Escolar Documentos

Profissional Documentos

Cultura Documentos

10 Gearbox Technical Information PDF

Enviado por

Chow KheeyewDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

10 Gearbox Technical Information PDF

Enviado por

Chow KheeyewDireitos autorais:

Formatos disponíveis

Bevel Gearboxes

Other

Bevel

Worm

Products Gearboxes Gear Pair

Screw

Gears

Bevel

Gears

Miter

Gears

CP Racks

& Pinions

Racks

Internal

Gears

Helical

Gears

Spur

Gears

Selection Guide

Essential data for selection

Load torque, type of prime mover, input speed, speed ratio,

running time, coupling method, and frequency of start and

stop.

PBX-T Type

KBX-L Type

KBX-T Type

Selection Procedure

The performance table in the catalog is based on the design

conditions that the prime mover is a motor, the load is uniform, and the unit runs 10 hours per day.

a) When using the units under any other condition, it is necessary to correct the value of load to torque by applying the

service factors shown in Table 1.

Corrected Load Torque = Load torque applied to gearbox x Service factor <See Table 1>.

Service factors (Sf)

Loading

condition

Table 1

Service factorsSf

Less than 3 hrs/day operation 310 hrs/day operation More than 10 hrs/day operation

Uniform load

1

1

1

1.25

1.25

1.50

Light impact load

1

1.25

1.25

1.50

1.50

1.75

Heavy impact

load

1.25

1.50

1.50

1.75

1.75

2.00

NOTE 1. Use the factors in parentheses when frequency of starts and stops exceed 10 times per hour.

2. Also, use the factors in parentheses when a prime mover other than a motor is used (for example,

an internal combustion engine).

Keep the corrected load torque at the speed at less than the allowed X

& Y axis torque (Speed ratio 1:1), or the allowable Y axis torque (Speed

ratio 1:2) shown in the performance table.

b Select an appropriate shaft layout from the shaft layout drawing for

each model.

c Check for overhang load space (O.H.L.)

Overhang load is a load applied beyond the bearing support. Examining the overhang load is indispensable whenever chains, belts, or gears

are used to couple the unit with the mating machinery.

TLE K1 K2

O.H.L.

(N) {kgf}

R

TLE Corrected load torque applied to the gearbox shaftNm

kgfm

R Pitch radius of sprocket, pulley, gear, etc., mounted on the gearbox shaftm

K1 Factor depending on the method of coupling <See Table 2>

K2 Factor depending on the position of load <See Table 3>

The value of O.H.L. from the equation above must be smaller than the value of allowable O.H.L. on

the X-and the Y-axis shown on the performance table.

Factor K1

Table 2

Factor K2

Table 3

Coupling method

K1

Position of load

K2

Chain, timing belt

1.00

Near the support

0.75

Gear

1.25

Middle of shaft

1.00

V belt

1.50

End of the shaft

1.50

dSelect a model capable to satisfy all of a), b) and c) obtained

above.

576

PBX-L Type

Position of load

End of the shaft

Middle of the shaft

Near the support

Bevel Gearboxes

Spur

Gears

Selection Examples

Application

Load torque

X-axis rotational speed

Speed Ratio

Shaft layout

Running time

Coupling method

Conveyor (uniform load)

78.4Nm8kgfm

300rpm

CBX-L Type

1 2

As illustrated at right

12 hours/day

X-axis Coupling

Motor

Y-axis Chain (positioned at the middle of the shaft)

Installation Horizontal

Location Indoors

Helical

Gears

Example 1

CBX-T Type

Internal

Gears

CBX-LB Type

Chain

Torque Analysis

TLE 78.4 1.25 98Nm

TLE 8 1.25 10kgfm

O.H.L. Analysis

O.H.L.on the Y-axis

O.H.L.

TLE K1 K2

98 1 1

1960N

R

100

2 1000

{ O.H.L.

TLE K1 K2

10 1 1

200kgf }

R

100

2 1000

Model Selection

Miter

Gears

Accordingly, corrected load torque applied to Y-axis.

CP Racks

& Pinions

Racks

Service factor under load is Sf 1.25 (Table 1).

