Escolar Documentos

Profissional Documentos

Cultura Documentos

Thermal Analysis of Electrical Machines Limits and Heat Transfer Principles

Enviado por

Anonymous sAmJfcVDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Thermal Analysis of Electrical Machines Limits and Heat Transfer Principles

Enviado por

Anonymous sAmJfcVDireitos autorais:

Formatos disponíveis

Power Engineering Briefing Note Series

http://www.eleceng.adelaide.edu.au/research/power/pebn/

Thermal Analysis of Electrical Machines :

Limits and Heat Transfer Principles

PEBN #3 (10 May 2008)

W.L. Soong

School of Electrical and Electronic Engineering

University of Adelaide, Australia

soong@ieee.org

Abstract this brief gives an overview of the thermal analysis of

electrical machines. The key thermal limitations in electrical

machines are often winding insulation life and demagnetisation

of the permanent magnets. The three key heat transfer

principles (conduction, convection and radiation) are introduced

drawing largely from Ref [2].

II. HEAT TRANSFER BY CONDUCTION

A. Conduction Principles

In AC electrical machines, heat transfer by conduction is the

main method by which power losses from the conductors are

transferred to the outside of the machine. The heat flux is

given by [2] :

dT

T

=k

W/m 2

k

(1)

dx

t

where dT/dx is the rate of change of temperature with position,

T is the temperature difference across the material, t is the

thickness of the material and k is the thermal conductivity of

material in W/(m.K).

Typical values for the thermal

conductivity of common materials is given in Table 3.

TABLE 3. TYPICAL THERMAL CONDUCTIVITY VALUES [1,4]

I. THERMAL LIMITING FACTORS

Material

air @ 25oC

stator coils (typical)

Nomex slot liner

epoxy (unfilled)

insulation (typ)

epoxy (silica filled)

thermal epoxy

lamination material

steel

copper

A. Winding Insulation

The temperature capability of insulation materials used in

electrical machines is grouped in classes as shown in Table 1.

TABLE 1. COMMON INSULATION CLASSES [1]

Class

Class A

Class B

Class F

Class H

Maximum Operating Temperature

105oC

130oC

155oC

180oC

Thermal Conductivity

0.025 W/(m.K)

0.06 0.09 [3]

0.13

0.19

0.2

0.3

14

20 46

50

385

B. Conduction Analysis Example : Slot Temperature Rise

The insulation on copper windings is very sensitive to over

temperature operation.

The Arrhenius law states that

insulation life expectancy roughly halves for every 10oC rise

in temperature. For example consider a class F insulation

(155oC) with an expected life of 20,000 hrs. If this is operated

at 175oC temperature, which is 20oC above its design value,

then its expected life is one quarter of its design value, that is

5,000 hrs. Note if the material is operated at 135oC, that is

20oC below design value, its expected life will be 80,000 hrs.

What is an acceptable current density J (A/mm2) for

electrical machines? Consider a deep parallel-sided slot as

shown in Fig. 1, so that the heat flow can be assumed to be

one-dimensional in a horizontal direction.

coil

iron

B. Permanent Magnets

heat flux

The magnetic properties of permanent magnets (PM) are

temperature dependent and limit their allowable operating

temperature range.

position

TABLE 2. SINTERED PERMANENT MAGNET PROPERTIES [2]

Property

Curie Temperature

Max. Working Temp.

Temp. Co-efficient of

BR

Ferrite

450oC

250oC

-0.2%/oC

NdFeB

310-350oC

80-200oC

-0.08%/oC to

-0.15%/oC

SmCo

700-800oC

250-350oC

-0.045%/oC to

-0.08%/oC

temp rise

-wS/2

The Curie temperature is the temperature at which the PM

irreversibly loses magnetization and represents the ultimate

temperature limit. A more practical limit is the maximum

working temperature shown.

