Escolar Documentos

Profissional Documentos

Cultura Documentos

Ametecs Crane Desigh & Details

Enviado por

Jayakrishnan RadhakrishnanDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Ametecs Crane Desigh & Details

Enviado por

Jayakrishnan RadhakrishnanDireitos autorais:

Formatos disponíveis

Brochure Lifting Equipment

LIFTING EQUIPMENT

AMETECS

Al Makki Engineering & Technical Services, Plot 47, M-5, Mussafah Industrial Area,

Post Box 70362, Abu Dhabi, UAE

Tel: +971-2-5552426 Fax: +971-2-5540040

E-mail: info@ametecs.com

Brochure Lifting Equipment

Table of Contents

Introduction ............................................................................................................................................ 2

Types of cranes manufactured by AMETECS .......................................................................................... 3

Slewing Jib Cranes ................................................................................................................................... 4

Portable Davits ........................................................................................................................................ 6

Monorail cranes ...................................................................................................................................... 7

Overhead travelling cranes ..................................................................................................................... 9

Counterbalance Floor Cranes................................................................................................................ 12

Features of DELTA Manual Hoist: ......................................................................................................... 13

Gantry Cranes ....................................................................................................................................... 14

Design & Development ......................................................................................................................... 17

Explosion Proof Cranes ......................................................................................................................... 20

Page | 1

Brochure Lifting Equipment

Introduction

AMETECS (Al Makki Engineering & Technical

Services) was started in 1983 primarily as an

Oilfield Services Company. Since then, we

have ventured into the field of specialized

fabrication, design and manufacture of

special purpose machinery, material handling

and lifting equipment, penstocks, ASMECertified pressure vessels, aircraft ground

service equipment, storage tanks and

precision tooling.

thereby providing considering local conditions

and application environment gives good

trouble free service life

AMETECS has a full-fledged, well-equipped

fabrication and machine shop in Mussafah

Industrial Area, Plot No 47 (M-5). We have a

covered area of approximately 1200 m2 and

an open area of nearly 1000 m2. Apart from

this, a CAD-supported design section with

qualified engineers has been established

available to develop special purpose

equipment. AMETECS is also under the

approved vendor list for various government

organizations in the UAE (ADSSC, ADNOC,

ADCO etc)

Strict in-house quality assurance procedures

(to ISO 9001:2008) are followed to ensure

that the products delivered to our clients are

always of the highest quality.

AMETECS is also the authorized service and

Installation Company in U. A. E. for high-tech

specialized oil field electrical valve actuators

Bernard of France. We are one of the SPC

approved manufacturers of lifting and

handling equipment in the UAE.

Time-bound service and cost-effectiveness

AMETECS is also certified to manufacture

pressure vessels to ASME Sec VIII Div 1 (UStamped) and also for repair of vessels to

National Board Inspection Code (R-Stamp).

being our motto, AMETECS has successfully

enjoyed the patronage of all leading

petroleum companies in the UAE; along with

the Government and private sector

engineering or contracting establishments.

Several material handling equipment like jib

cranes, monorails, portable cranes etc have

been locally developed to meet specific

requirements and are working satisfactorily in

pumping stations for the past several years. In

special cases, alloy material have been used in

the construction of cranes and lifting systems;

Page | 2

We are also approved crane suppliers to

ADSSC, ADDC & Abu Dhabi Municipality.

Brochure Lifting Equipment

Types of cranes manufactured by AMETECS

AMETECS has developed the following systems for use in the region:

-

Slewing Jib Cranes (manual or electric; with slewing angles of 270o up to 360o)

o

Floor mounted (free standing)

Wall mounted

Portable davits

Monorail cranes

Electric (with dual-speed motions in all directions)

Manual

Overhead travelling cranes

o

Electrical (with dual-speed motions in all directions)

Manual

Counterbalance floor cranes

Gantry cranes

o

o

-

Manual light duty gantry cranes

Fixed height

Adjustable height

Heavy duty electrical gantry cranes

Explosion proof cranes

We are capable of designing and developing lifting systems specific to

client/project requirements. All cranes are painted as per project specifications.

Page | 3

Brochure Lifting Equipment

Slewing Jib Cranes

There are two types of slewing jib cranes that are manufactured by AMETECS:

1) Floor mounted (free standing)

Slewing jib cranes are the most versatile type of cranes. These are perfect for use in pump stations and

also underneath large bridge cranes; in open areas where it can serve several work stations. These

cranes can also be in used in loading docks or in machining and assembly operations where it can be

overlapped with other jibs to provide staged operation.