Application Line shaft drive

Load torque 58.8Nm6kgfm(uniform load) for each A,B and C

Rotational speed 600rpm

Speed Ratio 1 1

Shaft layout As illustrated at right

Running time 8 hours/day

Coupling method All couplings

Installation Horizontal

Location Indoors

In case of an inline shaft drive, load applied to the Y-axis varies

with the location of the gearbox. Therefore, an adequate model

must be selected individually for each position. Service factor

(Table 1) under the design condition is Sf=1.0 for all gearboxes.

Gearbox No.1

Corrected load torque applied to the X-axis that drives only load A is:

Load A

Load B

Load C

No.1

CBX-TB Type

No.2

CBX-TB Type

No.3

CBX-LB Type

Motor

Gearbox No.3

Corrected load torque applied to the X-axis that drives only load C is:

58.8 1.0 58.8Nm6 1.0 6kgfm

Corrected load torque applied to the Y-axis that drives load A, B and C is:

58.8 1.0 58.8Nm6 1.0 6kgfm

Corrected load torque applied to the Y-axis that drives only load C is:

(58.8 58.8 58.8) 1.0 176.4Nm

58.8 1.0 58.8Nm6 1.0 6kgfm

CBX-251LB is selected from the performance table.

(6 6 6 ) 1.0 18kgfm

CBX-401TB is selected from the performance table.

Gearbox No.2

Corrected load torque applied to the X-axis that drives only load B is:

58.8 1.0 58.8Nm6 1.0 6kgfm

Corrected load torque applied to the Y-axis that drives load B and C is:

Other

Bevel

Worm

Products Gearboxes Gear Pair

Example 2

Screw

Gears

Bevel

Gears

A model capable of satisfying all of the design conditions, torque and O.H.L. is CBX-322LB.

Model selection

No.1 gearbox isCBX-401TB

No.2 gearbox isCBX-321TB

No.3 gearbox isCBX-251LB

(58.8 58.8) 1.0 117.6Nm

(6 6) 1.0 12kgfm

CBX-321TB is selected from the performance table.

Please see our web site for corrections on KHK Catalogs.

577

Bevel Gearbox's - Moment of Inertia

Moment of Inertia of KBX Bevel Gearbox's

Unit

Spur

Gears

Type

Catalog No.

KBX-101L

KBX-102L

Helical

Gears

KBX-151L

KBX-152L

KBX-201L

KBX-202L

Internal

Gears

KBX-101T

KBX-102T

T

KBX-151T

KBX-152T

Miter

Gears

CP Racks

& Pinions

Racks

KBX-201T

KBX-202T

4.45 10 -6

8.65 10 -6

5.30 10 -5

1.47 10 -4

1.79 10 -4

3.15 10 -4

4.75 10 -6

8.93 10 -6

5.60 10 -5

1.50 10 -4

1.94 10 -4

3.28 10 -4

Unit

Type

Catalog No.

Pinion Shaft (X-axis)

Gear Shaft (Y-axis)

CBX-192L

1.86 10 -4

7.43 10 -4

CBX-251L

CBX-191L

2.48 10 -

1.03 10 -3

CBX-321L

CBX-402L

CBX-191T

CBX-251T

T

4.00 10 -4

CBX-252L

CBX-401L

Bevel

Gears

Screw

Gears

Gear Shaft (Y-axis)

Moment of Inertia of CBX Bevel Gearbox's

CBX-192T

Other

Bevel

Worm

Products Gearboxes Gear Pair

4.45 10 -6

2.16 10 -6

5.30 10 -5

3.65 10 -5

1.79 10 -4

7.85 10 -5

4.75 10 -6

2.23 10 -6

5.60 10 -5

3.37 10 -5

1.94 10 -4

8.20 10 -5

CAUTION The moments of inertia shown in this table are reference values. Please use data only for reference.

CBX-322L

578

Pinion Shaft (X-axis)

CBX-252T

CBX-321T

CBX-322T

CBX-401T

CBX-402T

4.00 10 -

1.29 10 -3

8.95 10 -3

3.83 10 -3

4.05 10 -4

1.87 10 -4

2.50 10 -3

1.04 10 -3

4.08 10 -3

1.31 10 -3

9.20 10 -3

3.88 10 -3

4.00 10 -4

2.48 10 -3

4.13 10 -3

4.00 10 -3

5.18 10 -3

8.95 10 -3

1.53 10 -2

4.05 10 -4

7.48 10 -4

2.50 10 -3

4.15 10 -3

4.08 10 -3

5.25 10 -3

9.20 10 -3

1.55 10 -2

CAUTION The moments of inertia shown in this table are reference values. Please use data only for reference.

