Escolar Documentos

Profissional Documentos

Cultura Documentos

27-28 - PI Essay 1 PDF

Enviado por

yoursasim0 notas0% acharam este documento útil (0 voto)

24 visualizações2 páginasFPSO refers to a "Floating Production Storage and Offloading" vessel. Front End Engineering Design (FEED) is the project phase that follows upon completion of the conceptual design stage. Typical duration for executing a FEED Project is about six months to one year.

Descrição original:

Título original

27-28_PI Essay 1.pdf

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoFPSO refers to a "Floating Production Storage and Offloading" vessel. Front End Engineering Design (FEED) is the project phase that follows upon completion of the conceptual design stage. Typical duration for executing a FEED Project is about six months to one year.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

24 visualizações2 páginas27-28 - PI Essay 1 PDF

Enviado por

yoursasimFPSO refers to a "Floating Production Storage and Offloading" vessel. Front End Engineering Design (FEED) is the project phase that follows upon completion of the conceptual design stage. Typical duration for executing a FEED Project is about six months to one year.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 2

PROFESSIONAL INTERVIEW ESSAY

Process Engineer on a FEED

Project to Build an FPSO

for an Offshore Oil Field

by Ir. Mohd. Noor bin Abdullah

QUESTIONS:

(a) Describe your work as the process engineer on a FEED project to build the FPSO to operate at an offshore oil field off the

coast of Sarawak.

(b) Describe the work sequences and what time duration, additional expertise and experience as you would need on each

work from beginning to end of your involvement as the process engineer.

(c) Show the work inter-phases with other disciplines and the deliverables of your work.

Editors Note: FPSO refers to a Floating Production Storage

and Offloading vessel.

front End Engineering Design (FEED) is the project

phase that follows upon completion of the conceptual design

stage. In most cases, conceptual design starts with several

options and finishes with one final solution which serves

as the base case. The time duration for executing a FEED

project depends on the size and complexity of the FPSO

with consideration for the type of processing unit (e.g. gas

processing or oil processing, amount of oil, gas and water,

etc.). The typical duration is about six months to one year.

During the early stages of the project, as a process

engineer, I shall review all contractual documents

especially documents related to process engineering

requirement. Conceptual documents are normally given

by the Client to the design contractor (i.e. Consultant) for

review. The key documents to review include design basis

memorandum (DBM), philosophies, process flow diagram

(PFD) and specifications. The production profile of the oil

field will be given by the Client together with the composition

of the reservoir data.

Based on the key documents provided by the Client, as

a process engineer, I shall prepare a document called the

Process and Utility Design Basis (PUDB). The latter will

then be submitted to the Client for approval. The PUDB is

important as it ensures mutual agreement between a Client

and a Consultant and serves as the basis by which the

FPSO process design will be carried out. Next, simulation

runs shall be carried out to determine the sizing cases of the

system, equipment as well as process piping. In short, the

simulation output will be used as input in sizing calculations

as well as material selection study.

In order to ensure that all process deliverables are of

good quality before submission to the Client, they have

to be issued internally to other disciplines for checking.

During this stage, interfacing and coordination work with

other disciplines shall also be practiced. For example, the

Piping Department needs to be informed about sloping

requirement, straight length requirement, and the vessel

elevation to ensure that sufficient net positive suction head

is available (NPSHa) from the pumping system. For the

Electrical Department, the process engineer will provide

input to the electrical power load list by estimating the power

requirement of the equipment (typically absorbed power).

The typical Process engineering discipline deliverables are

as follows:

Process and Utility Design Basis

Equipment and Line Sizing Philosophy

Isolation and Valving Philosophy

Shutdown and Utility Design Basis

Safeguarding and Protection Philosophy

Process Flow Diagram (PFD)

Process Simulation Report

Heat and Material Balance (HMB)

Piping and Instrumentation Diagram (P&ID)

Equipment Datasheets

Instrument Specification/Datasheet (i.e. process data)

SAFE chart

Cause and Effect Matrices

Relief and Blowdown Report, etc.

After Inter-Discipline Check (IDC) issuance of the process

discipline deliverables, all comments from the other disciplines

(Piping, Mechanical, Electrical, Structural, Technical Safety)

shall be reviewed and incorporated accordingly.

Most Consultants do not have in-house expertise on

Material Selection and Corrosion Analysis. Normally, a third

party (i.e. a material specialist company) will be engaged to

ensure that suitable material selection for corrosion analysis

is incorporated in the design of a FPSO processing facility.