The remanent flux density BR for PM materials falls as the

temperature increases. This means that for PM machines

designed for high temperature operation, there can be a

significant difference between the back-emf at room

temperature and operating temperature. This decrease in the

remanent flux density also makes the machine more prone to

demagnetisation when high stator winding currents are present

and so this needs to be checked at the maximum expected

operating temperature.

pebn rv1.2.doc

position

0

wS/2

Fig. 1. Simplified thermal analysis of heat conduction through a deep,

parallel-sided slot showing the parabolic temperature distribution.

The heat flux increases linearly with the distance from the

centre of the slot. This results in a parabolic temperature

distribution with a peak value :

Tm =

pf J 2 ws2

8k

(2)

where :

pf : fraction of slot area which is copper (typically 30%)

: resistivity of conductor, for instance 2.36 10-8 .m at

120oC for copper

Page 19

24-Jul-08

Power Engineering Briefing Note Series

http://www.eleceng.adelaide.edu.au/research/power/pebn/

Allowable Current Density J [A/mm2]

J : is the current density in A/m2

k : thermal conductivity of the composite of the conductor,

air, insulation and varnish in the slot;

wS : is the width of the slot

Fig. 2 assumes a slot conductivity of 0.075 W/(mK) which

is typical for commercial induction machines [3]. The

allowable current density falls inversely with coil width. For

wide slots the allowable current density is very low. Hence

for large machines (e.g. power station generators) it is

necessary to pass coolant directly through the conductors to

achieve reasonable values of current density.

16

Assumptions

k = 0.075 W/(mK)

pf = 0.3

T = 75degC

= 2.36e-8 m (120degC)

no slot liner

14

12

10

values are about five times the natural convection co-efficient.

It can be roughly estimated as [2] :

h 3.95

The heat flux associated with electromagnetic radiation is

given by [2] :

= Th4 Ta4

4

2

0

10

15

20

25

30

35

Coil Width [mm]

Fig. 2. Maximum allowable conductor current density as a function of coil

width for a typical range of assumptions listed in the figure.

(6)

A. Natural Convection

The heat transfer co-efficient for natural convection around

an un-finned cylindrical motor of diameter D which is

mounted horizontally is approximately given by [2] :

0.25

T

(4)

h 1.324

W/m 2 /K

For instance for a 0.1 m diameter motor with a temperature

rise of 40oC, then h 5.9 W/m2/K and so from (3) the heat

flux is = 237 W/m2.

Ref. [5] gives typical values of heat transfer co-efficient for

natural convection as 2 25 W/m2/K for gases and 50 1000

W/m2/K for liquids.

which is comparable to that obtained by natural convection.

V. ROUGH RULES OF THUMB

(3)

where T is the difference in temperature between the cooling

medium and the hot surface and h is the heat transfer coefficient which depends on the properties of the fluid and its

velocity. There are two types of convection : natural

convection where fluid circulation is purely due to natural

movement of the fluid associated with thermal gradients while

forced convection is where the fluid circulation is driven by an

external fan, blower or pump.

Ref. [2] gives some rough rules of thumb as follows for the

maximum heat flux obtainable with a 40oC rise as roughly :

800 W/m2 for natural convection and radiation;

3,000 W/m2 for forced convection;

6,000 W/m2 for direct liquid cooling.

VI. REFERENCES

[1] E.S. Hamdi, Design of Small Electrical Machines, Wiley, 1994.

[2] J.R. Hendershot and T.J.E. Miller, Design of Brushless PermanentMagnet Motors, Magna Physics Publishing and Clarendon Press, 1994.

[3] D. Staton, A. Boglietti and A. Cavagnino, Solving the More Difficult

Aspects of Electric Motor Thermal Analysis in Small and Medium Size

Industrial Induction Motors, IEEE Transaction on Energy Conversion,

Vol. 20, Issue 3, Sept. 2005, pp. 620 628.

[4] http://en.wikipedia.org/wiki/Thermal_conductivity (accessed 10 May,

2008)

[5] F.P. Incropera and D.P. DeWitt, Introduction to Heat Transfer, Wiley,

1990.