Você também pode gostar

- Bonfiglioni 300 Series (NEMA)Documento276 páginasBonfiglioni 300 Series (NEMA)Pieter van der WaltAinda não há avaliações

- Process of Selection and Example of SelectionDocumento8 páginasProcess of Selection and Example of Selectionarvi_vinAinda não há avaliações

- Worm Gear Box Lenze TranstecnoDocumento31 páginasWorm Gear Box Lenze TranstecnoherpadianaAinda não há avaliações

- FANUC Servo Motor SelectionDocumento17 páginasFANUC Servo Motor Selectionmt7038Ainda não há avaliações

- Inertial Calcul PDFDocumento10 páginasInertial Calcul PDFatesarikAinda não há avaliações

- ConDrive - 12-2014Documento15 páginasConDrive - 12-2014Carlos Catalán PinoAinda não há avaliações

- Technical Reference OverviewDocumento17 páginasTechnical Reference OverviewHery Vázquez JiménezAinda não há avaliações

- Cone CVTDocumento4 páginasCone CVTArun KumarAinda não há avaliações

- Yuema CHCDocumento36 páginasYuema CHCyan.yanismanAinda não há avaliações

- Dimensions of Cardan ShaftsDocumento11 páginasDimensions of Cardan ShaftsAnirban GhoshAinda não há avaliações

- PC BRAKE Hydraulic2013Documento56 páginasPC BRAKE Hydraulic2013vijayAinda não há avaliações

- Motor Selection CalculatorDocumento5 páginasMotor Selection Calculatorjay100% (5)

- Ads RackselDocumento3 páginasAds RackselKiem TaAinda não há avaliações

- 26 181 GigerDocumento6 páginas26 181 GigerYouMineAinda não há avaliações

- Crane Girder Design ProcedureDocumento18 páginasCrane Girder Design ProcedureBhadresh Shah0% (1)

- Flywheel Types and DesignDocumento23 páginasFlywheel Types and DesignALL IN ONE0% (1)

- Off-Road Chapter 6Documento12 páginasOff-Road Chapter 6ahmetcinAinda não há avaliações

- Project Description S14Documento13 páginasProject Description S14behinddaplate9Ainda não há avaliações

- Operation Manual For San 1400 TPP HDR IV CC BG 135TDocumento155 páginasOperation Manual For San 1400 TPP HDR IV CC BG 135TCat Tom90% (10)

- CHAIN CalculationDocumento18 páginasCHAIN CalculationDmitrijs MuhinsAinda não há avaliações

- Selection and Adaptation of Hydraulic Cylinders For Tipper HoistingDocumento7 páginasSelection and Adaptation of Hydraulic Cylinders For Tipper HoistingManohar M Hegde100% (1)

- Braking Calculations: "What Do You Want The Brake To Do?"Documento4 páginasBraking Calculations: "What Do You Want The Brake To Do?"Youness AjaarrourAinda não há avaliações

- Oriental Motor Motor Sizing CalculationsDocumento10 páginasOriental Motor Motor Sizing CalculationsKha VeenAinda não há avaliações

- DTS - Unit - 2 PDFDocumento14 páginasDTS - Unit - 2 PDFmani100% (1)

- Sew Euro DriveDocumento5 páginasSew Euro DriveTINCHOYAAinda não há avaliações

- Shaft Diameter PDFDocumento8 páginasShaft Diameter PDFrusruleti100% (1)

- Mathcad - GeneralDocumento17 páginasMathcad - Generalapi-232034744Ainda não há avaliações

- Lifting Analysis GuideDocumento3 páginasLifting Analysis GuideNwosu Augustine100% (1)

- How Unbalance Affects Bearing LifeDocumento8 páginasHow Unbalance Affects Bearing Lifeagrocel_bhv5591Ainda não há avaliações

- 31 CR Mo V9Documento12 páginas31 CR Mo V9Jigar M. UpadhyayAinda não há avaliações

- HAISUNG Good3 - LowBacklash Reducer - CatalogDocumento12 páginasHAISUNG Good3 - LowBacklash Reducer - Catalog032indesignAinda não há avaliações

