeDocumento2 páginasSameer Bin Sadaqat: About Mesaadbinsadaqat123456Ainda não há avaliações

- Plastic Injection MoldsDocumento5 páginasPlastic Injection MoldsMue ChAinda não há avaliações

- Chapman, Greg Lr410 3450 Dulong, Jef Kt801 875 Carlson, Ty M645 1200 Keiser, Debra A908 450 Moreland, Barbarapl700 5000Documento1 páginaChapman, Greg Lr410 3450 Dulong, Jef Kt801 875 Carlson, Ty M645 1200 Keiser, Debra A908 450 Moreland, Barbarapl700 5000saadbinsadaqat123456Ainda não há avaliações

- Lakson Group PresentationDocumento32 páginasLakson Group PresentationFasih Ur RehmanAinda não há avaliações

- Lakson Group PresentationDocumento32 páginasLakson Group PresentationFasih Ur RehmanAinda não há avaliações

- Service Record of EngineersDocumento1 páginaService Record of Engineerssaadbinsadaqat123456Ainda não há avaliações

- Linear Programming Sensitivity Analysis: © 2007 Pearson EducationDocumento37 páginasLinear Programming Sensitivity Analysis: © 2007 Pearson Educationhussain.aabid309Ainda não há avaliações

- New Text Docu MentDocumento1 páginaNew Text Docu Mentsaadbinsadaqat123456Ainda não há avaliações

- HEC Form HungaryDocumento6 páginasHEC Form HungaryHasan AhmedAinda não há avaliações

- Policy Quota SeatsDocumento13 páginasPolicy Quota Seatssaadbinsadaqat123456100% (4)

- Sensitivity 2Documento28 páginasSensitivity 2saadbinsadaqat123456Ainda não há avaliações

- Two-Year Diploma Curriculum for Physiotherapy TechniciansDocumento21 páginasTwo-Year Diploma Curriculum for Physiotherapy Technicianssaadbinsadaqat123456Ainda não há avaliações

- Mcdonald'S Operations Management, 10 Decisions, ProductivityDocumento2 páginasMcdonald'S Operations Management, 10 Decisions, Productivitysaadbinsadaqat123456Ainda não há avaliações

- B56Documento3 páginasB56saadbinsadaqat123456Ainda não há avaliações

- Mcdonald'S Operations Management, 10 Decisions, ProductivityDocumento2 páginasMcdonald'S Operations Management, 10 Decisions, Productivitysaadbinsadaqat123456Ainda não há avaliações

- CSC Scholarship ProgramDocumento3 páginasCSC Scholarship Programsaadbinsadaqat123456Ainda não há avaliações

- New Text DoncumentDocumento1 páginaNew Text Doncumentsaadbinsadaqat123456Ainda não há avaliações

- Study Programmes Eligible FinalDocumento943 páginasStudy Programmes Eligible Finalsaadbinsadaqat123456Ainda não há avaliações

- Noori MehfilDocumento2 páginasNoori Mehfilsaadbinsadaqat123456Ainda não há avaliações

- Issb 1Documento7 páginasIssb 1saadbinsadaqat123456Ainda não há avaliações

- New Text DoncumentDocumento1 páginaNew Text Doncumentsaadbinsadaqat123456Ainda não há avaliações

- Issb 1Documento7 páginasIssb 1saadbinsadaqat123456Ainda não há avaliações

- ICT - Minimum Learning Competencies - Grade 9 and 10Documento8 páginasICT - Minimum Learning Competencies - Grade 9 and 10kassahunAinda não há avaliações

- Fuzzy LogicDocumento6 páginasFuzzy Logicl_boy93Ainda não há avaliações

- Join Beldex at The World Blockchain SummitDocumento2 páginasJoin Beldex at The World Blockchain SummitBeldexAinda não há avaliações

- Organizational Maturity LevelsDocumento1 páginaOrganizational Maturity LevelsArmand LiviuAinda não há avaliações

- Definition of operating modes and transmission fault codesDocumento22 páginasDefinition of operating modes and transmission fault codesAhmetAinda não há avaliações

- Pertemuan 9Documento10 páginasPertemuan 9vidiAinda não há avaliações

- Data Extraction From Hand-Filled Form Using Form TemplateDocumento7 páginasData Extraction From Hand-Filled Form Using Form TemplateEditor IJRITCCAinda não há avaliações