B. Forced Convection

Blowing air over the motor increases the heat transfer coefficient by the square root of the air velocity and typical

pebn rv1.2.doc

W/m 2

= 0.9 5.67 108 [ 60 + 273] [ 20 + 273] = 251 W/m 2

The heat transfer by convection is given by Newtons Law of

Cooling [2] :

W/m 2

is emissivity (1 for an ideal black body), a value of 0.9 is

more reasonable for a black-painted surface

= Stefan-Boltzmanns constant 5.67 x 10-8 W/(m2K4)

Th = temperature of hot object (K)

Ta = temperature of surroundings (K)

For example consider a temperature rise of 40oC above an

ambient of 20oC and a 0.9 value for emissivity, then the heat

flux is :

III. CONVECTION

= h T

(5)

IV. RADIATION

W/m 2 /K

For instance for an air velocity of 4 m/s blowing over a motor

which is 0.1 m long (5) gives a value of h 25 W/m2/K which

is roughly four times that for natural convection. For a 40oC

temperature difference this gives a heat flux of = 1000

W/m2.

Ref. [5] gives typical values of heat transfer co-efficient for

forced convection as 25 250 W/m2/K for gases and 50

20,000 W/m2/K for liquids.

v

L

Page 20

A WORD FOR TODAY

These are the words of the Amen, the faithful and true

witness, the ruler of God's creation. I know your deeds,

that you are neither cold nor hot. I wish you were either

one or the other! So, because you are lukewarmneither

hot nor coldI am about to spit you out of my mouth.

Revelation 3:14-16 (NIV)

24-Jul-08

Você também pode gostar

- Auto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenNo EverandAuto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenNota: 4 de 5 estrelas4/5 (2)

- Saturation Effects On Unbalanced Magnetic Pull in A Hydroelectric Generator With An Eccentric RotorDocumento7 páginasSaturation Effects On Unbalanced Magnetic Pull in A Hydroelectric Generator With An Eccentric RotorlAinda não há avaliações

- Damper Winding Influence On UMPDocumento8 páginasDamper Winding Influence On UMPSrinivas KamarsuAinda não há avaliações

- Binary Polar Liquids: Structural and Dynamic Characterization Using Spectroscopic MethodsNo EverandBinary Polar Liquids: Structural and Dynamic Characterization Using Spectroscopic MethodsNota: 5 de 5 estrelas5/5 (1)

- DC Motor PrimerDocumento26 páginasDC Motor PrimerastroltravlerAinda não há avaliações

- Application of Flexible AC Transmission System Devices in Wind Energy Conversion SystemsNo EverandApplication of Flexible AC Transmission System Devices in Wind Energy Conversion SystemsAinda não há avaliações

- End Winding Vibration Hydro GeneratorDocumento5 páginasEnd Winding Vibration Hydro Generatorpatel chandramaniAinda não há avaliações

- Guide For The Selection and Application of Energy-Efficient Motors PDFDocumento10 páginasGuide For The Selection and Application of Energy-Efficient Motors PDFEliseu RibeiroAinda não há avaliações

- 12 - 2006 PorofabDocumento16 páginas12 - 2006 PorofabsalekojicAinda não há avaliações

- The Corona Effect On High Voltage Transmission LinesDocumento4 páginasThe Corona Effect On High Voltage Transmission LinesOttoAinda não há avaliações

- Tavner PeterDocumento303 páginasTavner PeterManigandanAinda não há avaliações

- Calculation: Mutual of Circular Filaments DesiredDocumento10 páginasCalculation: Mutual of Circular Filaments DesiredJelena Blagojevic-IgnjatovicAinda não há avaliações

- The Knee Point Here Gives The Rated SpeedDocumento2 páginasThe Knee Point Here Gives The Rated SpeedtankimsinAinda não há avaliações

- Trends in Insulation Systems For Generator Hv-WindingsDocumento4 páginasTrends in Insulation Systems For Generator Hv-WindingsMaswady Bin MaskinAinda não há avaliações