2) Wall mounted

The wall mounted jib cranes provide hoist coverage and 200o rotation for individual use in bays, along

with walls or columns. As this type of crane can be installed very close to the underside of the lowest

ceiling obstruction, this jib has the advantage of providing maximum lift for the hoist. Two important

requirements for this type of jib crane are:

-

A structurally adequate wall or column to support the jib must be present

Sufficient clearance above the boom throughout its arc must be present

Page | 4

Brochure Lifting Equipment

Advantages of AMETECS floor mounted Slewing Jib Cranes

-

Ease of operation

o Loads can be positioned precisely, effortlessly and efficiently

o Precision tapered roller bearings in the fulcrum pin assembly provide smooth operation and

also extended life

o Full supporting triangular base plate gussets are used to minimize the column deflection

o 270o slewing angle

Ease of installation

o Independent head assembly installs separately for ease of installation

o Recessed bearing assembly allows greatly reduced clearances needed for installation

o Bolted head/arm connection which permits separate installation and provides maximum lift

for the hoist, since it can be installed very close to the underside of the lower ceiling

obstruction for greater headroom

o Movable bolted trolley stops

Safety

o Fulcrum pin retaining plate provides resistance to accidental upward dislodgement of the

head

o Overload protection as standard with electric hoists and optional with manual hoists

o Arm lock mechanism (in stainless steel) to prevent unauthorized usage of the crane

Power rotation

o Optional power rotation of the arm can be provided

Advantages of AMETECS wall mounted Slewing Jib Cranes

-

Ease of operation

o The fittings contain bronze bushings and oil-immersed thrust washers; which provide easy

rotation and superior load positioning

Ease of installation

o If the bracket centre dimension is 250 mm or less, the mast/jib connection is welded;

thereby providing the most economical means of installation

o If the bracket centre dimension is more than 250 mm, a bolted mast/jib connection is used;

which enables larger cranes to be transported disassembled for ease of handling during

installation

Safety

o Pre-fabricated steel fittings that provide excellent torsional rigidity

o Overload protection as standard with electric hoists and optional with manual hoists

o Arm lock mechanism (in stainless steel) to prevent unauthorized usage of the crane

Power rotation

o Optional power rotation of the arm can be provided

Page | 5

Brochure Lifting Equipment

Portable Davits

We offer lightweight davits primarily designed for submerged pump recovery from wet wells or holding

tanks. These davits can also be utilized for pallet stacking, machine loading and other maintenance

operations. The davits are available in either galvanized steel or aluminum(up to 500 kg) or stainless steel

construction. The davits are demountable and portable with in-ground, surface mounted or wall mounted

sockets.

Portable lifting davits can be easily dismantled for storage or transportation to other locations, as the

individual components can be handled and moved manually.

Features

-

Allows operator freedom to work close to

machines or over obstructions

Designed with safety in mind, this crane

meets all international safety standards

Robust, all welded construction

Manufactured from hollow steel box

sections for combined strength and

lightness

Can be fitted with heavy duty, double acting

pump or hoist

Hydraulic-pump models are fitted with

safety relief valve to prevent overload

Fitted with hard wearing polyurethane front

wheels and swivel castors on the rear for

easy movement of the crane when

operational

Rear swivel castors have brakes fitted

Safety latch provided with hoist/hook

Each crane to be individually tested to 25 %

overload as a complete unit

Comes with a 12 month guarantee

Painting system is 3-coat; with PU top coat as color of choice

Options

-

Either with hydraulic pump or manual hoist

Page | 6

Brochure Lifting Equipment

Monorail cranes

Monorails are an economical choice for lifting and transporting products along a fixed path. Perfect for

processes like moving raw materials or pumps, a monorail system is mounted to an existing overhead

structure to preserve floor space. For hard to reach areas where a bridge crane cannot go or areas where

ceiling height is a problem, a monorail system provides the

access you need.

AMETECS manufactures electric and manual monorail

systems. The system consists of an I-beam, mechanical end

stops, mounting clamps and the hoist (manual or electric).

Monorails by AMETECS are custom designed to fit any

building. Standalone support systems for monorails can also

be furnished. Standard monorail curved sections and track

devices such as switches, turntables, interlocks and

entry/exit sections can be furnished for optimum flexibility

in a conveyor, monorail, or combination bridge crane

monorail system.

Advantages of AMETECS Monorail Cranes

-

Ease of operation

o Monorails with electric hoists are manufactured with two-speed hoists; to enable

convenient lifting/lowering of the loads

o Monorails with manual hoists are provided with stainless steel SS 316 hand pull chain

o Monorail systems with two or more beams can be developed; to provide greater flexibility.

The various beams can be linked to one another with the use of interconnections

Ease of installation

o The beams are transported to site in smaller lengths; thereby making it easier and safer to

handle during installation

o Custom made mounting clamps are provided for each beam section

Safety

o Monorails with electric and manual hoists are fitted with mechanical end stops (with rubber

bumpers)

o In case of electric hoists, limit switches are also provided

o Overload protection as standard with electric hoists and optional with manual hoists

Interconnected monorails

o Two or more monorails can be interconnected with the use of curved interconnections; if

needed

Page | 7

Brochure Lifting Equipment

Monorail installed at Al Ain, Abu Dhabi Sewerage Services Co. (ADSSC) Project O-1797

Page | 8

Brochure Lifting Equipment

Overhead travelling cranes

AMETECS manufactures completely customized overhead travelling cranes. These cranes are compact,

customized as per client requirements and are easy to operate and maintain. The overhead travelling cranes

can either be single or double girder; and are of two types:

-

Electric (EOT Cranes)

Manual

Besides, the cranes can be designed to be either free standing (no existing support structure required) or

mounted inside existing structures.

Electric Overhead Travelling (EOT) Cranes

Electric Overhead Travelling (EOT) Cranes manufactured by AMETECS come with a complete two-speed

system as default (UP/DOWN/LEFT/RIGHT/FORWARD/BACKWARD). All controls are integrated into an

electric control panel that houses components like connectors, transformers, reverse contactors and fuses).

The control panel is with IP 65 protection.