- Lecture 5 Principles of Parallel Algorithm DesignDocumento30 páginasLecture 5 Principles of Parallel Algorithm Designnimranoor137Ainda não há avaliações

- Errors While Importing Matplotlib:: General FAQ's of Week-3 (PDS)Documento5 páginasErrors While Importing Matplotlib:: General FAQ's of Week-3 (PDS)Ragunathan SmgAinda não há avaliações

- N4 Xtend Training v3Documento3 páginasN4 Xtend Training v3Talha RiazAinda não há avaliações

- Advantys STB: Analog I/O Modules Reference GuideDocumento438 páginasAdvantys STB: Analog I/O Modules Reference Guidealfaomegalion85Ainda não há avaliações

- DCRS 5960 28F DCDocumento7 páginasDCRS 5960 28F DCPhạm Văn ThuânAinda não há avaliações

- Crisis and Curation: The Rise of Curated Crisis ContentDocumento5 páginasCrisis and Curation: The Rise of Curated Crisis ContentSophia B. LiuAinda não há avaliações

- Data-Driven Insights Leader with 6+ Years ExperienceDocumento3 páginasData-Driven Insights Leader with 6+ Years ExperienceAnil Kumar KAinda não há avaliações

- IN B.E. Degree Electronics & Communication Engineering: Year: I Teaching Schedule Examination Schedule RemarksDocumento161 páginasIN B.E. Degree Electronics & Communication Engineering: Year: I Teaching Schedule Examination Schedule RemarksGorakh Raj JoshiAinda não há avaliações

- CEO/PresidentDocumento2 páginasCEO/PresidentAshwath IrkalAinda não há avaliações

- I Asked ChatGPT To Find Me Free Money - by Paul RoseDocumento25 páginasI Asked ChatGPT To Find Me Free Money - by Paul RoseMario Antonio FioravanteAinda não há avaliações

- 114 CodeInspectorDocumento28 páginas114 CodeInspectorAbhishek KumarAinda não há avaliações

- MSM MBA DMT Individual Assignment September 2021Documento49 páginasMSM MBA DMT Individual Assignment September 2021online storeAinda não há avaliações

- ASTM STP1385 Durability 2000 Accelerated and Outdoor Weathering TestingDocumento186 páginasASTM STP1385 Durability 2000 Accelerated and Outdoor Weathering TestingKYAW SOEAinda não há avaliações

- Hawk Eye TechnologyDocumento14 páginasHawk Eye TechnologyDerrick MillerAinda não há avaliações

- List of AMD Accelerated Processing Units - WikipediaDocumento12 páginasList of AMD Accelerated Processing Units - WikipediaMD Showeb Arif SiddiquieAinda não há avaliações

- Bank of Baroda Annual ReportDocumento244 páginasBank of Baroda Annual Reportshah1703Ainda não há avaliações

- Analyzing The Effects of Social Media On The Hospitality IndustryDocumento21 páginasAnalyzing The Effects of Social Media On The Hospitality IndustryHa Le HiepAinda não há avaliações

- Unit-5 Activity and Multimedia With DatabasesDocumento186 páginasUnit-5 Activity and Multimedia With DatabasesSantosh KaleAinda não há avaliações

- Engineering Economy 7th Edition - Solution Manual (Arrastrado)Documento22 páginasEngineering Economy 7th Edition - Solution Manual (Arrastrado)Martin Gonzalez100% (1)

- 10 eSCO-IoT-ch6-v4Documento32 páginas10 eSCO-IoT-ch6-v4Yahya HajaliAinda não há avaliações

- Slide Bab 7 Proses Desain UI Step 8 9-VREDocumento85 páginasSlide Bab 7 Proses Desain UI Step 8 9-VREM Khoiru WafiqAinda não há avaliações

- Pi-Net Int'l Inc. v. JPMorgan Chase & Co., C.A. No. 12-282-SLR (D. Del. May 14, 2014) .Documento33 páginasPi-Net Int'l Inc. v. JPMorgan Chase & Co., C.A. No. 12-282-SLR (D. Del. May 14, 2014) .YCSTBlogAinda não há avaliações

- Sample User Profile QuestionnaireDocumento6 páginasSample User Profile QuestionnairemuzammilsiddiquiAinda não há avaliações