- A New Ieee Standard For Voltage Endurance Testing of Hydro Generator Stator CoilsDocumento4 páginasA New Ieee Standard For Voltage Endurance Testing of Hydro Generator Stator Coilsapi-3804964100% (1)

- Calculation of Cogging TorqueDocumento4 páginasCalculation of Cogging TorqueMehdi SepehriAinda não há avaliações

- Determining The Efficiency of Induction Machines, Converters and SoftstartersDocumento8 páginasDetermining The Efficiency of Induction Machines, Converters and Softstarterssadeq03Ainda não há avaliações

- THYRIPOL Operating InstructionsDocumento310 páginasTHYRIPOL Operating InstructionsCristian VillalbaAinda não há avaliações

- GVPI Assessment-EASA 2014 v2Documento7 páginasGVPI Assessment-EASA 2014 v2mersiumAinda não há avaliações

- Comparison of The Response of Doubly Fed and Fixed-Speed Induction Generator Wind Turbines To Changes in Network FrequencyDocumento3 páginasComparison of The Response of Doubly Fed and Fixed-Speed Induction Generator Wind Turbines To Changes in Network Frequencyalaaa3Ainda não há avaliações

- EL CID BrochureDocumento4 páginasEL CID BrochureeesacAinda não há avaliações

- Insulation System Comparison VPI Versus Resin RichDocumento9 páginasInsulation System Comparison VPI Versus Resin Richrifal1990Ainda não há avaliações

- Examples of Stator Winding Partial Dishcarge Due To Inverter DrivesDocumento4 páginasExamples of Stator Winding Partial Dishcarge Due To Inverter DrivesyogaAinda não há avaliações

- Diagnostic Insulation TestingDocumento5 páginasDiagnostic Insulation TestingkarthikumarAinda não há avaliações

- Wound Rotor Motor TestingDocumento5 páginasWound Rotor Motor Testingbige1911Ainda não há avaliações

- Analysis of Electrical MachineryDocumento66 páginasAnalysis of Electrical Machineryzabig100% (1)

- Compatibility Design of Non Salient Pole Synchronous GeneratorDocumento4 páginasCompatibility Design of Non Salient Pole Synchronous GeneratorEditor IJTSRDAinda não há avaliações

- IEEE Guide For Construction and Interpretation of Thermal Limit Curves For Squirrel-Cage MotorsDocumento5 páginasIEEE Guide For Construction and Interpretation of Thermal Limit Curves For Squirrel-Cage MotorsRaimundo LimaAinda não há avaliações

- Dynamic Modeling of PMSMDocumento10 páginasDynamic Modeling of PMSMHisham Magdi El DeebAinda não há avaliações

- Anti CoronaDocumento2 páginasAnti CoronamersiumAinda não há avaliações

- Current Harmonic Analysis of Multi Pulse Diode Rectifiers With Phase Shifting TransformerDocumento5 páginasCurrent Harmonic Analysis of Multi Pulse Diode Rectifiers With Phase Shifting TransformerJakka VenkatAinda não há avaliações

- Vdocument - in Generator Maintenance Frame 6 Users Groupframe 6 Users Grouporgwp Contentuploads2018096bDocumento27 páginasVdocument - in Generator Maintenance Frame 6 Users Groupframe 6 Users Grouporgwp Contentuploads2018096bMahesh MishraAinda não há avaliações

- Martzloff F.D.the Protection of Industrial Electronics and Power Conversion Equipment Against Power Supply and Data Line DisturbancesDocumento14 páginasMartzloff F.D.the Protection of Industrial Electronics and Power Conversion Equipment Against Power Supply and Data Line DisturbancesTheodore KyriakopoulosAinda não há avaliações

- Itmf 2013 11 Sperling EnuDocumento5 páginasItmf 2013 11 Sperling EnubcqbaoAinda não há avaliações

- Electrical SteelDocumento193 páginasElectrical SteelpavanupadhyeAinda não há avaliações

- Asynchronous MachinesDocumento34 páginasAsynchronous MachinesAndi FalihAinda não há avaliações