The type of EOT can either be

1) Top Running (girder and end carriages move on top of runway beams)

2) Under-Slung (girder and end carriages move below the runway beams)

Page | 9

Brochure Lifting Equipment

Advantages of AMETECS EOT Cranes:

-

Ease of operation

o Two-speed controls in all directions ensure that loads can be moved effortlessly and as per

operator preference

o Soft start motors provided for all motions

Efficient installation of cranes

o The beams are transported to site in smaller lengths; thereby making it easier and safer to

handle during installation

o AMETECS has a team of skilled workers specially trained for crane installation

Safety

o EOT cranes are equipped with limit switches for all motions

o Mechanical stops are also provided on the girder and runway beams; as back-up to the limit

switches

o All electrical panels are rated to NEMA 1 as a minimum

o Warning lights/siren can be provided as optional

o Overload protection as standard feature in all EOT cranes

o Motor protection circuit breakers provide additional protection for the crane motors;

especially in severe inching operations

Other features

o Heavy duty motors are provided to ensure long service hours without any breakdown

o Modular design covers a wide operating range

o Various crane beam to end carriage constructions available to ensure optimum use of head

rooms

o Standard hoists are low head room type; running on the bottom flange of the beam

o Possibility to fit a walkway to the crane; to serve the purpose of maintenance access to

many critical parts

o Radio remote controllers and automation feature are optional

Page | 10

Brochure Lifting Equipment

Manual Overhead Travelling Cranes

These cranes are supplied with a manual hoist and manual geared end carriages. The end carriages are

inter-connected through a specially designed load shaft to transfer the pull force effectively. Even for

manual overhead cranes, the configuration can either be top-running or under-slung.

Advantages of AMETECS EOT Cranes:

-

Ease of operation

o Minimum effort needed for hoisting

o Geared end carriages provided for long travel

Efficient installation of cranes

o The beams are transported to site in smaller lengths; thereby making it easier and safer to

handle during installation

o AMETECS has a team of skilled workers specially trained for crane installation

Safety

o Can be supplied with overload protection on the hoist (optional)

o Mechanical stops are also provided on the girder and runway beams

Other features

o Modular design covers a wide operating range

o Various crane beam to end carriage constructions available to ensure optimum use of head

rooms

o Rigid runways and superior load positioning no movement or crab-walking of the bridge

Page | 11

Brochure Lifting Equipment

Counterbalance Floor Cranes

Heavy duty counter-balance floor cranes are ideal

industrial lifting solutions where the lift must be

completed close to a piece of machinery or over

an obstruction; meaning a standard crane is not

suitable. These cranes are portable and trusted

across many industries and are suitable for

industrial/commercial use. The AMETECS range of

counter-balance cranes are available in ranges of

200 kg up to 2500 kg; and can be customized

completely to meet customer requirements. The

cranes can be easily moved in a workshop; as

they are fitted with heavy duty PU castors.

The Counter Balance Cranes are usually fitted

with hydraulic cylinders to enable lifting/lowering

of loads. In special cases where space restraints

are present, a fixed column with a manual hoist

can also be provided.

Features:

-

Allows operator freedom to work close to

machines or over obstructions

Designed with safety in mind, this crane

meets all international safety standards

Robust, all welded construction

Third-party MPI to be done all welds

Manufactured from hollow steel box

sections for combined strength and

lightness

Can be fitted with heavy duty, double

acting pump or hoist

Page | 12

Hydraulic-pump models are fitted with

safety relief valve to prevent overload

Fitted with hard wearing polyurethane

front wheels and swivel castors on the

rear for easy movement of the crane

when operational

Rear swivel castors have brakes fitted

Safety latch provided with hoist/hook

Hoist comes with overload limiter to

prevent lifting of excess load

Each crane to be individually tested to 25

% overload as a complete unit

Third-party certification can also be

provided

Test certificate to be provided with each

crane

Comes with a 12 month guarantee

Painting system is 3-coat; with PU top

coat as color of choice

Important Safety Information:

-

Always inspect the hoist and latch before

using

Never use a latch that is distorted or bent

Always make sure spring will force the

latch against the tip of the hook

The latch must never support the load

Never attempt to lift more than the SWL

limit of the crane

This crane must never be used for lifting

personnel

Brochure Lifting Equipment

Model shown to the left is with SWL 1000 kg

and bolted connections/fixed column, for a

special application. Hydraulically adjusted

arm can also be incorporated on request.

The hoist is of DELTA HOIST and comes with

an overload limiter.

Features of DELTA Manual Hoist:

-

Page | 13

Unit with overload limited kit

Precision machined and highly finished shafts, sprocket and

bearing housings

Brake system with steel protected shield

Roller bearing inside the chain sprocket supporting the load shaft

Asbestos-free brake lining

Ratchet disc with double ratchet pawls

All steel structure and gearing design specially designed to fit up

to Grade 100 load chain

A smoothly running hoisting device, even at the maximum load

Maximum effort to lift 1000 kg load is 304 N

Brochure Lifting Equipment

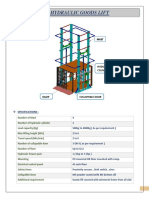

Gantry Cranes

Dependable and versatile, gantry cranes from AMETECS offer cost effective lifting portability that

can withstand the heaviest of loads. Easily assembled and disassembled, these cranes can be used

indoors or outdoors, whether mounted or mobile. Gantries are successfully utilized across multiple

industries and can also be used in stockyards, scrap yards and railway yards. The gantry cranes can

also be moved to a new location with less trouble than a free-standing overhead crane. Also, it is

easy to extend the length of the runway and working area of gantry cranes. The cranes can also be

designed for completely automatic operation; by interfacing with a PLC (part of AMETECS scope).