For the third party to carry out their work, they will require

at least PFD and HMB data along with stream compositions

(especially CO2, H2S and H2O data).

Similarly, for the hull design of the FPSO, if the design

contractor does not have its own internal specialist, the task

will be outsourced to a specialist third party. All the third party

works and deliverables shall be monitored and reviewed by

the design contractor. The third party is considered part of

the project team.

June 2012 JURUTERA |

27

PROFESSIONAL INTERVIEW ESSAY

LOW HEAT

After the IDC stage, the next milestone is Issued For

Review (IFR) where the deliverables will be submitted to

the Client for review. There will be no fabrication contractor

involvement during the FEED stage.

Upon the approval of IFR issuance, the next milestone

is Issued For HAZOP (IFH) where the deliverables are

prepared for HAZOP (Hazard and Operability Study).

HAZOP shall be conducted by an independent third party.

Here, all hazards, operational and design issues will be

analysed and discussed. After the HAZOP exercise is

completed, all the resulting recommendations shall be

reviewed and closed out. A HAZOP closed-out report will

be prepared and submitted to the Client and the third party

that conducted the HAZOP.

The process engineer shall also provide input to the other

disciplines through Piping and Instrumentation Diagrams

(P&IDs) and process datasheets as well as resolve queries

from the other disciplines including the Client and the third

party. The process engineer shall also attend the PDMS

review to ensure that the piping and layout design, such as

the pipe routing and equipment elevation, are according to

specifications.

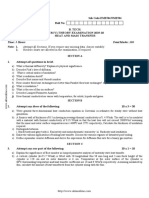

INTER-DISCIPLINE CHECK

(IDC)

1 2 MONTHS

ISSUED FOR REVIEW

(IFR)

1 2 MONTHS

ISSUED FOR HAZOP

(IFH)

1 2 MONTHS

ISSUED FOR DESIGN

(IFD)

2 3 MONTHS

Figure 1: Work flow of deliverables

Ultra Series Low Heat is specially developed to

reduce peak temperature in mass concreting as

compared to conventional concrete using Ordinary

Portland Cement.

Ultra Series Low Heat is effective to resist

chloride and sulphate attack for marine situations

and to improve overall concrete durability.

LAFARGE CONCRETE (MALAYSIA) SDN BHD (95483-H)

2, Jalan Kilang, 46050 Petaling Jaya,

Selangor Darul Ehsan, Malaysia.

Tel : (603) 7787 2000

Fax : (603) 7781 7675 / 7787 2129

www.lafarge.com.my

28

| JURUTERA June 2012

Every project will have a quality audit. The process

engineer has to ensure that all documentation is in

compliance with the company and the projects quality

standards. The process engineer also has to ensure that the

workflow and work instructions have been complied with.

Apart from the technical activities, the process engineer

also has to work with or support the project management

team (PMT). The process engineer shall attend weekly

progress meetings to keep up to date with the status of the

project (i.e. target deliverables submission date, planned

activities for the week and the following week, and other

areas of concern) as well as keep tabs on the projects

development as a whole.

To summarise, the work sequence is shown in Figure 1.

The final stage of the FEED project is when all deliverables

are issued for design (IFD). In order to achieve this stage,

all comments from the Client and other disciplines as well

as HAZOP recommendations shall be incorporated.

Você também pode gostar

- Guidelines Project ScheduleDocumento7 páginasGuidelines Project ScheduleyoursasimAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Introduction To Project Control 1 PDFDocumento14 páginasIntroduction To Project Control 1 PDFyoursasimAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- Resource Progress Curves in Primavera P6Documento7 páginasResource Progress Curves in Primavera P6yoursasimAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- 1-Integration PMP SmartnotesDocumento22 páginas1-Integration PMP Smartnotesmagdi badranAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Track Earned ValueDocumento20 páginasTrack Earned Valueyoursasim100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Sup Mat 01Documento3 páginasSup Mat 01yoursasimAinda não há avaliações

- Minuto hd8761Documento64 páginasMinuto hd8761Eugen Vicentiu StricatuAinda não há avaliações

- Eps 400 New Notes Dec 15-1Documento47 páginasEps 400 New Notes Dec 15-1BRIAN MWANGIAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Solution Manual For Understanding Business 12th Edition William Nickels James Mchugh Susan MchughDocumento36 páginasSolution Manual For Understanding Business 12th Edition William Nickels James Mchugh Susan Mchughquoterfurnace.1ots6r100% (51)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Mutant Epoch Mature Adult Content Mutations v1Documento4 páginasThe Mutant Epoch Mature Adult Content Mutations v1Joshua GibsonAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Apc 10kva Ups ManualDocumento36 páginasApc 10kva Ups Manualraj rajAinda não há avaliações