- El-CID Testing PDFDocumento16 páginasEl-CID Testing PDFA.YOGAGURUAinda não há avaliações

- WEG Winding Damages Single Phase Motors 50041274 Brochure English WebDocumento1 páginaWEG Winding Damages Single Phase Motors 50041274 Brochure English WebalejoAinda não há avaliações

- Design of Electrical Apparatus: A Course Material OnDocumento144 páginasDesign of Electrical Apparatus: A Course Material OnBARANIDHARAN TAinda não há avaliações

- Rotary-Linear Machines - A SurveyDocumento4 páginasRotary-Linear Machines - A Surveyarnika33Ainda não há avaliações

- Basics of Electrical Machine DesignDocumento7 páginasBasics of Electrical Machine DesignvirenpandyaAinda não há avaliações

- MV Circuit-Breakers Fluarc For Switching MotorDocumento20 páginasMV Circuit-Breakers Fluarc For Switching MotorarieberdikarieAinda não há avaliações

- Mit PDFDocumento143 páginasMit PDFLuciano EncisoAinda não há avaliações

- Z Z Z Z: General RemarksDocumento11 páginasZ Z Z Z: General Remarksadi nu100% (1)

- AC To DC Power Conversion IEEEDocumento40 páginasAC To DC Power Conversion IEEEvthiyagainAinda não há avaliações

- DC Power Circuit Breaker BasicsDocumento9 páginasDC Power Circuit Breaker Basics曾乙申Ainda não há avaliações

- On Induction RegulatorDocumento19 páginasOn Induction RegulatorGyanchand SinghAinda não há avaliações

- Design of Saturable Reactors 31295000058858Documento112 páginasDesign of Saturable Reactors 31295000058858aj7scribd100% (1)

- 02 DT - New IEC StandardDocumento2 páginas02 DT - New IEC StandardkfaliAinda não há avaliações

- Motor WindingsDocumento12 páginasMotor WindingsAbiodun IloriAinda não há avaliações

- VSC For HVDC ConnectionsDocumento13 páginasVSC For HVDC ConnectionsRavi TejaAinda não há avaliações

- Differences Between Low Voltage DobleDocumento11 páginasDifferences Between Low Voltage DobleFelipe Andres100% (1)

- Brushless ExciterDocumento7 páginasBrushless ExcitervgarudaAinda não há avaliações

- Micadur Compact Industry Insulation System For RotatingDocumento8 páginasMicadur Compact Industry Insulation System For Rotatingreygrant3900100% (2)

- Water Cooled Axial Flux Motor High TorqueDocumento7 páginasWater Cooled Axial Flux Motor High TorqueSteven SullivanAinda não há avaliações

- Microgrids Black StartDocumento7 páginasMicrogrids Black StartLalit ChoudharyAinda não há avaliações

- Transformer and Inductor Design Handbook Chapter 19Documento10 páginasTransformer and Inductor Design Handbook Chapter 19Brijendra VermaAinda não há avaliações

- E1 27Documento11 páginasE1 27Neel GalaAinda não há avaliações

- Transformer and Inductor Design Exercises by Bill RobbinsDocumento9 páginasTransformer and Inductor Design Exercises by Bill RobbinsMajor PrinceAinda não há avaliações

- Commandbutton1 Commandbutton2: Shaft 2 Dia 0.5 Bevel 2 Dia 2Documento1 páginaCommandbutton1 Commandbutton2: Shaft 2 Dia 0.5 Bevel 2 Dia 2Anonymous sAmJfcVAinda não há avaliações

- Icepak-Intro 14.5 L01 Agenda and ANSYS Intro PDFDocumento11 páginasIcepak-Intro 14.5 L01 Agenda and ANSYS Intro PDFAnonymous sAmJfcVAinda não há avaliações

- 02 2 Maxwell Eddy CurrentDocumento12 páginas02 2 Maxwell Eddy CurrentAnonymous sAmJfcVAinda não há avaliações

- Models - Mph.heat Transient AxiDocumento6 páginasModels - Mph.heat Transient AxiAnonymous sAmJfcVAinda não há avaliações