The types of gantry cranes manufactured by AMETECS can be divided into two categories:

-

Manual light duty gantries

These cranes are of the A-Frame type and can be easily moved to any location in a facility.

This type of crane is cost effective for areas with infrequent lifts. There are again two types

of manual gantries:

a. Fixed Height

These cranes are available in fixed heights

depending on the requirement. Square tubing

uprights, knee braces and channel bases are used

to provide stable lifting and movement. The beam

is bolted to the upright to ensure safe connection.

The standard model is supplied with molded

phenolic casters for easy movement.

b. Adjustable Height

These gantries are similar in construction to

the fixed height; but the square tubing

uprights are capable of movement in outer

sleeves. Depending on the height required, the

upright can be bolted on to the outer sleeves.

Maximum heights on this system range from 7

feet to 14 feet. The other features remain

same as the fixed height gantry.

The light duty gantries can also be supplied with electric hoists (optional). In addition, the

light duty gantries can also be manufactured in light weight aluminum structure (up to SWL

of 3 t). More details of the light weight gantry cranes will be furnished on request.

Brochure Lifting Equipment

-

Heavy duty electric gantry cranes

Powered gantry cranes are typically used for larger, high capacity jobs where operators

require less manual features. The standard configuration is A-frame type. However, for

applications that cannot have traffic on one side of the crane, AMETECS can develop singleleg gantry cranes. All powered gantry cranes are furnished with motor drives to ride on Vgroove track crane rail directly on the floor by use of PU wheels. For outdoor and higher

rated cranes, double flanged wheels are used.

Heavy duty electrical gantry cranes from AMETECS are designed to provide dependable,

durable lifting solutions. Each crane is manufactured in line with all relevant international

standards.

To summarize, the following types of gantry cranes can be manufactured by AMETECS:

1) Trackless gantry with floor guide

These cranes are ideal for applicatons requiring a

gantry to run against a wall. A guide angle lags to

the floor along the wall guiding the guiding which

directly travels on the floor on PU wheels.

These types of cranes can also be used in open

areas where a guide angle on the floor is not

practical. A selector switch can be incorporated in

the control panel to selectively turn each motor

ON and OFF to compensate for skewing.

2) Single leg, top running end carriage

The single leg design maximizes space utility in confined,

narrow areas by traveling down an aisle on PU wheels

while the other end of the I-Beam mounts on an end

truck travelling on an overhead runway.

3) Single leg, under slung end carriage

A single leg gantry can also be used with an under slung

end carriages on one side which travels on the bottom

flange of an overhead runway beam.

Page | 15

Brochure Lifting Equipment

Gantry crane installed at Qatar Steel (Masaeed, Doha), 4 T SWL, with grab. Crane is PLC controlled

for complete automatic operation.

Page | 16

Brochure Lifting Equipment

Design & Development

AMETECS is equipped with a fully-fledged design department specific to lifting equipment. Our

trained personnel help in providing our customers with most suitable lifting system. All design is

performed on exclusive design workstations and using the latest software; thereby totally

eliminating the need for shop testing of models before complete fabrication. This has resulted in a

great saving of time and cost; which in turn benefits the end user. All design calculation results are

incorporated in our technical submittal; providing total clarity to the client and consultant at the

time of review.

Few snap shots of our design outputs are shown below:

Design of jib crane deflection diagram

Page | 17

Design of jib crane foundation forces

Brochure Lifting Equipment

Design of free standing EOT deflection diagrams

Design of free standing EOT member strength check

Page | 18

Brochure Lifting Equipment

Design of free standing EOT foundation forces

Page | 19

Brochure Lifting Equipment

Explosion Proof Cranes

AMETECS has manufactured a wide range of explosion proof hoists, with close awareness of the

customer requirements. Our explosion proof cranes have been used in various fields such as

chemicals, oil & gas where safety in production is evident. All hoists used by us with our explosion

proof cranes are according to the new ATEX 100a (94/09/CE applicable in 2003) and CE regulations

(CE marking, documentation, CE certificate approval).

Hazardous areas are defined by three main criteria:

-

The type of hazard

The likelihood of the hazard being present in flammable concentrations

The (auto) ignition temperature of the hazardous material

Type of hazard (Groups)

The hazard will be in the form of a gas, vapour, dust or fibre.

Gases and vapours are categorized in terms of their ignition energy or the maximum experimental

safe gap (in respect of flameproof protection). This categorization leads to the Gas Groups:

Mining

Surface Industry

Group I

Group II

IIA

IIB

IIC

Propane

Ethylene

Hydrogen

Methane

Group IIC is the most severe group. Hazards in this group can be ignited very easily.

Dusts and fibres are classified under Group III. Dusts and fibres are also defined in terms of their

ignition properties including dust cloud ignition properties.