- Shaft DesignDocumento7 páginasShaft DesignRafael ReyesAinda não há avaliações

- Iso1940 PDFDocumento12 páginasIso1940 PDFAlejandro Cruz MayaAinda não há avaliações

- Bearing Calculation: Extract From The Railway Technical Handbook, Volume 1, Chapter 5, Page 106 To 121Documento18 páginasBearing Calculation: Extract From The Railway Technical Handbook, Volume 1, Chapter 5, Page 106 To 121avabhyankar9393Ainda não há avaliações

- Screw Jack CalculationsDocumento6 páginasScrew Jack CalculationsDaniel SherwinAinda não há avaliações

- Ic EngineDocumento72 páginasIc Enginekedirabduri88Ainda não há avaliações

- V-BELTS Web 2012 9 0Documento58 páginasV-BELTS Web 2012 9 0Zohaib AlamAinda não há avaliações

- ATV Braking Power Calculation PDFDocumento2 páginasATV Braking Power Calculation PDFDiegostfAinda não há avaliações

- Hydro TurbinesDocumento17 páginasHydro TurbinesSavesh Tripathi100% (1)

- Main ShaftDocumento7 páginasMain Shaftcosta59dac9242Ainda não há avaliações

- Cross Travel Motor Power Calculation:: For Steelage IndustriesDocumento22 páginasCross Travel Motor Power Calculation:: For Steelage IndustriessteelageAinda não há avaliações

- Epicyclic Gear Train ApparatusDocumento8 páginasEpicyclic Gear Train ApparatusGurmeet Mehma83% (6)

- Cod.1828 - r4 Nema InputDocumento306 páginasCod.1828 - r4 Nema InputidontlikeebooksAinda não há avaliações

- Usa Tech Calculation PDFDocumento35 páginasUsa Tech Calculation PDFRizwan HameedAinda não há avaliações

- Calculation and Design of The Fly Wheel For Small and Medium CompDocumento7 páginasCalculation and Design of The Fly Wheel For Small and Medium CompAkshay PundeAinda não há avaliações

- Motoare Chiaravalli MelcateDocumento20 páginasMotoare Chiaravalli MelcateAza Vali100% (1)

- Power Press Design, BrakesDocumento9 páginasPower Press Design, Brakeszeynell70100% (2)

- Bearing SelectionDocumento6 páginasBearing SelectionKenneth ChawAinda não há avaliações

- Brake Torque Application DataDocumento0 páginaBrake Torque Application Dataellie210879Ainda não há avaliações

- Motion Control Basics PDFDocumento8 páginasMotion Control Basics PDFFouad ElhajjiAinda não há avaliações

- NMRV AllDocumento42 páginasNMRV AllHEMANTKHERAAinda não há avaliações

- Calculating Idler L10 LifeDocumento9 páginasCalculating Idler L10 LifeJSweda100% (1)

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNo EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsAinda não há avaliações

- Southern Marine Engineering Desk Reference: Second Edition Volume IiNo EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiAinda não há avaliações

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceAinda não há avaliações

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkNo EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkAinda não há avaliações

- Modeling of Complex Systems: Application to Aeronautical DynamicsNo EverandModeling of Complex Systems: Application to Aeronautical DynamicsAinda não há avaliações

- 3.4 Earthwork (Class F)Documento5 páginas3.4 Earthwork (Class F)blueoceanAinda não há avaliações

- 60KL Mild Steel Bitument Tank PDFDocumento1 página60KL Mild Steel Bitument Tank PDFChow KheeyewAinda não há avaliações

- Mohamad Syazli Fathi - Ne... Construction (Concrete)Documento29 páginasMohamad Syazli Fathi - Ne... Construction (Concrete)Chow KheeyewAinda não há avaliações

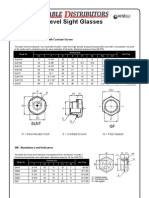

- 130-Level Sight Gauges.Documento4 páginas130-Level Sight Gauges.Chow KheeyewAinda não há avaliações

- LNG Infrastructure Bulk TankDocumento2 páginasLNG Infrastructure Bulk TankChow KheeyewAinda não há avaliações

- API 650 Rafter DesignDocumento12 páginasAPI 650 Rafter Designrongweius100% (1)