- Distribution TransformerDocumento17 páginasDistribution TransformerveerendraprasadAinda não há avaliações

- Solidworks Api Demystified: Who Am I?Documento8 páginasSolidworks Api Demystified: Who Am I?Anonymous sAmJfcVAinda não há avaliações

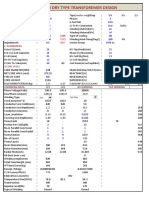

- Guaranteed Technical Particulars: 1. SpecificationsDocumento2 páginasGuaranteed Technical Particulars: 1. SpecificationsAnonymous sAmJfcVAinda não há avaliações

- Models - Heat.electronic Enclosure CoolingDocumento20 páginasModels - Heat.electronic Enclosure CoolingAnonymous sAmJfcVAinda não há avaliações

- Distribution TransformerDocumento17 páginasDistribution TransformerveerendraprasadAinda não há avaliações

- Calculating Core TemperatureDocumento6 páginasCalculating Core TemperatureAnonymous sAmJfcVAinda não há avaliações

- 800kva Cast Dry TransformerDocumento1 página800kva Cast Dry TransformerAnonymous sAmJfcV100% (1)

- Furnace & Rectifier TransformersDocumento3 páginasFurnace & Rectifier Transformersjoydeep_d3232Ainda não há avaliações

- SolidWorks API Series 1 - Programming & Automation PDFDocumento268 páginasSolidWorks API Series 1 - Programming & Automation PDFAnonymous sAmJfcV86% (7)

- Haritha ThesisDocumento105 páginasHaritha ThesisAnonymous sAmJfcVAinda não há avaliações

- 5cast Resin Dry-Type TransformerDocumento2 páginas5cast Resin Dry-Type TransformerAnonymous sAmJfcVAinda não há avaliações

- Siemens MS2014Documento4 páginasSiemens MS2014Carlos TuestaAinda não há avaliações

- SolidWorks Simulation Black BookDocumento40 páginasSolidWorks Simulation Black BookAnonymous sAmJfcV50% (6)

- 800kva Cast Dry TransformerDocumento1 página800kva Cast Dry TransformerAnonymous sAmJfcV100% (1)

- Pierce 1991Documento7 páginasPierce 1991Anonymous sAmJfcVAinda não há avaliações

- Models - Acdc.ecore TransformerDocumento34 páginasModels - Acdc.ecore TransformerAnonymous sAmJfcVAinda não há avaliações

- Convection Heat Transfer CoefficientDocumento9 páginasConvection Heat Transfer CoefficientAnonymous sAmJfcVAinda não há avaliações

- Halac Sy 1958Documento5 páginasHalac Sy 1958Anonymous sAmJfcVAinda não há avaliações

- Transformer Design and Optimization - A Literature SurveyDocumento26 páginasTransformer Design and Optimization - A Literature Surveykrmurali2000Ainda não há avaliações

- Steady State Temperature Distribution of Cast Resin Dry Type Transformer Based On New Thermal Model Using Finite Element MethodDocumento5 páginasSteady State Temperature Distribution of Cast Resin Dry Type Transformer Based On New Thermal Model Using Finite Element MethodAnonymous sAmJfcVAinda não há avaliações

- Technical Specifcation of Electrical MaterialsDocumento53 páginasTechnical Specifcation of Electrical MaterialsAnonymous sAmJfcVAinda não há avaliações

- Transformer Dry Type Handbook1Documento73 páginasTransformer Dry Type Handbook1Anonymous sAmJfcVAinda não há avaliações

- OMTDocumento19 páginasOMTjamos200Ainda não há avaliações

- Lay Ministers Grid 110406 - TEAC GRIDDocumento5 páginasLay Ministers Grid 110406 - TEAC GRIDosbertodiazAinda não há avaliações

- Roots Words of The EnglishDocumento2 páginasRoots Words of The EnglishBhagesh Bhosle KhorjuvekarAinda não há avaliações