Likelihood of the hazard being present in flammable concentrations (Zones)

The likelihood of the hazard being present in flammable concentrations will vary from place to

place. A location very close to an open source of hazard will have a high likelihood of a flammable

atmosphere. On the other hand, outside a flanged pipe containing a flammable liquid, the likelihood

of a flammable atmosphere being present is much lower since it will only occur if the flange

leaks. Rather than work with an infinite range of possibilities, three zones are defined.

Gases and Vapours

There are three zones for gases and vapours:

Page | 20

Brochure Lifting Equipment

Zone 0

Flammable atmosphere highly likely to be present may be present for long periods

or even continuously

Zone 1

Flammable atmosphere possible but unlikely to be present for long periods

Zone 2

Flammable atmosphere unlikely to be present except for short periods of time

typically as a result of process fault condition

Zone zero is the most severe zone (the highest probability of flammable atmosphere

presence). Equipment for this zone needs to be very well protected against providing a source of

ignition.

Dusts

There are three zones for dusts:

Zone 20

Dust cloud likely to be present continuously or for long periods

Zone 21

Dust cloud likely to be present occasionally in normal operation

Zone 22

Dust cloud unlikely to occur in normal operation, but if it does, will only exist for a

short period

Ignition temperature of the hazardous material (temperature classes)

As well as considering the protection against electrical arcs and sparks igniting a flammable

atmosphere, consideration needs to be given to the surface temperature of equipment. (Most

electrical apparatus dissipates some heat!) Flammable materials are categorized according to their

ignition temperature. Again, rather than work with an infinite range, six temperature classes are

defined as follows:

T-Class

Hazards will not ignite at temperatures

below

T1

450oC

T2

300oC

T3

200oC

T4

135oC

T5

100oC

T6

85oC

The bigger the T-number the lower is the temperature.

The Temperature classification will be marked on items of equipment. If the hazardous area in which

you are installing equipment has gases or vapours with a low auto-ignition temperature then you will

need equipment with a bigger T-Number so as to ensure that any hot surfaces on the equipment will

not ignite the hazard.

Page | 21

Brochure Lifting Equipment

Al Makki Engineering and Technical Services Ltd, Plot 47, M-5, Mussafah Industrial Area,

Post Box 70362, Abu Dhabi, UAE

Tel: +971 2 5552426

Fax: +971 2 5540040

E-mail: ametecs@eim.ae

Page | 22

Você também pode gostar

- HS - Marine KatalogDocumento20 páginasHS - Marine KatalogGogyAinda não há avaliações

- ZP10-1430 Stinger Winch Operator's ManualDocumento22 páginasZP10-1430 Stinger Winch Operator's ManualIvan MaltsevAinda não há avaliações

- TM-ZT1004H: ModelDocumento5 páginasTM-ZT1004H: ModelKormandi KDAAinda não há avaliações

- Muir 500 ManualDocumento28 páginasMuir 500 ManualLight HouseAinda não há avaliações

- RR - UnrepDocumento2 páginasRR - UnrepRAJESH GANESANAinda não há avaliações

- Towing Winch Emergency Release Systems-Cu Aplicare Din 2020Documento4 páginasTowing Winch Emergency Release Systems-Cu Aplicare Din 2020tonyAinda não há avaliações

- HX1 Horizontal Windlass Iss 2Documento24 páginasHX1 Horizontal Windlass Iss 2edgar luisAinda não há avaliações

- CR-Catalog2 FEB08 PDFDocumento23 páginasCR-Catalog2 FEB08 PDFanjangandak2932Ainda não há avaliações

- Capstan - Shin Myung Tech - SMCAPDocumento19 páginasCapstan - Shin Myung Tech - SMCAPjohn smith0% (1)

- FRC Davit 3 Tech DescriptionDocumento5 páginasFRC Davit 3 Tech DescriptionSamo SpontanostAinda não há avaliações

- Design and Manufacturing of Fixture for Leveling End Carriage AssemblyDocumento11 páginasDesign and Manufacturing of Fixture for Leveling End Carriage AssemblySumit TatedAinda não há avaliações

- TTS Hose Handling CranesDocumento4 páginasTTS Hose Handling CranesCaptIsqanAinda não há avaliações

- Liebherr Offshore Cranes Product Range enDocumento20 páginasLiebherr Offshore Cranes Product Range enCarlos Gonzalez Torres0% (1)

- Cranes Cargo PDFDocumento4 páginasCranes Cargo PDFpangestu100% (1)

- Crane Load Chart-D-008 R2 (2) 52Documento1 páginaCrane Load Chart-D-008 R2 (2) 52sdAinda não há avaliações

- 11-Winches.50 2002 200603Documento16 páginas11-Winches.50 2002 200603Mohamed SalemAinda não há avaliações

- Flyer TL-FADocumento20 páginasFlyer TL-FAmingo622Ainda não há avaliações

- 3t Monorail Provision CraneDocumento21 páginas3t Monorail Provision CranesridharAinda não há avaliações

- Liebherr Crane Summary Specification P131L LCC4740-0 19-12-2014Documento8 páginasLiebherr Crane Summary Specification P131L LCC4740-0 19-12-2014CallumWoodwardAinda não há avaliações

- ADA511843 RampaDocumento78 páginasADA511843 Rampanorbertocuellar100% (1)

- Lattice vs Knuckle Boom Cranes: Key DifferencesDocumento2 páginasLattice vs Knuckle Boom Cranes: Key DifferencesG.SWAMI100% (2)