- Prince Ryan B. Camarino Introduction To Philosophy of The Human PersonDocumento2 páginasPrince Ryan B. Camarino Introduction To Philosophy of The Human PersonKyle Aureo Andagan RamisoAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Compuware DCRUM Intro 2012 Version 12.00Documento142 páginasCompuware DCRUM Intro 2012 Version 12.00JanAinda não há avaliações

- FinancialAccountingTally PDFDocumento1 páginaFinancialAccountingTally PDFGurjot Singh RihalAinda não há avaliações

- Watt AC-DC Converters: FeaturesDocumento3 páginasWatt AC-DC Converters: FeatureskofidAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Boomer L2 D - 9851 2586 01Documento4 páginasBoomer L2 D - 9851 2586 01Pablo Luis Pérez PostigoAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Bilge Günsel TEL531E Detection and Estimation Theory W #1-2Documento25 páginasBilge Günsel TEL531E Detection and Estimation Theory W #1-2ahmetAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- MHD Exam 6 MaterialDocumento179 páginasMHD Exam 6 Materialnaexuis5467100% (1)

- Btech Me 5 Sem Heat and Mass Transfer Eme504 2020Documento2 páginasBtech Me 5 Sem Heat and Mass Transfer Eme504 2020SuryaAinda não há avaliações

- Characteristics of Victorian BritainDocumento3 páginasCharacteristics of Victorian BritainmwaqasenggAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Memo For Completed RubricDocumento3 páginasMemo For Completed Rubricnisev2003Ainda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1091)

- 5G, 4G, Vonr Crash Course Complete Log AnaylsisDocumento11 páginas5G, 4G, Vonr Crash Course Complete Log AnaylsisJavier GonzalesAinda não há avaliações

- Erp FinalDocumento33 páginasErp FinaltenetchatAinda não há avaliações

- Reading Comprehension Lesson Plan FinalDocumento9 páginasReading Comprehension Lesson Plan Finalapi-254917183Ainda não há avaliações

- Philippines and Singapore Trade Relations and Agreements: 1. What Leads To Said Agreement?Documento11 páginasPhilippines and Singapore Trade Relations and Agreements: 1. What Leads To Said Agreement?Ayrah Erica JaimeAinda não há avaliações

- A. Erfurth, P. Hoff. Mad Scenes in Early 19th-Century Opera PDFDocumento4 páginasA. Erfurth, P. Hoff. Mad Scenes in Early 19th-Century Opera PDFbiarrodAinda não há avaliações

- KITZ - Cast Iron - 125FCL&125FCYDocumento2 páginasKITZ - Cast Iron - 125FCL&125FCYdanang hadi saputroAinda não há avaliações

- Global Governance and Interstate SystemDocumento25 páginasGlobal Governance and Interstate SystemRay Stephen SantosAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- AWANA Handbook 2010-2011Documento8 páginasAWANA Handbook 2010-2011carriepratchard100% (1)

- Infoblatt Skischulen Trends Port eDocumento18 páginasInfoblatt Skischulen Trends Port eAustrian National Tourism BoardAinda não há avaliações

- Diagnostic Report: Patient Name: Pranav Chauhan PRANM050319990B 0009VA060799Documento2 páginasDiagnostic Report: Patient Name: Pranav Chauhan PRANM050319990B 0009VA060799pranav chauhanAinda não há avaliações

- 热虹吸管相变传热行为CFD模拟 王啸远Documento7 páginas热虹吸管相变传热行为CFD模拟 王啸远小黄包Ainda não há avaliações

- Practical Econometrics Data Collection Analysis and Application 1st Edition Hilmer Test BankDocumento27 páginasPractical Econometrics Data Collection Analysis and Application 1st Edition Hilmer Test Bankdavidhallwopkseimgc100% (28)

- CESC Performance Task Quarter 1Documento3 páginasCESC Performance Task Quarter 1MarinaM.CubiaAinda não há avaliações

- C779-C779M - 12 Standard Test Method For Abrasion of Horizontal Concrete SurfacesDocumento7 páginasC779-C779M - 12 Standard Test Method For Abrasion of Horizontal Concrete SurfacesFahad RedaAinda não há avaliações

- Minolta Spotmeter f-1 PDFDocumento50 páginasMinolta Spotmeter f-1 PDFmacpator100% (1)