- Secrets of Surat Al KahfDocumento14 páginasSecrets of Surat Al Kahfbintang_82825555100% (1)

- 'My Controversial Client' (Johan Peters)Documento97 páginas'My Controversial Client' (Johan Peters)Johan PetersAinda não há avaliações

- Atc PDFDocumento41 páginasAtc PDFAntony JebarajAinda não há avaliações

- Championing Intellectual Pluralism: EditorialDocumento8 páginasChampioning Intellectual Pluralism: EditorialFabian QuincheAinda não há avaliações

- Novena Prayer To The Sacred Heart of JesusDocumento1 páginaNovena Prayer To The Sacred Heart of Jesusjezreel mae100% (3)

- The Rescue FindingsDocumento8 páginasThe Rescue FindingsBini Tugma Bini Tugma100% (1)

- God's Not DeadDocumento1 páginaGod's Not DeadLyda Sandstede100% (1)

- Family Wisdom by Robin SharmaDocumento2 páginasFamily Wisdom by Robin Sharmaritam chakrabortyAinda não há avaliações

- Critical Journal Review: Bilingual Physic Education 2017Documento6 páginasCritical Journal Review: Bilingual Physic Education 2017febry sihiteAinda não há avaliações

- Resume SyntaxDocumento8 páginasResume SyntaxKhorinAinda não há avaliações

- No StoneDocumento15 páginasNo StoneRachel EscrupoloAinda não há avaliações

- The Essence of Critical Thinking.Documento2 páginasThe Essence of Critical Thinking.juanobandoAinda não há avaliações

- An Irish Solution To An Irish Problem by DR Shane Butler (Dept of Sociology, TCD)Documento8 páginasAn Irish Solution To An Irish Problem by DR Shane Butler (Dept of Sociology, TCD)David LeeAinda não há avaliações

- FascismDocumento71 páginasFascismNitin JainAinda não há avaliações

- Hatsumi InterviewDocumento2 páginasHatsumi Interviewkosh30700Ainda não há avaliações

- Patricia Benner TFNDocumento14 páginasPatricia Benner TFNMenly BalofinosAinda não há avaliações

- Becoming An Adaptive Leader PDFDocumento8 páginasBecoming An Adaptive Leader PDFPau Sian LianAinda não há avaliações

- The Zero Point Energy of The Quantum-VacuumDocumento5 páginasThe Zero Point Energy of The Quantum-VacuumBob HwknsAinda não há avaliações

- 14 Days Prayer For Total HealingDocumento137 páginas14 Days Prayer For Total Healingnkugwa6brian80% (5)

- Programme-Academic and SocialDocumento20 páginasProgramme-Academic and SocialMartín GonzálezAinda não há avaliações

- Rhetorical AnalysisDocumento4 páginasRhetorical Analysisapi-302414270Ainda não há avaliações

- Empathy: Rumbling With VulnerabilityDocumento4 páginasEmpathy: Rumbling With VulnerabilityClaire TsaoAinda não há avaliações

- 21 Jusmag v. NLRCDocumento2 páginas21 Jusmag v. NLRCRem Serrano83% (6)

- Sue Vice - Introducing Bakhtin-Manchester University Press (1998)Documento264 páginasSue Vice - Introducing Bakhtin-Manchester University Press (1998)Sümeyra HamaratAinda não há avaliações

- Silverman, Isbell - Andean Archaeology II - Art, Landscape, and Society-Springer US (2002)Documento294 páginasSilverman, Isbell - Andean Archaeology II - Art, Landscape, and Society-Springer US (2002)foxtrout100% (1)

- (BW) Change Management 100 Success Secrets - The Complete Guide To Process, Tools, Software and Training in Organizational Change ManagementDocumento170 páginas(BW) Change Management 100 Success Secrets - The Complete Guide To Process, Tools, Software and Training in Organizational Change Managementnmohammadi100% (5)

- Thesis - Exergy - A Useful ConceptDocumento377 páginasThesis - Exergy - A Useful Conceptdanpopescu4u100% (1)