- Morris Manual Hoists Winches BrochureDocumento5 páginasMorris Manual Hoists Winches BrochurefirlimustariAinda não há avaliações

- Crane 3 GP160-0516-2Documento222 páginasCrane 3 GP160-0516-2cengiz kutukcuAinda não há avaliações

- 1200-Palfinger Grijpers 2Documento4 páginas1200-Palfinger Grijpers 2ZoebairAinda não há avaliações

- Khan Cranes PresentationDocumento28 páginasKhan Cranes PresentationMili Marius100% (1)

- To Meet Your Challenges: Foldable Knuckle Boom Telescopic Boom Jib Knuckle Boom Heavy Duty Foldable Knuckle BoomDocumento24 páginasTo Meet Your Challenges: Foldable Knuckle Boom Telescopic Boom Jib Knuckle Boom Heavy Duty Foldable Knuckle BoompradewoAinda não há avaliações

- P103102 - 11.00 - Doc - Freedom Manual-Old Chain Selection Guide PDFDocumento45 páginasP103102 - 11.00 - Doc - Freedom Manual-Old Chain Selection Guide PDFAnonymous M0OEZEKoGiAinda não há avaliações

- 10te Air TuggerDocumento1 página10te Air TuggerjohariakAinda não há avaliações

- Marine Deck Machinery SolutionsDocumento44 páginasMarine Deck Machinery Solutionshendrasaputralingga8Ainda não há avaliações

- Quality Control Measurement Report Subject: Propeller Push Up. Rudder & Propeller Section Nord HoustonDocumento2 páginasQuality Control Measurement Report Subject: Propeller Push Up. Rudder & Propeller Section Nord HoustonAhmed Magdy100% (1)

- LH 185 DS 0062 6Documento6 páginasLH 185 DS 0062 6Primelift Safety Resources LimitedAinda não há avaliações

- MacGregor GL Cargo CraneDocumento2 páginasMacGregor GL Cargo CraneDharmawan100% (1)

- Watertight Sliding DoorDocumento21 páginasWatertight Sliding DoorarnoldbusaAinda não há avaliações

- 850m3 split-type hopper barge design packageDocumento1 página850m3 split-type hopper barge design packageJOSEPH ANTONY100% (1)

- Liebherr Subsea Offshore Cranes RL-K AHC Active Heave Compensation Brochure 12904-0Documento4 páginasLiebherr Subsea Offshore Cranes RL-K AHC Active Heave Compensation Brochure 12904-0brunosamaeianAinda não há avaliações

- Services Quick Reference Guide: QRG-2021-02-26-revision - Indd 1Documento104 páginasServices Quick Reference Guide: QRG-2021-02-26-revision - Indd 1MahmoudAinda não há avaliações

- FRC Davit 4 Prep InstallationDocumento6 páginasFRC Davit 4 Prep InstallationSamo SpontanostAinda não há avaliações

- Damen Winch - OperatingManual - v1Documento25 páginasDamen Winch - OperatingManual - v1phankhoa83-1Ainda não há avaliações

- Active Heave Compensation Winch System - ACE Winches PDFDocumento24 páginasActive Heave Compensation Winch System - ACE Winches PDFxxshAinda não há avaliações

- Jacks Winches Catalogue 2013Documento36 páginasJacks Winches Catalogue 2013frdsimAinda não há avaliações

- Instruction Manual: Board CraneDocumento10 páginasInstruction Manual: Board CraneKL PetrachkovAinda não há avaliações

- Ejemplo Sepson-manual-EN-dec - 2014 PDFDocumento91 páginasEjemplo Sepson-manual-EN-dec - 2014 PDFAngelAinda não há avaliações

- DS DLV2000 Crane Accomodation Vessel PDFDocumento3 páginasDS DLV2000 Crane Accomodation Vessel PDFlalit100% (1)

- Atlas Davit 2500 PDFDocumento14 páginasAtlas Davit 2500 PDFChief EngineerAinda não há avaliações

- Hydraulically Driven Deck MachineryDocumento2 páginasHydraulically Driven Deck MachineryMohamed FouadAinda não há avaliações

- Sea Horizon SpecificationDocumento2 páginasSea Horizon SpecificationSyafiq HalimAinda não há avaliações

- Operation Manual YALEDocumento56 páginasOperation Manual YALEmarija1967Ainda não há avaliações

- DRW ManualDocumento120 páginasDRW Manualhniwan40Ainda não há avaliações

- CB-142 English Manual Mb-070102-1e-Cb&drwgDocumento31 páginasCB-142 English Manual Mb-070102-1e-Cb&drwgTaufiq Omar HasanAinda não há avaliações

- RT Drive Device User ManualDocumento13 páginasRT Drive Device User ManualJohn SimancaAinda não há avaliações

- Telescopic Boom Cranes - Lifetime ExcellenceDocumento3 páginasTelescopic Boom Cranes - Lifetime ExcellenceAzwar SalehAinda não há avaliações

- Material Hoist Kit Operators Manual PDFDocumento27 páginasMaterial Hoist Kit Operators Manual PDFSajeewa LakmalAinda não há avaliações

- Goods Lift Catalog-DtpDocumento5 páginasGoods Lift Catalog-DtpNikunj PatelAinda não há avaliações