- MAGMA HOUSE, 24 Park Street, Kolkata - 700016 (WWW - Magma-Hdi - Co.in)Documento3 páginasMAGMA HOUSE, 24 Park Street, Kolkata - 700016 (WWW - Magma-Hdi - Co.in)SamaAinda não há avaliações

- 27S DataSheet 7 PDFDocumento2 páginas27S DataSheet 7 PDFmaiquelernAinda não há avaliações

- Vespa Brand PaperDocumento25 páginasVespa Brand PaperAox Axe100% (1)

- Stomp The Elephant in The OfficeDocumento29 páginasStomp The Elephant in The OfficeVerusGlobalAinda não há avaliações

- Sidcul DataDocumento13 páginasSidcul DataSnv Agarwal50% (2)

- A SCOOT Bibliography:: Results PapersDocumento21 páginasA SCOOT Bibliography:: Results PapersJaime SarriaAinda não há avaliações

- Summer Training Project Report: Banasthali University C-Scheme Jaipur Campus, RajasthanDocumento74 páginasSummer Training Project Report: Banasthali University C-Scheme Jaipur Campus, Rajasthandrdipin100% (3)

- Manual Crl-Somaca Belt SanderDocumento14 páginasManual Crl-Somaca Belt SanderLuis Elisur ArciaAinda não há avaliações

- Shock AbsorberDocumento19 páginasShock AbsorberAnirban Mitra100% (1)

- Checklist - LTO - Transferring Ownership of Private Motor Vehicles and MotorcyclesDocumento2 páginasChecklist - LTO - Transferring Ownership of Private Motor Vehicles and MotorcyclesLRMAinda não há avaliações

- TeraFlex 2011 CatalogDocumento96 páginasTeraFlex 2011 Catalog2008JKAinda não há avaliações

- The Overwurked American Juliet B. SchurDocumento34 páginasThe Overwurked American Juliet B. SchurCarlos Gen WarashiAinda não há avaliações

- 10017Documento2 páginas10017Alex RamirezAinda não há avaliações

- Se 3 Patroller Service ManualDocumento152 páginasSe 3 Patroller Service ManualthiagoAinda não há avaliações

- Estima Service ManualDocumento3 páginasEstima Service Manualbobby aldave0% (9)

- HMT Limited Project ReportDocumento32 páginasHMT Limited Project ReportRahul ThakurAinda não há avaliações

- Manual de RepuestosDocumento378 páginasManual de RepuestosRemHenryAinda não há avaliações

- 2008 10 76-128Documento55 páginas2008 10 76-128astralwizAinda não há avaliações

- TVS Motor CompanyDocumento7 páginasTVS Motor Companycodyrhodes90Ainda não há avaliações

- Internship Training in Ashok LeylandDocumento54 páginasInternship Training in Ashok Leylandmuneerpp91% (11)

- 2x Unlock TimeDocumento2 páginas2x Unlock TimeVicente TanAinda não há avaliações

- Renault Twizy Na "Algarve ResidentDocumento1 páginaRenault Twizy Na "Algarve ResidentGrupo Renault PortugalAinda não há avaliações

- Channel PromotionDocumento27 páginasChannel PromotionSrinivas Reddy PalugullaAinda não há avaliações

- PGE BMW IChargeForward Final ReportDocumento51 páginasPGE BMW IChargeForward Final ReportMinhHyAinda não há avaliações

- Date Daf 2Documento2 páginasDate Daf 2sorinnafAinda não há avaliações

- BMW Investor Presentation May 2016Documento39 páginasBMW Investor Presentation May 2016Mirela GrAinda não há avaliações

- Investment Scenario in Indian Auto Auto Ancillary Industry/1057Documento4 páginasInvestment Scenario in Indian Auto Auto Ancillary Industry/1057Koustav S MandalAinda não há avaliações

- What's Under The Bonnet?: Car ExpensesDocumento2 páginasWhat's Under The Bonnet?: Car Expensesliehuan wangAinda não há avaliações

- Training ReportDocumento28 páginasTraining ReportjohnAinda não há avaliações

- Emil Kreiskott GMBH Crane GearsDocumento31 páginasEmil Kreiskott GMBH Crane GearsjayendrajaviAinda não há avaliações