- SP2552-2-15-1 UM (From Inspector 2023)Documento667 páginasSP2552-2-15-1 UM (From Inspector 2023)kodrys100% (1)

- 400te Linear WinchDocumento2 páginas400te Linear Winchjohariak100% (1)

- Viking: Product ManualDocumento26 páginasViking: Product ManualCristian RobiconAinda não há avaliações

- Factory Acceptance Test Procedure for Pedestal Crane 1676Documento29 páginasFactory Acceptance Test Procedure for Pedestal Crane 1676Anonymous 1ykzuaxWgYAinda não há avaliações

- Heavy-Duty ROV Spec Sheet with LARSDocumento2 páginasHeavy-Duty ROV Spec Sheet with LARSJen QianhuiAinda não há avaliações

- 05fd3059b7e730dacb756f9e61a425f5Documento12 páginas05fd3059b7e730dacb756f9e61a425f5yzmouseAinda não há avaliações

- Chapter OneDocumento38 páginasChapter Oneabiy balkewAinda não há avaliações

- Method Statement For Installation SS PipesDocumento14 páginasMethod Statement For Installation SS PipesJayakrishnan RadhakrishnanAinda não há avaliações

- MST of Installation of BiogasDocumento29 páginasMST of Installation of BiogasJayakrishnan RadhakrishnanAinda não há avaliações

- Pipe Sizing Formula & Velocity ReferenceDocumento3 páginasPipe Sizing Formula & Velocity ReferenceJayakrishnan RadhakrishnanAinda não há avaliações

- Condensation Trap Slab ProposalDocumento1 páginaCondensation Trap Slab ProposalJayakrishnan RadhakrishnanAinda não há avaliações

- Pipe Sizing Calculation SheetDocumento14 páginasPipe Sizing Calculation SheetJayakrishnan RadhakrishnanAinda não há avaliações

- Compressed Air HSEDocumento50 páginasCompressed Air HSEOdalis ToscanoAinda não há avaliações

- Latest Service Water DemandDocumento4 páginasLatest Service Water DemandJayakrishnan RadhakrishnanAinda não há avaliações

- Method Statement For UNDERGROUND SS WRAPSDocumento13 páginasMethod Statement For UNDERGROUND SS WRAPSJayakrishnan Radhakrishnan100% (1)

- UASB Booster Pressure CalculationDocumento143 páginasUASB Booster Pressure CalculationJayakrishnan RadhakrishnanAinda não há avaliações

- Top 10 Best Water Treatment Companies in The World 2018 - Trending Top MostDocumento9 páginasTop 10 Best Water Treatment Companies in The World 2018 - Trending Top MostJayakrishnan RadhakrishnanAinda não há avaliações

- Digestor Puddle Pipe Arrangement.Documento1 páginaDigestor Puddle Pipe Arrangement.Jayakrishnan RadhakrishnanAinda não há avaliações

- Water ClcuDocumento12 páginasWater ClcujnmanivannanmechAinda não há avaliações

- Application For NRK ID CardDocumento4 páginasApplication For NRK ID CardvipinchombalaAinda não há avaliações

- Suction Specific Speed × 3/) ) ( ( ÷ (NPSHR)Documento2 páginasSuction Specific Speed × 3/) ) ( ( ÷ (NPSHR)Jayakrishnan RadhakrishnanAinda não há avaliações

- Estimation Man HourDocumento241 páginasEstimation Man HourAnonymous ynJByUs52% (42)

- Estimation Man HourDocumento241 páginasEstimation Man HourAnonymous ynJByUs52% (42)

- Tools Technology For Water Treatment PlantsDocumento2 páginasTools Technology For Water Treatment PlantsJayakrishnan RadhakrishnanAinda não há avaliações

- MBR V Conv ComparisonDocumento10 páginasMBR V Conv ComparisonJayakrishnan RadhakrishnanAinda não há avaliações

- Fluropolymer Coating.Documento15 páginasFluropolymer Coating.Jayakrishnan RadhakrishnanAinda não há avaliações

- Concrete Anchor Design GuideDocumento21 páginasConcrete Anchor Design GuideAri PranantaAinda não há avaliações

- Fiberglass Grating BrochureDocumento16 páginasFiberglass Grating BrochureJayakrishnan RadhakrishnanAinda não há avaliações

- Piping ComparisonDocumento1 páginaPiping ComparisonDenstar Ricardo SilalahiAinda não há avaliações

- ? VLOOKUP (T17,'Pipe Dim.'!$B$2:$D$32,3,'Pipe Dim.'!B4:B32) Hdpe VLOOKUP (T18,'Pipe Dim.'!$I$1:$J$23,2,'Pipe Dim.'!I2:I23) UPVCDocumento1 página? VLOOKUP (T17,'Pipe Dim.'!$B$2:$D$32,3,'Pipe Dim.'!B4:B32) Hdpe VLOOKUP (T18,'Pipe Dim.'!$I$1:$J$23,2,'Pipe Dim.'!I2:I23) UPVCJayakrishnan RadhakrishnanAinda não há avaliações

- Piping ComparisonDocumento1 páginaPiping ComparisonDenstar Ricardo SilalahiAinda não há avaliações

- PD Blower Maintence Details GeneralDocumento1 páginaPD Blower Maintence Details GeneralJayakrishnan RadhakrishnanAinda não há avaliações

- Galvanic Corrossion & The Prevention.Documento27 páginasGalvanic Corrossion & The Prevention.Jayakrishnan RadhakrishnanAinda não há avaliações

- Fluropolymer Coating.Documento1 páginaFluropolymer Coating.Jayakrishnan RadhakrishnanAinda não há avaliações

- Operating and Static Water Level of Surge TanksDocumento1 páginaOperating and Static Water Level of Surge TanksJayakrishnan RadhakrishnanAinda não há avaliações

- Series 380 BrouchersDocumento6 páginasSeries 380 BrouchersJayakrishnan RadhakrishnanAinda não há avaliações

- Aurora 3800 Series PumpsDocumento8 páginasAurora 3800 Series PumpsJayakrishnan Radhakrishnan100% (1)

- Maglev Trains - How Maglev Trains Work - by Alex Landovskis & Veronique RondeaDocumento3 páginasMaglev Trains - How Maglev Trains Work - by Alex Landovskis & Veronique RondeaarnavraizadakhushiAinda não há avaliações

- 50 555circuits PDFDocumento152 páginas50 555circuits PDFleonelartesano2Ainda não há avaliações

- Project Report On Gas Plant at NTPC DadriDocumento16 páginasProject Report On Gas Plant at NTPC DadriSunil MåüřÿäAinda não há avaliações

- 075 Oil Mist Application Manual PDFDocumento34 páginas075 Oil Mist Application Manual PDFAdolfo EirasAinda não há avaliações

- B2 Exam PracticeDocumento7 páginasB2 Exam PracticemonicanacaAinda não há avaliações

- Overhead Crane Supporting Structures 115Documento3 páginasOverhead Crane Supporting Structures 115Gogy100% (1)

- C04 - Gold Souq Bus Station To Government Workshop Dubai Bus Service TimetableDocumento8 páginasC04 - Gold Souq Bus Station To Government Workshop Dubai Bus Service TimetableDubai Q&AAinda não há avaliações

- Monsoon PrecautionsDocumento5 páginasMonsoon PrecautionsNipun NarayanAinda não há avaliações

- Gdce Je Pway Tmo Application FormDocumento1 páginaGdce Je Pway Tmo Application Formnellai kumarAinda não há avaliações

- BH Girder Technology Overview and Case StudiesDocumento34 páginasBH Girder Technology Overview and Case StudiesAnton Husen PurboyoAinda não há avaliações

- Environmental and Social Due Diligence Report Manzanillo Port 201407 PDFDocumento108 páginasEnvironmental and Social Due Diligence Report Manzanillo Port 201407 PDFSetiadi MargonoAinda não há avaliações

- Bombardier Transportation FLEXX MetroDocumento4 páginasBombardier Transportation FLEXX MetroWuily Mogollón EscobarAinda não há avaliações

- Cross Section: Transportation EngineeringDocumento9 páginasCross Section: Transportation EngineeringAbdirizak HussienAinda não há avaliações

- Best Transportation Choice ModelDocumento10 páginasBest Transportation Choice ModelDimi ProtoAinda não há avaliações

- 54e1 60e1 Railway Turnouts Techspec WebDocumento36 páginas54e1 60e1 Railway Turnouts Techspec WebShah SudAaisAinda não há avaliações

- GRS Guide - LR 1Documento137 páginasGRS Guide - LR 1Siddu BiradarAinda não há avaliações

- Route 19 From Perris - Moreno ValleyDocumento5 páginasRoute 19 From Perris - Moreno ValleyBenson TautalaAinda não há avaliações

- Fairfax County Bus System Map: MarylandDocumento1 páginaFairfax County Bus System Map: MarylandsleaderhAinda não há avaliações

- Bombardier Presentation LOC DivisionDocumento30 páginasBombardier Presentation LOC DivisionVictor NencuAinda não há avaliações

- Sharma 20133Documento20 páginasSharma 20133rajimuruganAinda não há avaliações

- The High Line Park, NY - An Architectural ReviewDocumento11 páginasThe High Line Park, NY - An Architectural ReviewEoghan Hurley100% (1)

- Prife Plan India.v2.2Documento16 páginasPrife Plan India.v2.2JTS Maju Jaya Sdn BhdAinda não há avaliações

- 24th Bza MasDocumento1 página24th Bza MasGowri Sankara Rao UritiAinda não há avaliações

- Modicon M238 Logic Controller TM238LDD24DTDocumento9 páginasModicon M238 Logic Controller TM238LDD24DTtruongmanhkiemAinda não há avaliações

- Classic Trains May 2021Documento102 páginasClassic Trains May 2021mur100% (2)

- Intelligent Train Engine To Avoid Accidents and Railway Gate ControllingDocumento3 páginasIntelligent Train Engine To Avoid Accidents and Railway Gate ControllingInternational Journal of Innovative Science and Research TechnologyAinda não há avaliações

- 52 ShaktipithsDocumento8 páginas52 Shaktipithsshakti2arvindAinda não há avaliações

- Executive Summary CSTM PNVL FAST CORRIDOR PDFDocumento21 páginasExecutive Summary CSTM PNVL FAST CORRIDOR PDFAayushi GodseAinda não há avaliações

- Som CrapDocumento2 páginasSom CrapRobert OppenheimerAinda não há avaliações

- Riders ACDCDocumento7 páginasRiders ACDCxavi lopeçAinda não há avaliações